INTRODUCTION

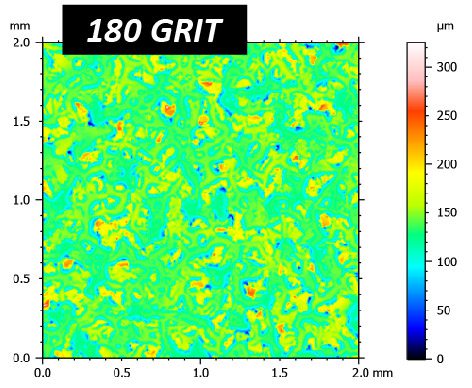

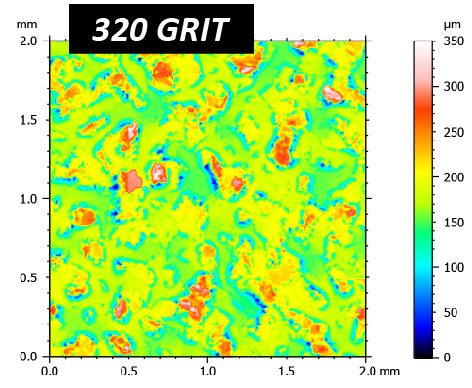

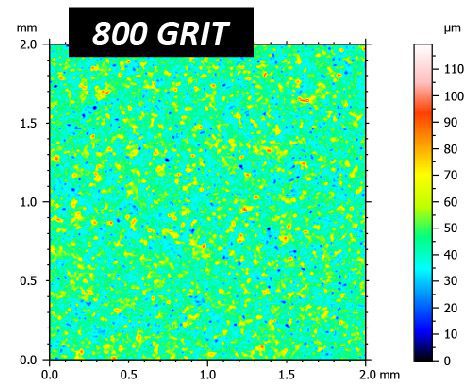

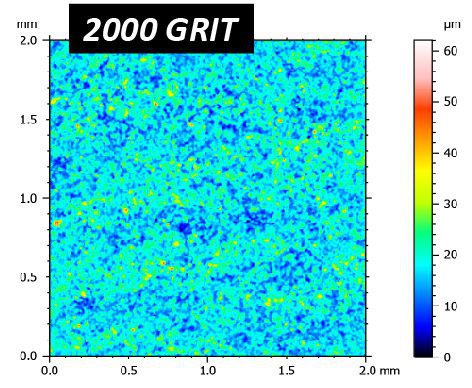

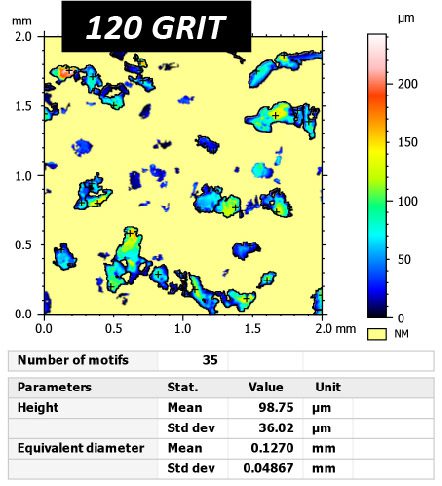

