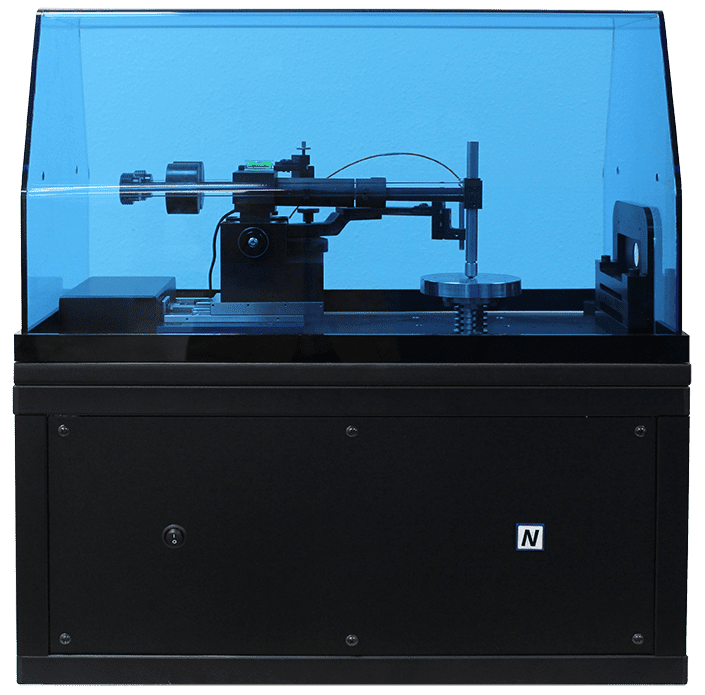

NANOVEA Tribometers offer precise and repeatable wear and friction testing using ISO and