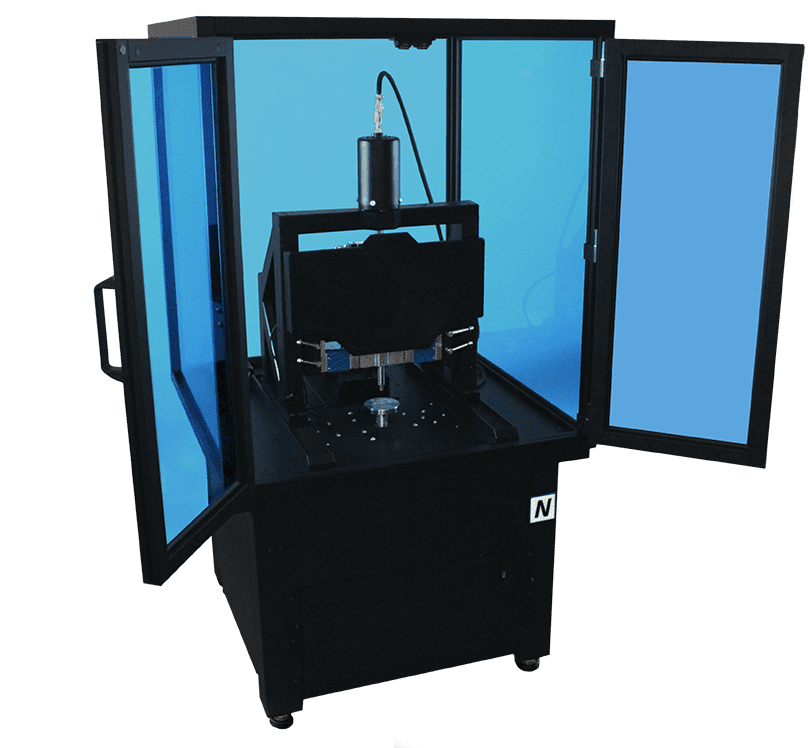

Linear Module

Linear Wear Friction Test reproduces the linear reciprocating motion found in many real-world tribology mechanisms.

How does it work?

