INTRODUCTION

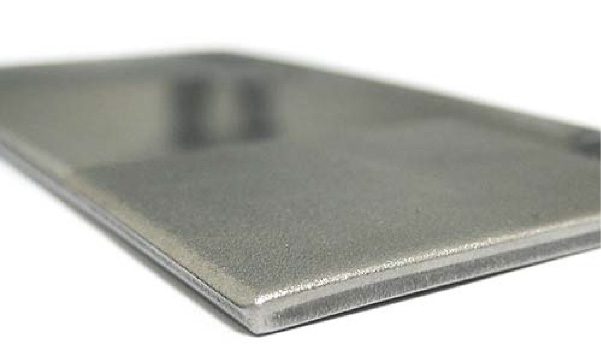

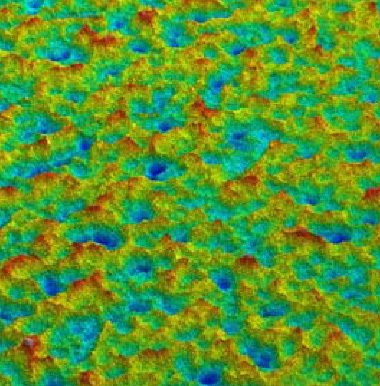

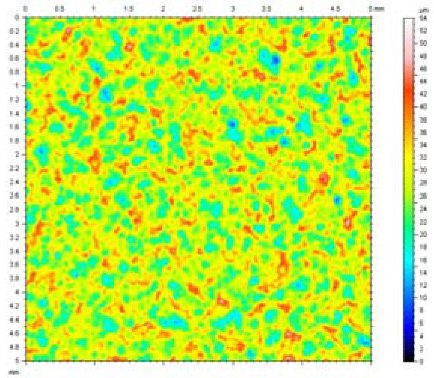

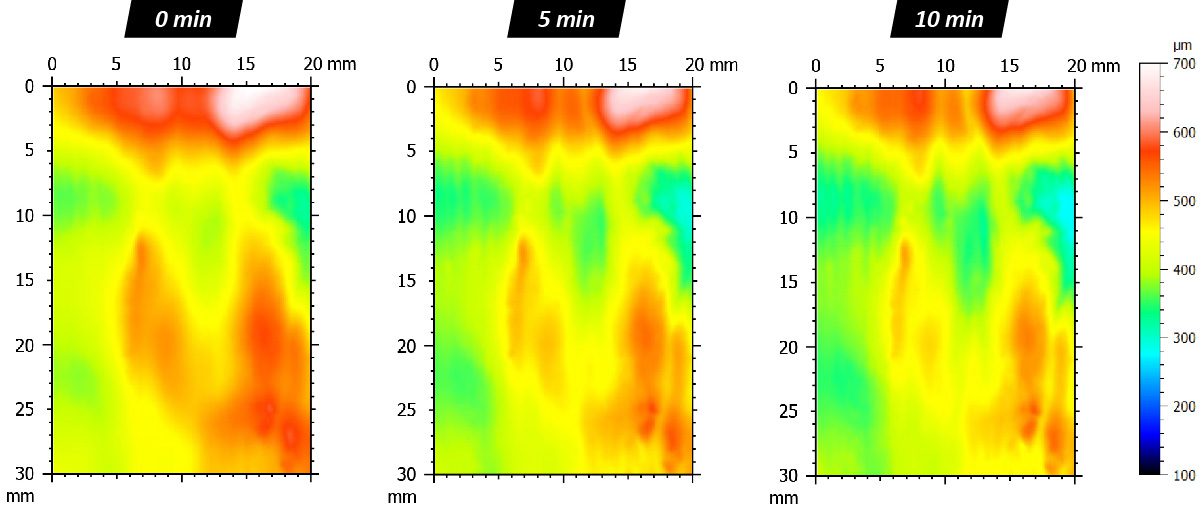

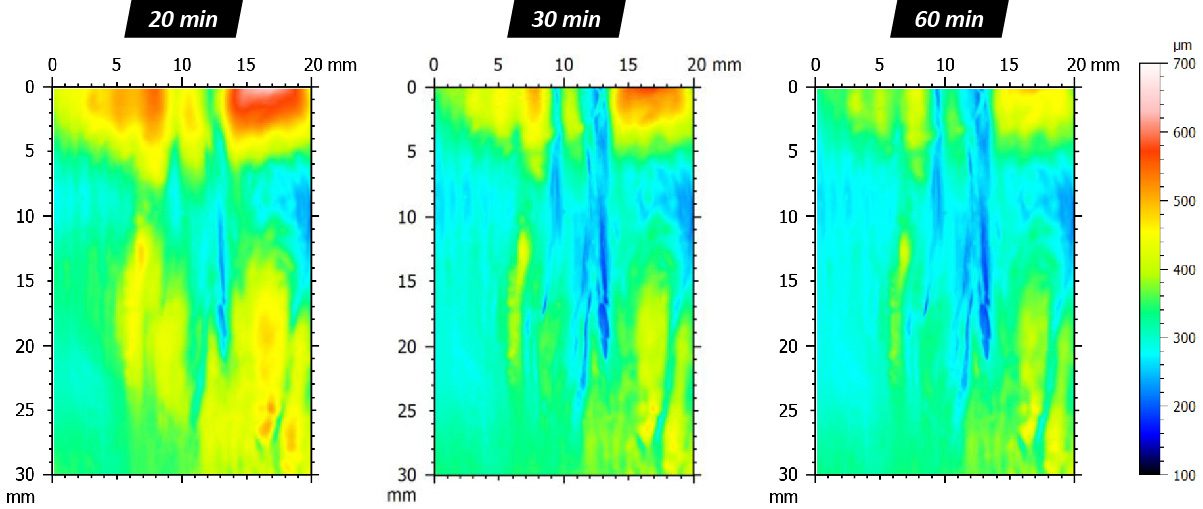

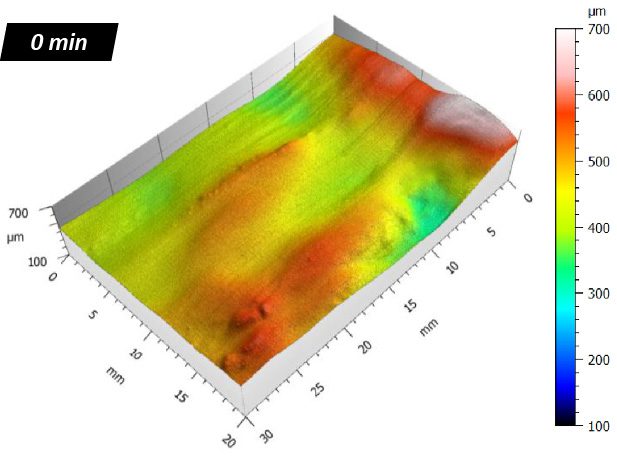

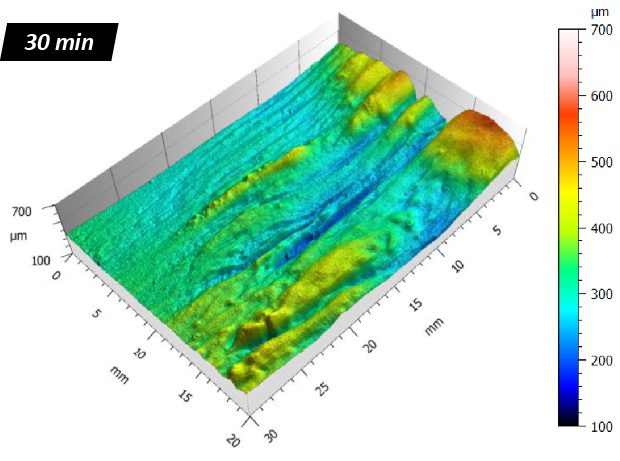

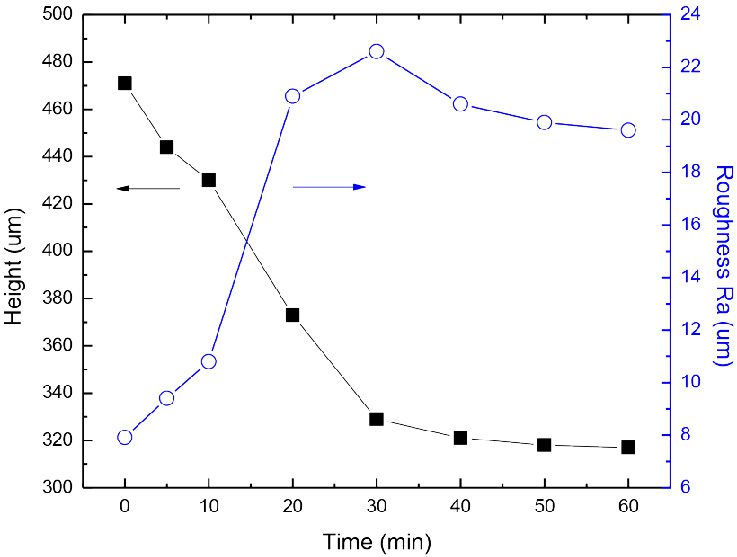

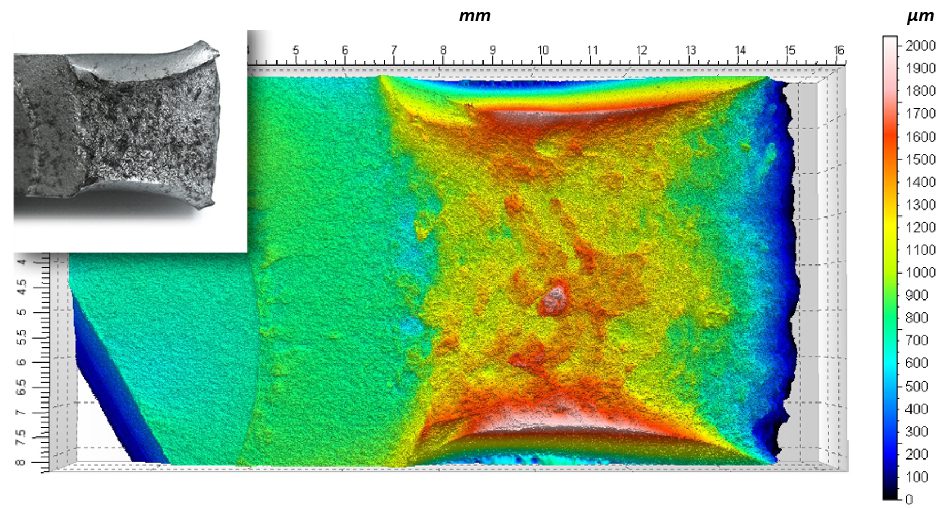

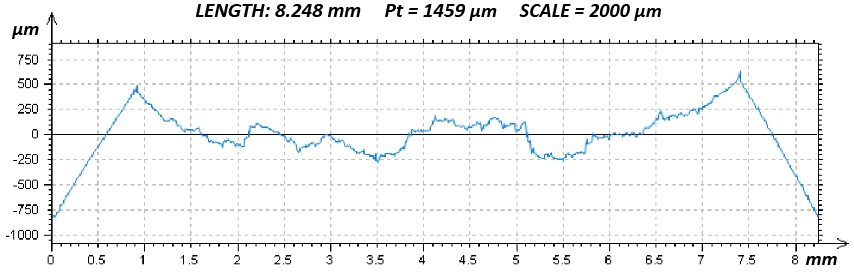

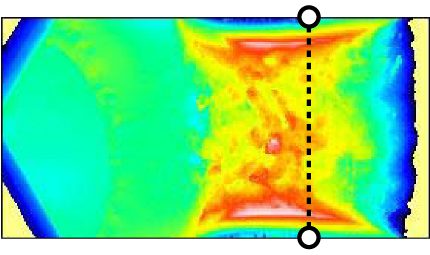

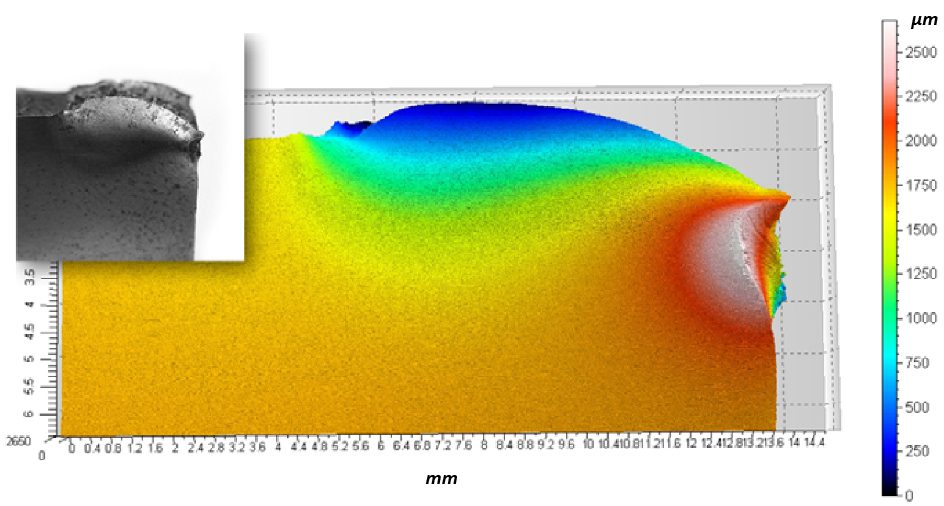

