Monthly Archives: April 2018

Polymeric Tube Finish and Dimension

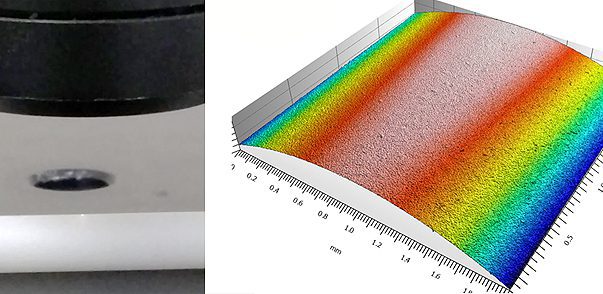

Tubes made from polymeric material are commonly used in many industries ranging from automotive, medical, electrical, to many other categories. In this study, medical catheters made of different polymeric materials were studied using the Nanovea 3D Non-Contact Profilometer to measure surface roughness, morphology, and dimensions. Surface roughness is crucial for catheters as many problems with catheters, including infection, physical trauma, and inflammation can be linked with the catheter surface. Mechanical properties, such as coefficient of friction, can also be studied by observing surface properties. These quantifiable data can be obtained to ensure the catheter can be used for medical applications.