INTRODUCTION

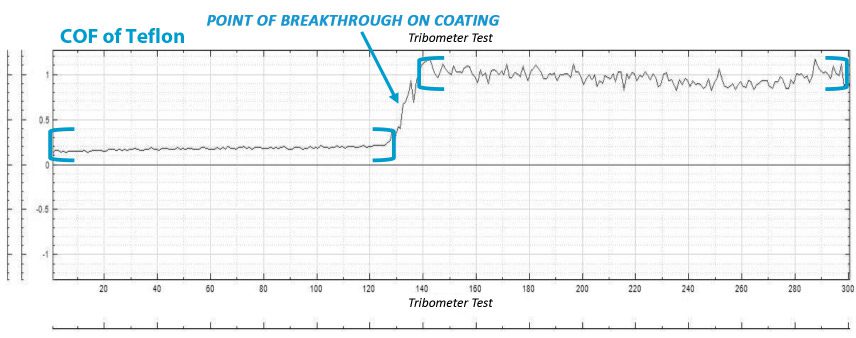

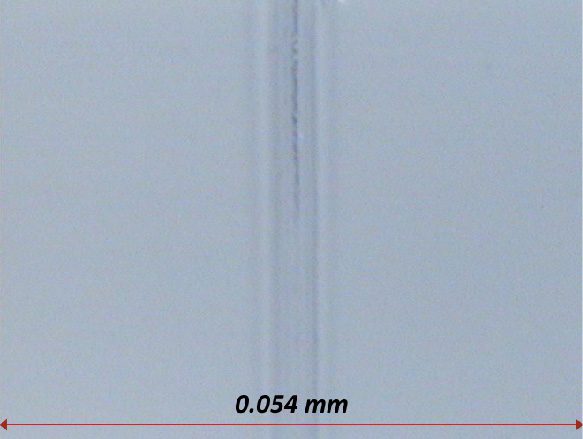

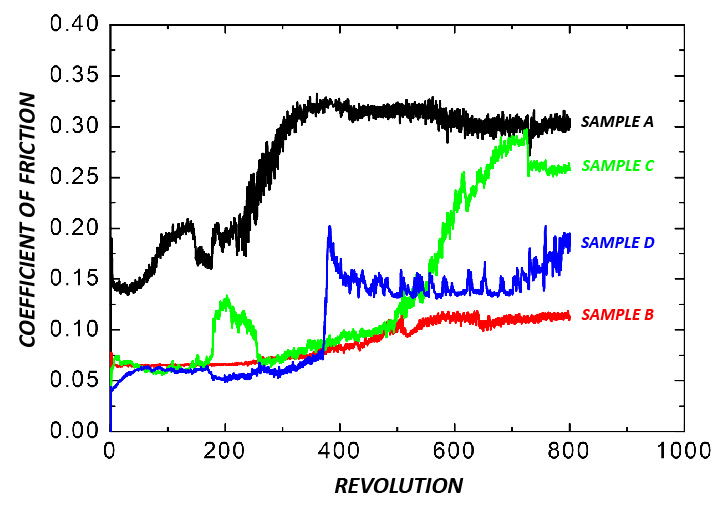

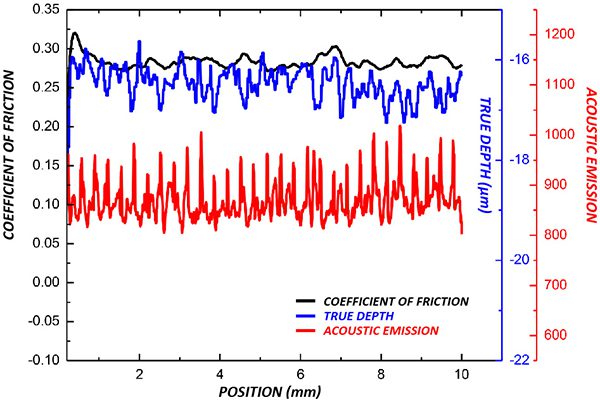

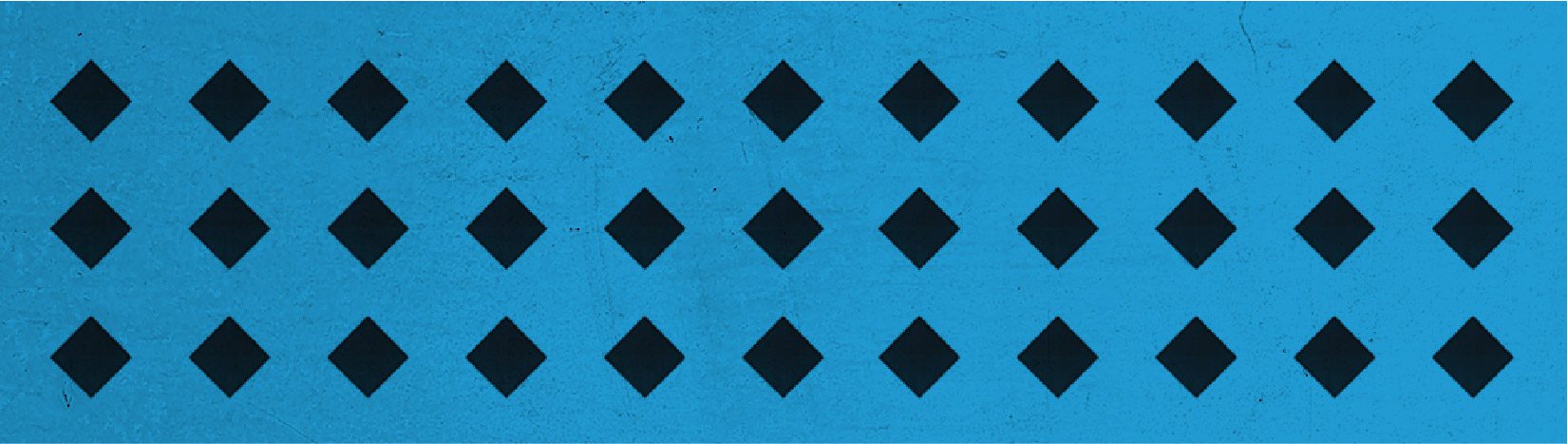

Polytetrafluoroethylene (PTFE), commonly known as Teflon, is a polymer with an exceptionally low coefficient of friction (COF) and excellent wear resistance, depending on the applied loads. PTFE exhibits superior chemical inertness, high melting point of 327°C (620°F), and maintains high strength, toughness, and self-lubrication at low temperatures. The exceptional wear resistance of PTFE coatings makes them highly sought-after in a wide range of industrial applications, such as automotive, aerospace, medical, and, notably, cookware.