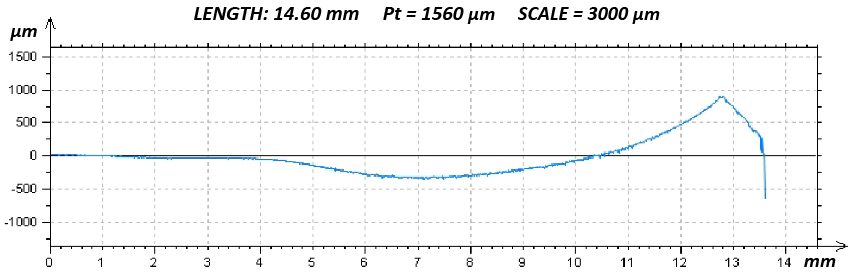

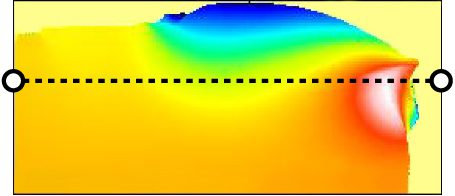

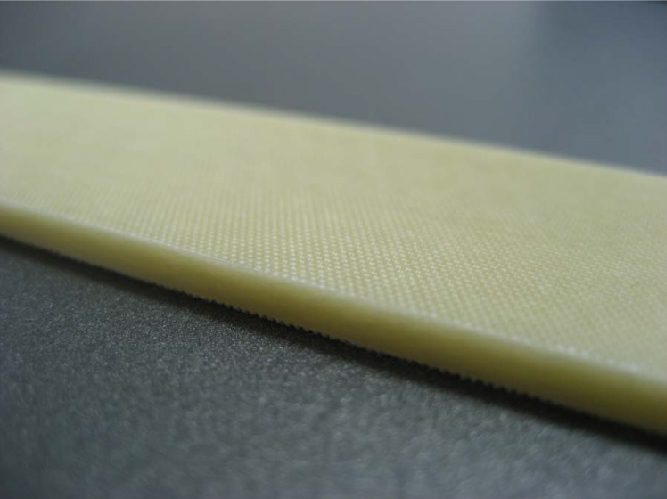

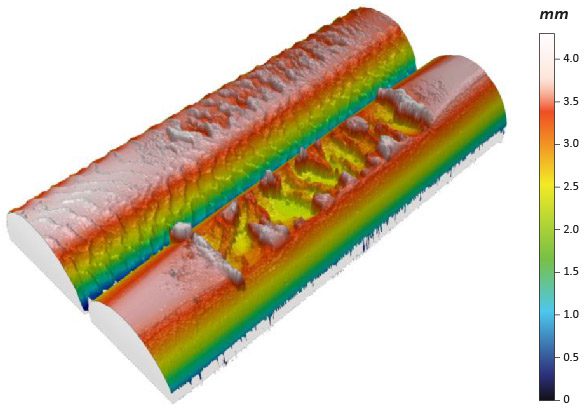

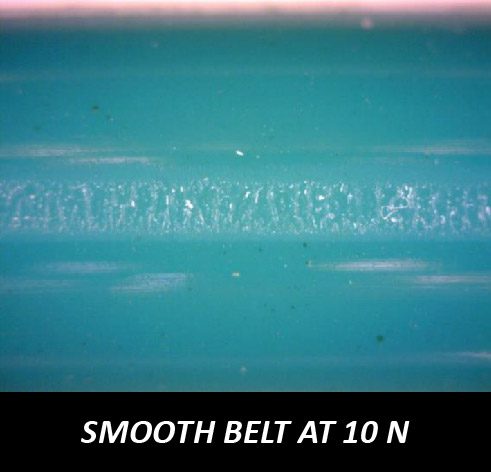

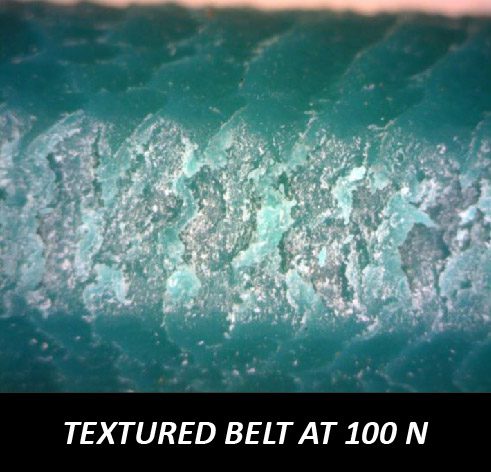

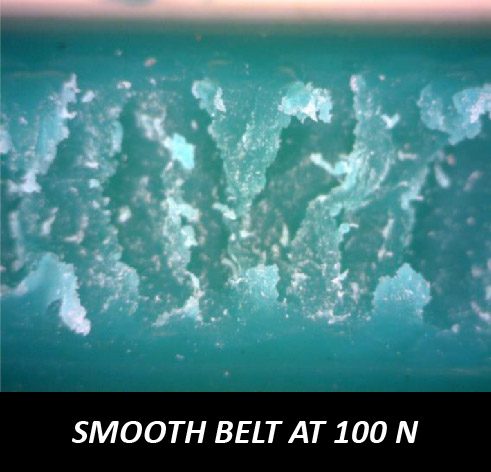

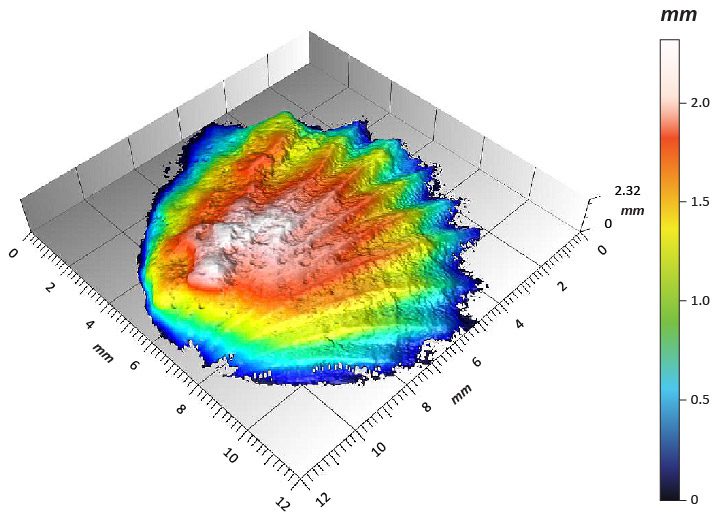

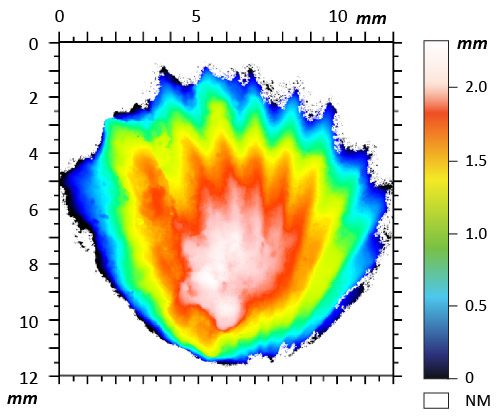

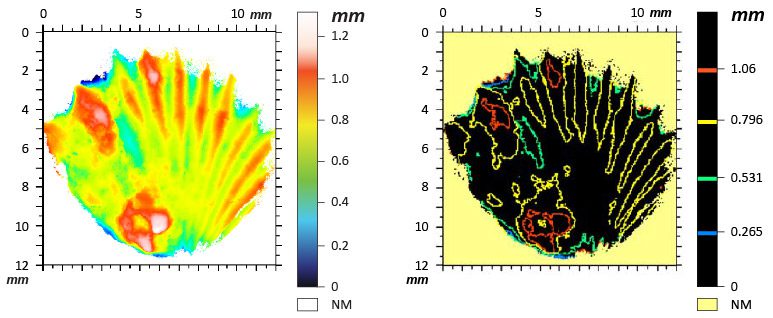

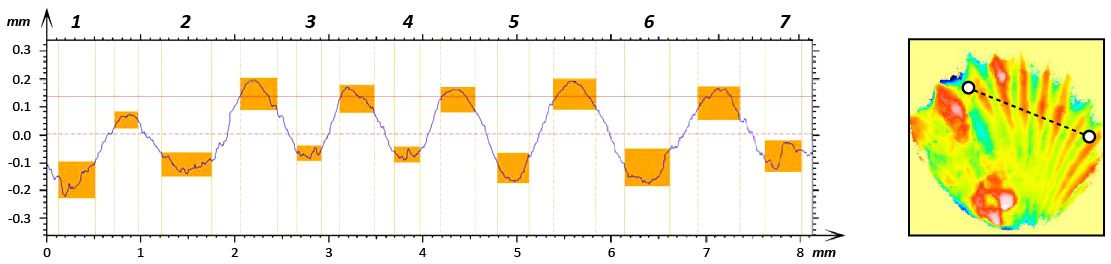

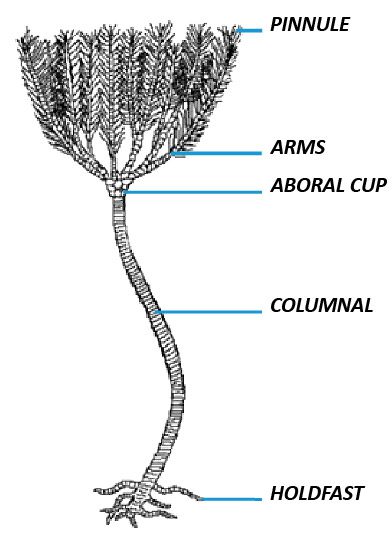

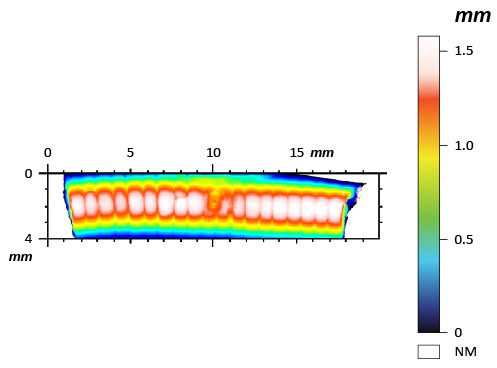

