Monthly Archives: September 2018

Comparison of Ridge Spacing and Wear Rate on 3D Printed Materials

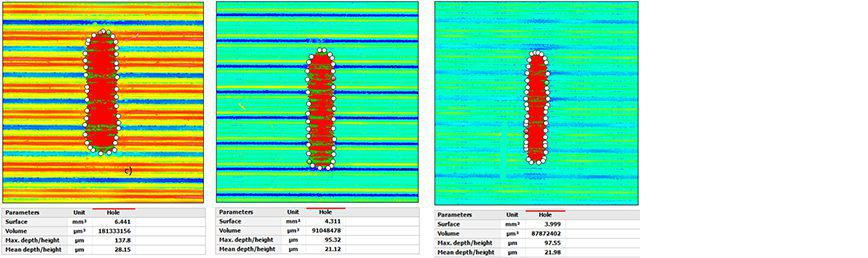

3D printed material is gaining rise due to its ability to create a large variety of shapes and features without the use of time consuming input. 3D printing does have its limitations, however, such as in the lack of materials that can be used and strength of products. To understand how the quality of 3D printed materials can be improved, the Nanovea Tribometer can be used to conduct wear testing.

Comparison of Ridge Spacing and Wear Rate on 3D Printed Material

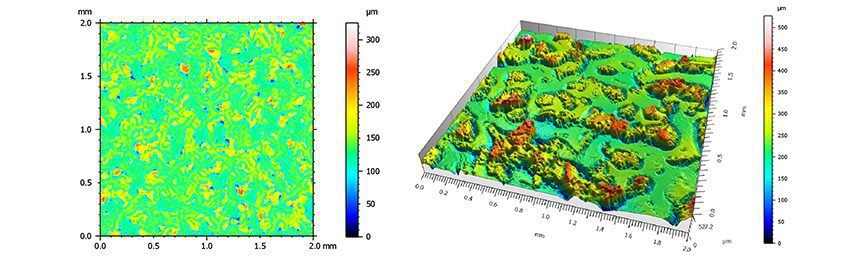

Roughness and Particle Diameter of Sandpaper

Sandpaper is a common commercially available product used as an abrasive. The most common

use for sandpaper is to remove coatings or to polish a surface with its abrasive properties. These

abrasive properties are classified into grits, each related to how smooth or rough of a surface

finish it will give. To achieve desired abrasive properties, manufactures of sandpaper must ensure

that the abrasive particles are of a specific size and have little deviation. To quantify the quality

of sandpaper, Nanovea’s 3D Non-Contact Profilometer can be used to obtain the Sa height

parameter and average particle diameter of a sample area.