IMPORTANCE OF QUANTITATIVE EVALUATION OF PTFE COATINGS

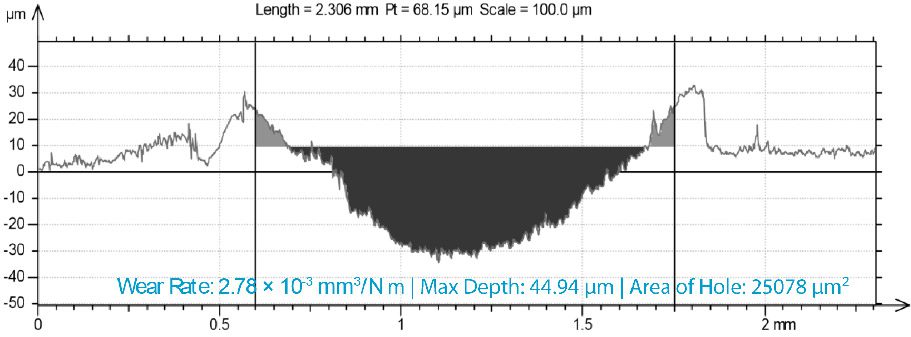

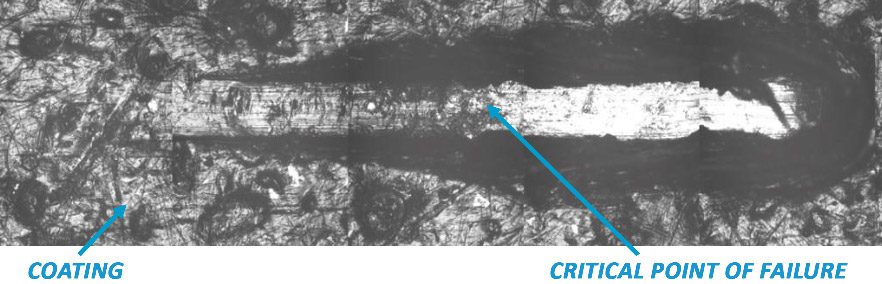

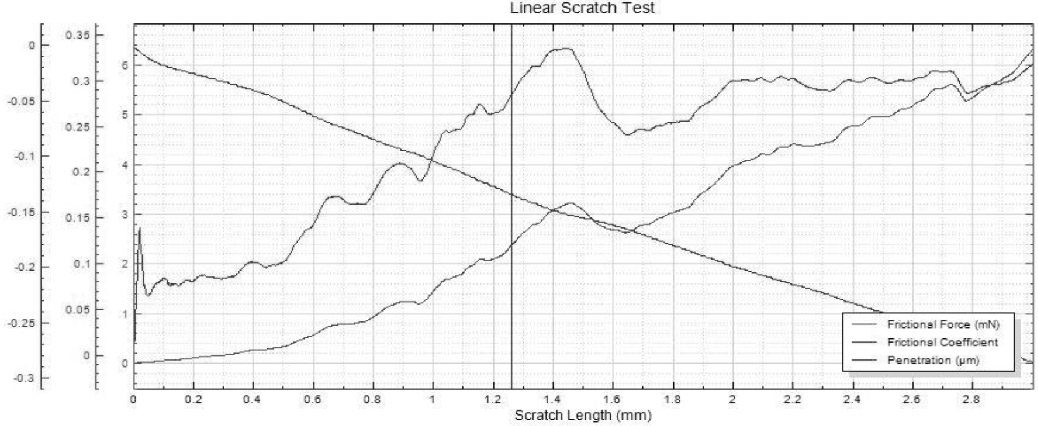

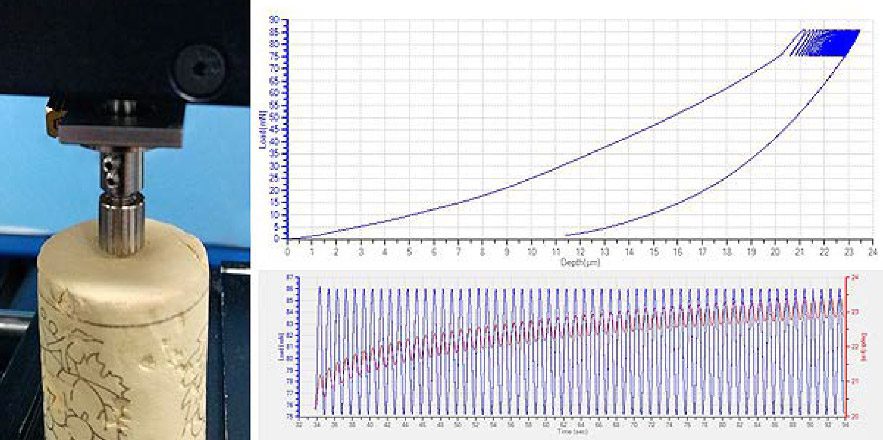