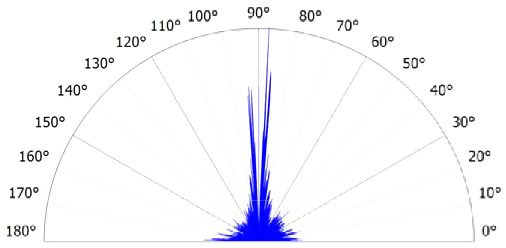

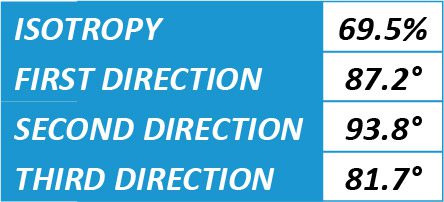

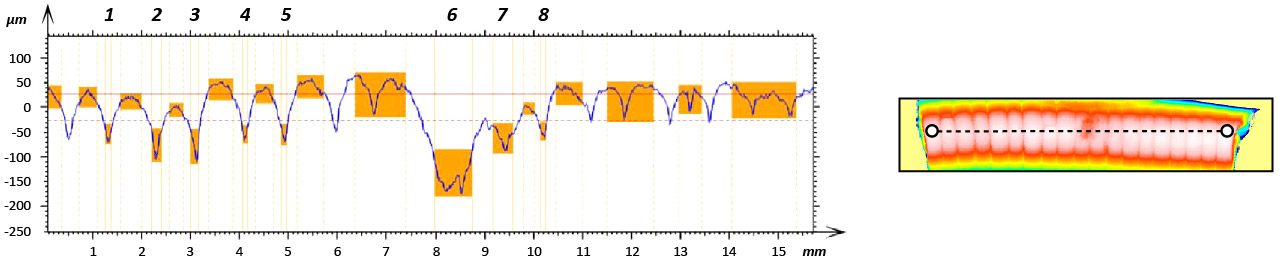

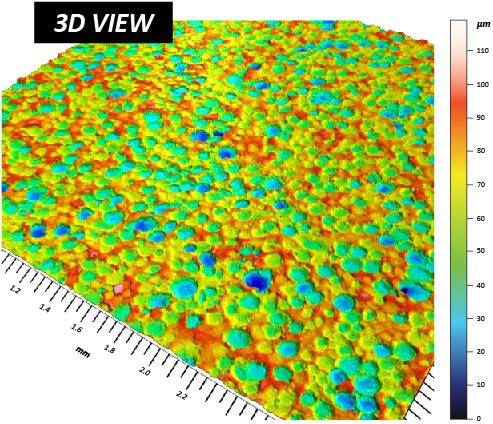

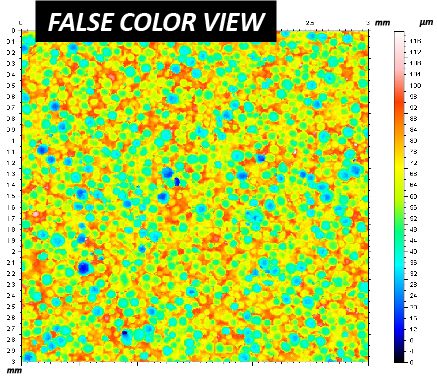

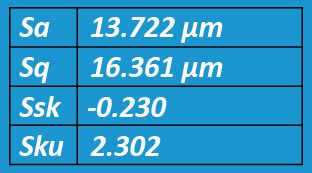

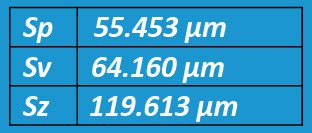

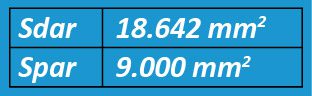

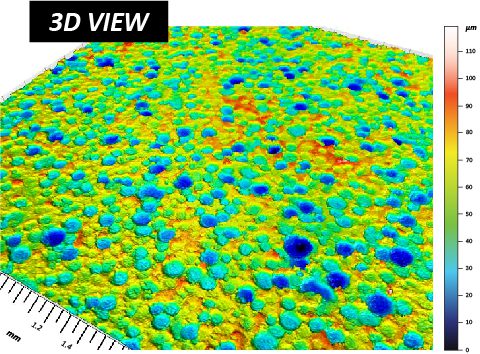

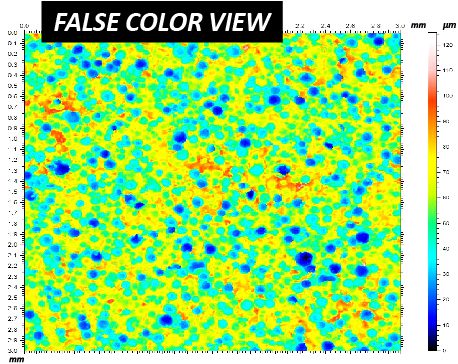

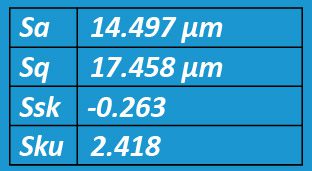

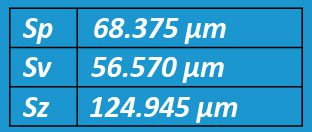

