INTRODUCTION

Acrylic urethane paint is a type of fast-dry protective coating widely used in a variety of industrial applications, such as floor paint, auto paint, and others. When used as floor paint, it can serve areas with heavy foot and rubber-wheel traffic, such as walkways, curbs and parking lots.

IMPORTANCE OF SCRATCH AND WEAR TESTING FOR QUALITY CONTROL

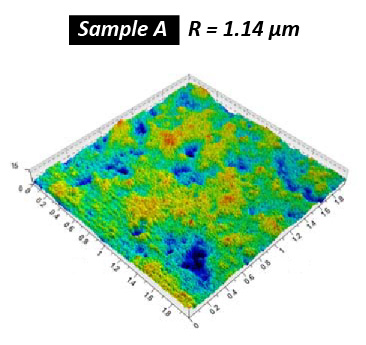

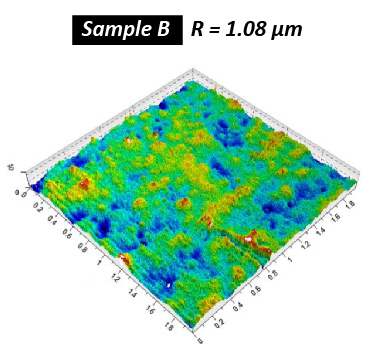

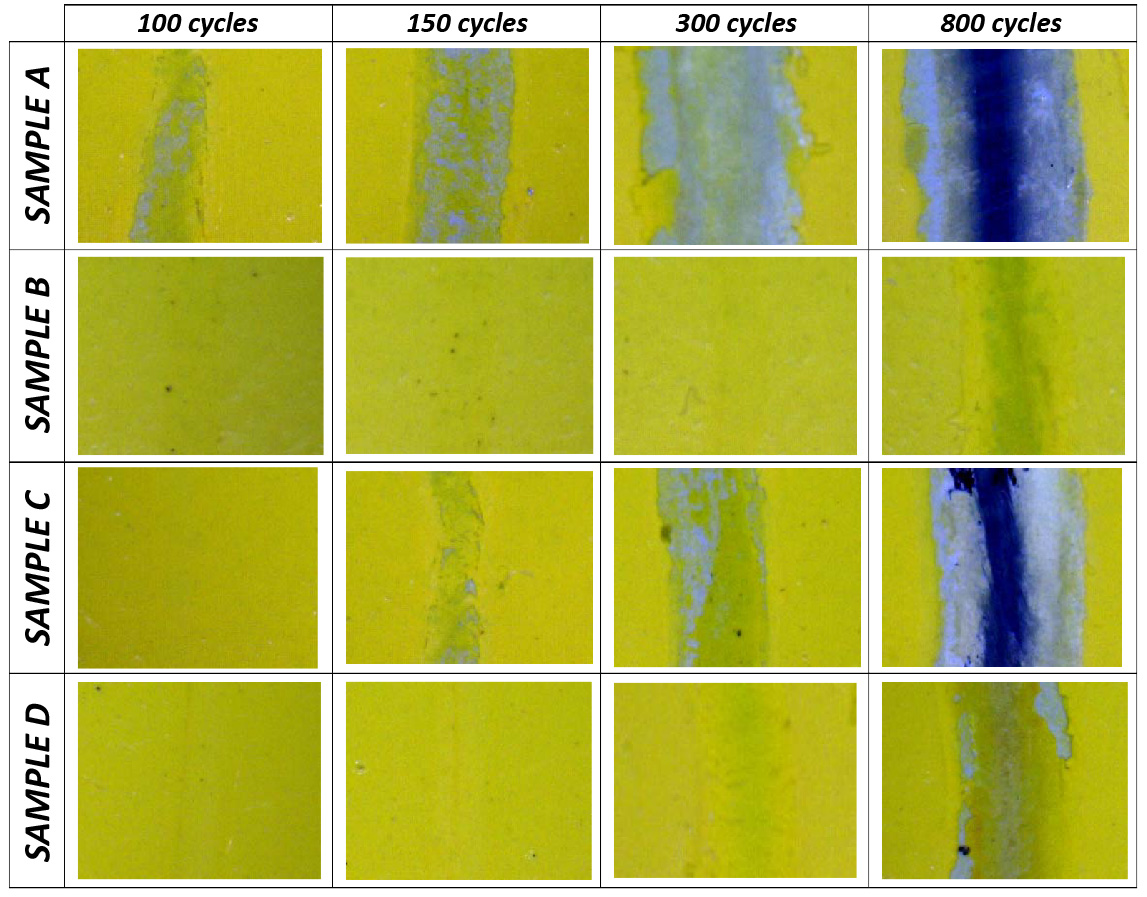

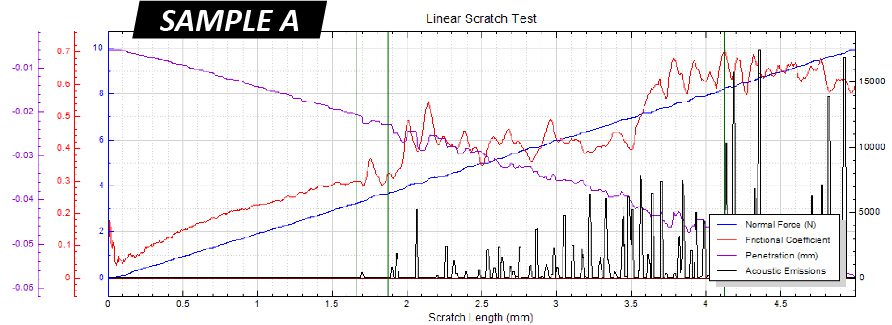

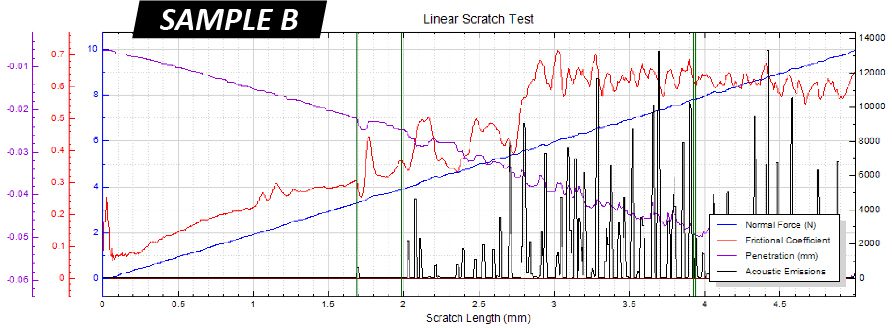

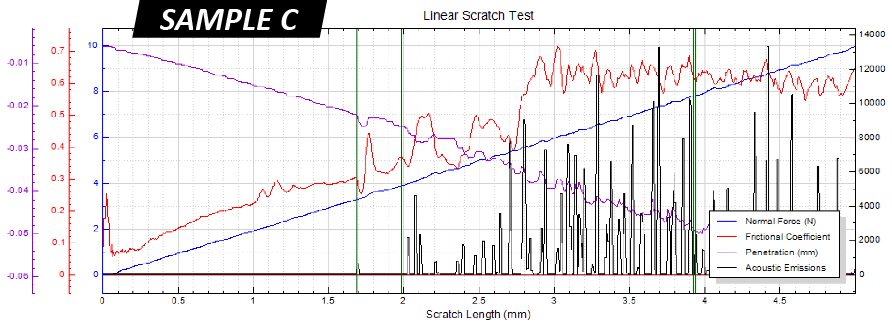

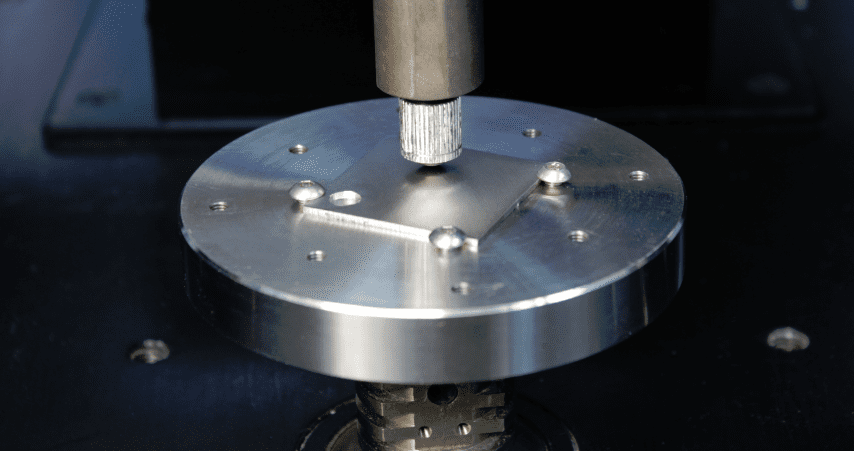

Traditionally, Taber abrasion tests were carried out to evaluate the wear resistance of acrylic urethane floor paint according to the ASTM D4060 standard. However, as mentioned in the standard, “For some materials, abrasion tests utilizing the Taber Abraser may be subject to variation due to changes in the abrasive characteristics of the wheel during testing.”1 This may result in poor reproducibility of test results and create difficulty in comparing values reported from different laboratories. Moreover, in Taber abrasion tests, abrasion resistance is calculated as loss in weight at a specified number of abrasion cycles. However, acrylic urethane floor paints have a recommended dry film thickness of 37.5-50 μm2.

