Monthly Archives: October 2018

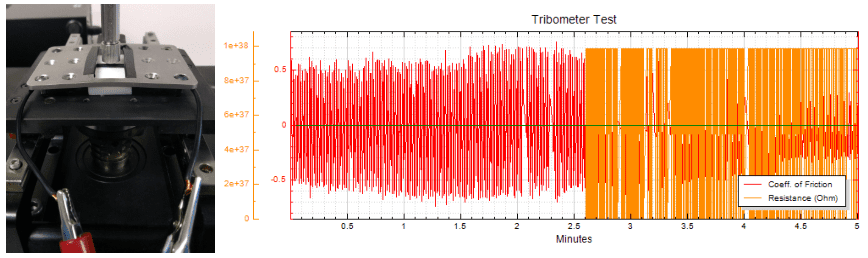

Fatigue Testing of Wire with Electrical Conductance Apparatus

Electrical wires are the most common form of interconnects between electrical devices. Wires are usually made of copper (and sometimes aluminum) due to copper’s ability to conduct electricity very well, ability to bend, and its cheap cost. Outside of material, wires can also be assembled in different ways. Wires can come be obtained in different sizes, usually denoted by gauges. As the wire diameter increases, the wire gauge decreases. Longevity of the wire will change with wire gauge. The difference in longevity can be compared by conducting a reciprocating linear test with the Nanovea Tribometer to simulate fatigue.

Fatigue Testing of Wire with Electrical Conductance Apparatus

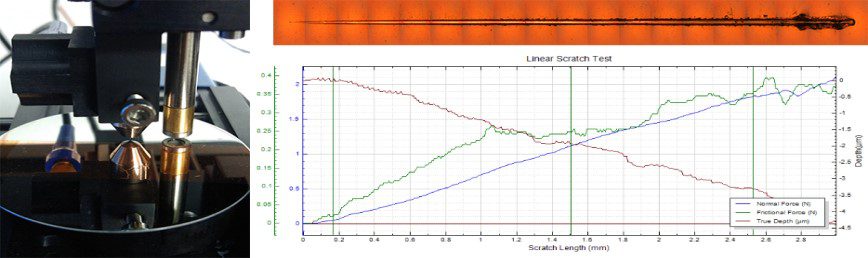

Scratch Testing on Multi-Layered Thin Film

Coatings used extensively throughout multiple industries to preserve the underlying layers, to create electronic devices, or to improve surface properties of materials. Due to their numerous uses coatings are extensively studied, but their mechanical properties can be difficult to understand. Failure of coatings can occur in the micro/nanometer range from surface-atmosphere interaction, cohesive failure, and poor substrate-interface adhesion. A consistent method to test for coating failures is scratch testing. By applying a progressively increasing load, cohesive (e.g. cracking) and adhesive (e.g. delamination) failures of coatings can be quantitatively compared.