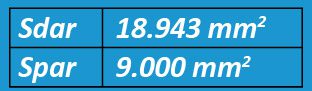

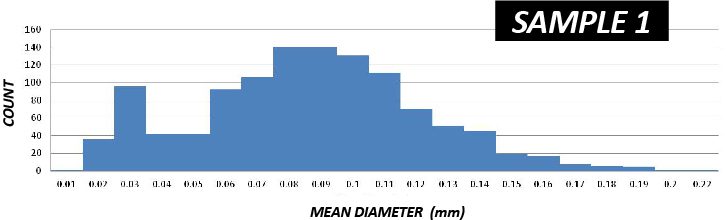

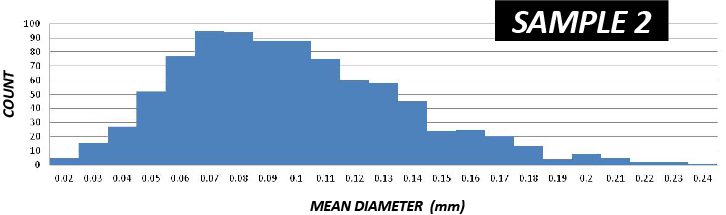

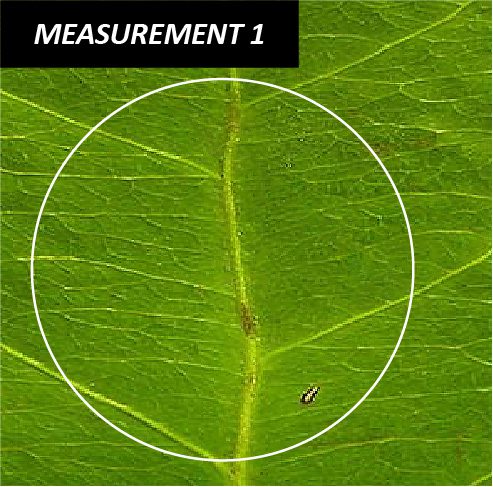

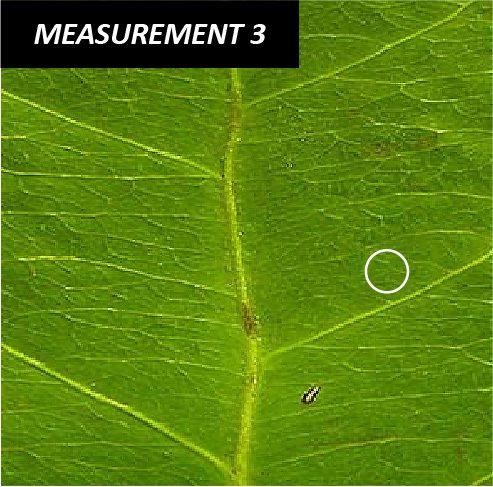

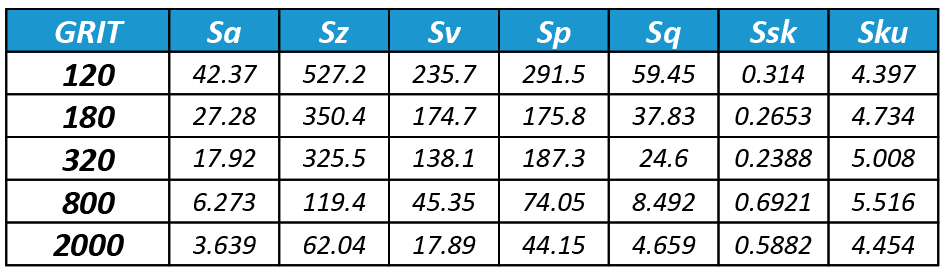

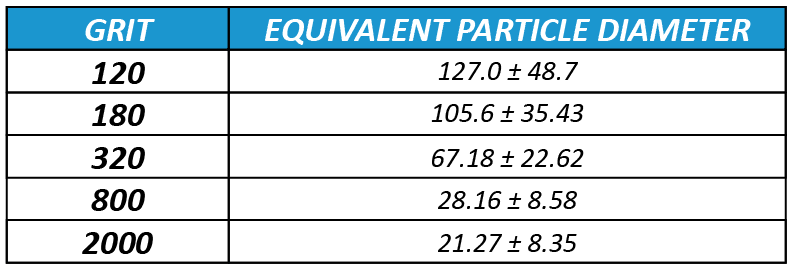

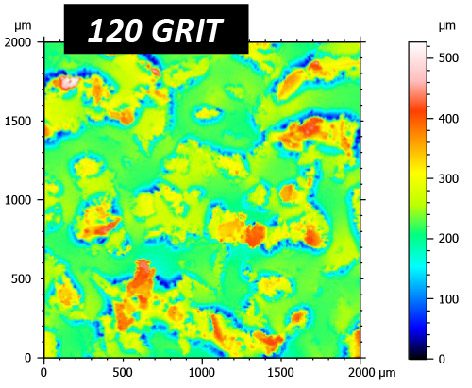

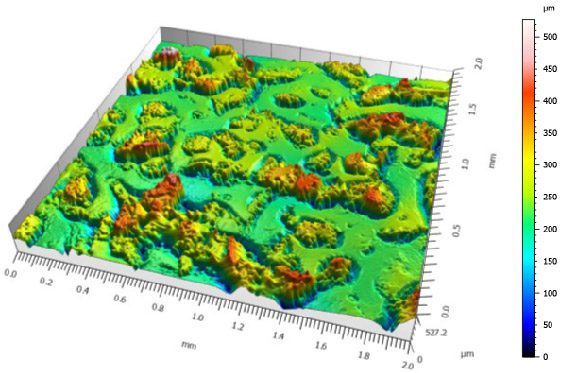

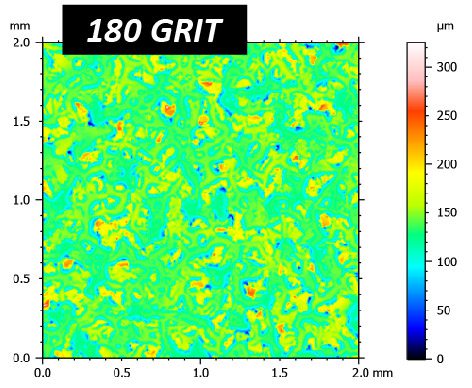

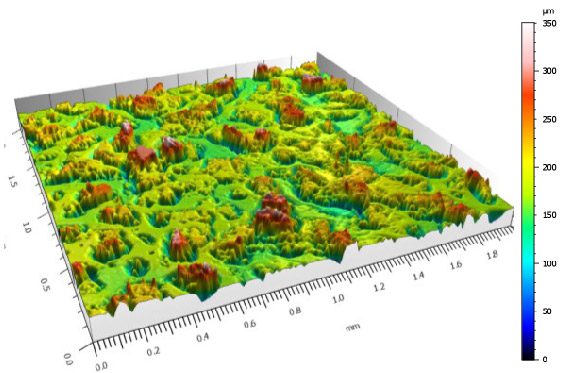

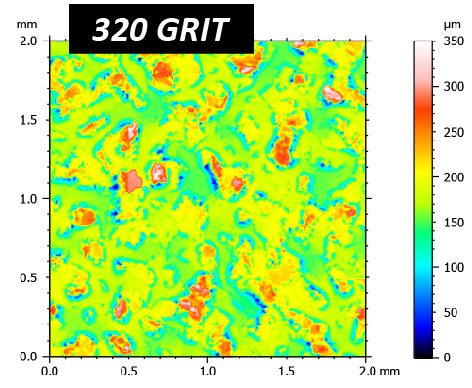

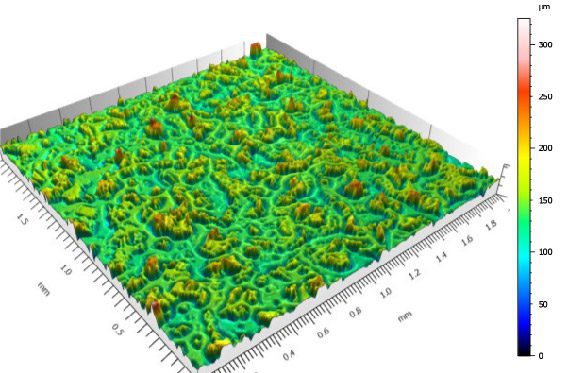

