Category: Laboratory Testing

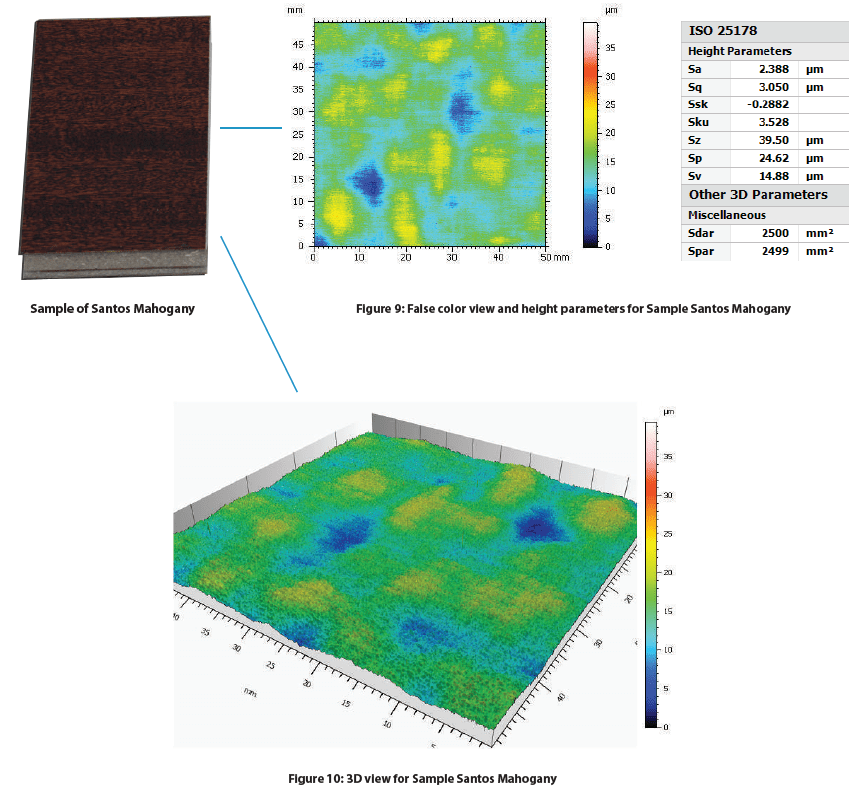

High Speed Scanning w/ Non-contact Profilometry

Introduction:

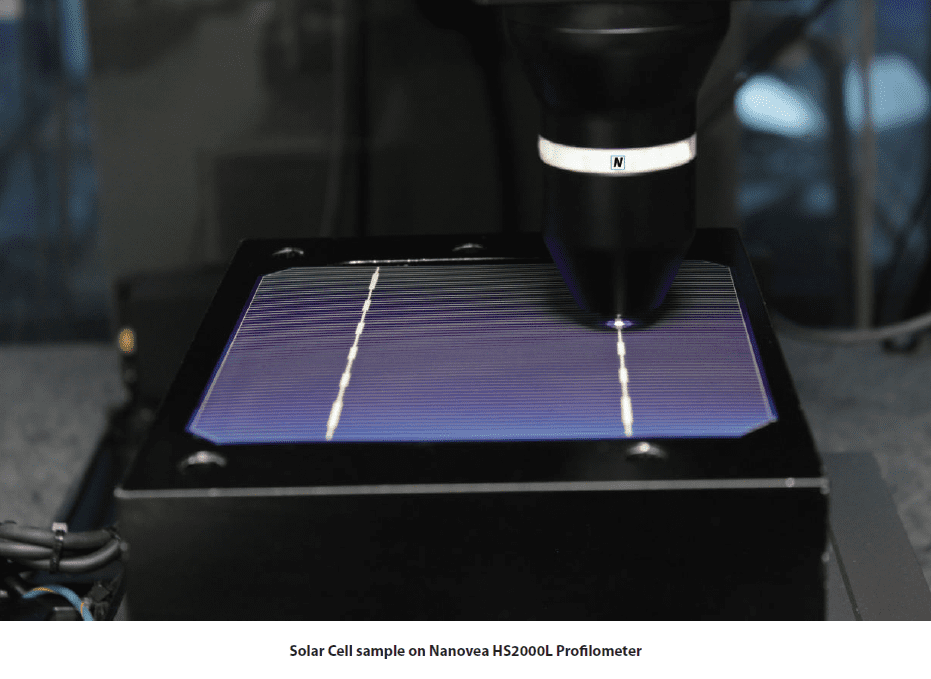

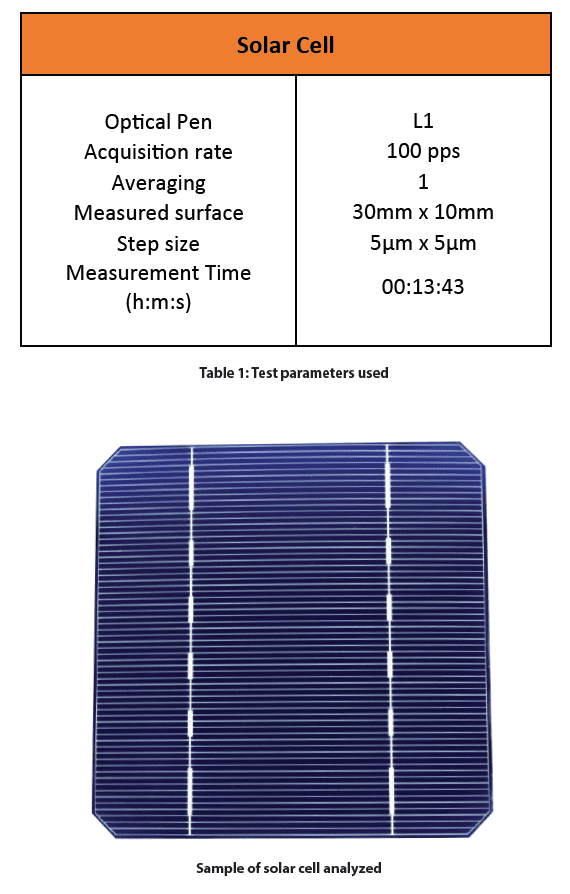

Quick and easy set-up surface measurements save time, effort and are essential for quality control, research and development and production facilities. The Nanovea Non-Contact Profilometer is capable of performing both 3D & 2D surface scans to measure nano to macro scale features on any surface, providing broad range usability.

