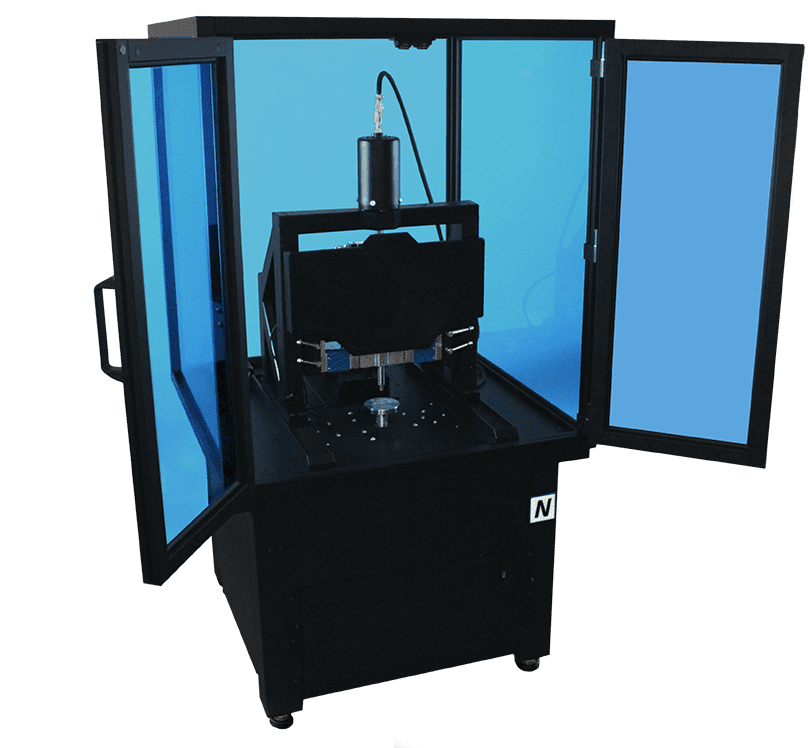

Block-On-Ring Module

Previous

Next

Block-on-Ring Test is a widely used technique that evaluates the sliding wear behaviors of materials in many different simulated conditions.

How does it work?

A Block-On-Ring test allows a reliable ranking of material couples for

specific tribological applications.

A block is pressed down on a rotating ring.

Extreme Versatility

STANDARDS

- ASTM G77

- ASTM G137

* Instrument parameter limits may differ from those specified within the standard.

Properties Analyzed

- Friction Coefficient

- Wear Rates

- Failure Points

- Lubrication Studies

- Friction vs Speed

- Friction vs Load (T2000)

SENSORS

- Depth

- Acoustic Emission

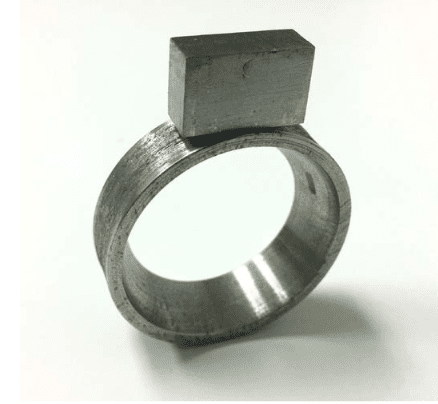

Rotating Lower Sample

- Ring (34.98mm outer diameter) – material can vary

- Rotating speed capability up to 5,000 rpm

Fixed Upper Sample

- Steel Block (15.75×10.16×6.35mm)

(Diamond, WC, Rubber and many other materials) - 3, 6, 10 and 25mm ball

- Custom ball sizes

- Custom Pins

- Flat Plate

- Custom geometries

Environmental Conditions

- Liquid Cup and Liquid Heating up to 150 °C

- Lubrication Drop by Drop

- Humidity Control

- Cooling Chamber -40 °C

- Various Gases

- Vacuum (Custom)

- Cryogenic Adapter (Custom)