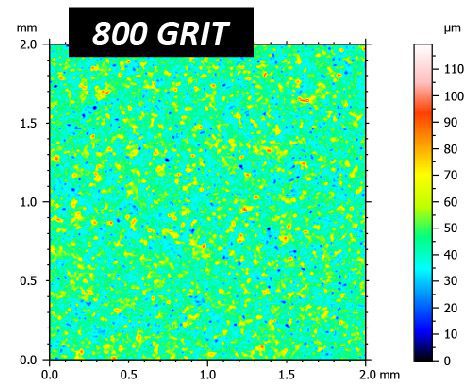

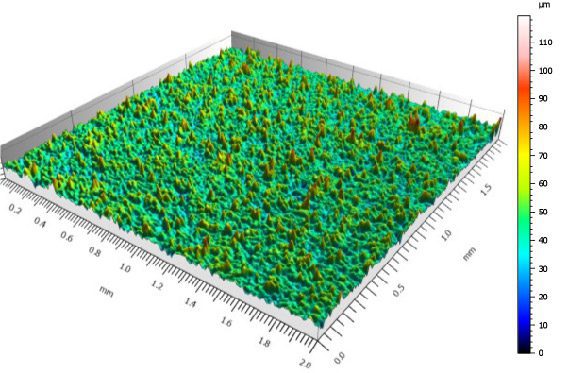

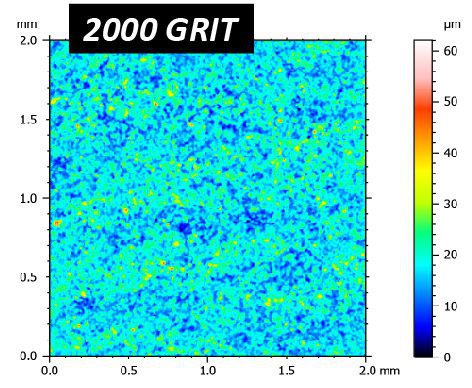

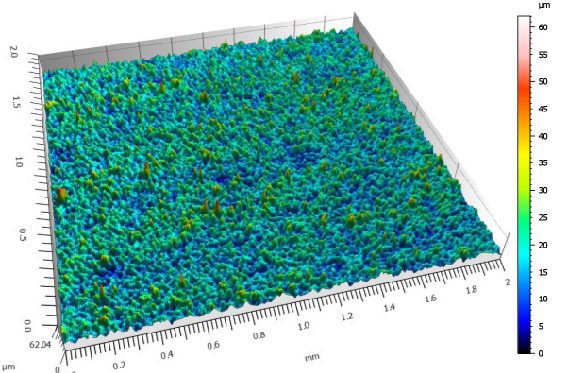

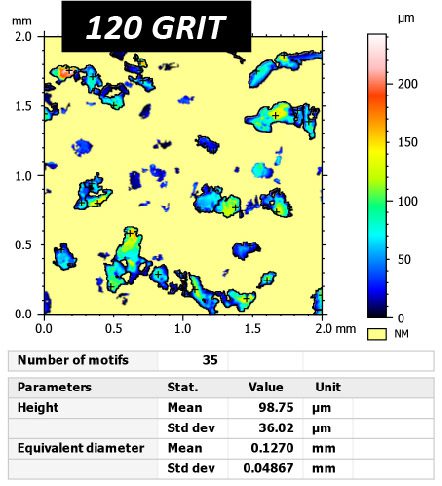

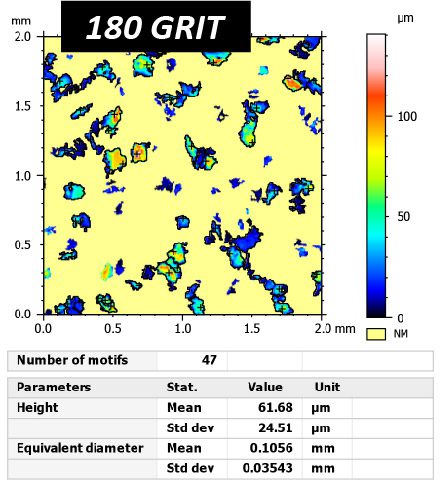

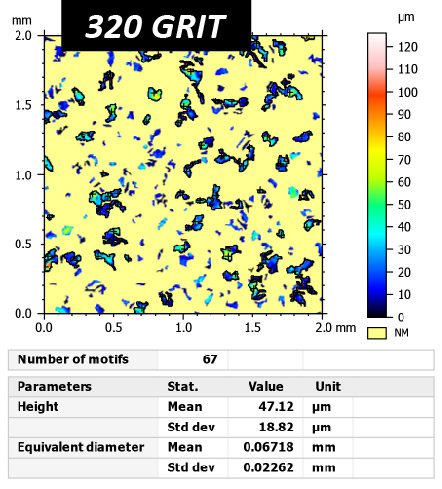

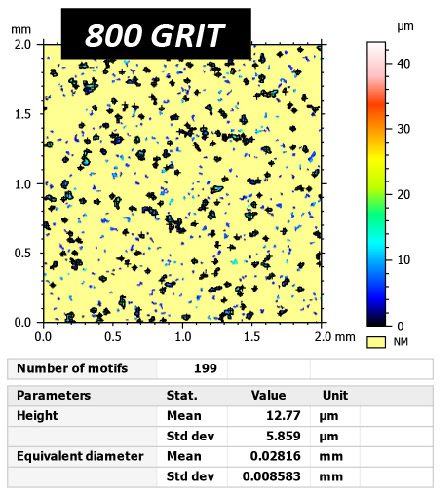

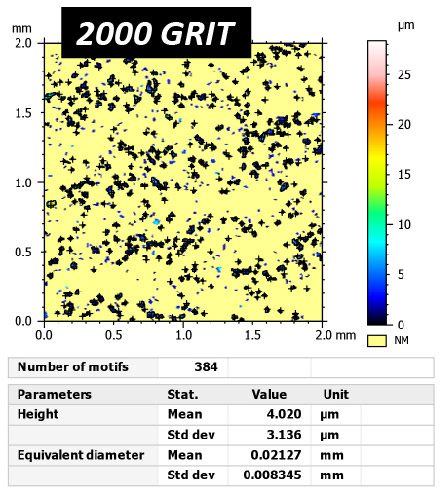

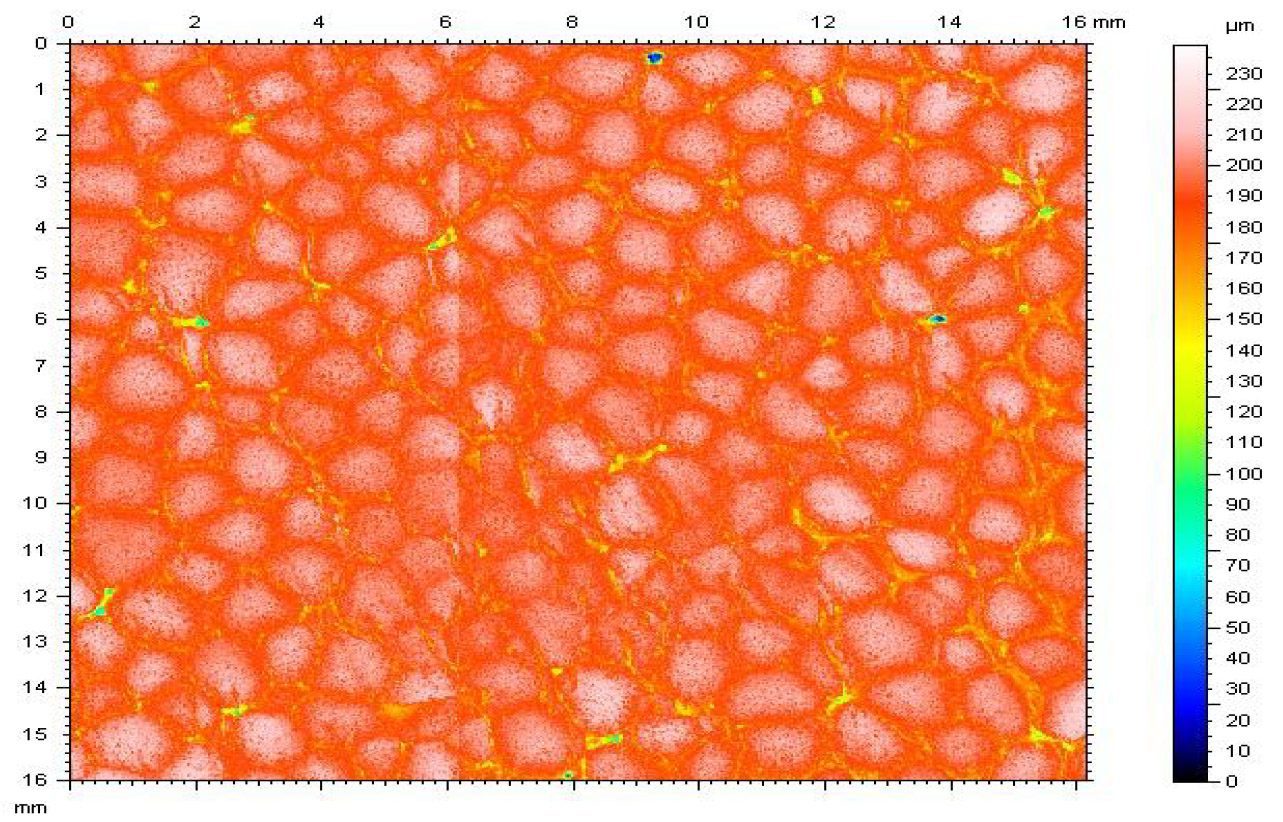

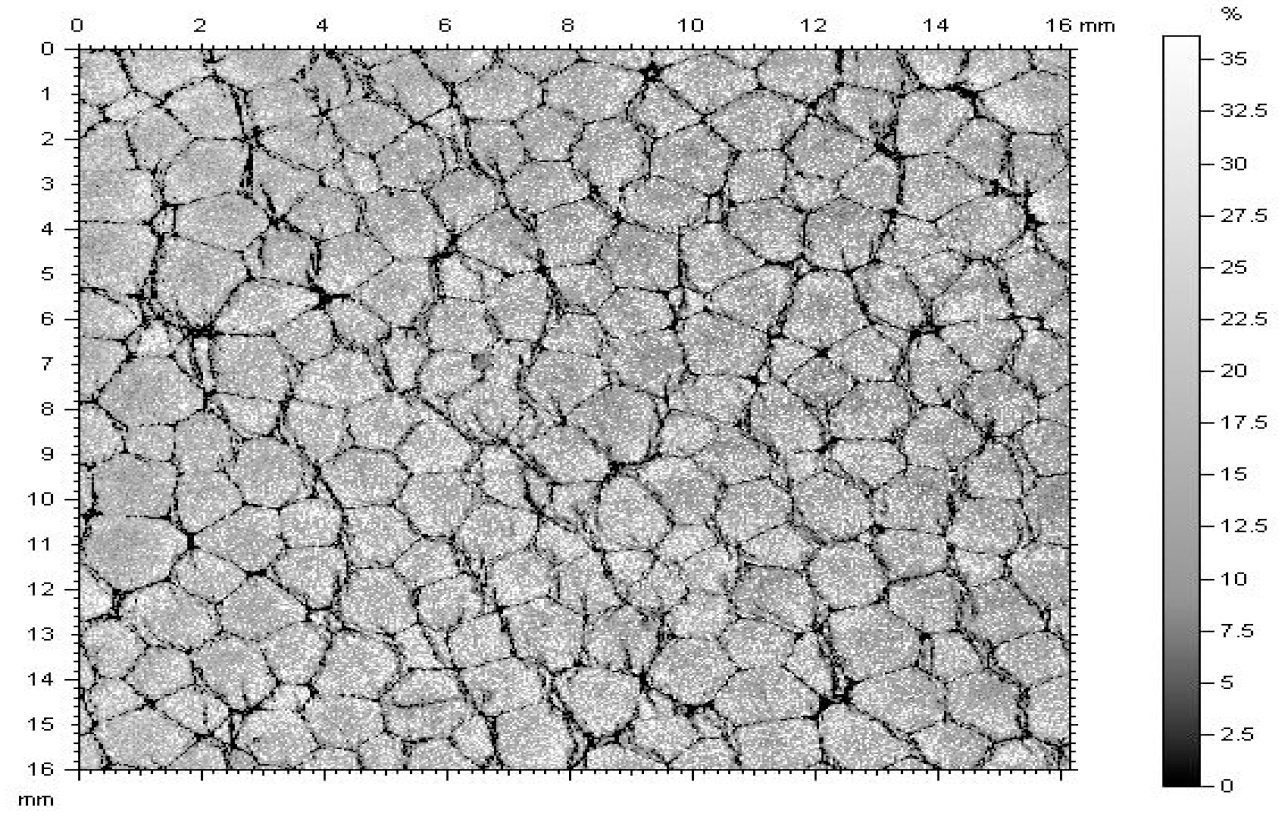

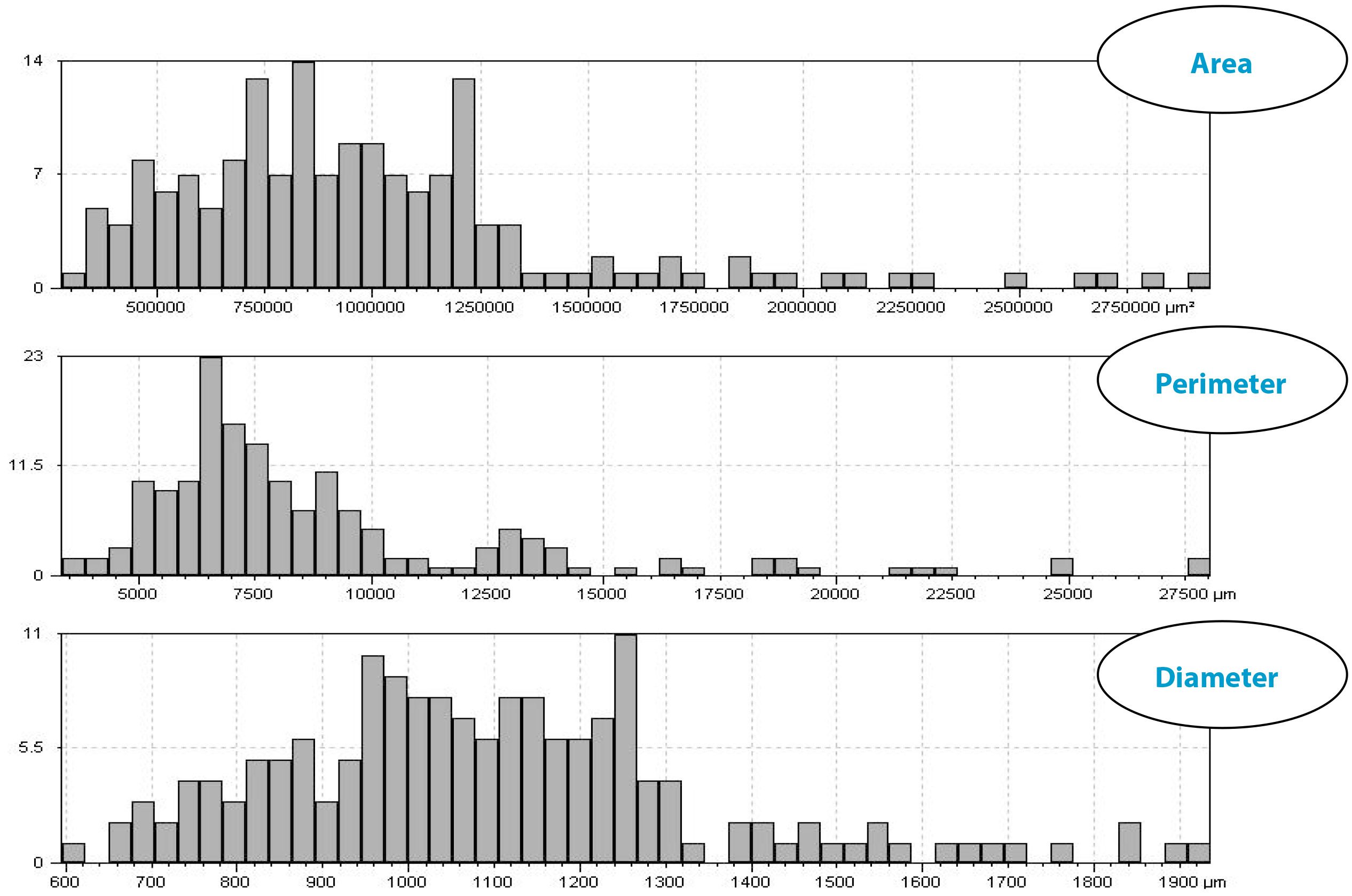