ASTM compliant rotative and linear modes, with optional high temperature wear, lubrication and tribo-corrosion modules available in one pre-integrated system. NANOVEA’s unmatched range is an ideal solution for determining the full range of tribological properties of thin or thick, soft or hard coatings, films and substrates.

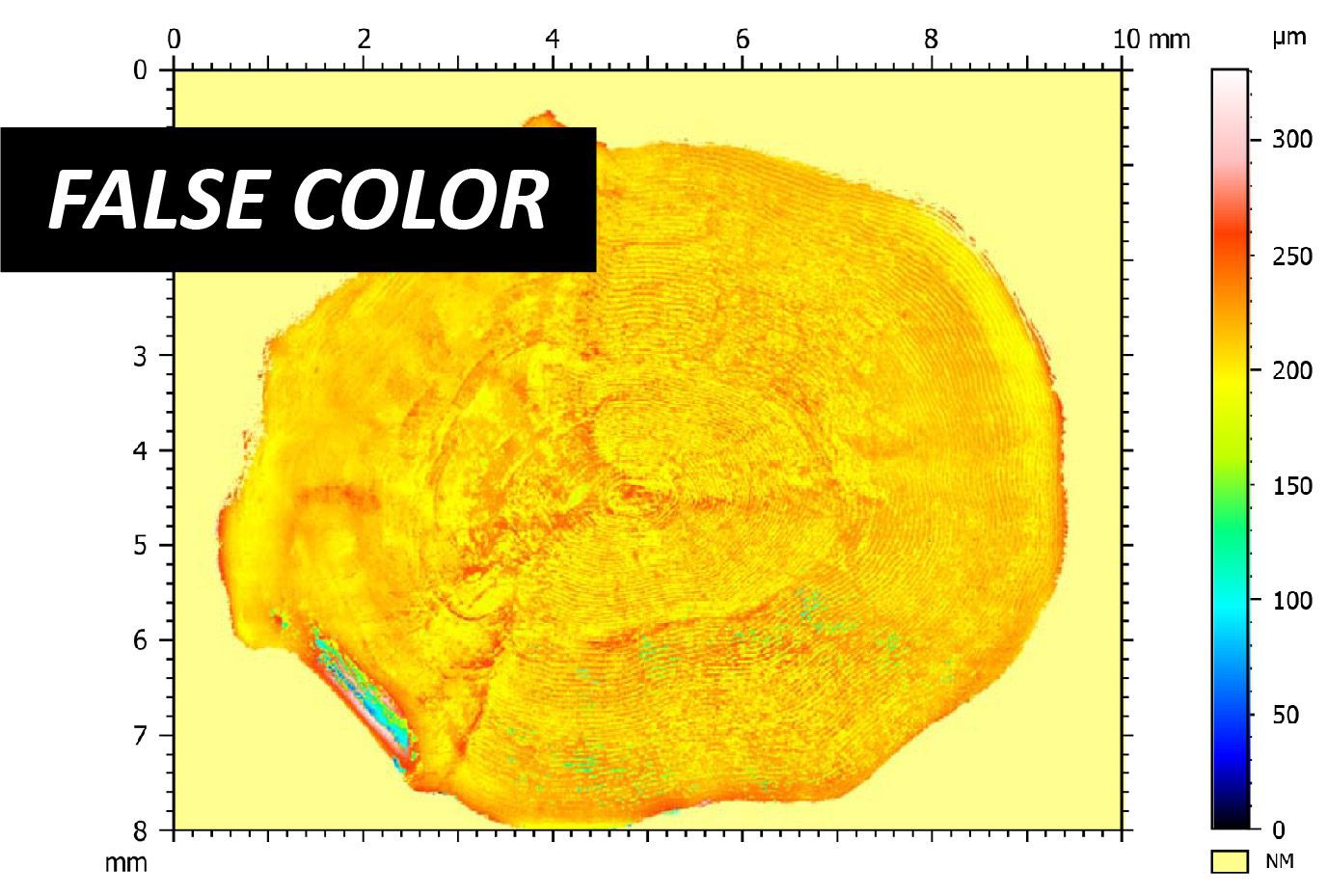