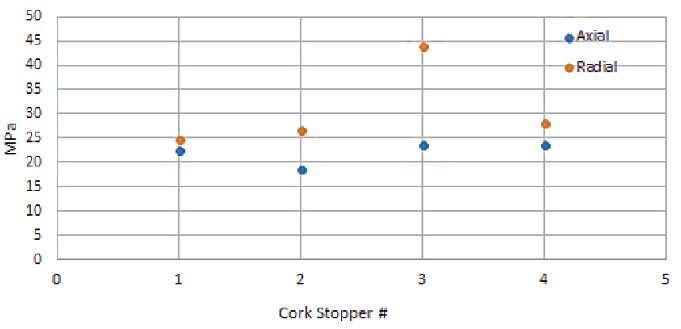

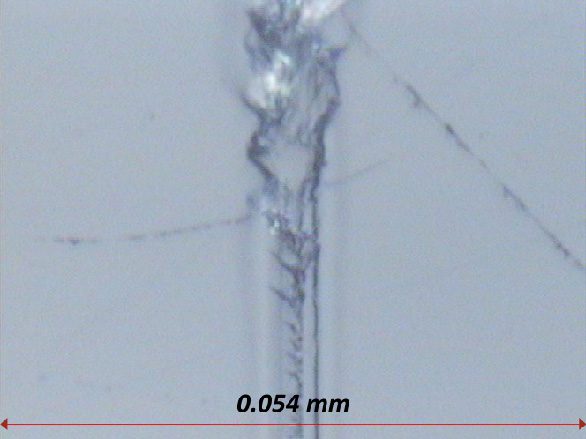

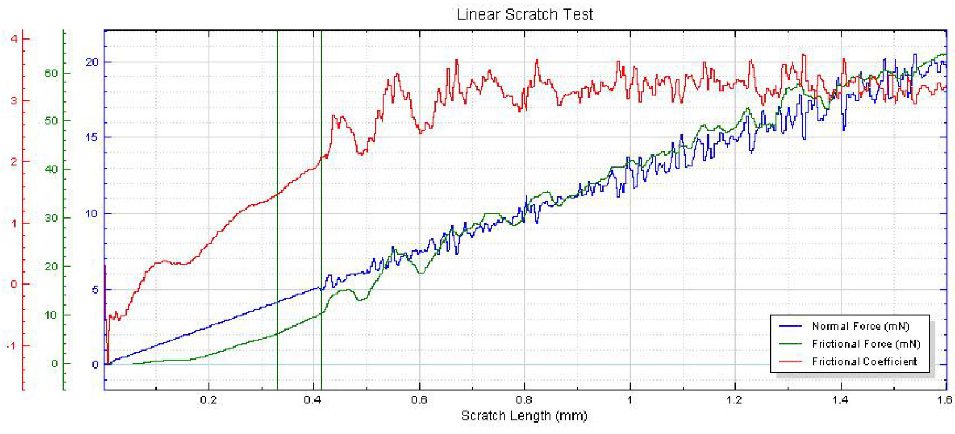

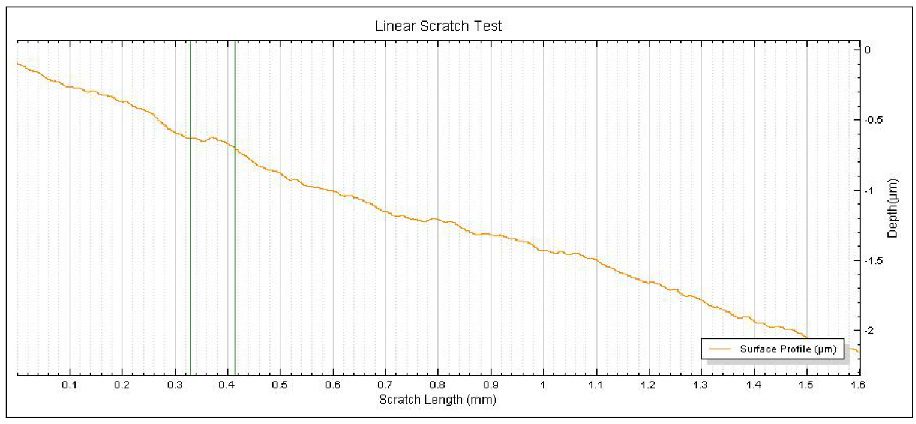

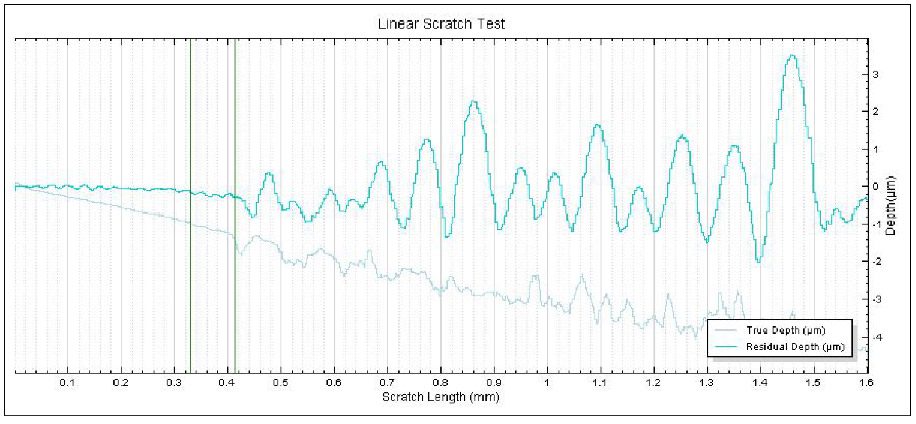

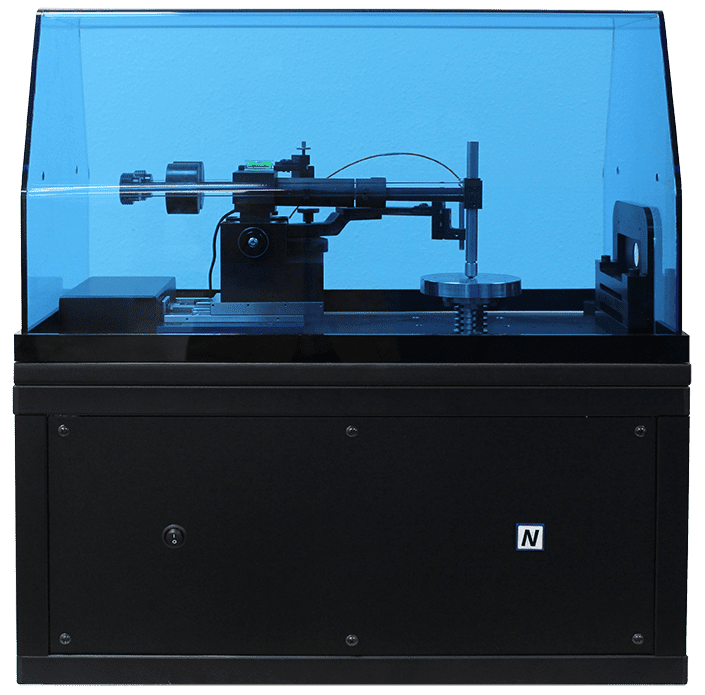

