INTRODUCTION

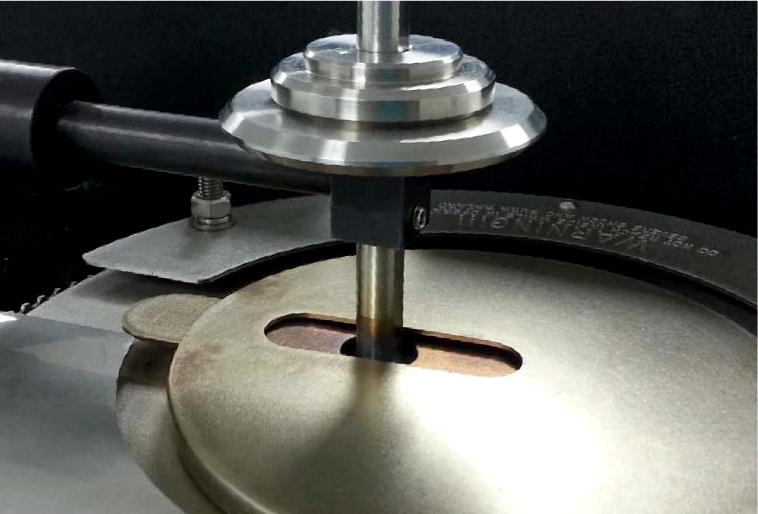

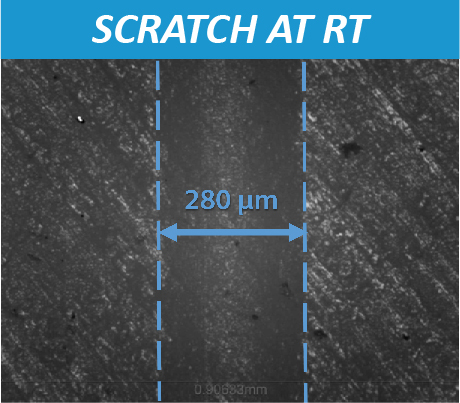

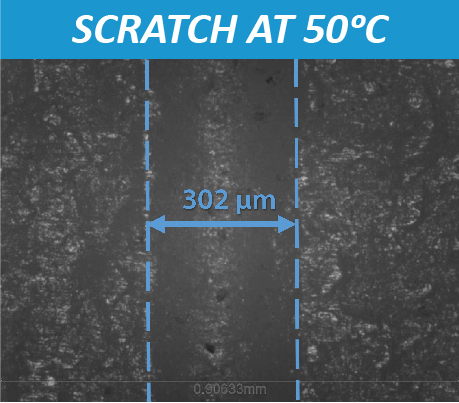

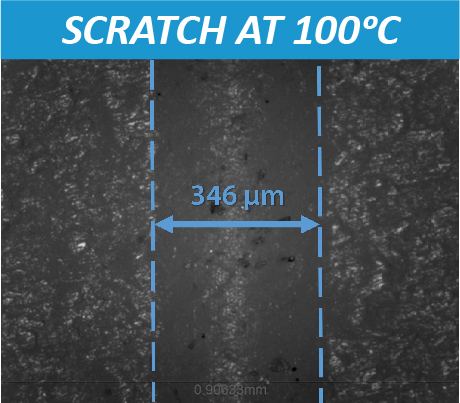

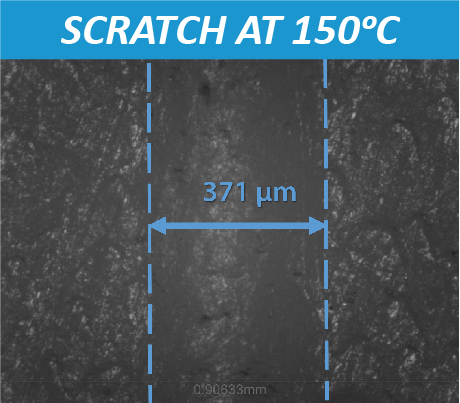

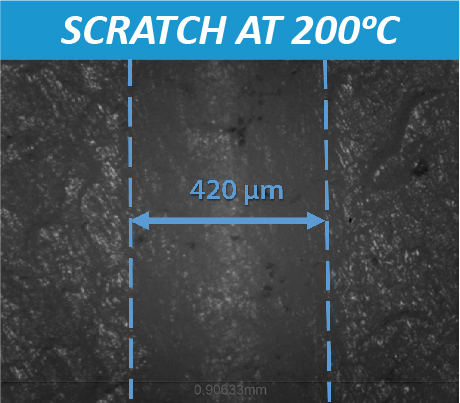

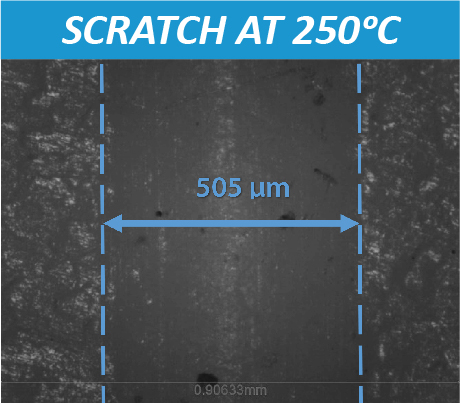

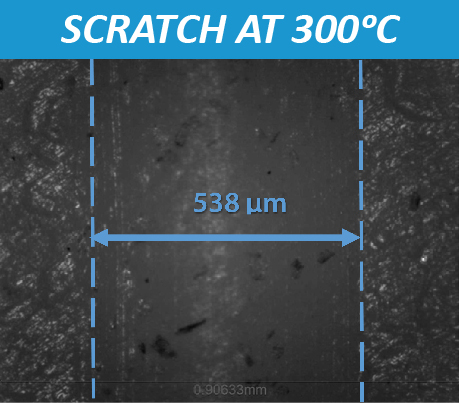

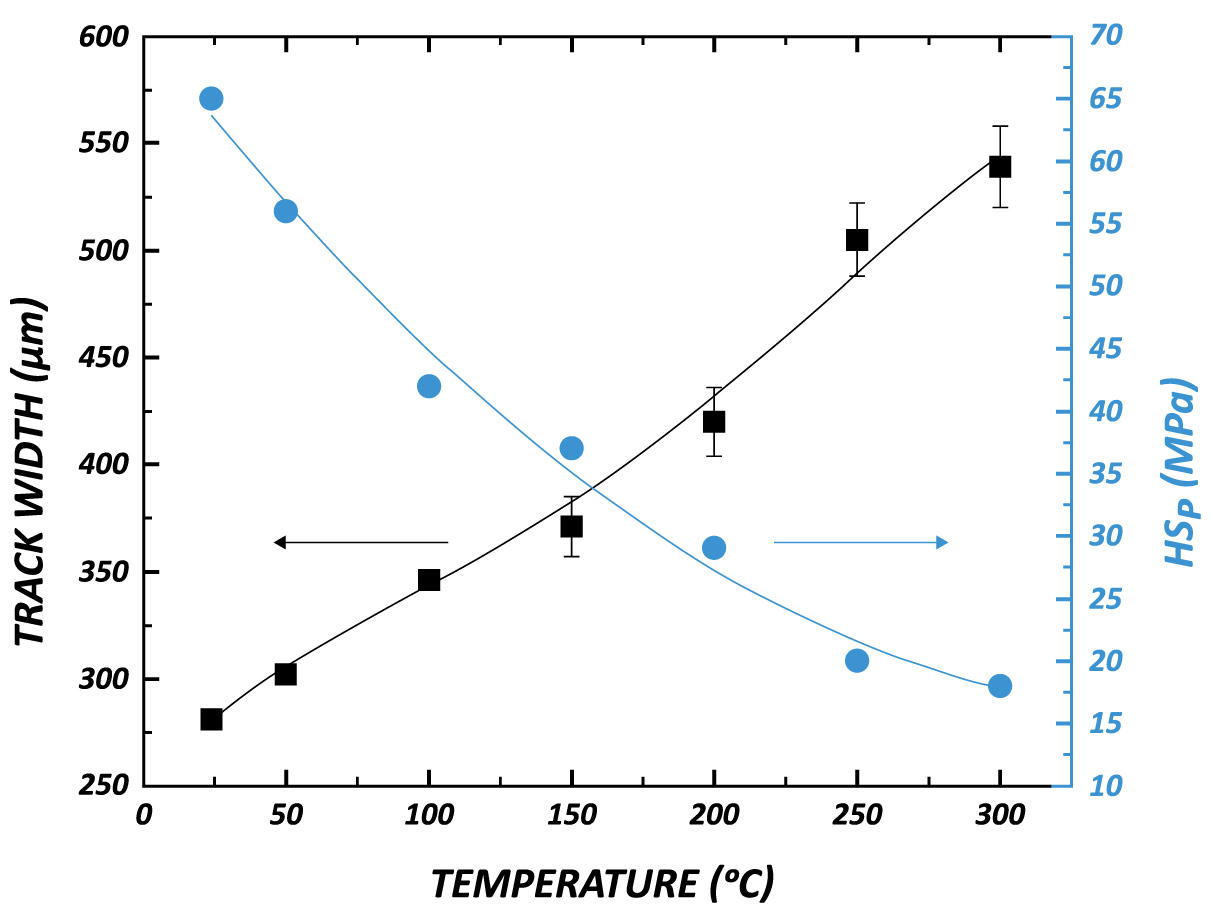

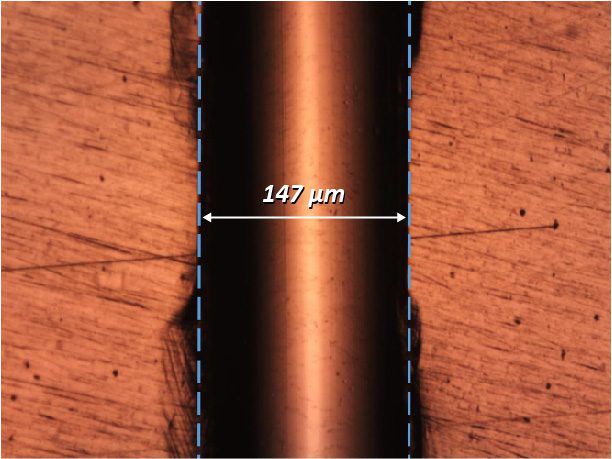

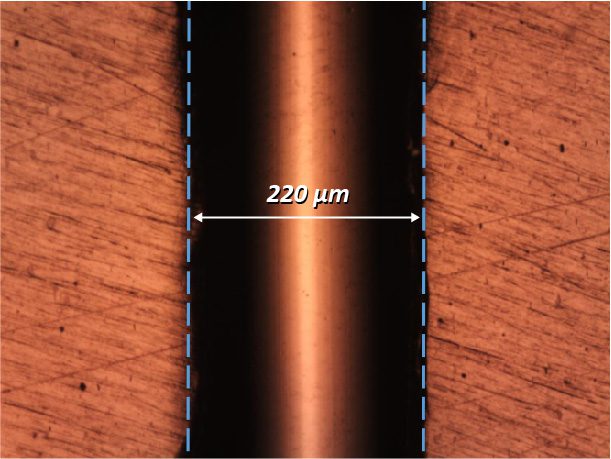