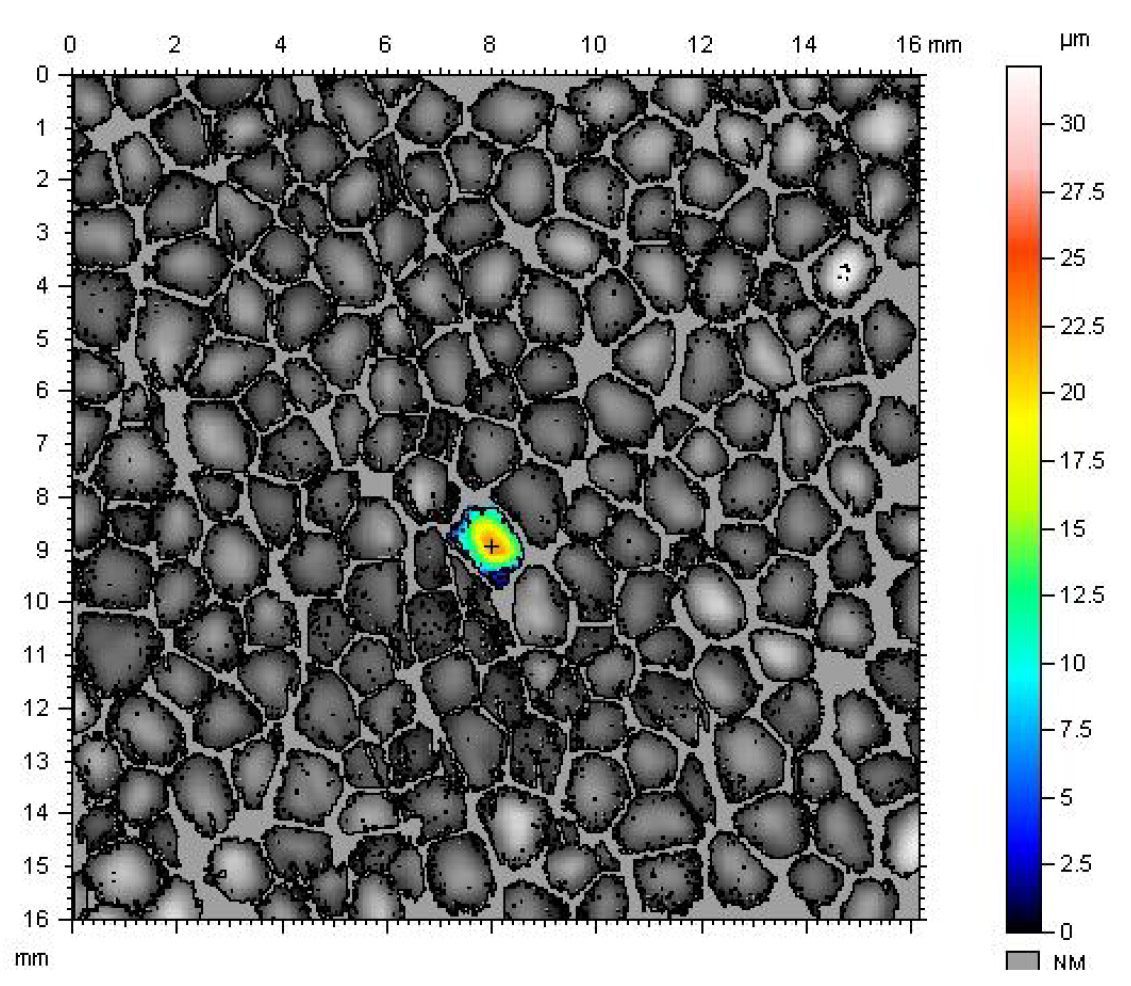

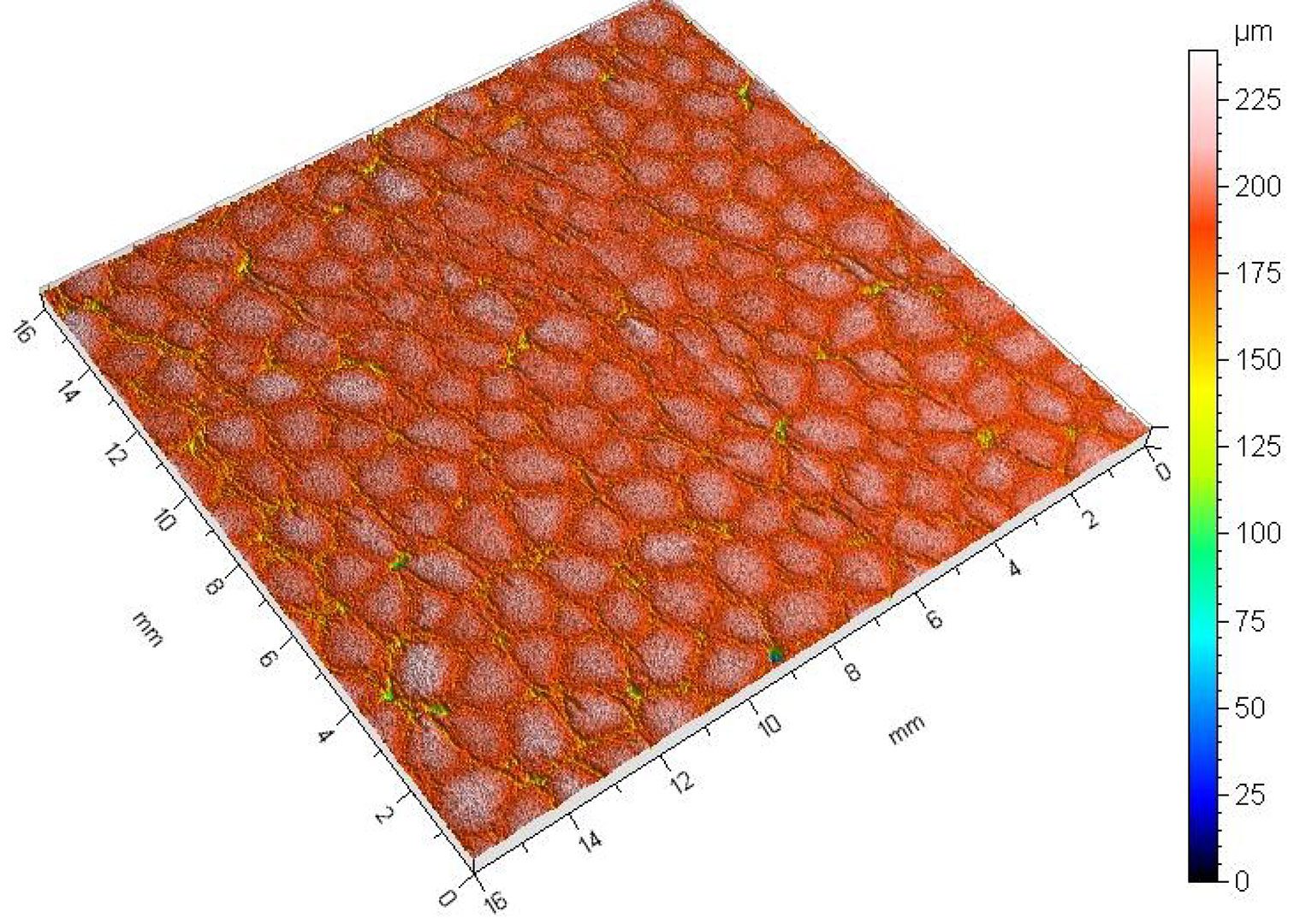

Shot peening is a process in which a substrate is bombarded with spherical metal, glass, or ceramic beads—commonly referred to as “shot”—at a force intended to induce plasticity on the surface. Analyzing the characteristics before and after peening provides crucial insights for enhancing process comprehension and control. The surface roughness and coverage area of dimples left by the shot are especially noteworthy aspects of interest.