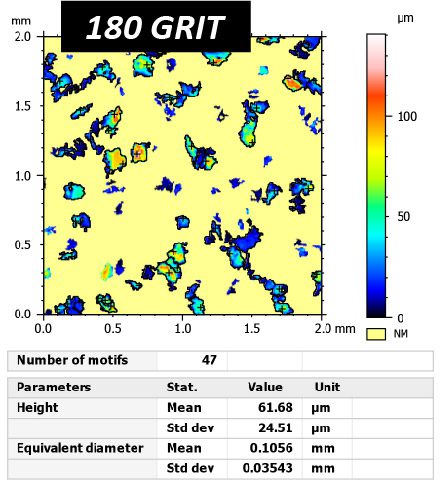

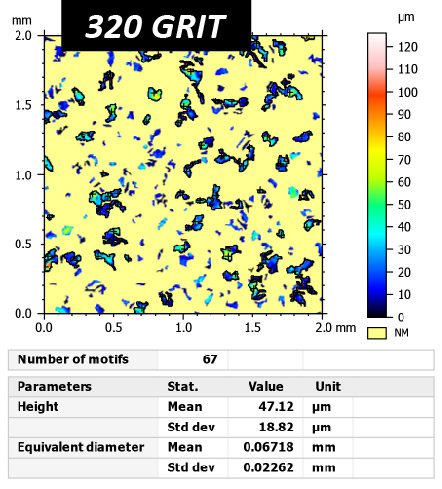

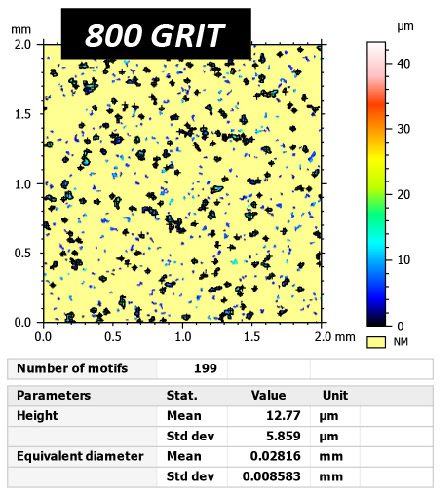

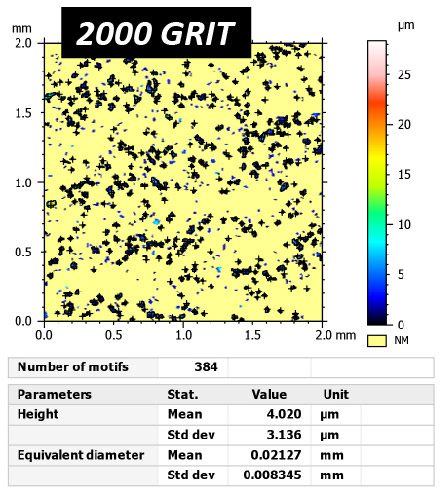

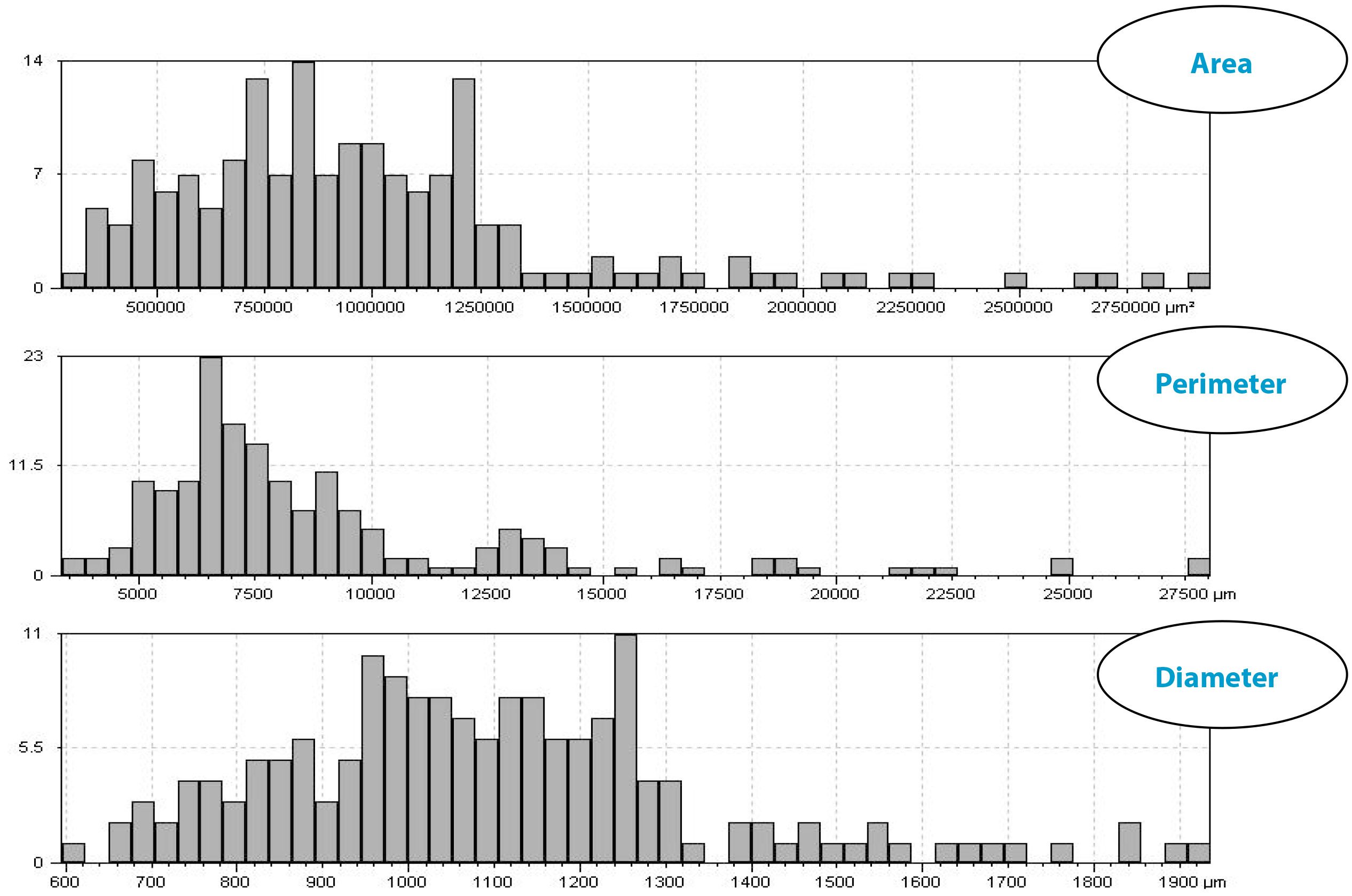

Sandpaper is a common commercially available product used as an abrasive. The most common use for sandpaper is to remove coatings or to polish a surface with its abrasive properties. These abrasive properties are classified into grits, each related to how smooth or