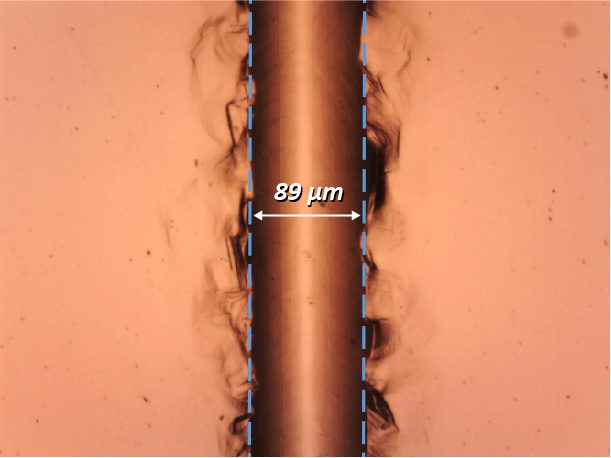

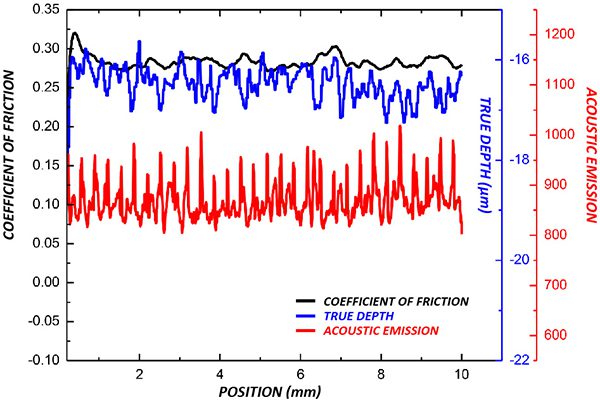

Hardness measures the resistance of materials to permanent or plastic deformation. Originally developed by a German mineralogist Friedrich Mohs in 1820, scratch hardness test determines the hardness of a material to scratches and abrasion due to friction from a sharp object1. The Mohs’ scale is a comparative index rather than a linear scale, therefore a more accurate and qualitative