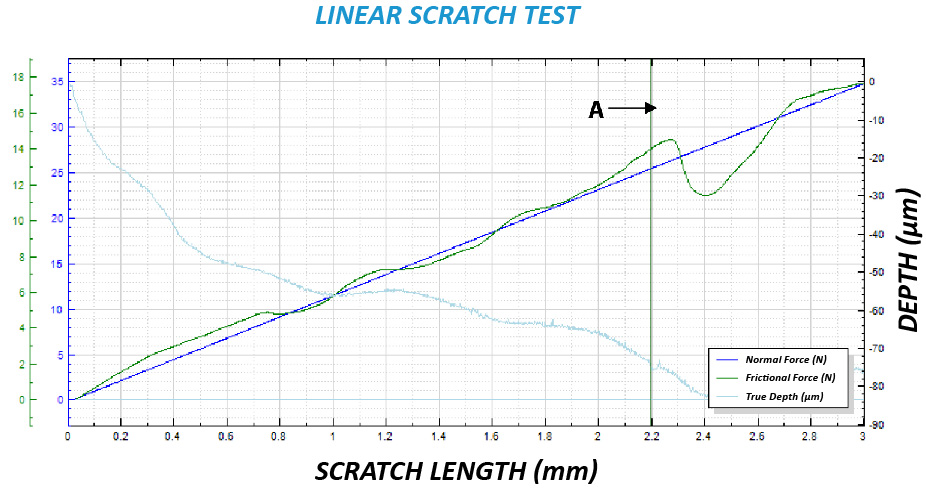

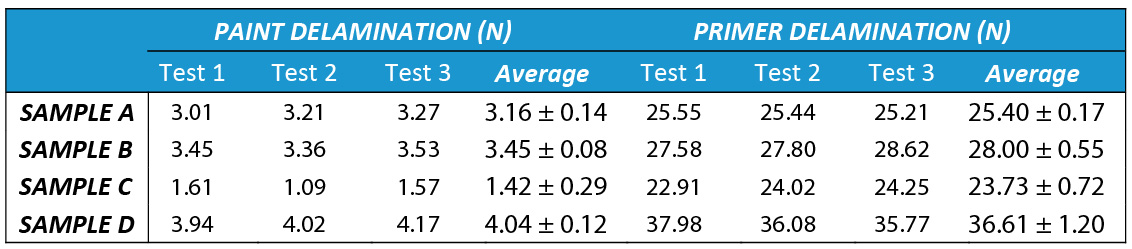

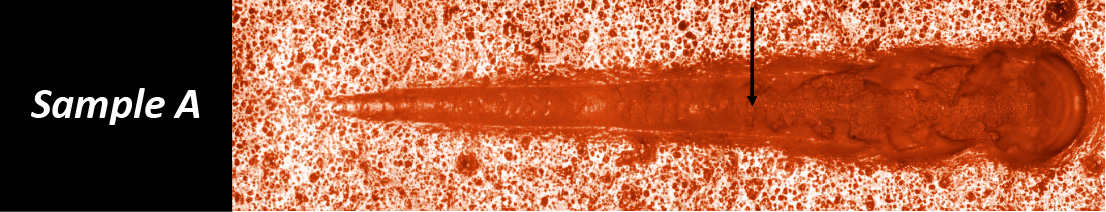

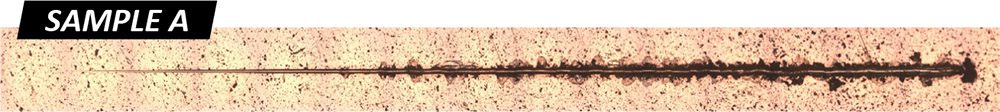

The aggressive abrasion process by Taber Abraser can quickly wear through the acrylic urethane coating and create mass loss to the substrate leading to substantial errors in the calculation of the paint weight loss. The implant of abrasive particles in the paint during the abrasion test also contributes to errors. Therefore, a well-controlled quantifiable and reliable measurement is crucial to ensure reproducible wear evaluation of the paint. In addition, the scratch test allows users to detect premature adhesive/cohesive failures in real-life applications.