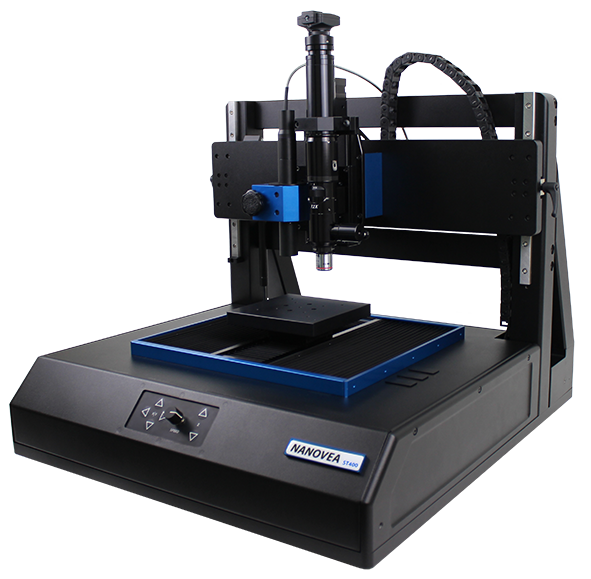

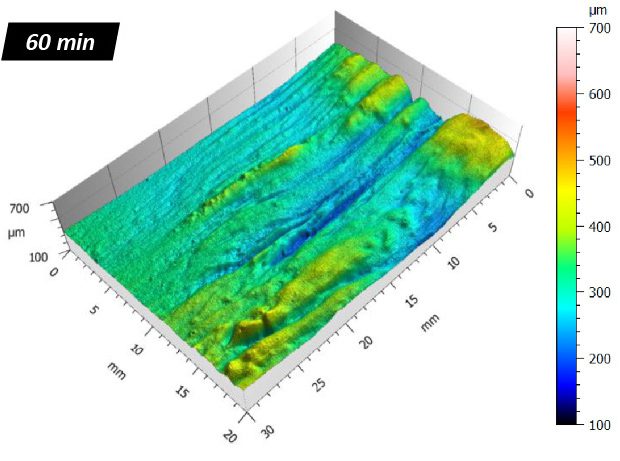

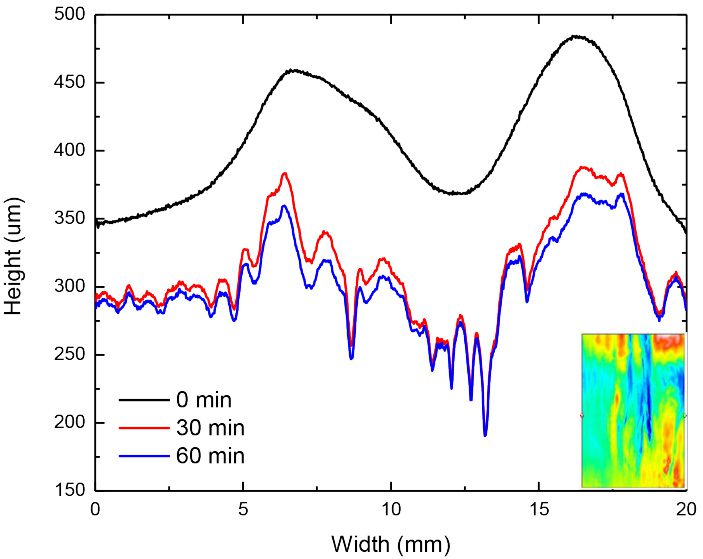

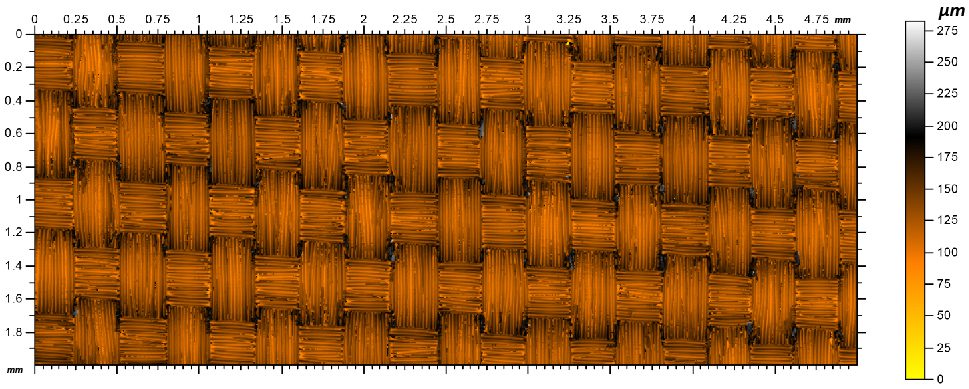

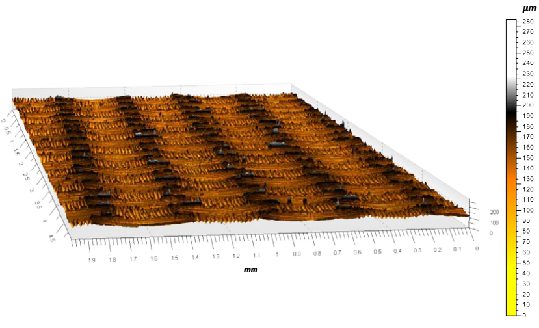

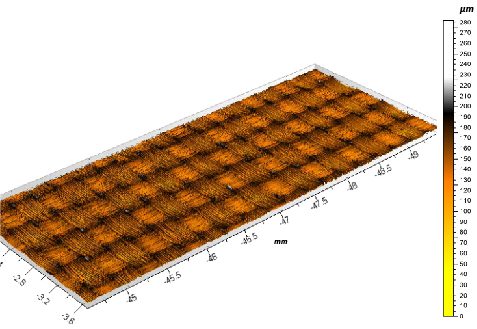

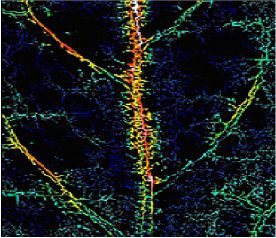

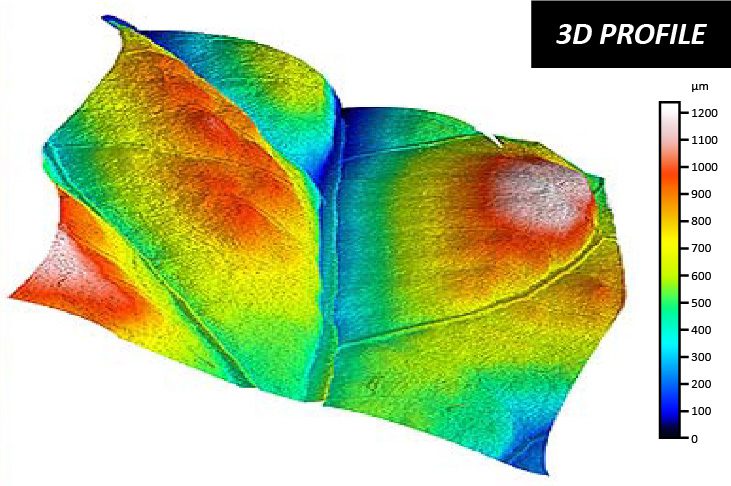

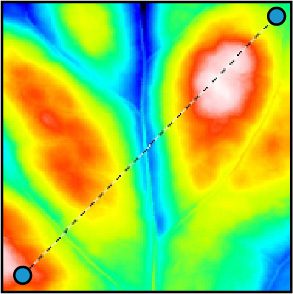

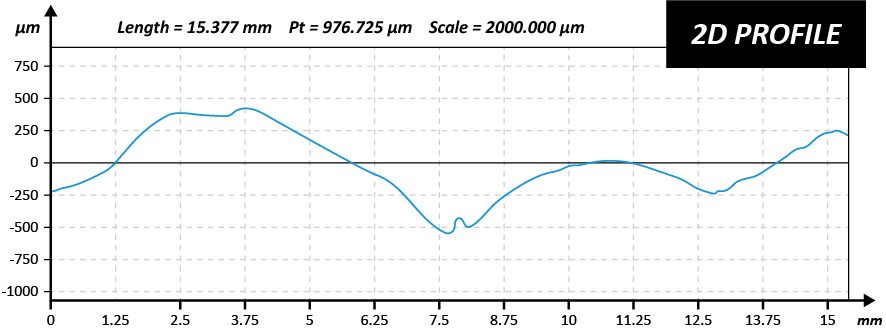

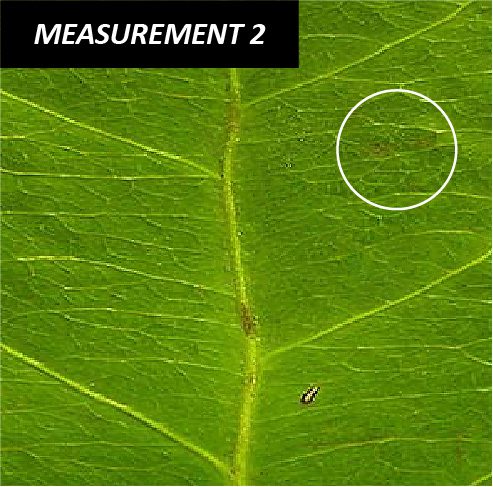

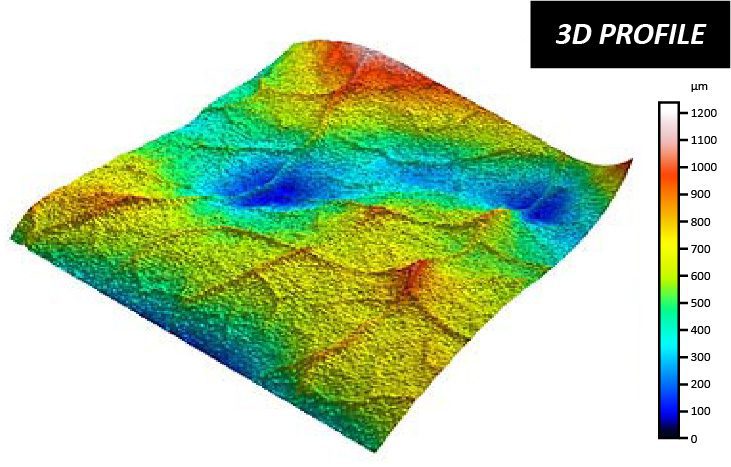

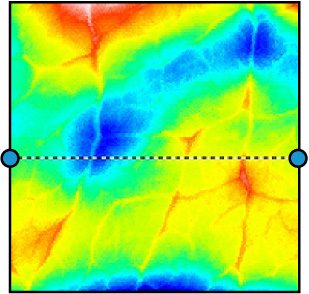

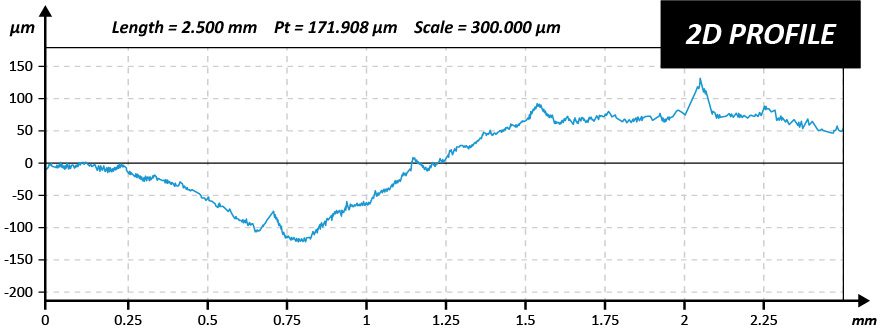

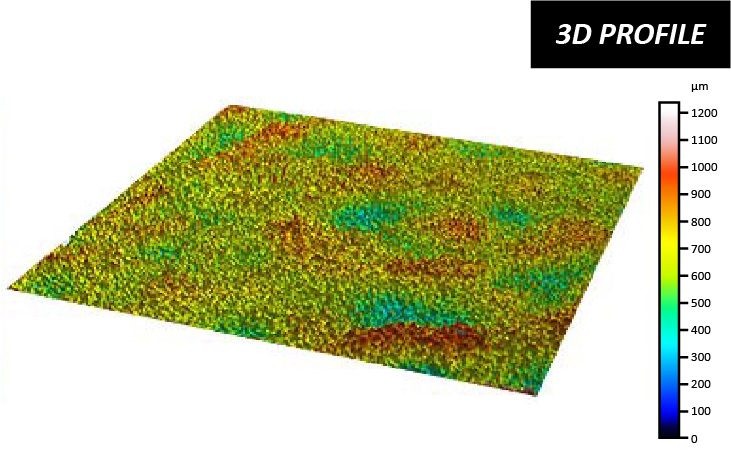

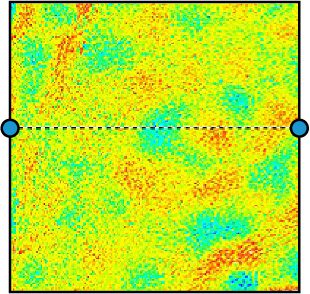

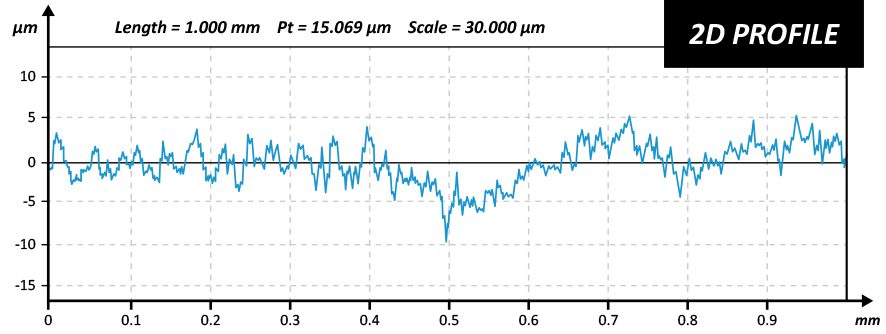

Importance of 3D Non-Contact Profilometer for Shot-Peened Surface Analysis

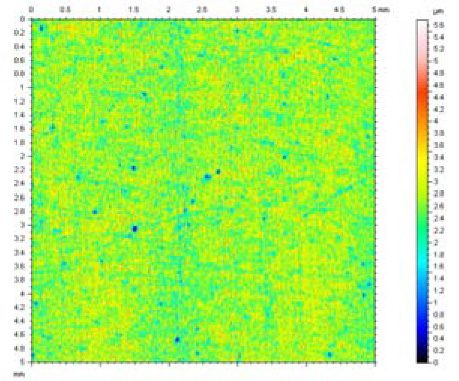

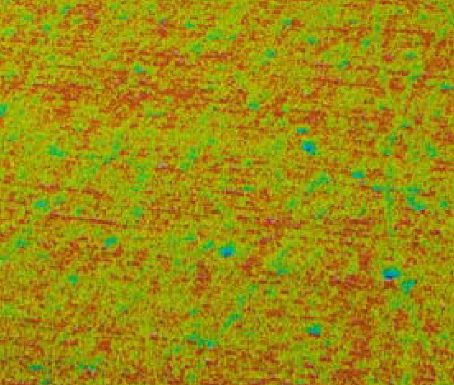

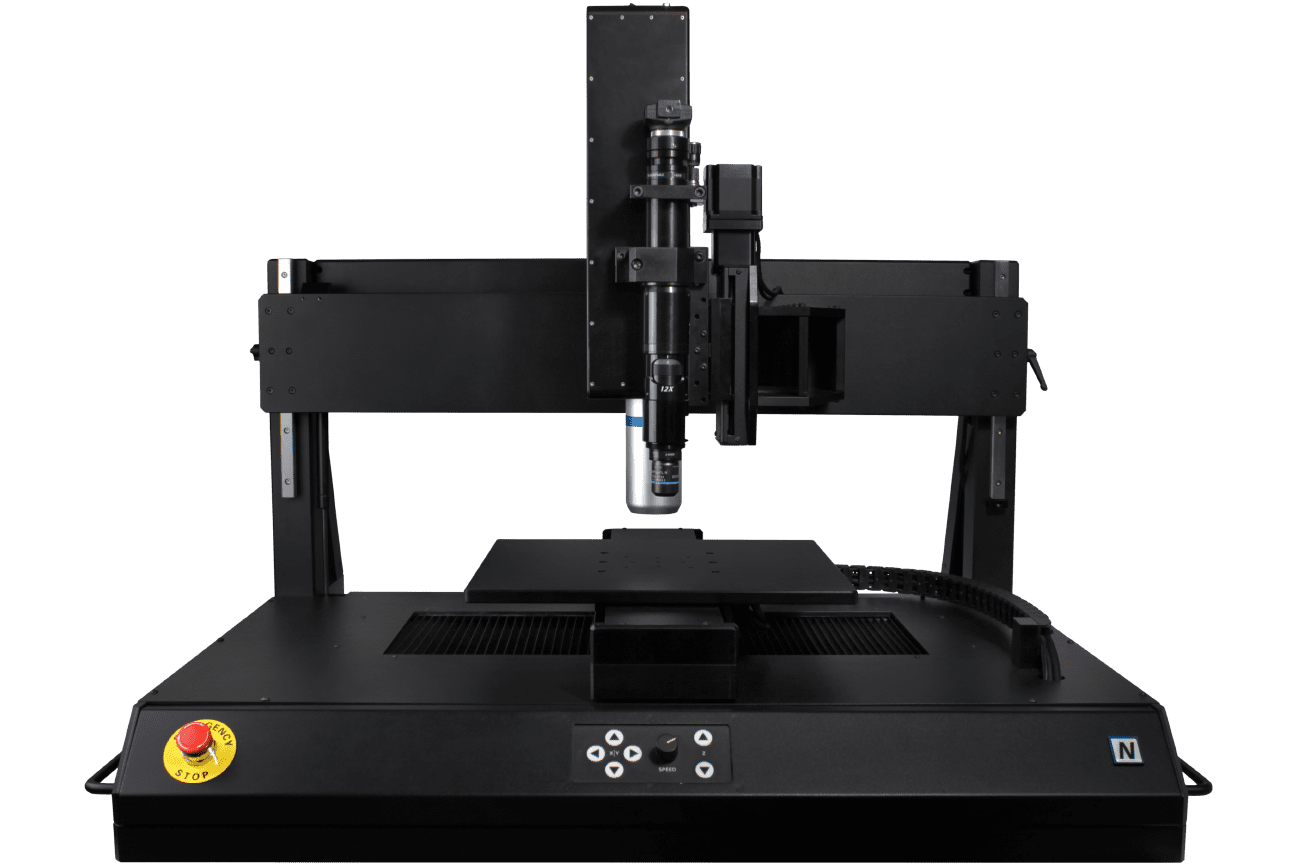

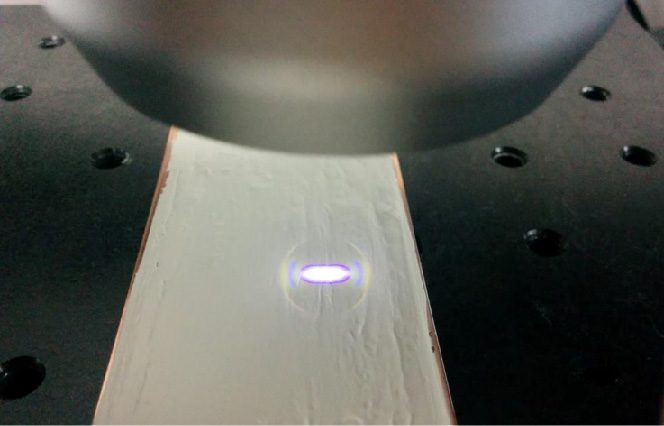

