Monthly Archives: June 2016

Brush Bristle Stiffness Performance Using Tribometer

Brushes are among the most basic and widely used tools in the world. They can be used to remove material (toothbrush, archaeological brush, bench grinder brush), apply material (paintbrush, makeup brush, gilding brush), comb filaments, or add a pattern. As a result of the mechanical and abrasive forces on them, brushes constantly have to be replaced after moderate use. For example toothbrush heads should be replaced every three to four months because of fraying as a result of repeated usage. Making the toothbrush fiber filaments too stiff risks wearing away the actual tooth instead of soft plaque. Making the toothbrush fibers too soft makes the brush lose its form faster. Understanding the changing bend of the brush, as well as the wear and overall change in shape in the filaments under different loading conditions is necessary to design brushes that better fulfill their application.

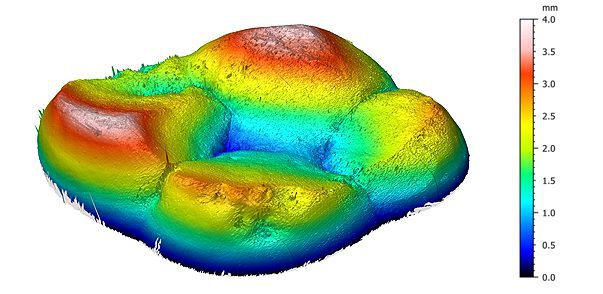

Dental Wear Surface Subtraction Using 3D Profilometry

Dental wear, the loss of tooth material due to reasons other than cavities and sudden dental trauma over the course of a lifetime, is a normal process in all adults. The topmost layer of a tooth is enamel, which is the hardest substance in the human body, and cannot be naturally restored. Enamel can wear away from tooth-to-tooth, tooth-to-foreign body, or tooth-to-dental crown wear, as well as a result of exposure to acidic environments. It is important to be able to precisely measure the wear rate, volume loss, and change in topography of a tooth or dental crown in order to be able to effectively slow down tooth wear. All these calculations can be made using a surface subtraction study.

Surface wear subtraction studies are critical in any application looking at the topographic change in a relatively small area in relation to the entire sample. Such studies can effectively quantify surface wear, corrosion, or the degree of similarity between two parts or molds. Being able to precisely measure the surface area and volume loss of an area of interest is vital in order to properly design wear or corrosion resistant coatings, films, and substrates

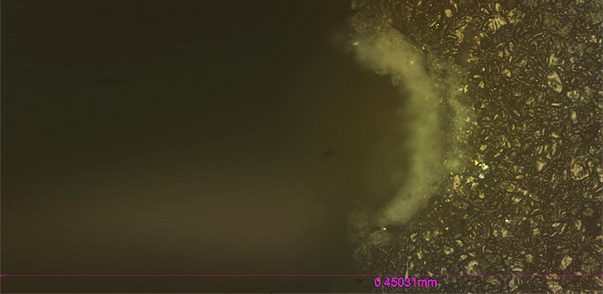

Edge Chipping Resistance Using Macroindentation

The resistance of the edges of brittle materials to chipping or flaking from concentrated loads is a critical property for dental restoration ceramics, resin composites, edge-mounted optical devices, ceramic tool bits, thin semiconductor chips, and many other materials. The edge chipping resistance test provides a method to quantify and measure the fracture resistance, toughness, and edge chip strength of these materials. This method uses a conical indenter to chip the rectangular edge of a brittle sample at set distances from the edge. Archeological evidence has revealed that this method is similar to the way early humans selected stones to make tools and weapons. Hundreds of thousands of years later, edge chipping tests remain a critical tool for applications where edge toughness is concerned.