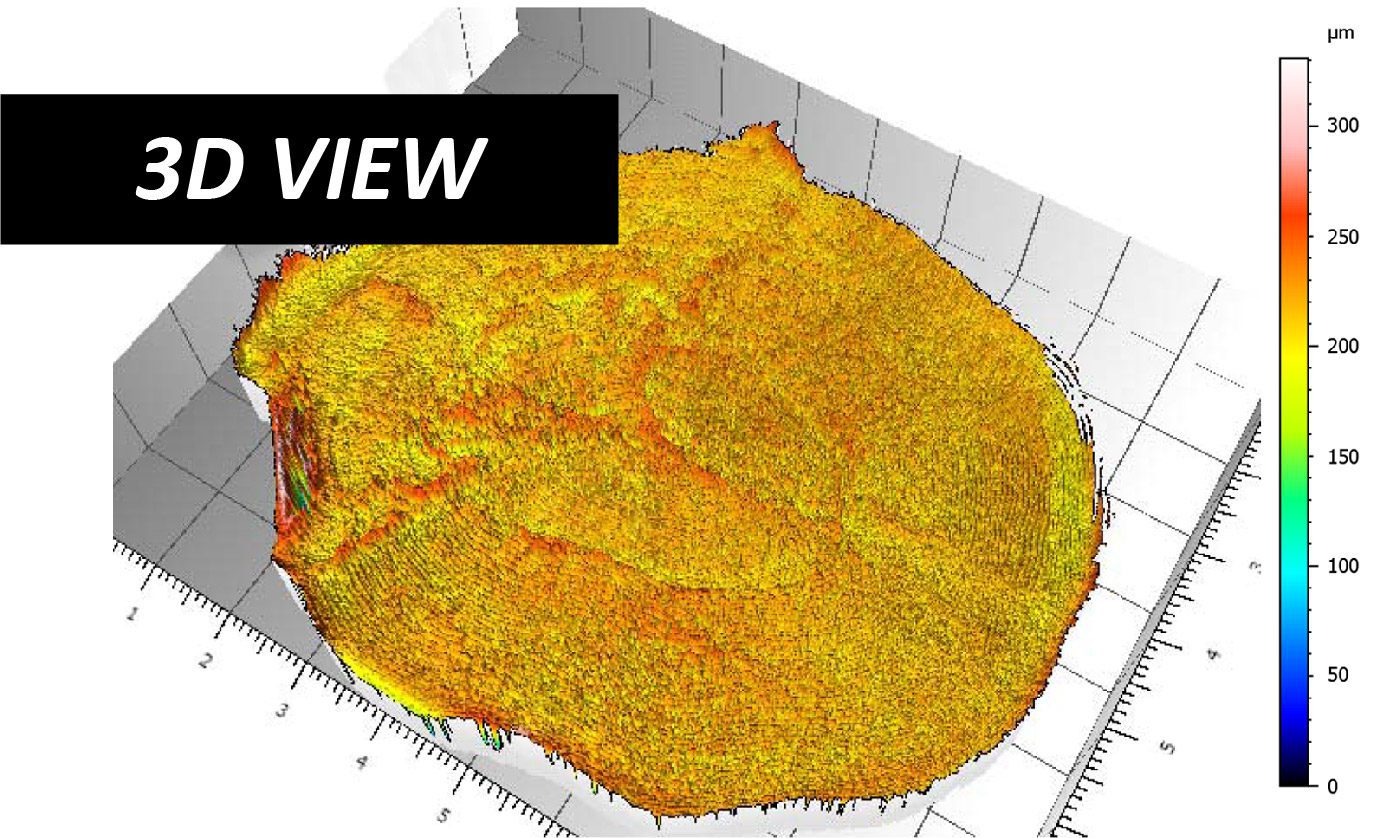

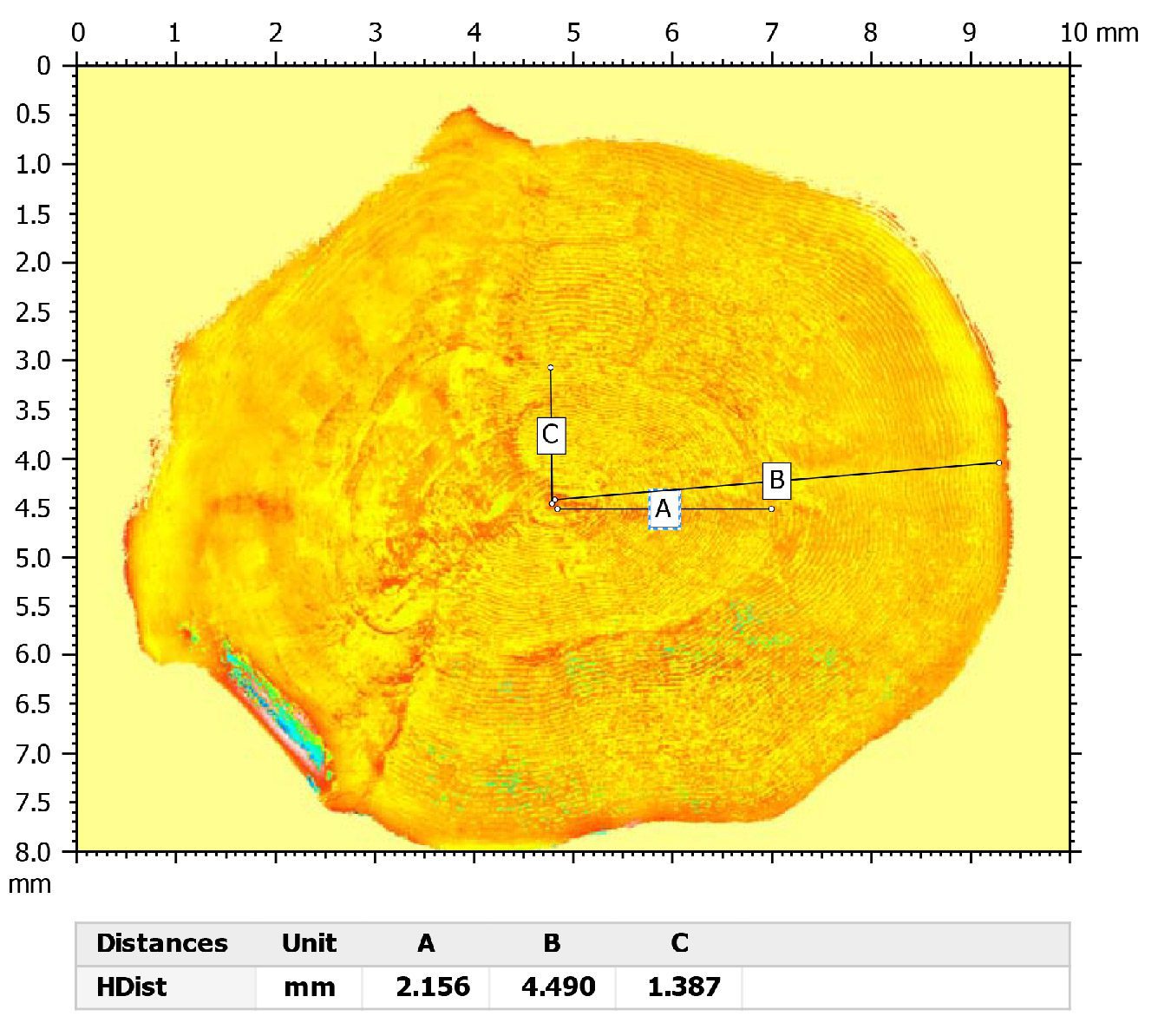

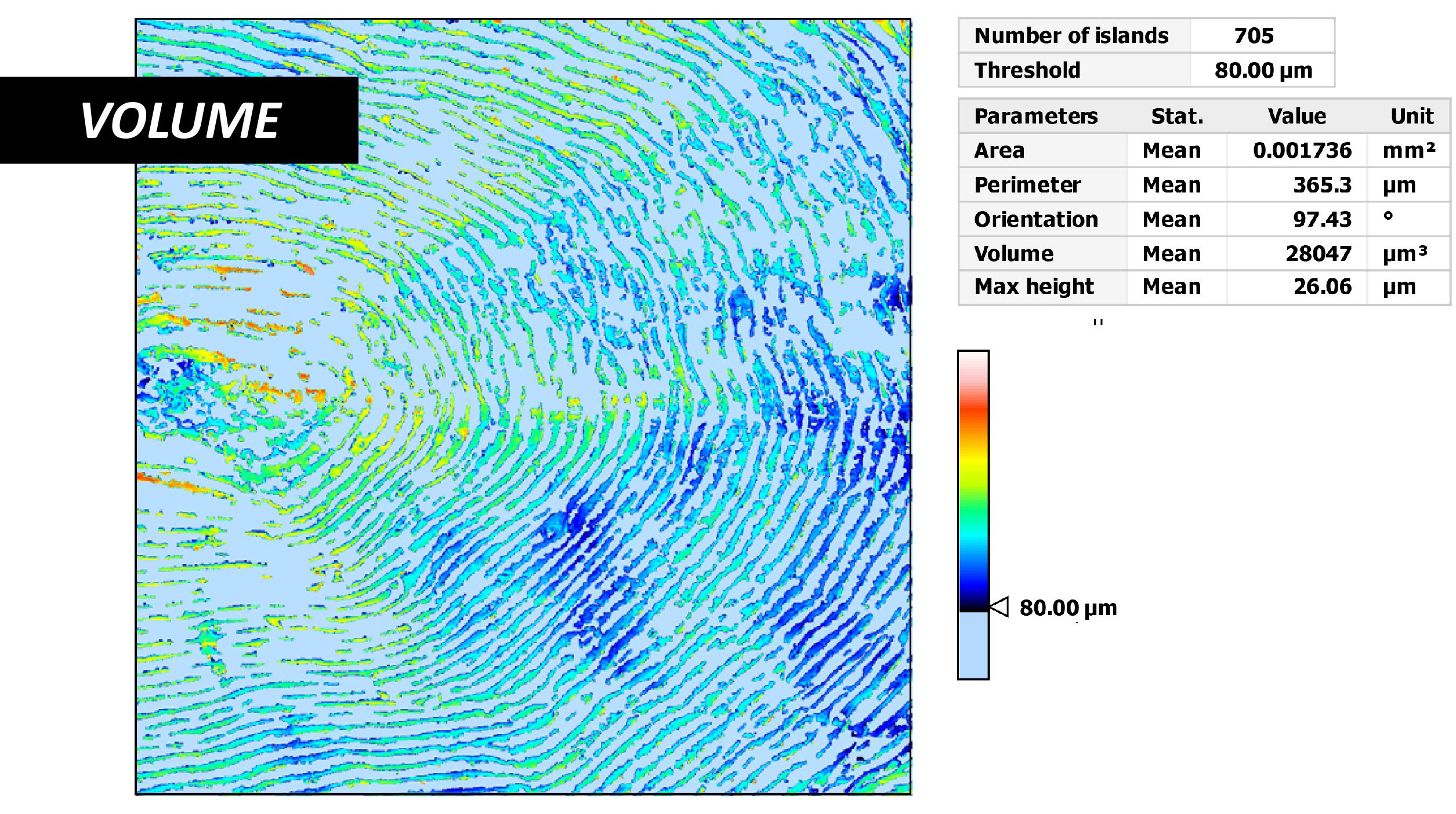

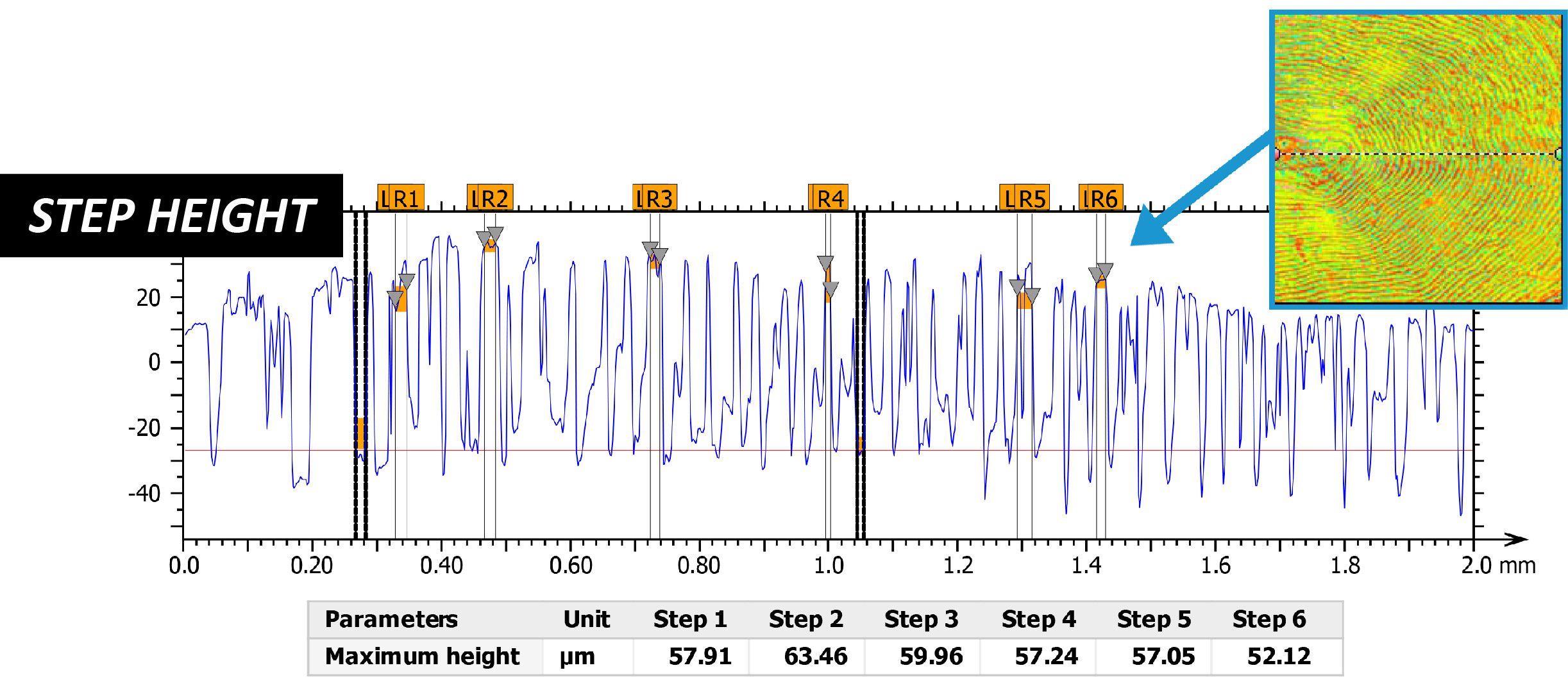