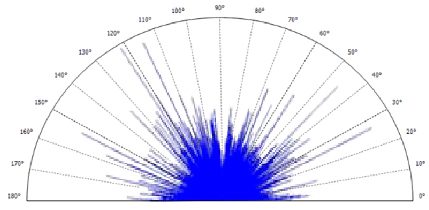

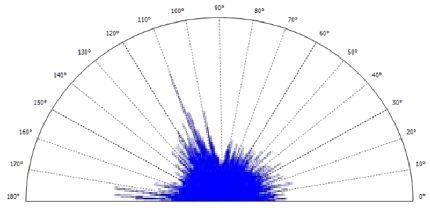

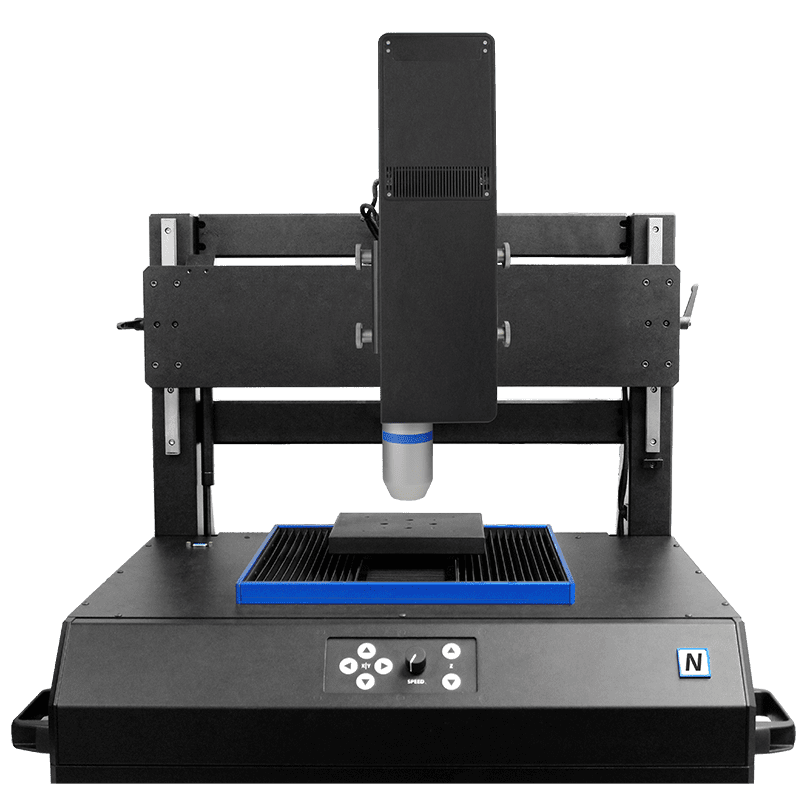

Unlike traditional contact profilometers, which have traditionally been used for shot-peened surface analysis, 3D non-contact measurement provides a complete 3D image to offer a more comprehensive understanding of coverage area and surface topography. Without 3D capabilities, an inspection will solely rely on 2D information, which is insufficient for characterizing a surface. Understanding the topography, coverage area, and roughness in 3D is the best approach for controlling or improving the peening process. NANOVEA’s 3D Non-Contact Profilometers utilize Chromatic Light technology with a unique capability to measure steep angles found on machined and peened surfaces. Additionally, when other techniques fail to provide reliable data due to probe contact, surface variation, angle, or reflectivity, NANOVEA Profilometers succeed.