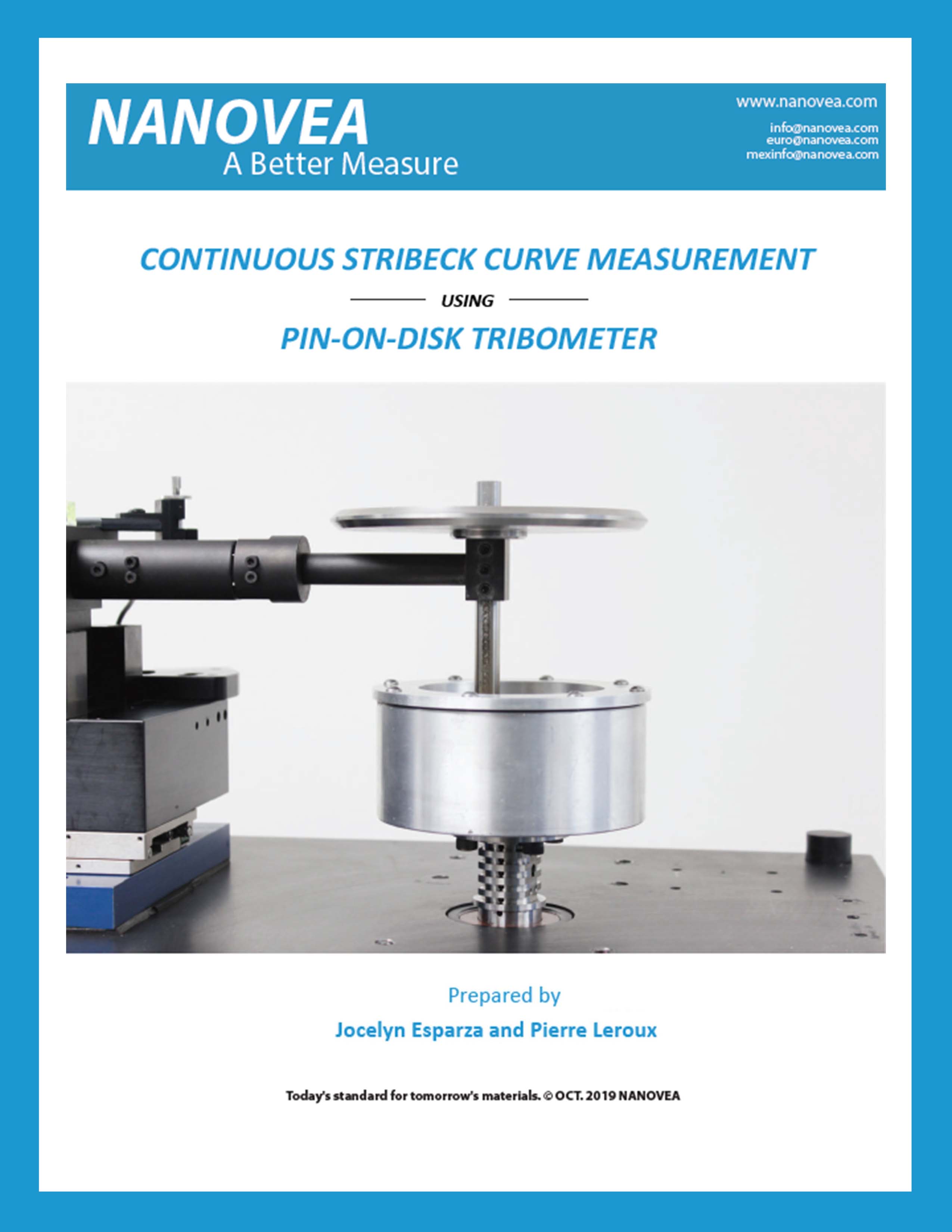

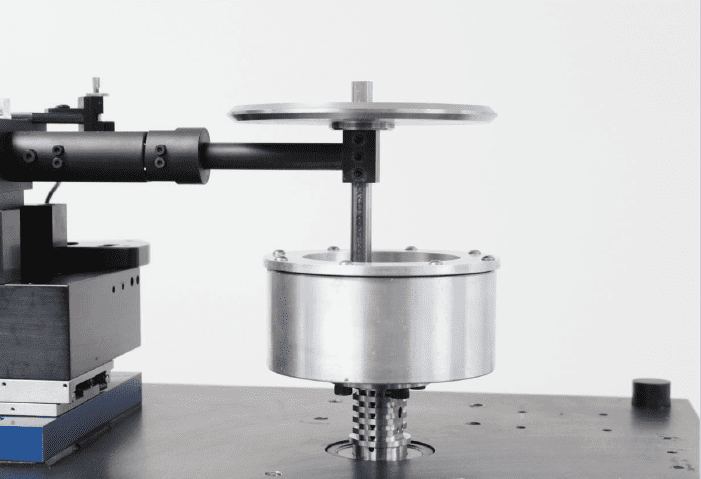

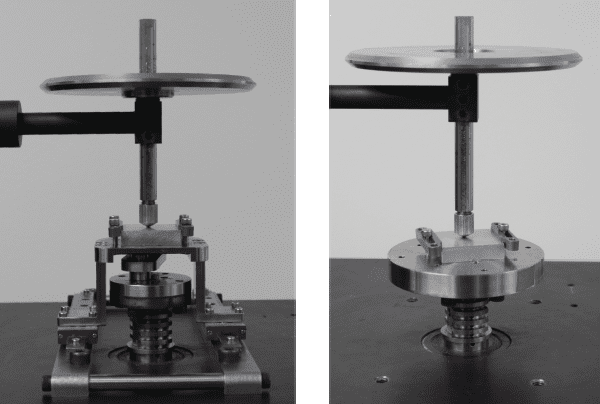

Continuous Stribeck Curve Measurement using Pin-on-Disk Tribometer

Introduction:

When lubrication is applied to reduce the wear/friction of moving surfaces, the lubrication contact at the interface can shift from several regimes such as Boundary, Mixed and Hydrodynamic Lubrication. The thickness of the fluid film plays a major role in this process, mainly determined by the fluid viscosity, the load applied at the interface and the relative speed between the two surfaces. How the lubrication regimes react to friction is shown in what is called a Stribeck [1-4] curve.