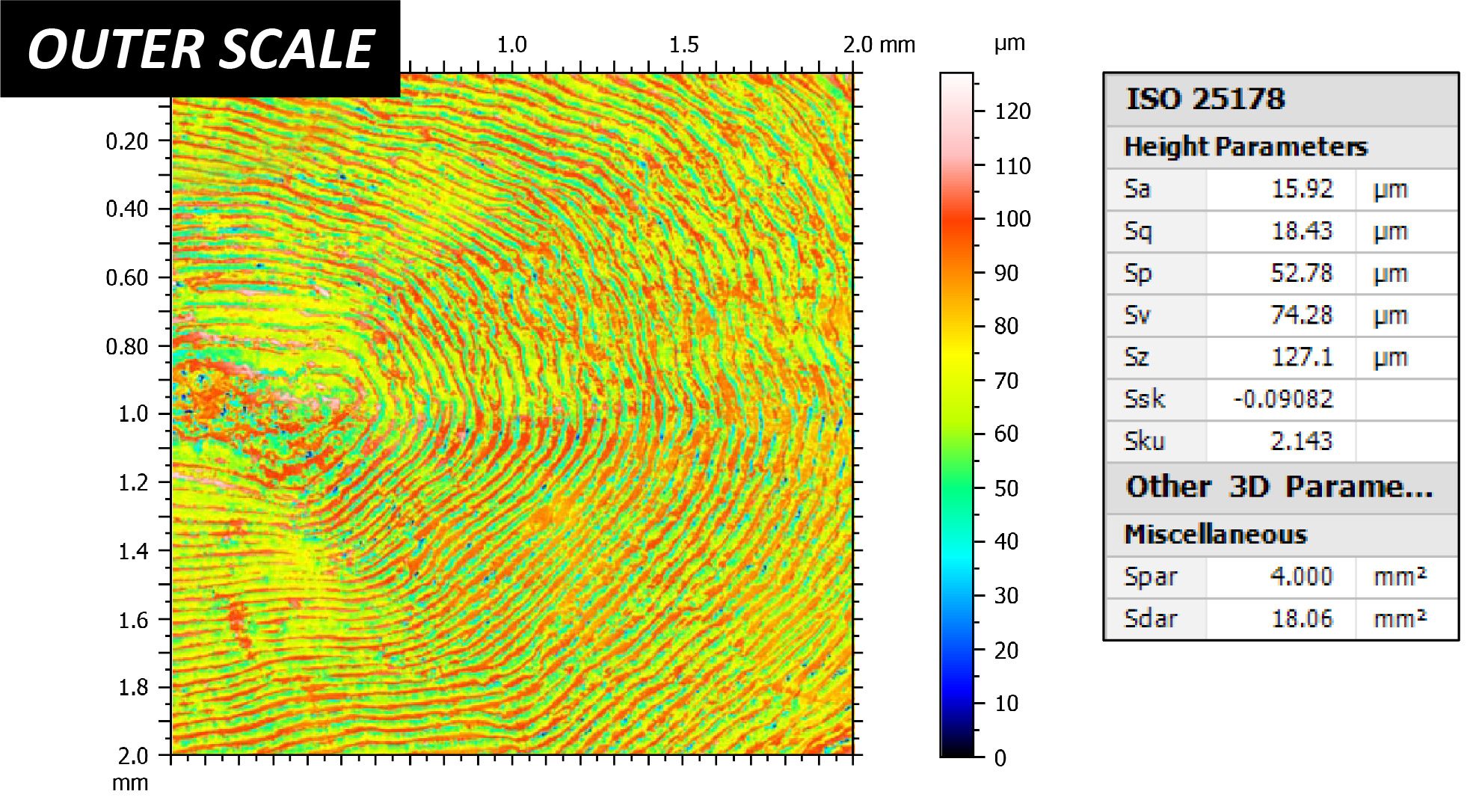

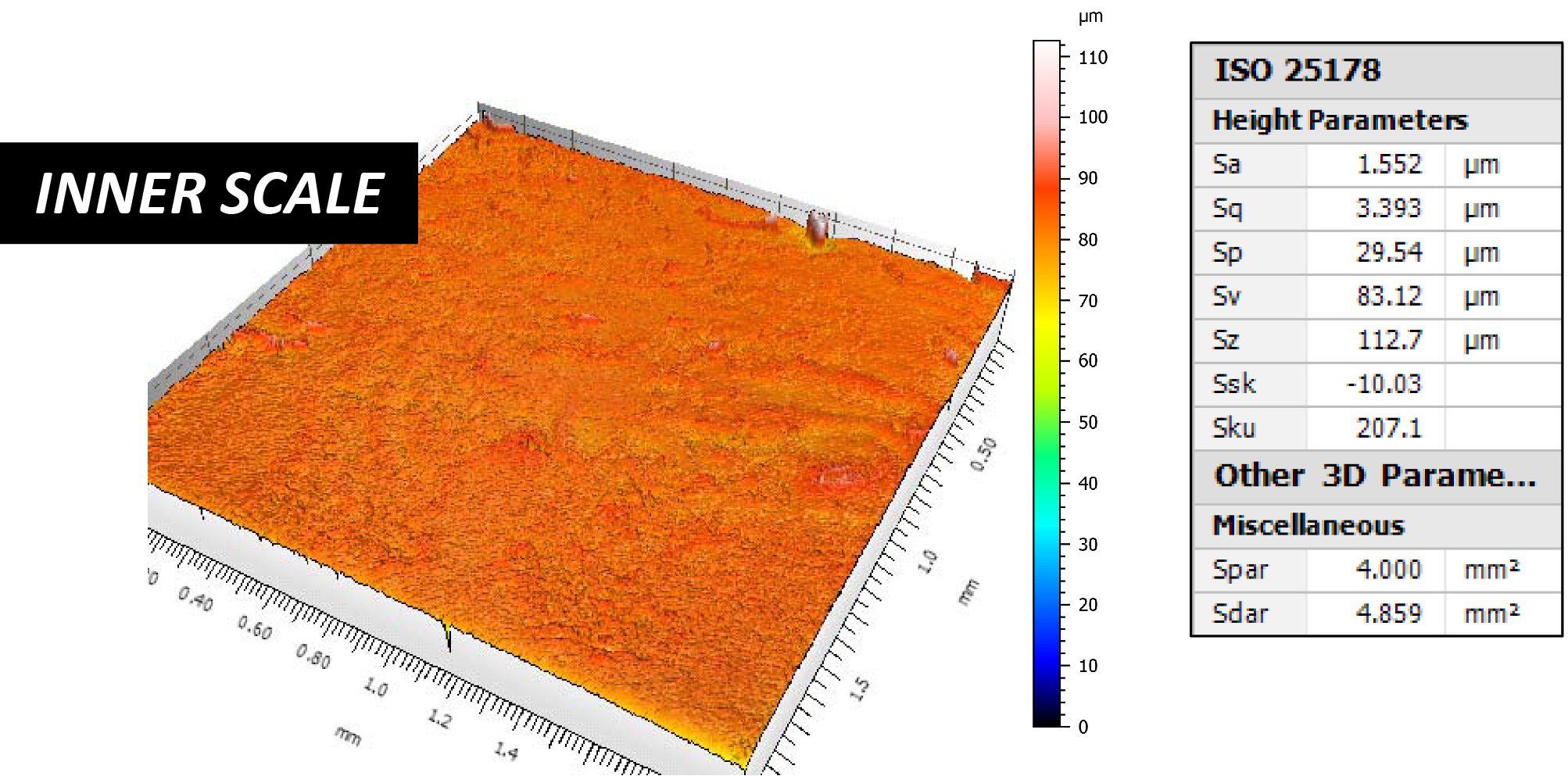

Optional 3D Non-Contact Profilers are available for high resolution 3D imaging of wear tracks in addition to other surface measurements such as roughness.