Monthly Archives: July 2018

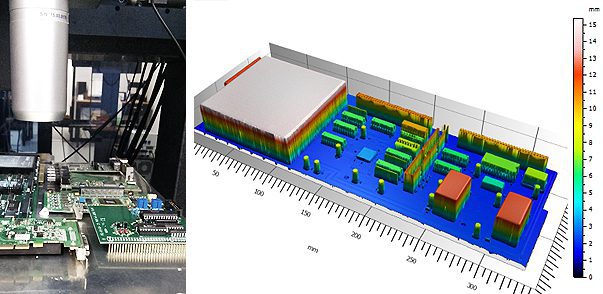

Automated Large Area Profilometry of PCB

Scaling up of manufacturing processes is necessary for industries to grow and keep up with constantly increasing demands. As manufacturing process scales up, the tools used in quality control also need to be scaled up. These tools must be fast to keep up with the production rate, while still maintaining high accuracy to meet product tolerance limits. Here, the Nanovea HS2000 Profilometer, with Line Sensor, showcases its value as a quality control instrument with its fast, automated, and high-resolution large area profilometry capabilities.

Video Clip or App Note: Automated Large Area Profilometry of PCB

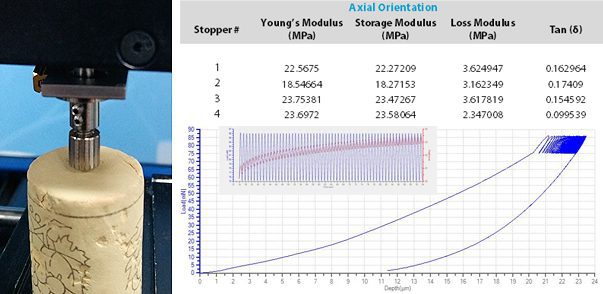

Dynamic Mechanical Analysis With Nanoindentation

The quality of corks depends heavily on its mechanical and physical property. Its ability to seal wine can be identified as these important factors: flexibility, insulation, resilience, and impermeability to gas and liquids. By conducting dynamic mechanical analysis (DMA) testing, its flexibility and resilience properties can be gauged with a quantifiable method. These properties are characterized with Nanovea Mechanical Tester’s Nanoindentaion in the form of Young’s modulus, storage modulus, loss modulus, and tan delta (tan (δ)). Other data that can be gathered from DMA testing are phase shift, hardness, stress, and strain of the material.