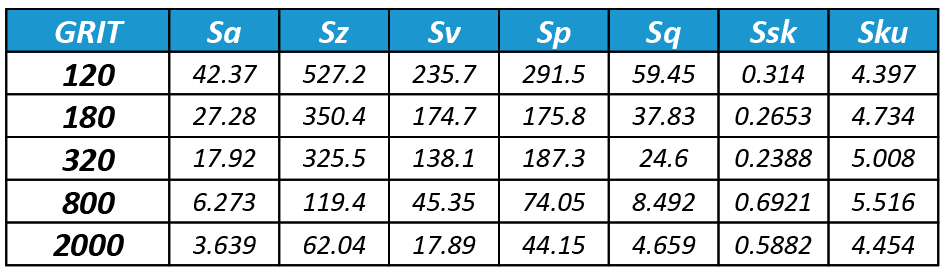

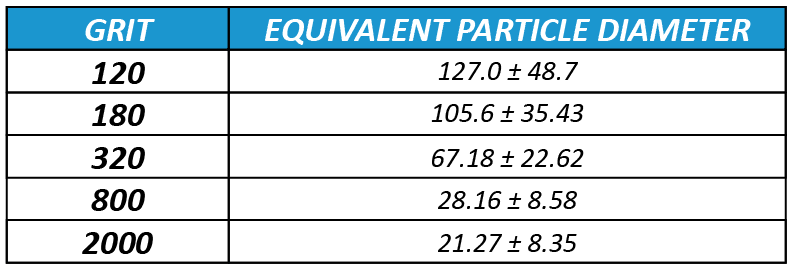

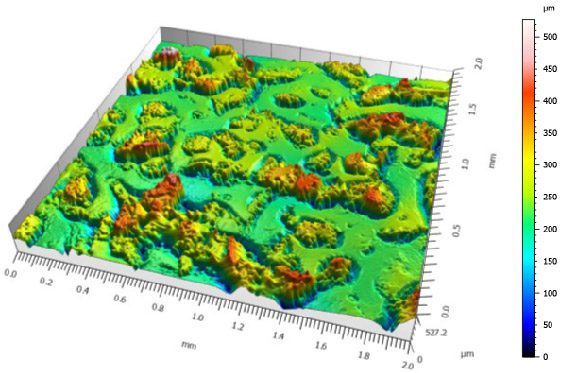

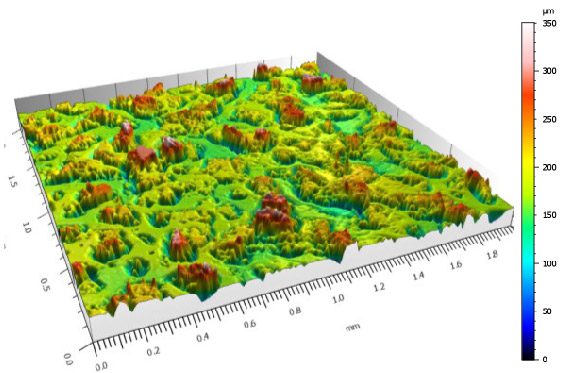

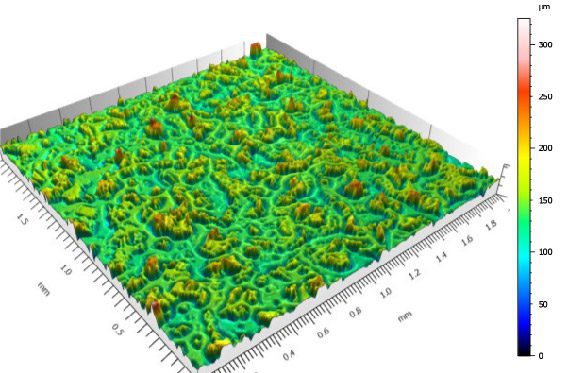

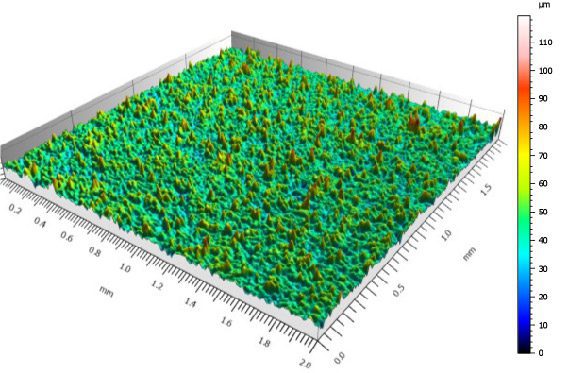