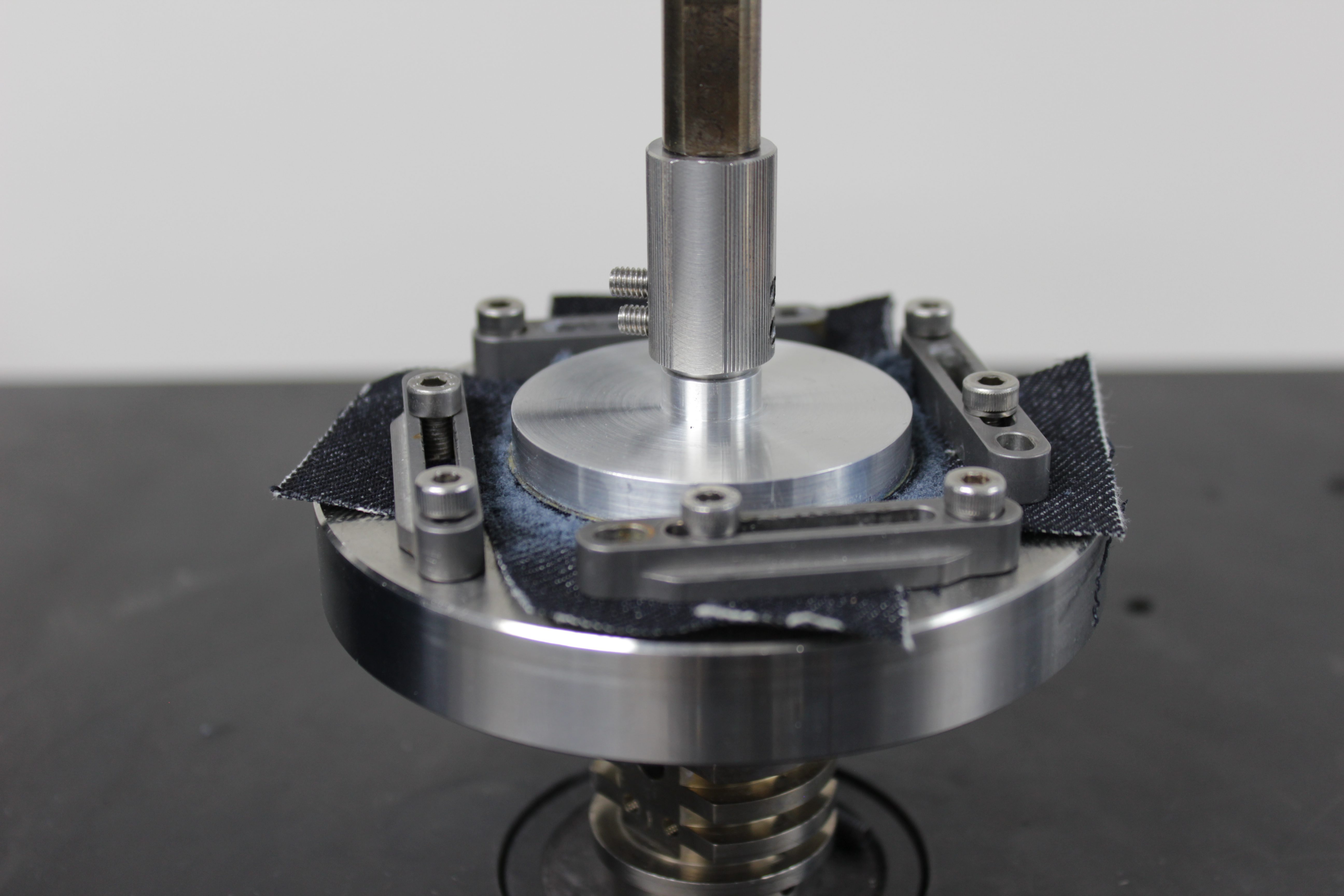

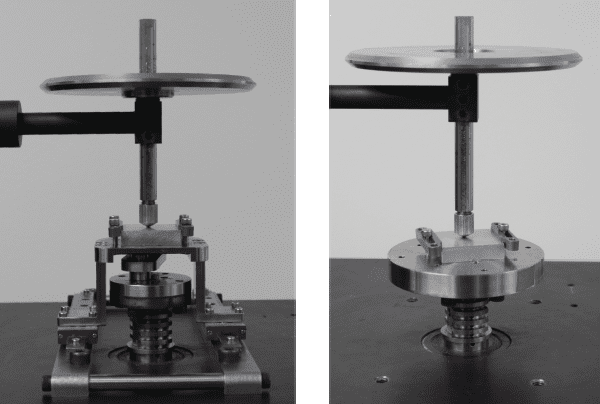

A at, pin or ball tip is loaded onto a test sample with a precise weight.

The test samples can be of varied shape (such as cylindrical)

as long as there is a at zone of a certain length in the direction of

movement. The length of the track can be adjusted prior to starting

the measurement.

As the test starts, the tip creates a linear wear

track (zigzag pattern also possible). Because of the integrated 16bit

external position encoder, friction can be displayed for any specific

point for each pass.

This is essential to accurately study the trend of friction across the full length of the test.

Extreme Versatility

STANDARDS

- ASTM G133

- ASTM G171

- ASTM F732

- ASTM D1894

- ASTM G132

* Instrument parameter limits may differ

from those specified within the standard.

Properties Analyzed

- Friction Coefficient

- Wear Rates

- Failure Points

- Electrical Resistance

- Lubrication & Corrosion Studies

- Friction vs Speed

- Scratch Hardness

- Friction versus Load

SENSORS

- Depth

- Acoustic Emission

- Electrical Resistance

Rotating Lower Sample

- Samples with flat surface for the test

- Cylindrical Samples

- Any types of materials

Fixed Upper Sample

- 3, 6, 10 and 25mm ball

- Custom ball sizes

- Custom Pins

- Flat Plate

- Custom geometries

- Diamond, WC, Rubber and

many other materials

Environmental Conditions

- 900°C Heating Oven

- Liquid Cup and Liquid Heating up to 150 °C

- Lubrication Drop by Drop

- Humidity Control

- Cooling Chamber -40 °C

- Corrosion Testing Cup

- Various Gases

- Vacuum (Custom)