IN-LINE

PROFILER

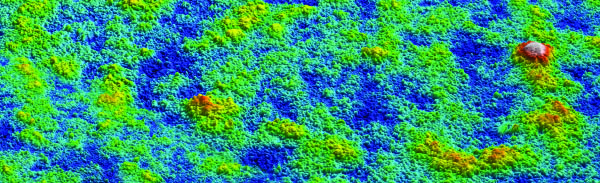

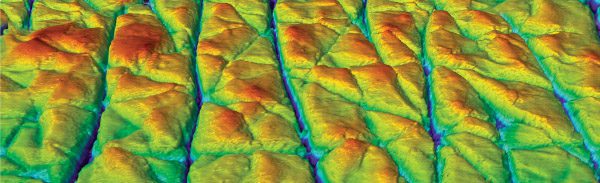

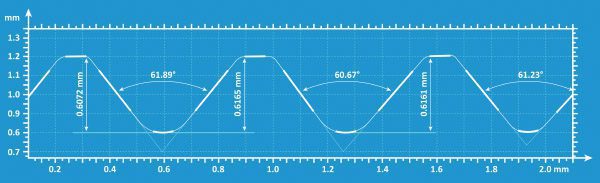

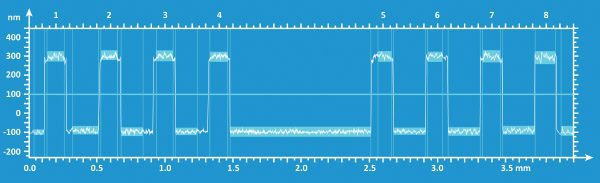

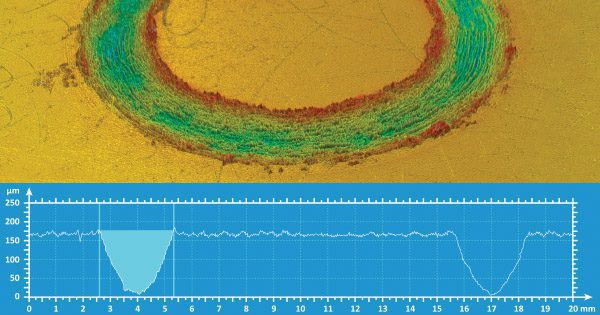

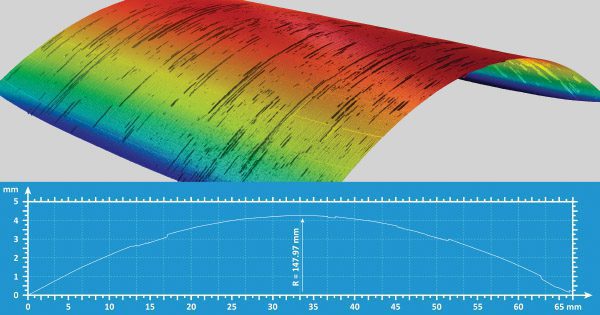

QC Roughness,

Texture

& Finish

IN-SITU MEASUREMENT

& REAL-TIME FEEDBACK

NANOVEA’s unique software provides measurements and analysis of any surface in real time with acquisition rates of more than 1,300,000 points/sec.

One of its numerous features, Pass & Fail criteria specific to each sensor or average of all sensors, helps to effectively identify surface defects derived from materials processing and product manufacturing.

TRIGGERED

IN-LINE INSPECTION

CONTINUOUS

IN-LINE INSPECTION

Multiple non-contact profiler sensors can be installed to monitor roughness and textures of different areas at the same time. Capable of determining roughness of a sample without contact,

Chromatic Light technology allows for a reliable in-line surface quality inspection of the end product.

Best for steep angles

Fast for large areas

Very easy to use

No Image Stitching

No Sample Prep

No Refocusing

2D & 3D NON-CONTACT PROFILOMETRY

HIGH QUALITY QUALITY CONTROL

SEAMLESS INTEGRATION

We provide personalized full integration support, including specific mounting structures so you don’t have to worry about disrupting your established process.