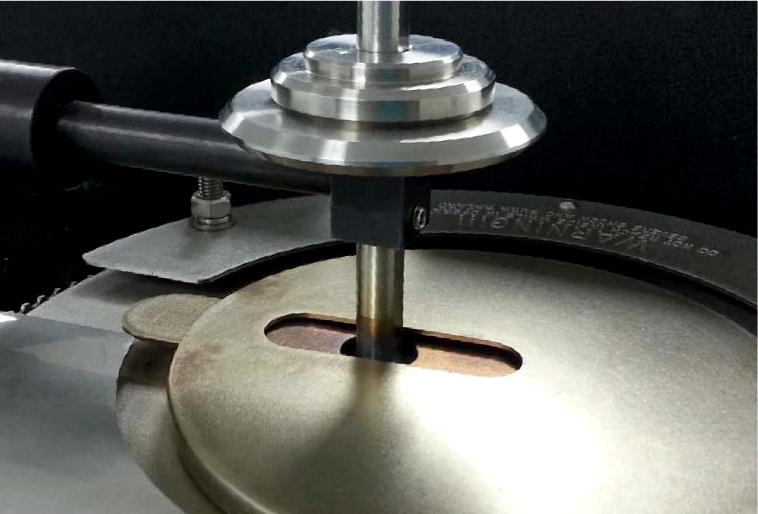

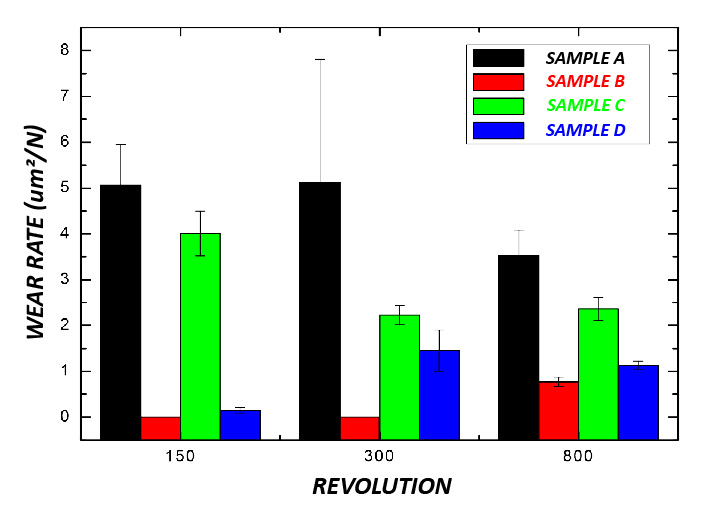

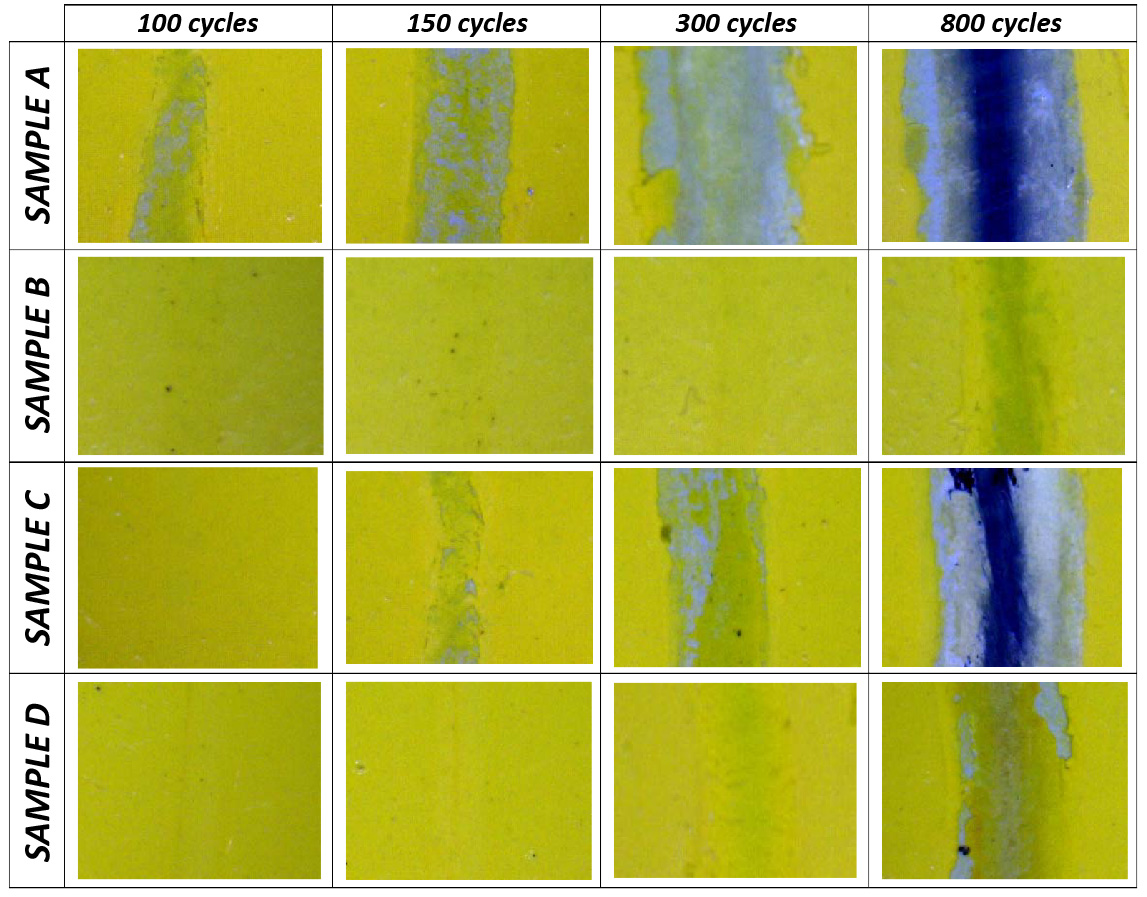

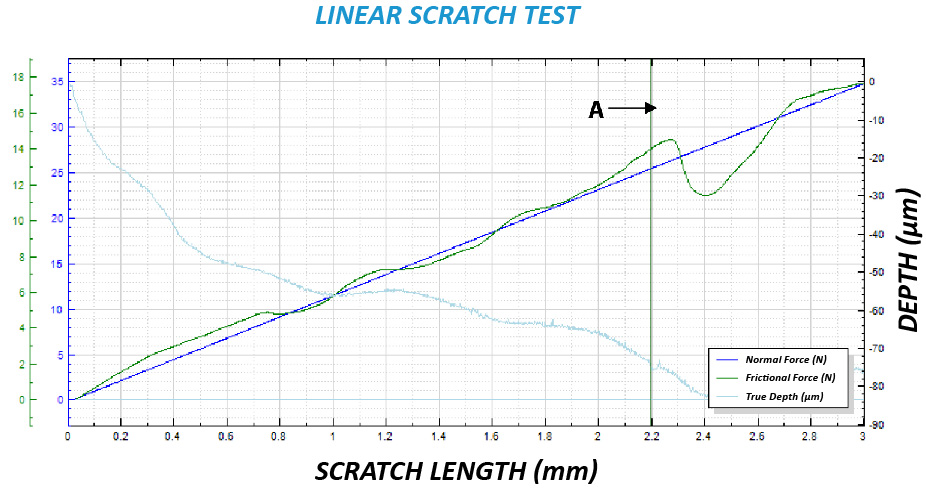

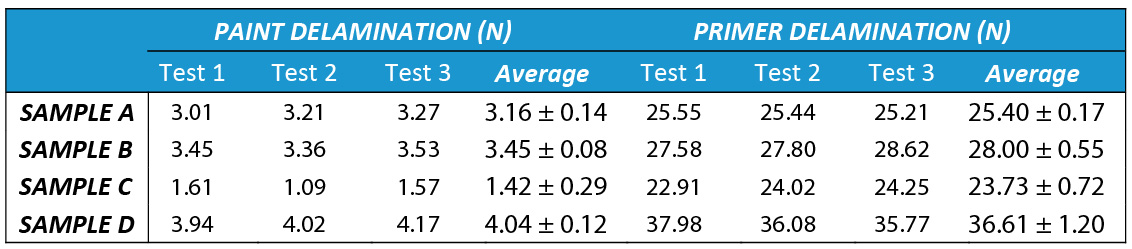

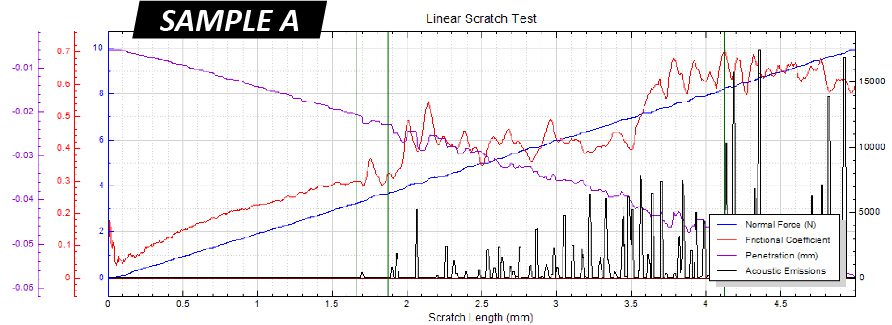