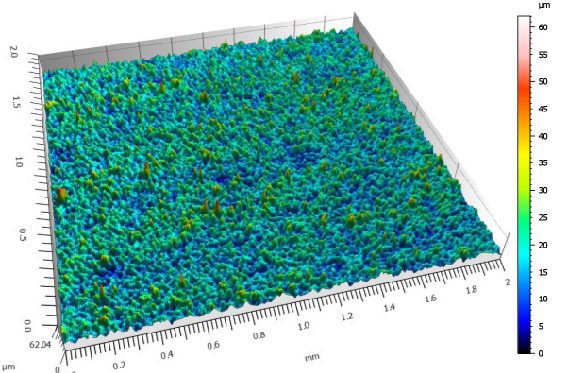

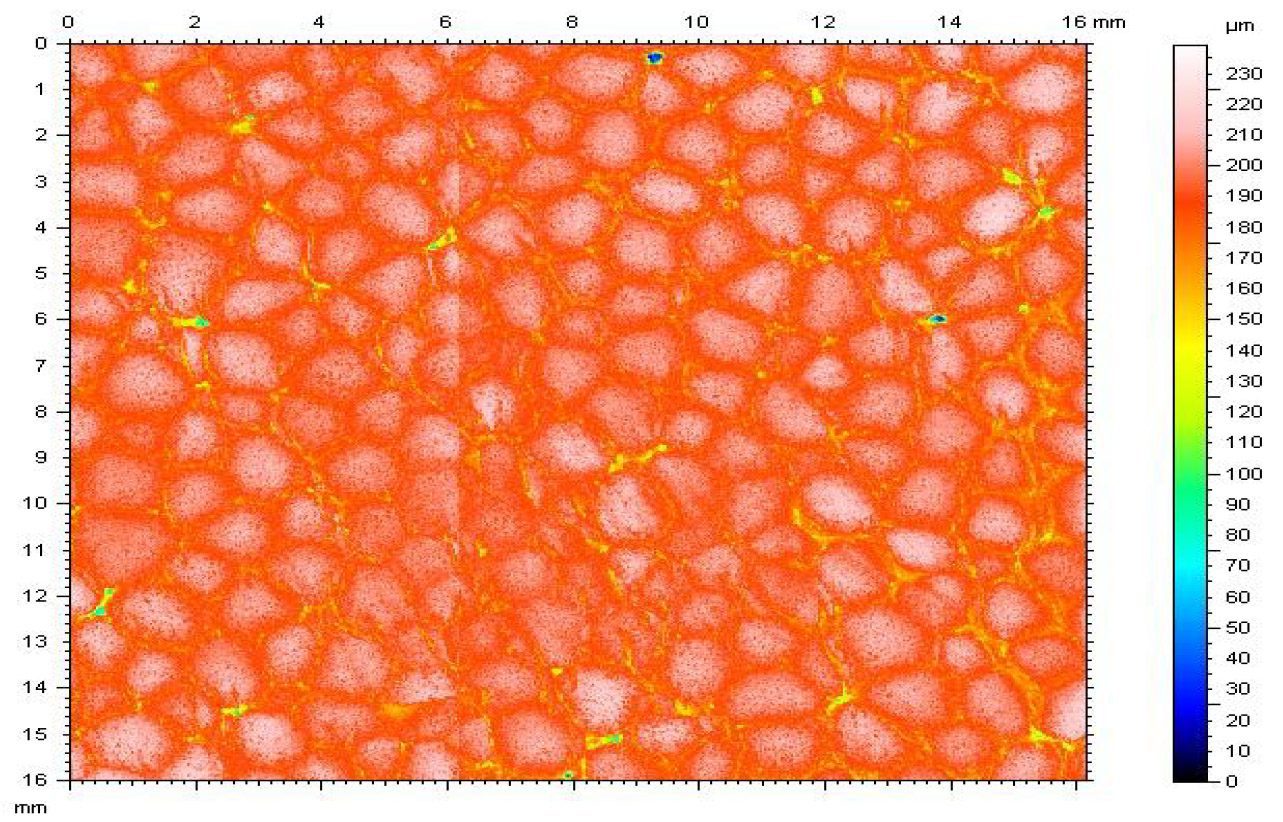

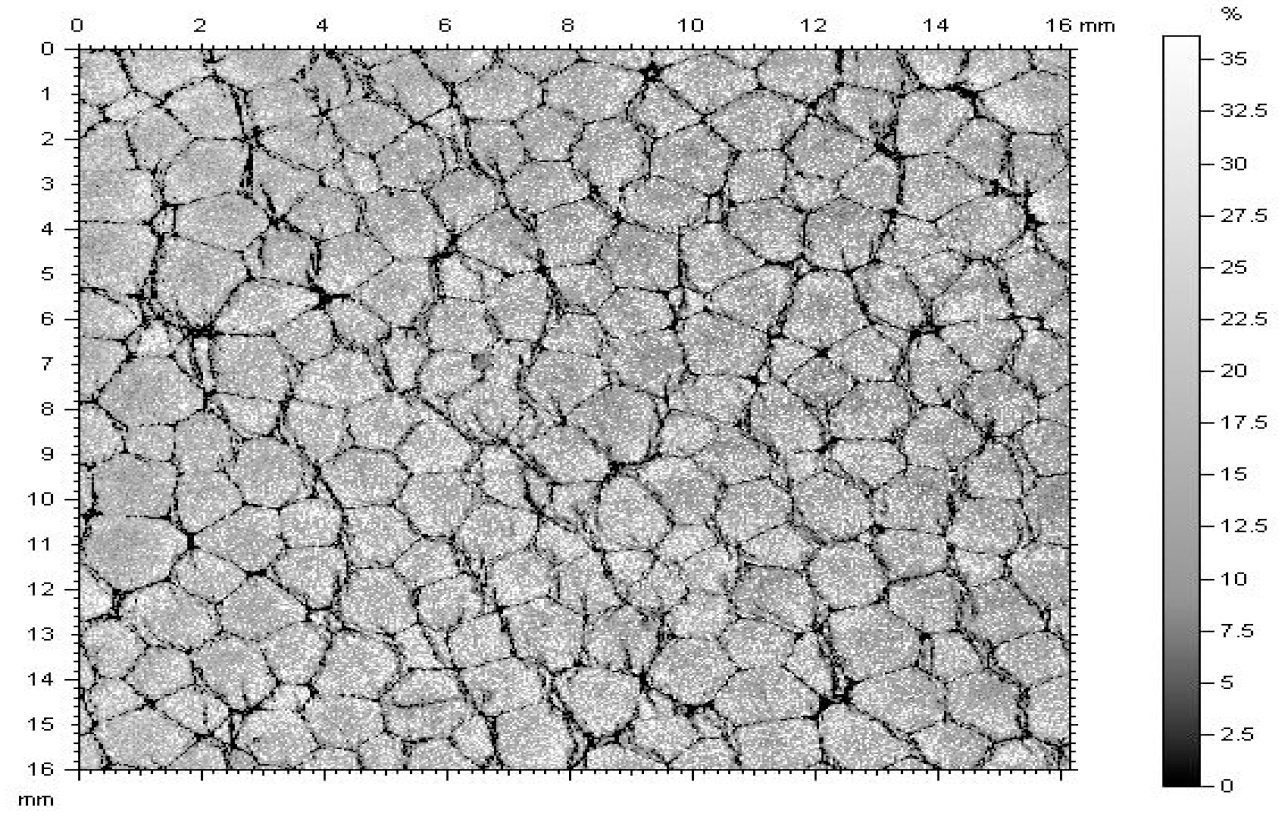

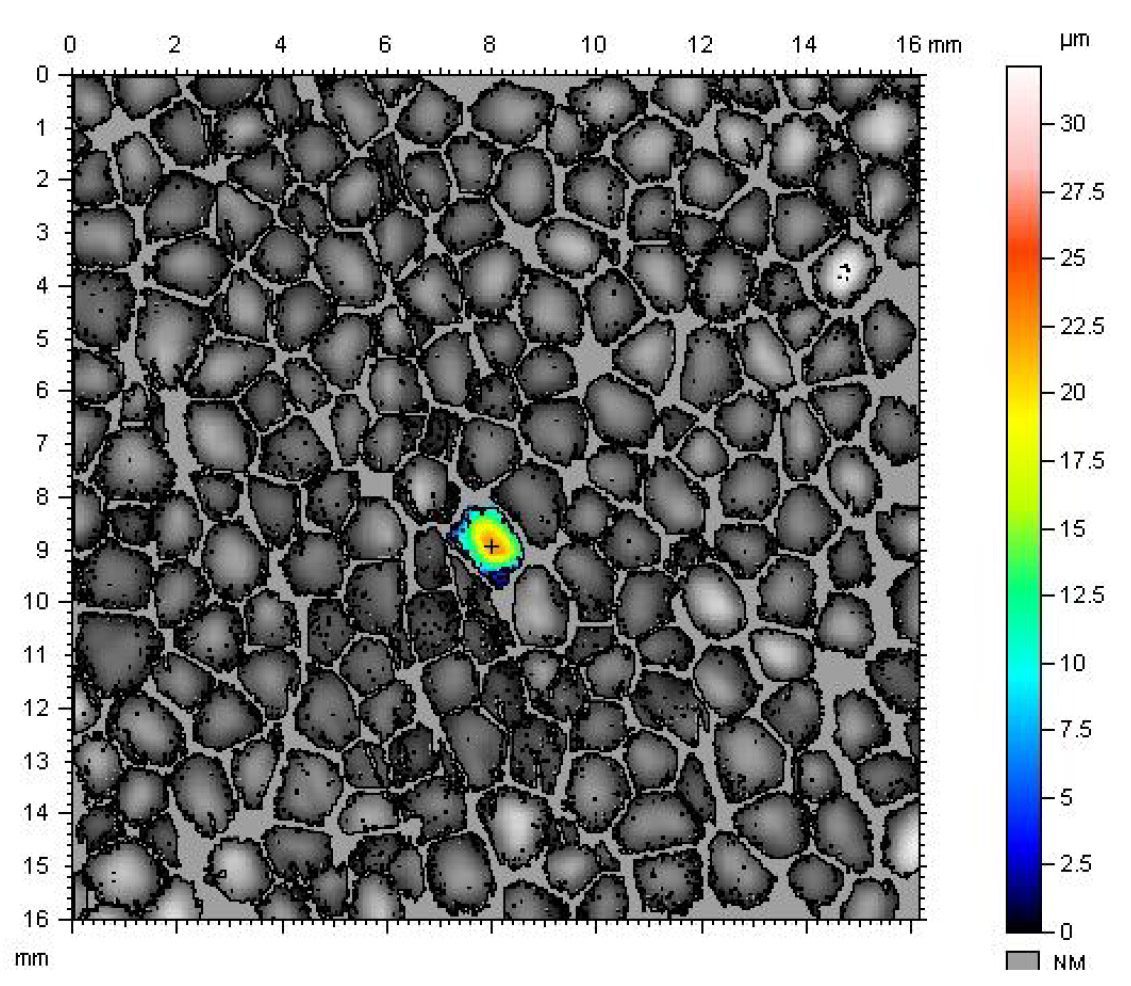

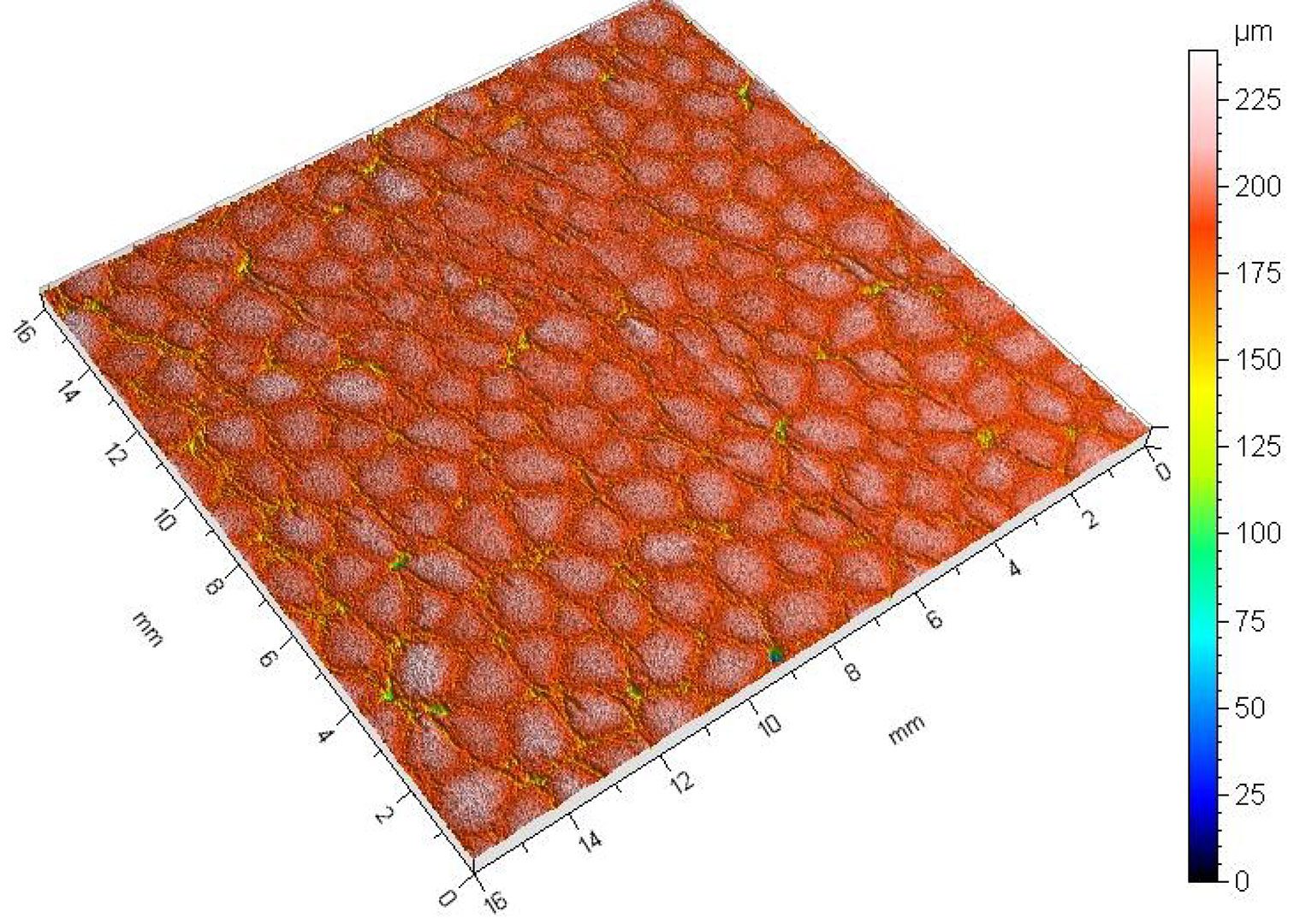

rough of a surface finish it will give. To