In this study we demonstrate for the first time the ability to measure a continuous Stribeck Curve. Using the Nanovea Tribometer advanced step-less speed control, from 15000 to 0.01 rpm, within 10 minutes the software directly provides a complete Stribeck Curve. The simple initial setup only requires users to select the Exponential Ramp Mode and enter initial and final speeds, rather than having to perform multiple tests or program a stepwise procedure at different speeds requiring data stitching for the conventional Stribeck curve measurements. This advancement provides precise data throughout lubricant regime evaluation and substantially reduces time and cost. The test shows a great potential to be used in different industrial engineering applications.

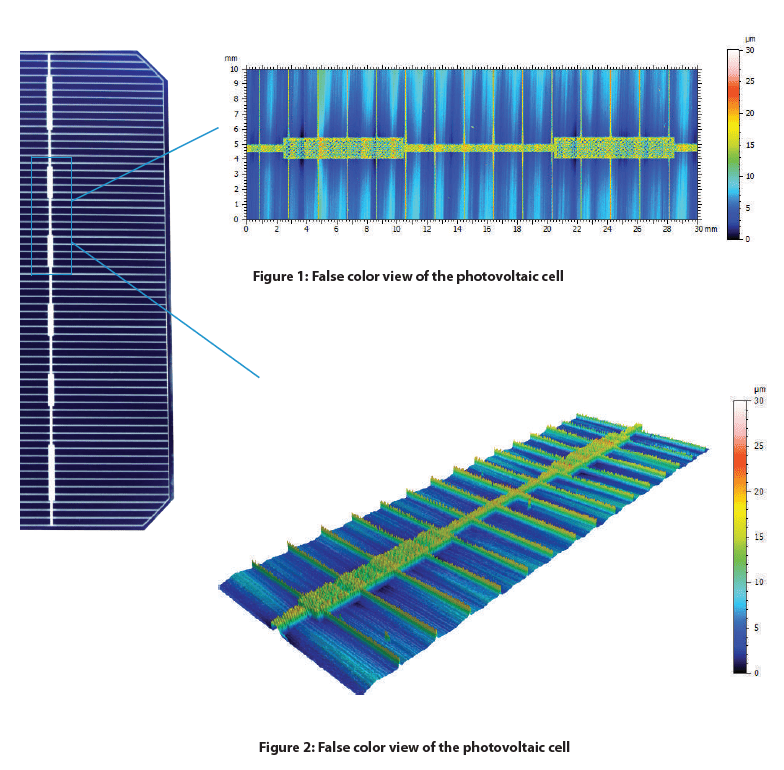

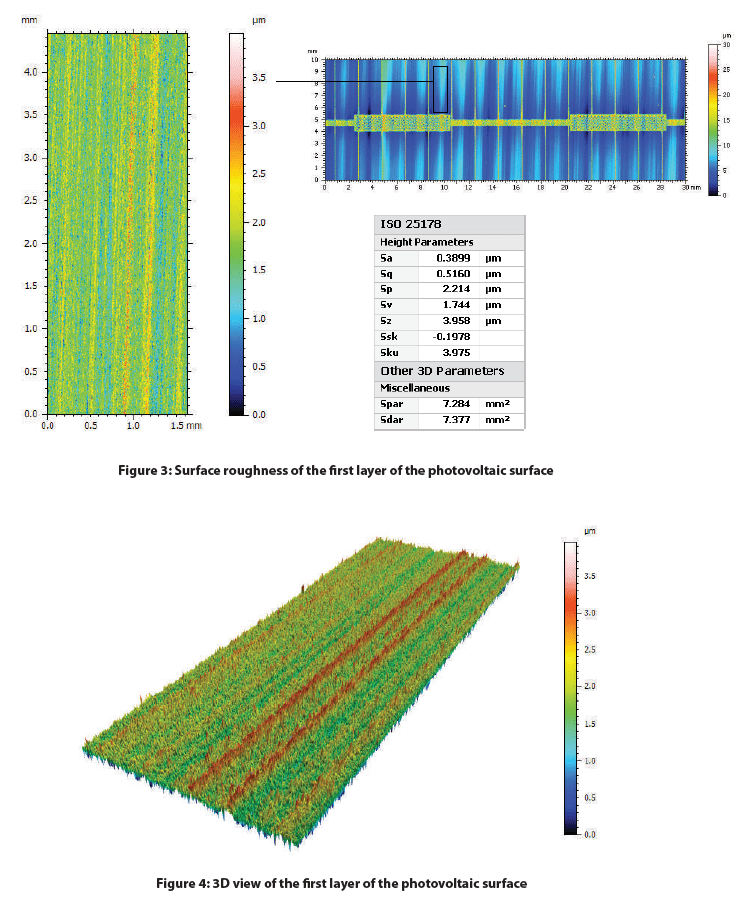

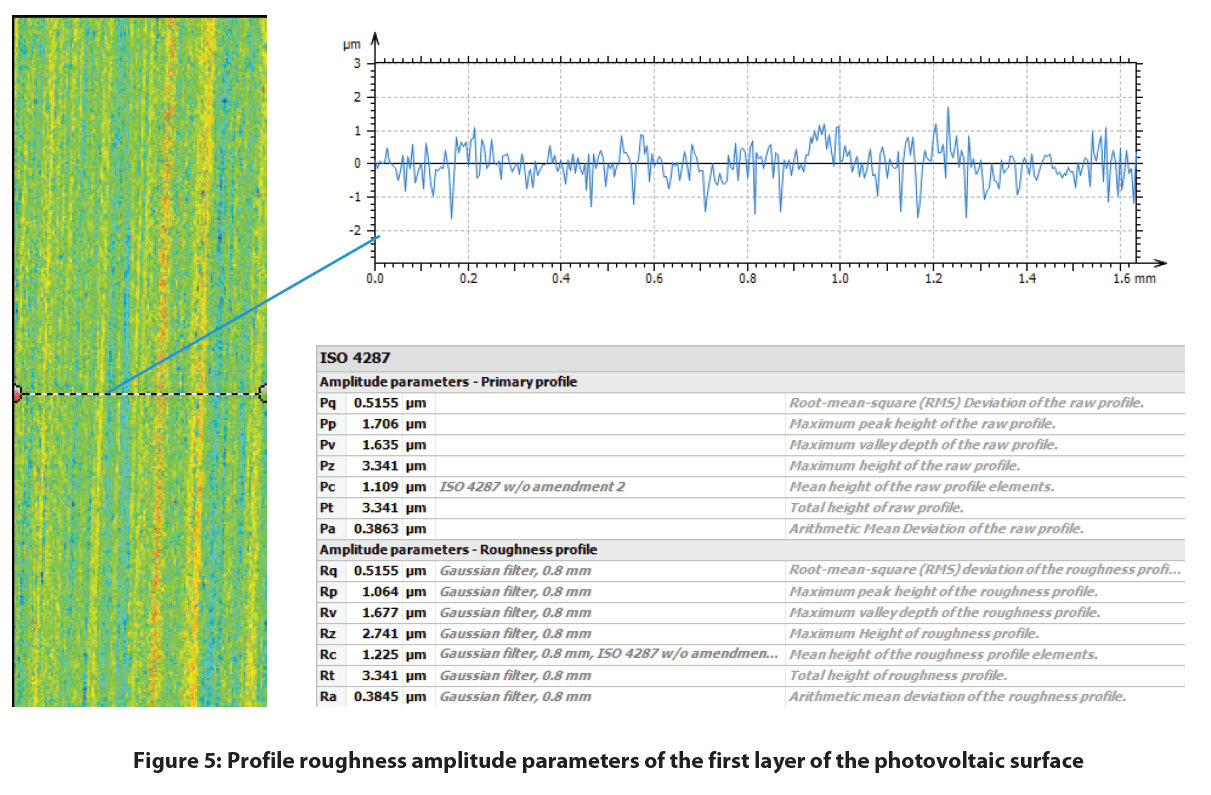

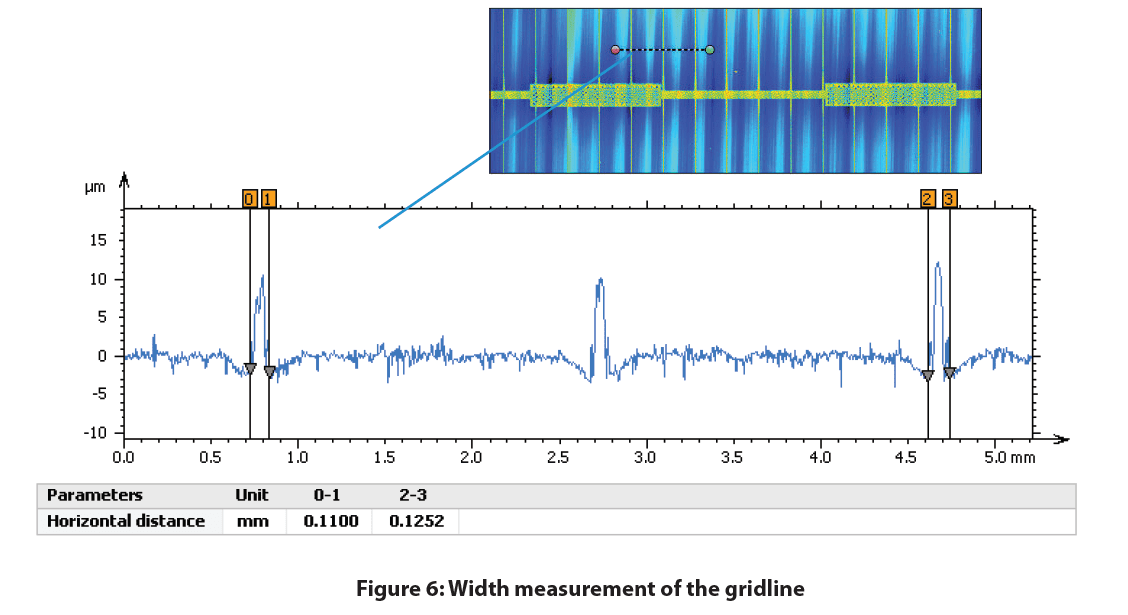

Surface Roughness and Features of a Solar Cell

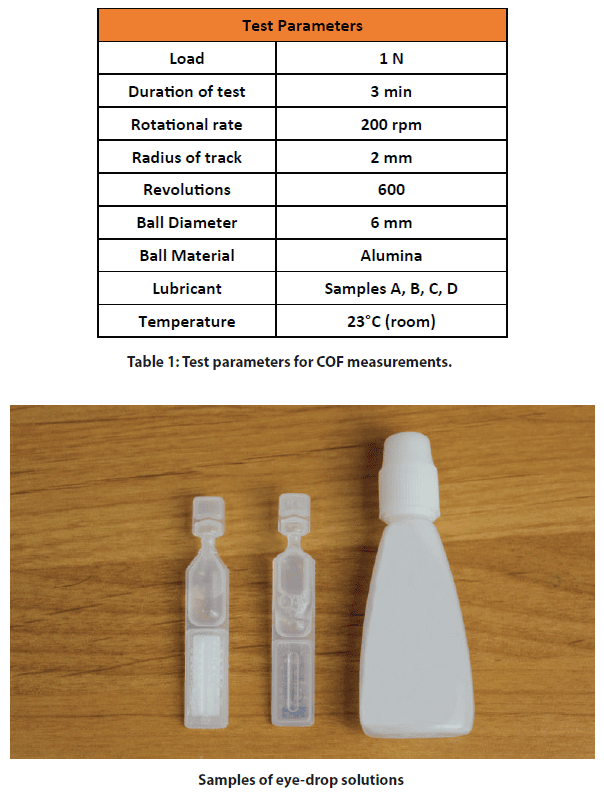

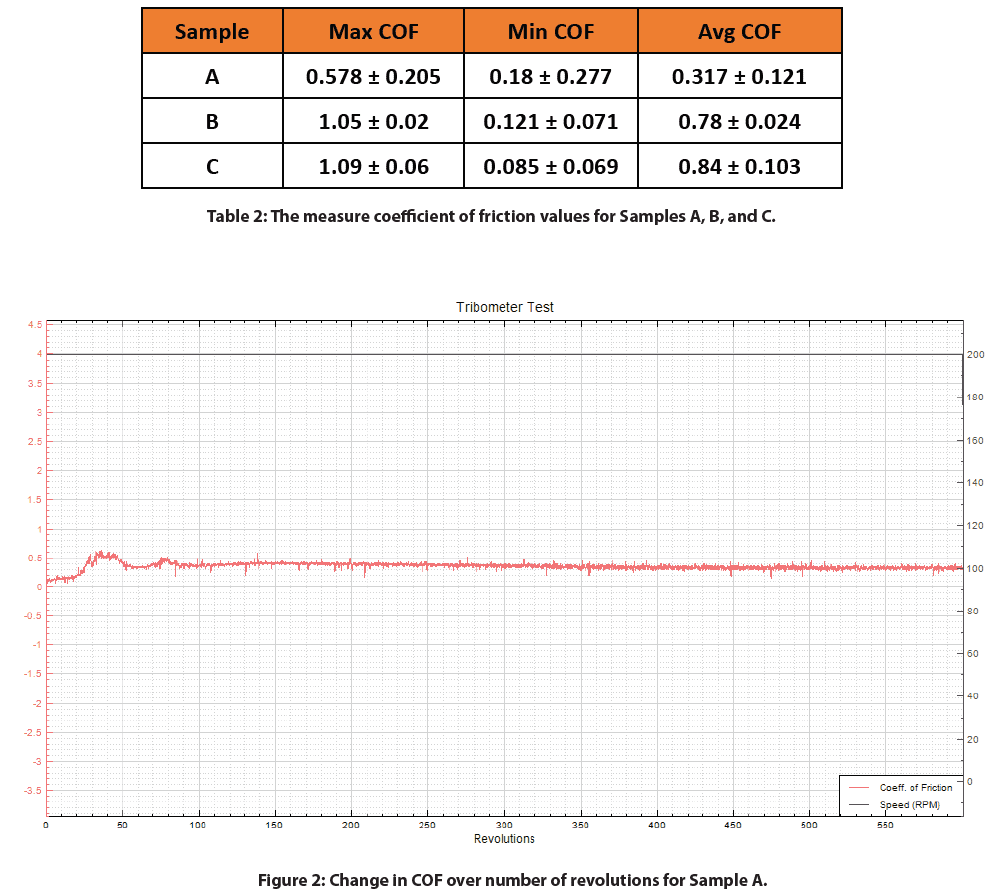

Lubricating Eye Drop Comparison using the Nanovea T50 Tribometer

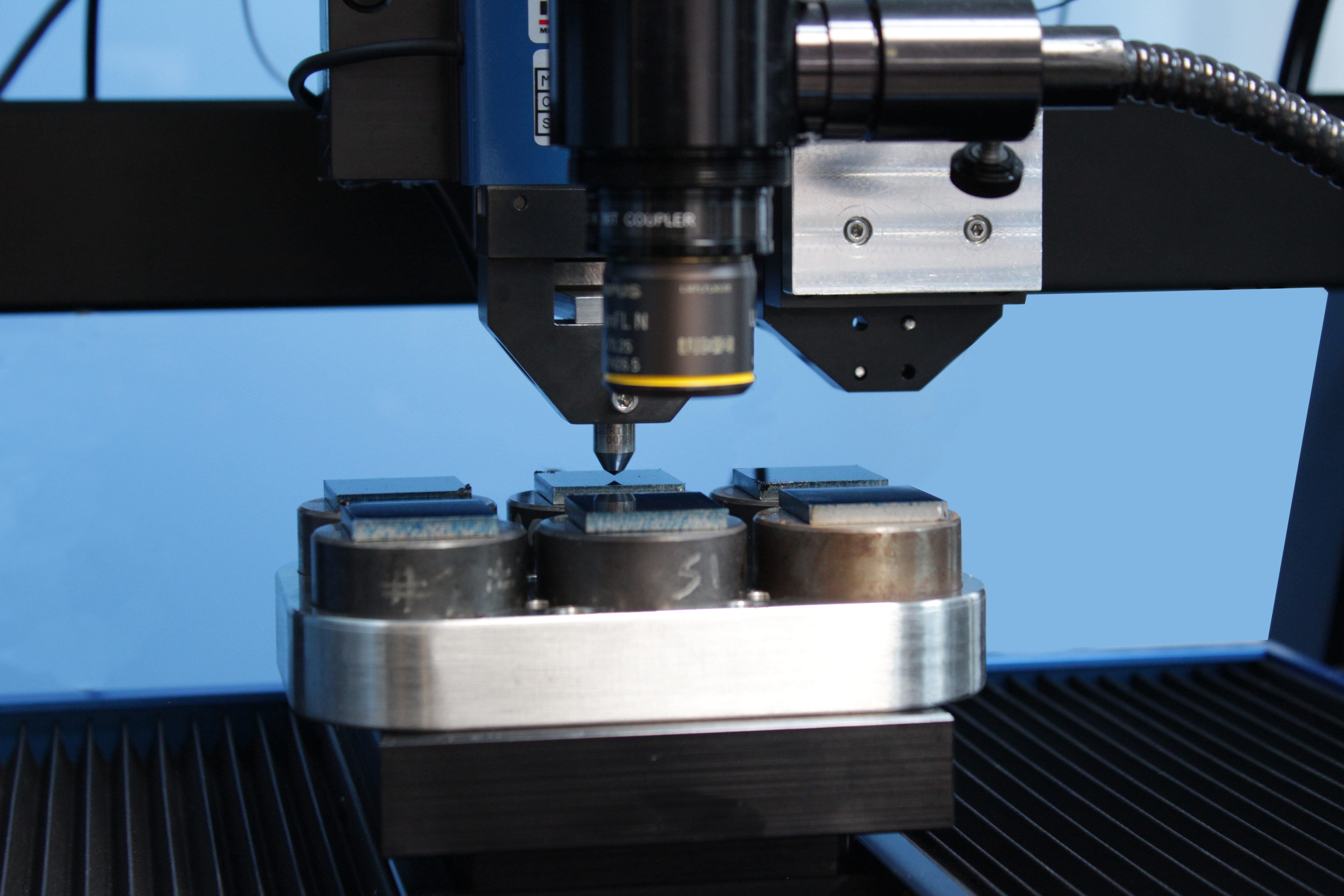

Multi Scratch Automation of Similar Samples using the PB1000 Mechanical Tester

Introduction :

Coatings are widely used in various industries because of their functional properties. A coating’s hardness, erosion resistance, low friction, and high wear resistance are just some of the many properties that make coatings important. A commonly used method to quantify these properties is scratch testing, this allows for a repeatable measurement of a coating’s adhesive and/or cohesive properties. By comparing the critical loads at which failure occurs, the intrinsic properties of a coating can be evaluated.

