Monthly Archives: February 2013

High Speed Nano Wear Testing Breakthrough

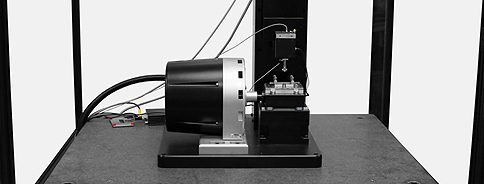

Feb 20, 2013 – Irvine, CA – Nanovea announced today the completion of a Nano Wear Testing System capable of speeds as high as 1400mm/sec. The unique length of stroke, up to 10mm, combined with a linear movement at a rate up to 70Hz, and possibly at higher frequencies, allows speeds never before available for Nano Wear Testing.

Wear testing instruments have existed for more than half a century. From the beginning, testing loads were typically higher than 1N and speeds were slow except in more recent fretting applications where displacement would be limited to 10’s of microns. Then Nanoindentation first appeared in the late 80’s with the capability to provide much lower loads. The first systems were, and still are in majority, based on a coil system with no feedback control loop. Feedback control loop is essential to provide superior load control when the position of contact is moved such as that required for scratch or wear testing. Nano Scratch Testing with piezo load cell combination appeared in the late 90’s. The first systems used cantilever technologies that gave sufficient speed to the feedback control during scratch and wear testing but the speed of displacement was, and still is limited to below 10mm/sec. For many applications the service life require a very high number of cycles to ensure that the device will hold up after years of use. At the slow speed available with cantilever technologies it could take more than 6 months to accomplish a single wear test. This is impractical and clearly slows down development and approval of new technology.

Nanovea is able to attain faster speeds and secure control of the loads during Nano Wear Testing by using a coil speaker system for quick and smooth displacement. Adding the use of the Nanovea Nano Module with a piezo actuator and an ultra-sensitive load cell creates a quick load control with vertical mounting to ensure superior response to speed.

“We were given the opportunity to really prove our team’s capability here with this project. We are very proud of this achievement. This new technology will speed up the introduction of new devices with increased service life to the customer market.” –CEO, Pierre Leroux

Here are examples of materials we tested this month:

Mechanical:

• Nanoindentation of wire cross sections

• Nanoindentation of Y2O3 thin films

• Nanoscratch of thin polymer films

• Nanoscratch of catheters

• Microindentation of oil-well cement

3D Non-Contact Profilometry:

• Roughness of catheters

• Finish of processed leather

• Topography of thin film particle contaminants

• Coplanarity of ball grid arrays

• Step height of microchannels

• Stribeck Curve evaluation of various lubrication

High Speed Nanotribology Testing Breakthrough

Feb 21, 2013 – Irvine, CA – Nanovea announced today the completion of a Nanotribology System capable of speeds as high as 1400mm/sec. The unique length of stroke, up to 10mm, combined with a linear movement at a rate up to 70Hz, and possibly at higher frequencies, allows speeds never before available for Nano Wear Testing.

Wear testing instruments have existed for more than half a century. From the beginning, testing loads were typically higher than 1N and speeds were slow except in more recent fretting applications where displacement would be limited to 10’s of microns. Then Nanoindentation first appeared in the late 80’s with the capability to provide much lower loads. The first systems were, and still are in majority, based on a coil system with no feedback control loop. Feedback control loop is essential to provide superior load control when the position of contact is moved such as that required for scratch or wear testing. Nano Scratch Testing with piezo load cell combination appeared in the late 90’s. The first systems used cantilever technologies that gave sufficient speed to the feedback control during scratch and wear testing but the speed of displacement was, and still is limited to below 10mm/sec. For many applications the service life require a very high number of cycles to ensure that the device will hold up after years of use. At the slow speed available with cantilever technologies it could take more than 6 months to accomplish a single wear test. This is impractical and clearly slows down development and approval of new technology.

Nanovea is able to attain faster speeds and secure control of the loads during Nano Wear Testing by using a coil speaker system for quick and smooth displacement. Adding the use of the Nanovea Nano Module with a piezo actuator and an ultra-sensitive load cell creates a quick load control with vertical mounting to ensure superior response to speed.

“We were given the opportunity to really prove our team’s capability here with this project. We are very proud of this achievement. This new technology will speed up the introduction of new devices with increased service life to the customer market.” –CEO, Pierre Leroux

Texture Consistency Measurement Using 3D Profilometry

In this application the Nanovea ST400 Profilometer is used to measure the texture consistency of linoleum flooring. The intended surface texture here should be a repetitive structure with the same relative size. Measuring a small area should show how consistent this texture is being produced.