achieve desired abrasive properties, manufactures of sandpaper must ensure that the abrasive particles are of a specific size and have little deviation. To quantify the quality of sandpaper, NANOVEA’s 3D Non-Contact Profilometer can be used to obtain the arithmetic mean (Sa) height parameter and average particle diameter of a sample area.

IMPORTANCE OF 3D NON-CONTACT OPTICAL PROFILER FOR SANDPAPER

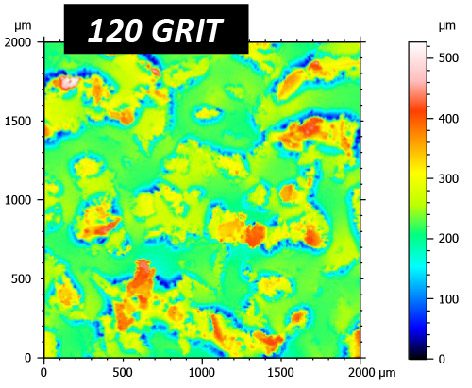

When using sandpaper, interaction between abrasive particles and the surface being sanded must be uniform to obtain consistent surface finishes. To quantify this, the surface of the sandpaper can be observed with NANOVEA’s 3D Non-Contact Optical Profiler to see deviations in the particle sizes, heights, and spacing.