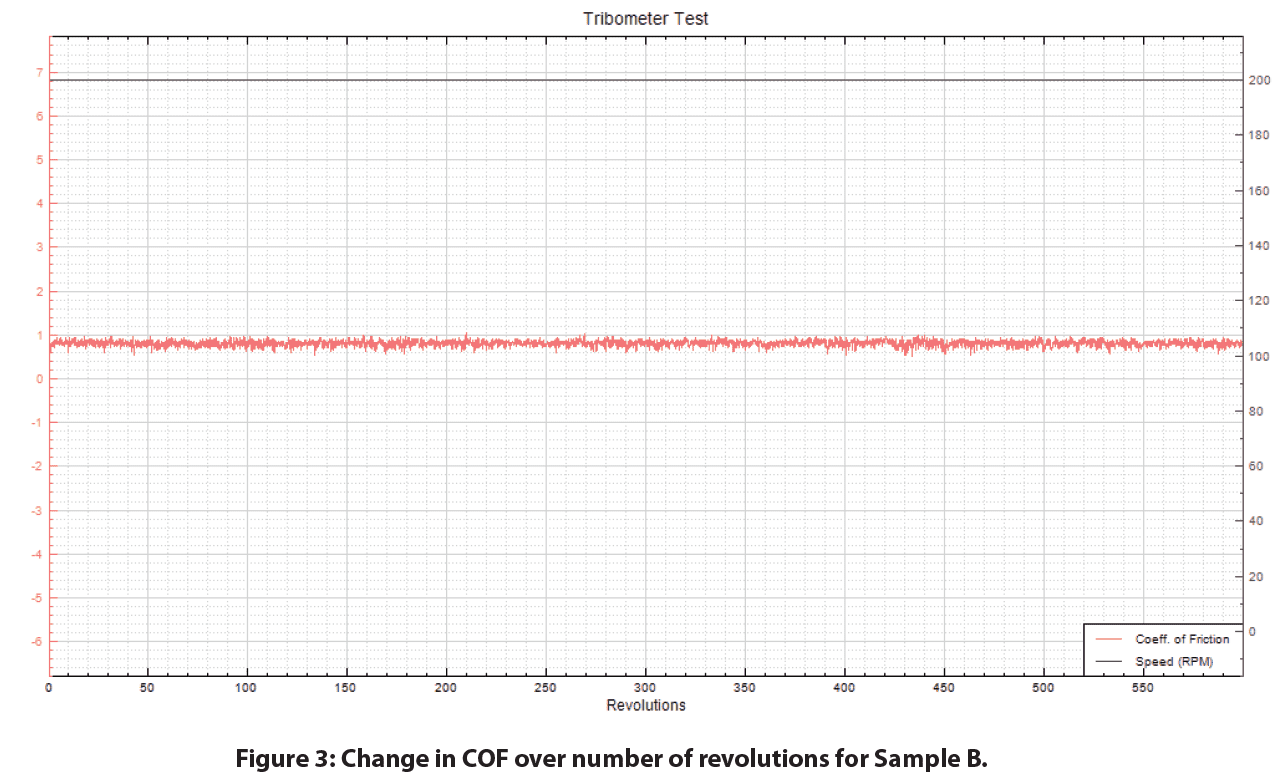

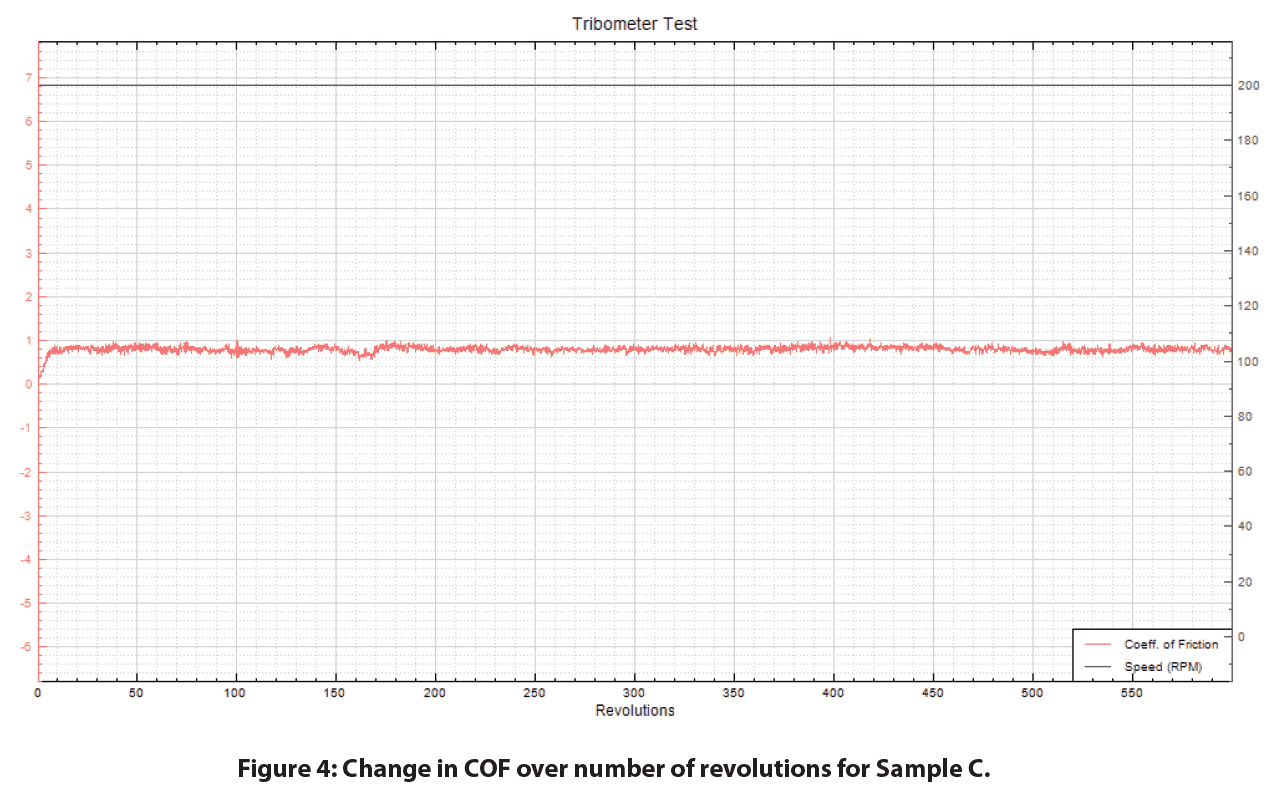

Rotative or Linear Wear & COF? (A Comprehensive Study Using the Nanovea Tribometer)

Wear is the process of removal and deformation of material on a surface as a result of the mechanical action of the opposite surface. It is influenced by a variety of factors, including unidirectional sliding, rolling, speed, temperature, and many others. The study of wear, tribology, spans many disciplines, from physics and chemistry to mechanical engineering and material science. The complex nature of wear requires isolated studies toward specific wear mechanisms or processes, such as adhesive wear, abrasive wear, surface fatigue, fretting wear, and erosive wear. However, “Industrial Wear” commonly involves multiple wear mechanisms occurring in synergy.

Linear reciprocating and Rotative (Pin on Disk) wear tests are two widely used ASTM-compliant setups for measuring sliding wear behaviors of materials. Since the wear rate value of any wear test method is often used to predict the relative ranking of material combinations, it is extremely important to confirm the repeatability of the wear rate measured using different test setups. This enables users to carefully consider the wear rate value reported in the literature, which is critical in understanding the tribological characteristics of materials.

