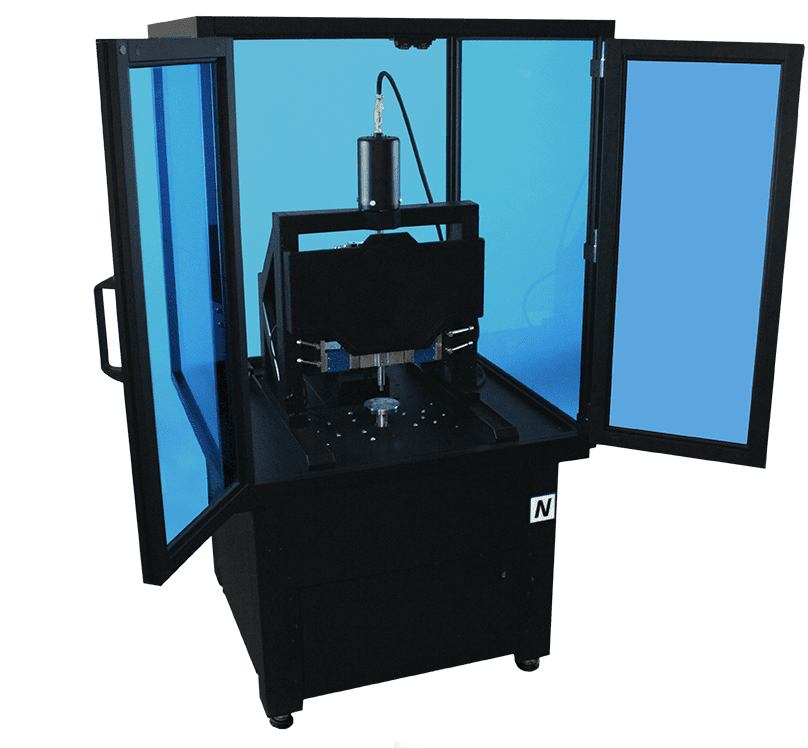

Corrosion Module

Tribocorrosion is a surface degradation process resulting from simultaneous tribological and electrochemical actions in a corrosive environment.

How does it work?