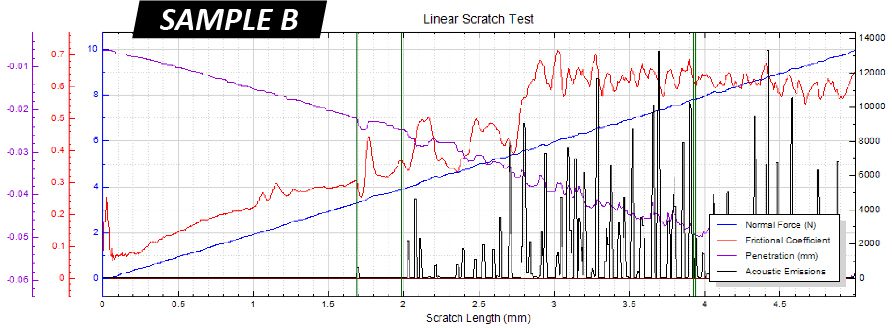

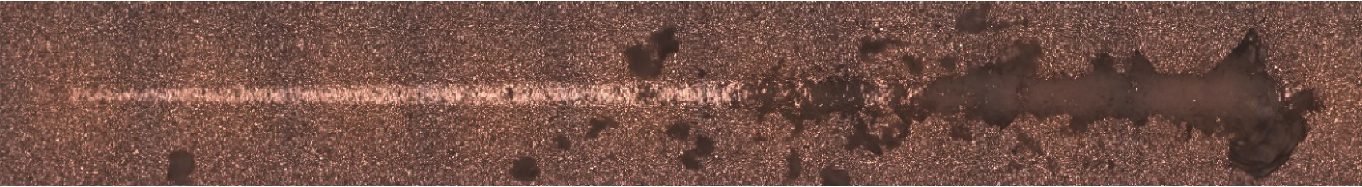

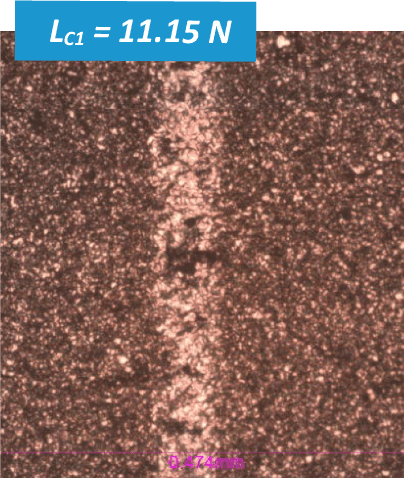

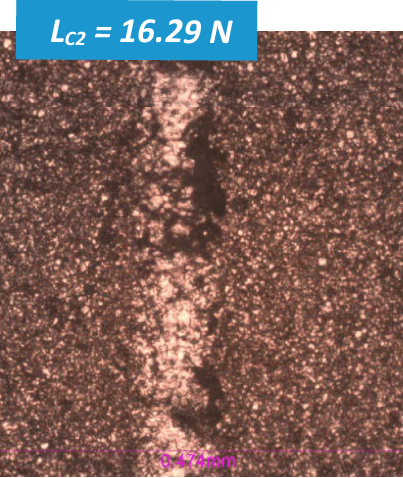

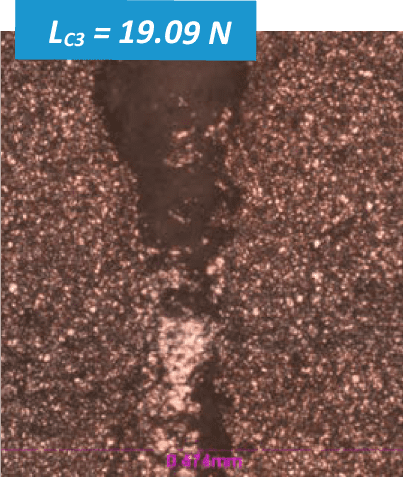

