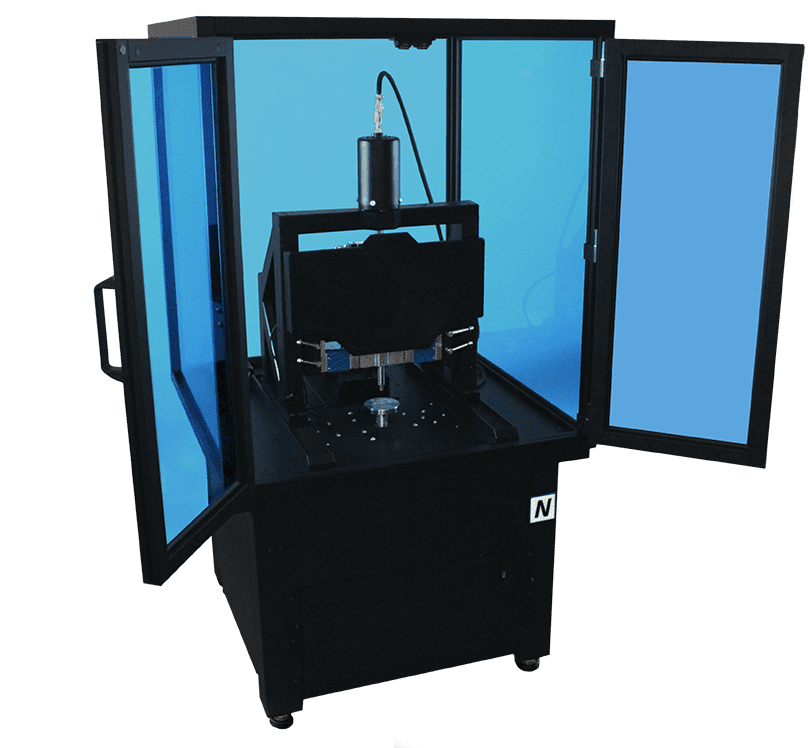

Liquid Module

Liquid modules are used to carry out wear and friction experiments in liquids or lubricants. Different liquid solutions can simulate the wear process for realistic applications for various industrial applications.

How does it work?

For example, the biomaterials for biological replacements such as

joints, stents, and dental roots, require excellent long-term

resistance and adequate strength in a liquid environment.

The parts in the motor engines should be protected by proper

lubrication to reduce wear and friction and to extend lifespan.

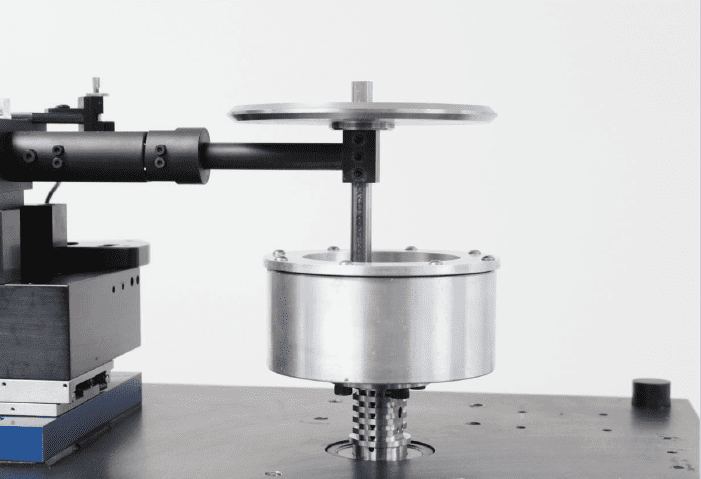

Combining with the precise control of speed and continuous

change of speed, a continual Stribeck Curve for the test lubricant

can be measured.

A liquid heating coil is available to heat the liquid in the cups up to 150°C. An accessory to the cup is the drop by drop lubrication option which allows lubrication test even at 5000rpm.

Extreme Versatility

Modules

- Rotative

- Linear

- Scratch

- Block-on-Ring & Ring-on-Ring Wear (custom)

Properties Analyzed

- Wear Rates

- Friction versus speed

- Stribeck Curve