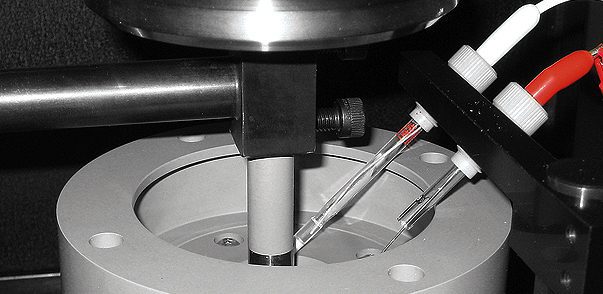

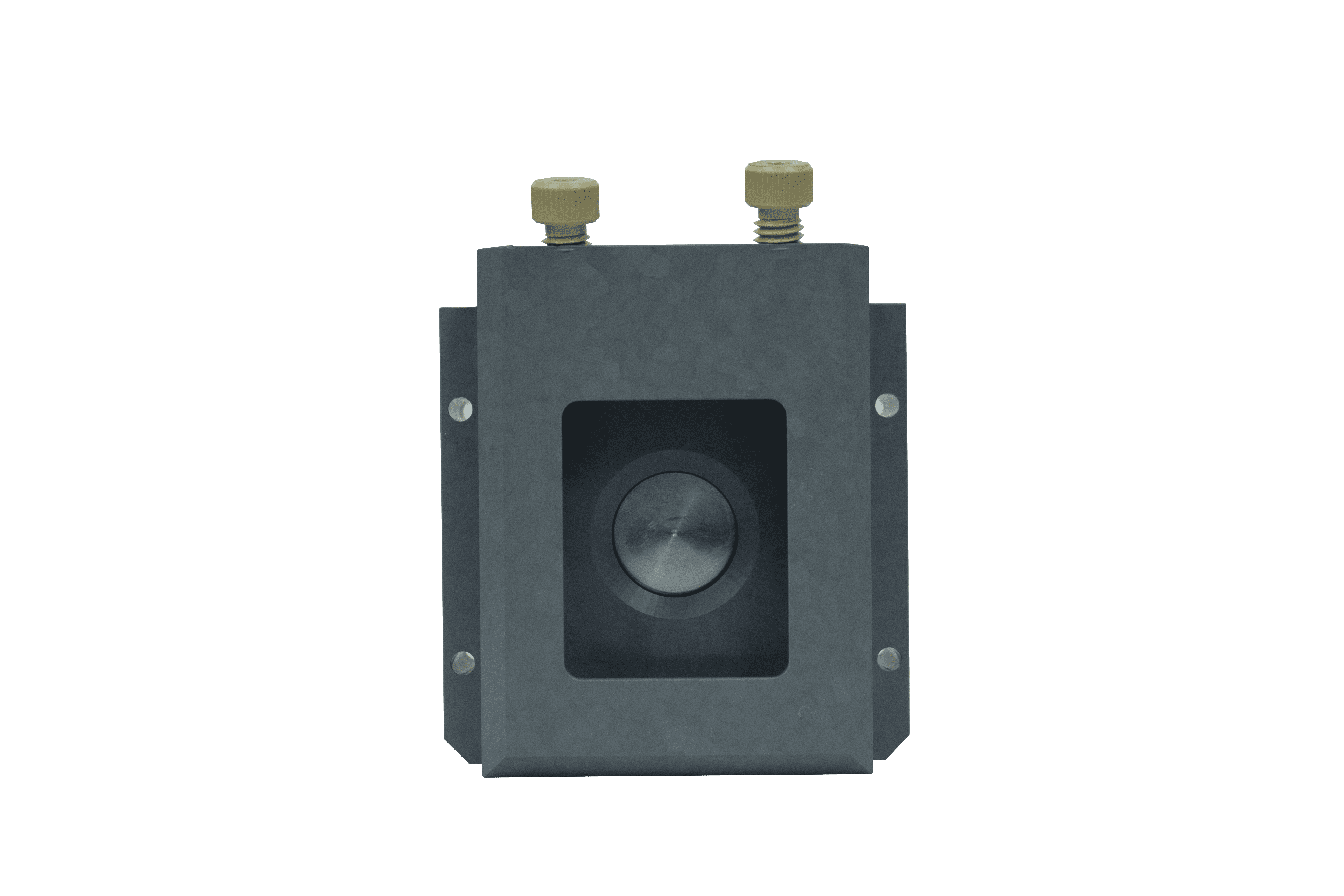

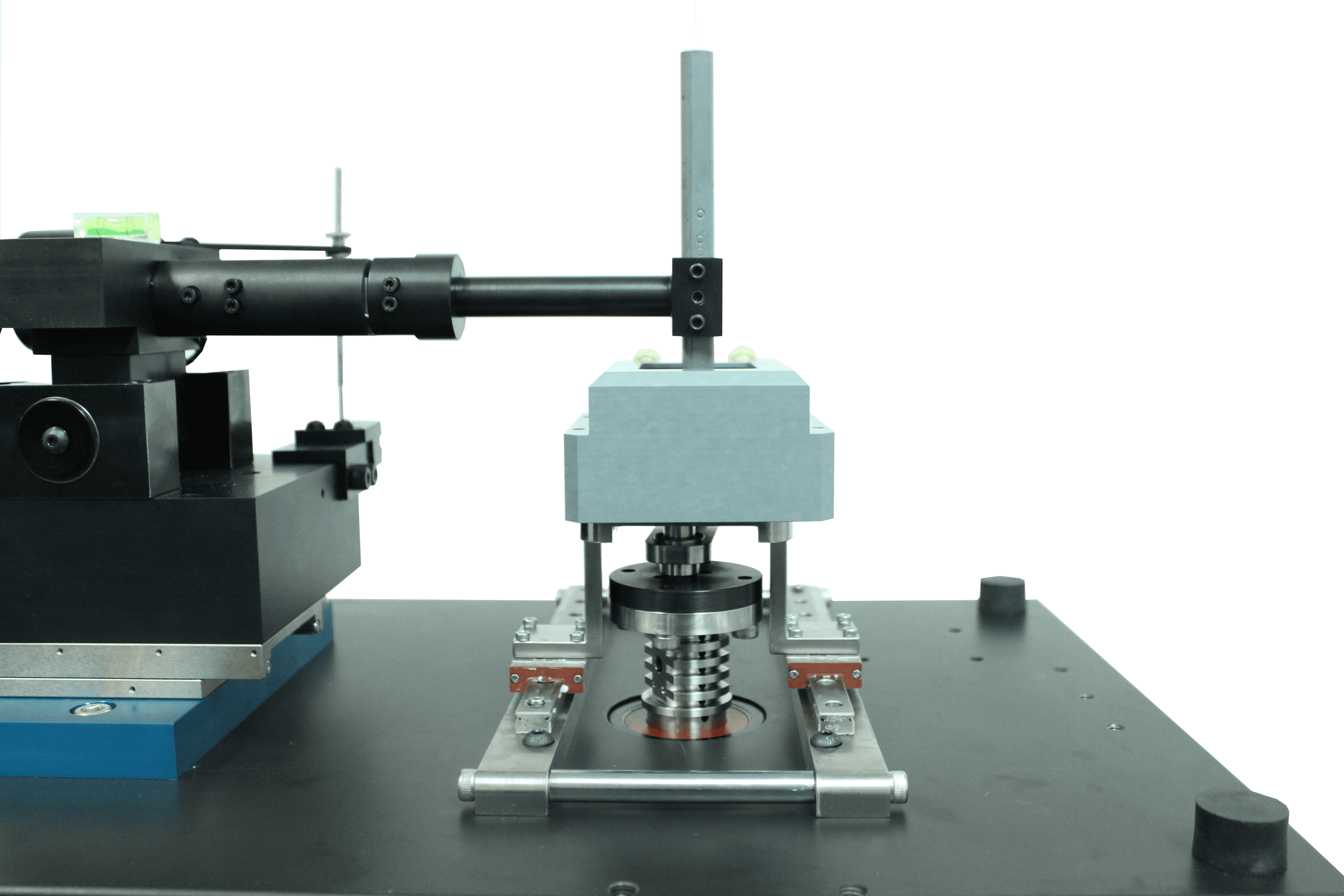

Wear and corrosion experiments are conducted simultaneously using a sliding ball-on-plate configuration, where the contact is totally immersed in the test electrolyte.

The tribocorrosion module is a three-terminal electrochemical cell installed on the sample stage, with the sample, a platinum wire and an Ag/AgCl, NaCl (sated) electrode acting as working, counter and reference electrodes, respectively. The open circuit potential (OCP) is measured in situ to monitor the evolution of the tribocorrosion process.

The reduction of OCP works as an indicator for the failure of the protective films. The change of coefficient of friction (COF) also provides insight into different stages of the wear development.

The wear tests can be carried out under anodic or cathodic polarization conditions to either accelerate or inhibit the corrosion process, in order to investigate the effect of corrosion reactions on the tribocorrosion rate.

Extreme Versatility

Modules

- Rotating (custom) Max of 40N load

- Linear (Max of 40N)

Properties Analyzed

- Corrosion Resistance

- Tribocorrosion Behavior

- Wear at Open Circuit Potential

- Potentiodynamic Polarization

- Wear at Anodic/Cathodic Potential

- Electrochemical Impedance Spectroscopy Analysis