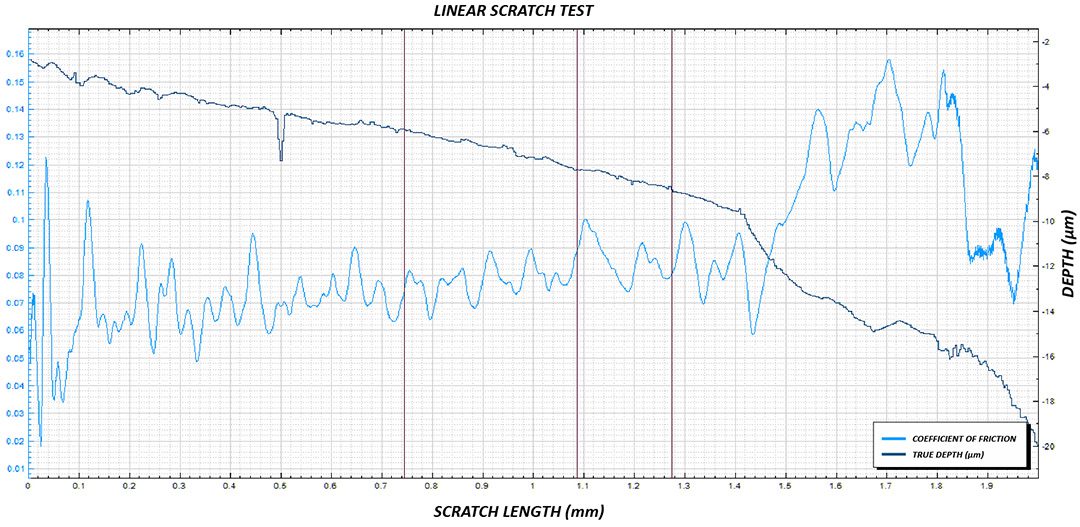

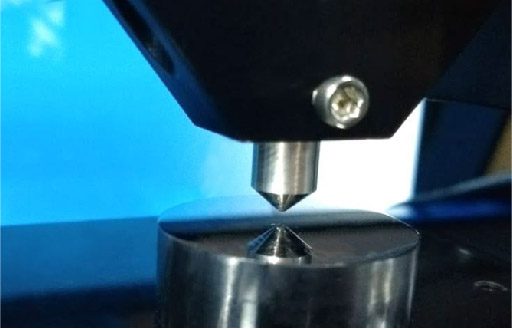

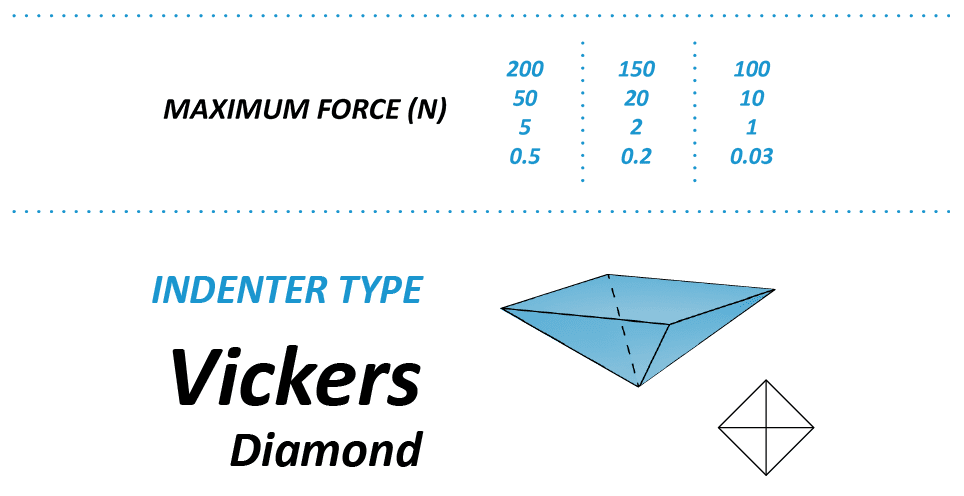

The combination of a super low coefficient of friction (COF), excellent wear resistance, and exceptional chemical inert- ness at high temperatures makes PTFE an ideal choice for non-stick pan coatings. To further enhance its mechanical processes during R&D, as well as ensure optimal control over malfunction prevention and safety measures in the Quality Control process, it is crucial to have a reliable technique for quantity evaluating the tribomechanical processes of PTFE coatings. Precise control over surface friction, wear, and adhesion of the coatings is essential to ensure their intended performance.