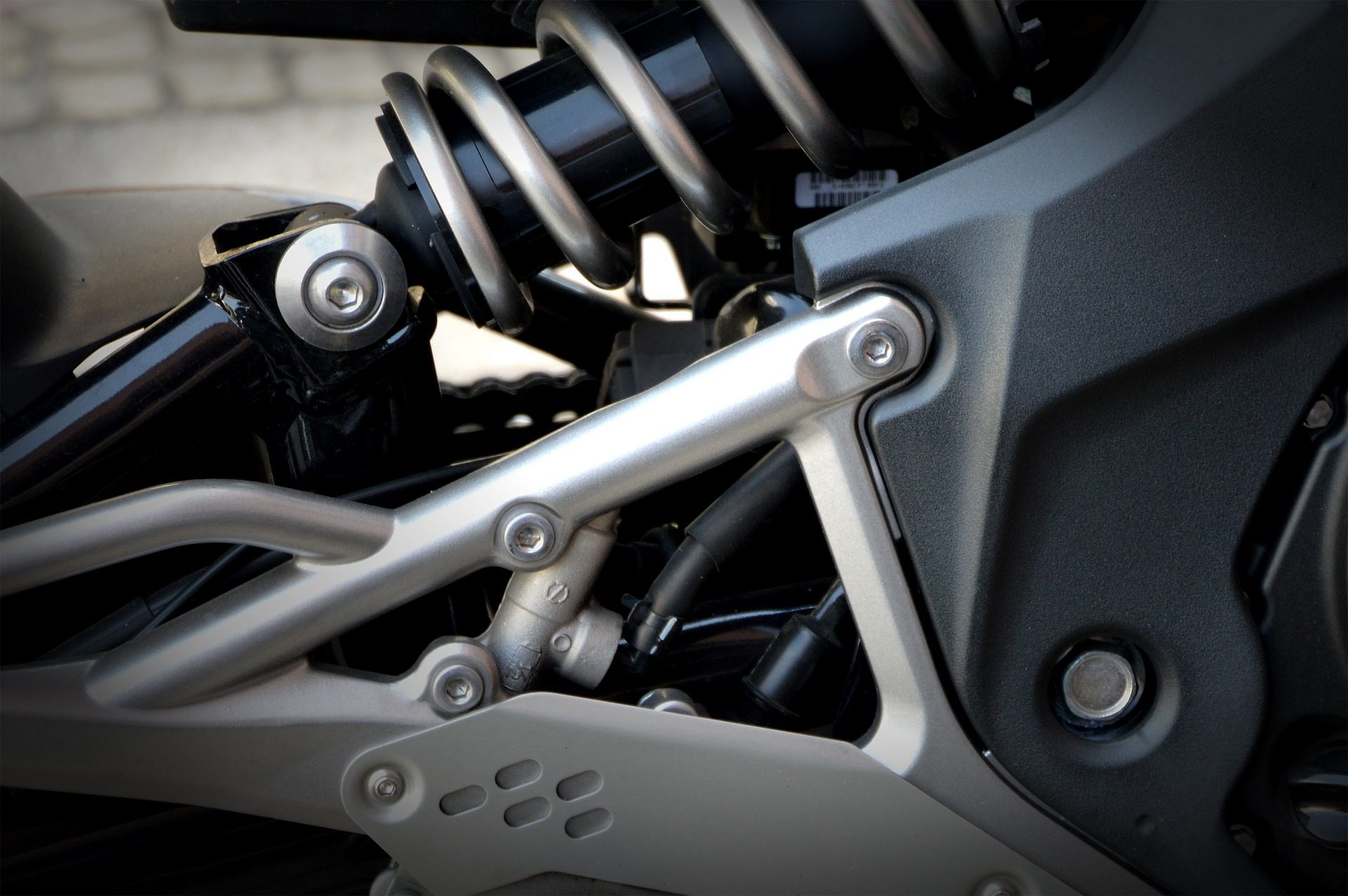

Nano Mechanical Characterization of Spring Constants

A spring’s ability to store mechanical energy has a long history of use. From bows for hunting to locks for doors, spring technology has been around for many centuries. Nowadays we rely on springs, be it from mattresses, pens, or automotive suspension, as they play a vital role in our daily lives. With such a wide variety of use and designs, the ability to quantify their mechanical properties is necessary.

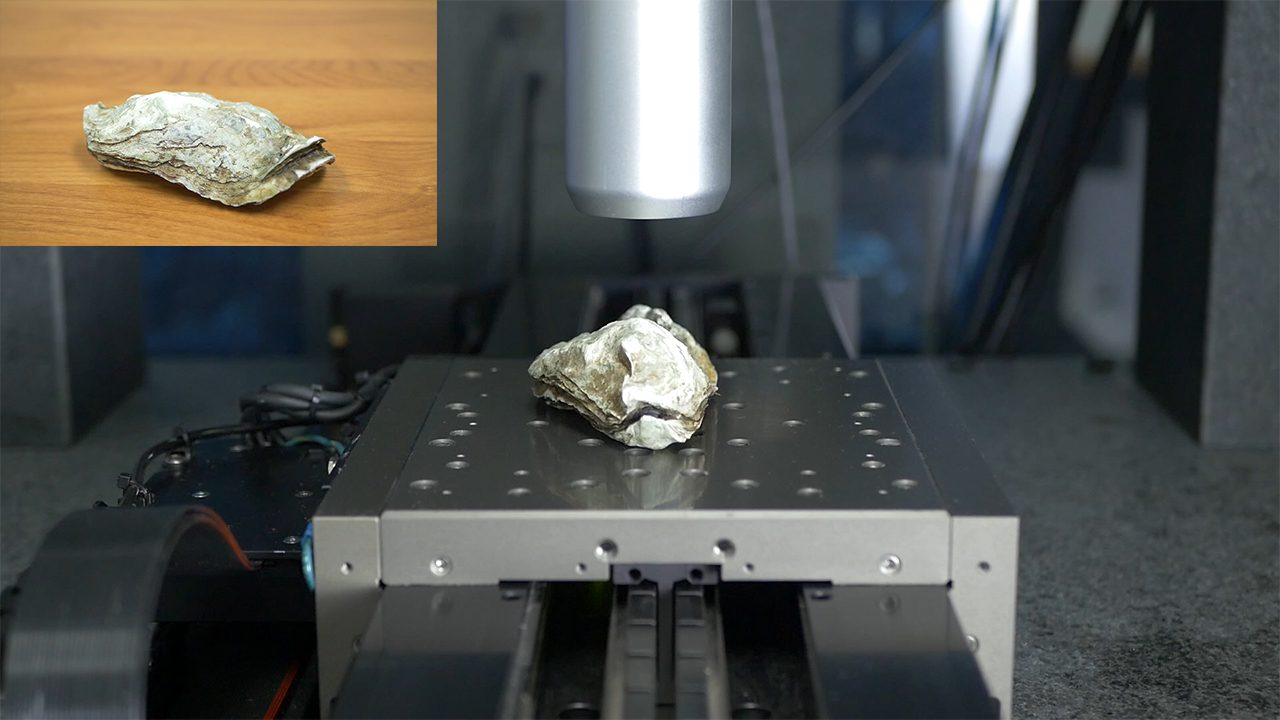

High Speed Characterization of an Oyster Shell

Large samples with complex geometries can prove difficult to work with due to sample preparation, size, sharp angles, and curvature. In this study an oyster shell will be scanned to demonstrate the Nanovea HS2000 Line Sensor’s capability to scan a large, biological sample with complex geometry. While a biological sample was used in this study, the same concepts can be applied to other samples.

Mechanical Broadview Map Selection Tool

We’ve all heard the term, time is money. Which is why many companies constantly seek methods of expediting and improving various processes, it saves time. When it comes to indentation testing, speed, efficiency and precision can be integrated into a quality control or R&D process when using one of our Nanovea Mechanical Testers. In this application note, we will be showcasing an easy way of saving time with our Nanovea Mechanical Tester and Broad View Map and Selection Tool software features.