scratch hardness measurement was developed as described in ASTM standard G171-032. It measures the average width of the scratch created by a diamond stylus and calculates the scratch hardness number (HSP).

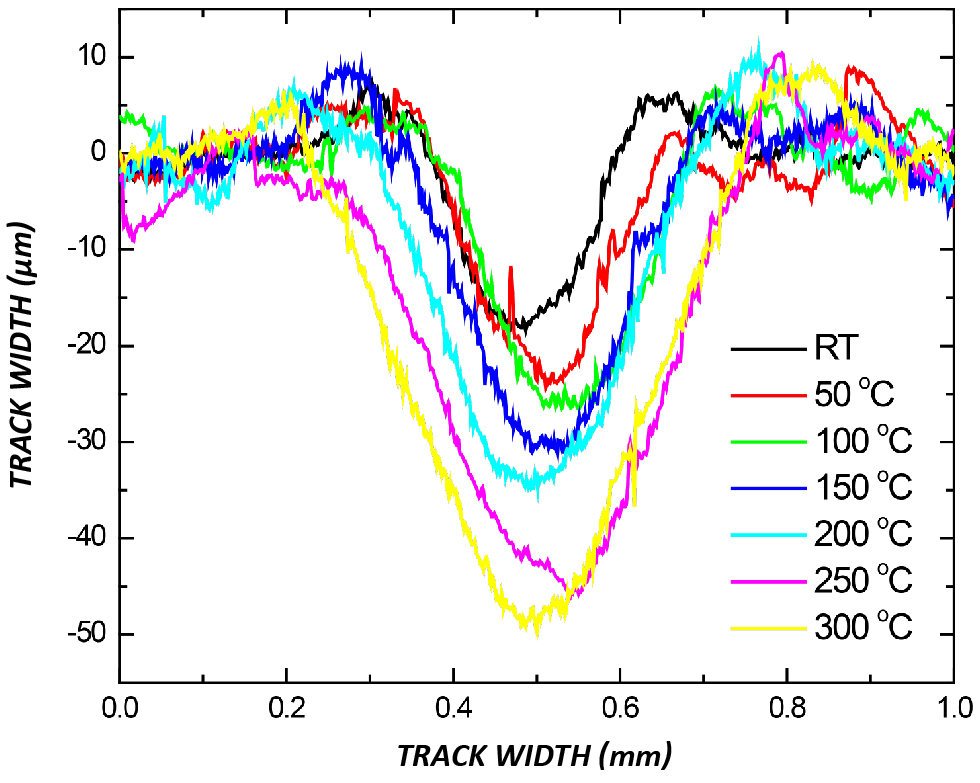

IMPORTANCE OF SCRATCH HARDNESS MEASUREMENT AT HIGH TEMPERATURES

Materials are selected based on the service requirements. For applications involving significant temperature changes and thermal gradients, it is critical to investigate the mechanical properties of materials at high temperatures to be fully aware of the mechanical limits. Materials, especially polymers, usually soften at high temperatures. A lot of mechanical failures are caused by creep deformation and thermal fatigue taking place only at elevated temperatures. Therefore, a reliable technique for measuring hardness at high temperatures is in need to ensure proper selection of the materials for high temperature applications.