Monthly Archives: February 2012

Surface Area Measurement of Oxidation With 3D Profilometry

The 3D Non Contact Profilometer will be used to characterize the surface area measurement of two samples with A1SiN coatings, one with a low level of silicon the other with a high level. The A1SiN coating was deposited on H13 Steel by magnetron sputtering then submitted to an oxidation resistance test (900°C-1hour).

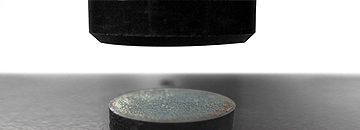

Tribological Characterization of Ti-WS2 Coating

In this report we will review the tribological characterization of Ti-WS2 coating deposited by Magnetron Sputtering technique. The friction and wear tribology will be obtained with the Tribometer in reciprocating mode and an integrated optical profiler will be used to obtain wear rate.

Here are examples of materials we tested this month:

Mechanical:

• Nanoindentation of microseal

• Nanoindentation compression of micro ceramic

• Nanoindentation of micro rubber features

• Nano Scratch of microfeatures

• Nano Friction microtube

• Micro Scratch of engine parts

• Microindentation of coil coatings

• Microindentation yield strength of micro rods

3D Non-Contact Profilometry:

• Topography of rubber samples

• Profile of micro parts

• Roughness of metal samples

• Roughness of wood samples

• Coplanarity of micro features

• Step height of microchannels

• Volume loss of micro pits

• Friction testing of liquid with micro particles

• Friction testing of metal samples

• Wear resistance of hard coatings

• Wear resistance of tile samples

• Wear resistance of polished concrete