Monthly Archives: December 2018

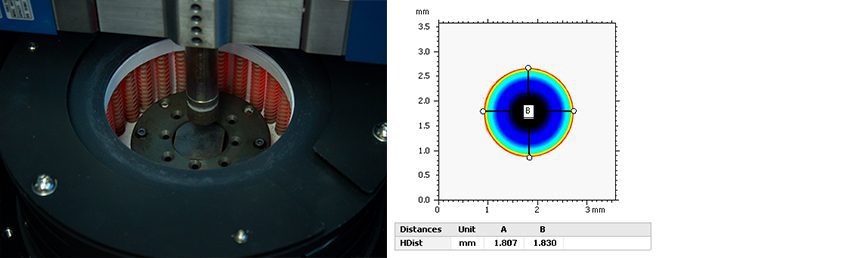

1000°C Brinell Hardness w/ T2000 Tribometer

Material properties, such as reactivity and strength, can drastically change at higher temperatures. This makes high temperature applications, (e.g. jet engines, fabrication chamber material, and even cookware) require careful material selection. Thus, it is important to understand how materials behave in different temperature conditions. The strength of a material can be measured by using the Nanovea T2000 Tribometer. To demonstrate this, a steel sample was used to conduct Brinell hardness testing from temperatures ranging from 25°C to 925°C.

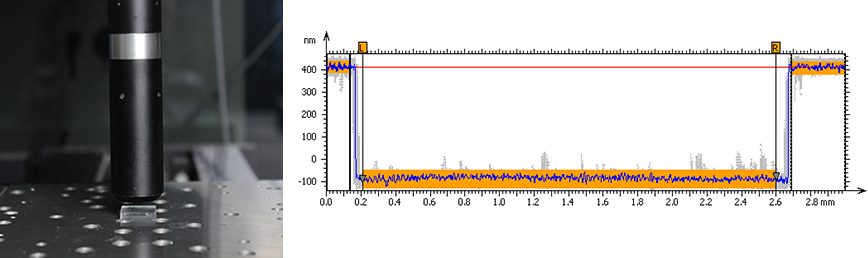

500nm Glass Step Height: Extreme Accuracy with Non-Contact Profilometry

Surface characterization are current topics undergoing intense study. The surfaces of materials are important since they are the regions where physical and chemical interactions between the material and environment occur. Thus, being able to image the surface with high resolution has been desirable, since it allows scientists to visually observe the smallest surface details. Common surface imaging data includes topography, roughness, lateral dimensions, and vertical dimensions. Identifying the load bearing surface, spacing and step height of fabricated microstructures, and defects on the surface are some applications that can be obtained from surface imaging. All surface imaging techniques, however, are not created equal.

500nm Glass Step Height: Extreme Accuracy with Non-Contact Profilometry