Monthly Archives: March 2016

American Coatings Show 2016 | Visit Nanovea @ Booth 2773

Visit Nanovea at American Coatings Show 2016 booth 2773. The Jr25 Profilometer will be displayed on-site for live demos. For more information or to request guest passes please Contact Nanovea.

Low Temperature Tribology

A reliable measurement of low temperature tribology, static and dynamic coefficient of friction, COF, as well as wear behavior is needed in order to better understand the tribological performance of materials for sub-zero applications. It provides a useful tool to correlate the frictional property with the influence of various factors, such as reactions at the interface, interlocking surface features, cohesion of surface films, and even microscopic solid static junctions between surfaces at low temperatures.

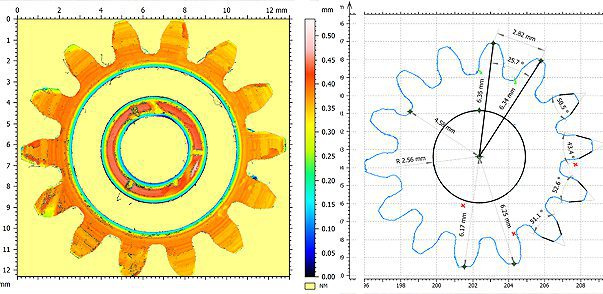

Gear Contour Analysis

Manufacturing of high precision gears requires stringent quality control, in order to obtain the best operational conditions and energy efficiency. Surface defects on the gears may lead to negative impact on the gear mesh quality. Moreover, during the service time, wear and tear takes places, creating surface defects such as dents and cracks in the gears that may result in decreased power transmission efficiency and potential mechanical failure. An accurate and quantifiable tool for surface inspection is in need. Unlike a touch probe technique, the Nanovea Profilometer performs 3D contour analysis of the sample without touching, making it possible to precisely scan samples with a complex shape, such as gears of different geometry.

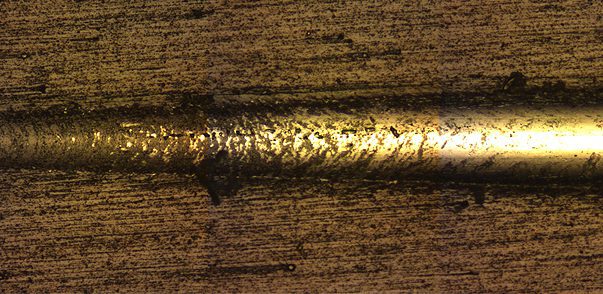

Macro Adhesion Failure of DLC

bits and bearings. Under such extreme conditions, sufficient cohesive and adhesive strength of the coating/substrate system becomes vital. In order to select the best metal substrate for the target application and to establish a consistent coating process for DLC, it is critical to develop a reliable technique to quantitatively assess cohesion and adhesion failure of different DLC coating systems.

Cohesive & Adhesive Strength of DLC Using Macro Scratch Testing