Category: Laboratory Testing

Low Temperature Tribology

A reliable measurement of low temperature tribology, static and dynamic coefficient of friction, COF, as well as wear behavior is needed in order to better understand the tribological performance of materials for sub-zero applications. It provides a useful tool to correlate the frictional property with the influence of various factors, such as reactions at the interface, interlocking surface features, cohesion of surface films, and even microscopic solid static junctions between surfaces at low temperatures.

Macro Adhesion Failure of DLC

bits and bearings. Under such extreme conditions, sufficient cohesive and adhesive strength of the coating/substrate system becomes vital. In order to select the best metal substrate for the target application and to establish a consistent coating process for DLC, it is critical to develop a reliable technique to quantitatively assess cohesion and adhesion failure of different DLC coating systems.

Cohesive & Adhesive Strength of DLC Using Macro Scratch Testing

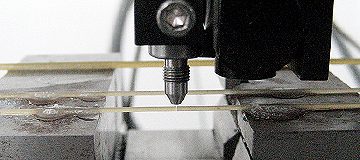

High Temperature Scratch Hardness Using Tribometer

Materials are selected based on the service requirements. For applications involving significant temperature changes and thermal gradients, it is critical to investigate the mechanical properties of materials at high temperatures to be fully aware of the mechanical limits. Materials, especially polymers, usually soften at high temperatures. A lot of mechanical failures are caused by creep deformation and thermal fatigue taking place only at elevated temperatures. Therefore, a reliable technique for measuring high temperature scratch hardness is in need to ensure proper selection of the materials for high temperature applications.

High Temperature Scratch Hardness Using Tribometer

Scratch Hardness Measurement Using Tribometer

In this study, the Nanovea Tribometer is used to measure the scratch hardness of different metals. The

capacity of performing scratch hardness measurement with high precision and reproducibility makes

Nanovea Tribometer a more complete system for tribological and mechanical evaluations.

Mechanical & Tribological Properties of Carbon Fiber

Combined with the wear test by Tribometer and surface analysis by Optical 3D Profilometer, we

showcase the versatility and accuracy of the Nanovea instruments in testing composite materials

with directional mechanical properties.

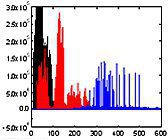

Wear Testing Glass With Acoustic Emissions Monitoring

The wear behavior of three types of glass (Regular glass, Galaxy S3 glass and Sapphire coated glass) is compared in a controlled and monitored manner using the Nanovea Tribometer equipped with an AE detector. In this study, we would like to show the application of AE detection during wear and its correlation with the evolution of coefficient of friction (COF).

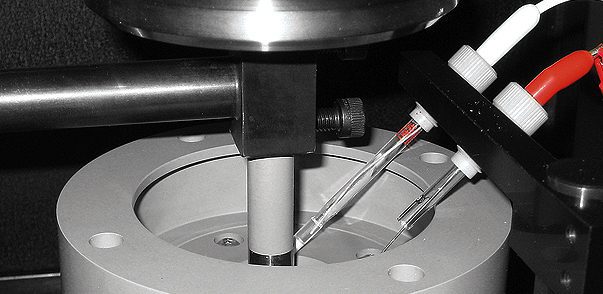

Tribocorrosion Wear Evaluation of Protective Coating

The tribocorrosion process of the DLC coatings on different types of steel substrates is simulated using the Nanovea Tribometer. In this study, we would like to showcase that Nanovea Tribometer equipped with the Tribocorrosion Module is an ideal tool for evaluating the performance of protective coatings used in wear and corrosion environment.

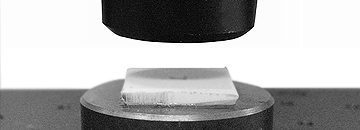

3 Point Bend Test Using Microindentation

In this application, the Nanovea Mechanical Tester, in Microindentation mode, is used to measure the flexural strength (using 3 Point Bend) of various sized rod samples (pasta) to show a range of data. 2 different diameters were chosen to demonstrate both elastic and brittle characteristics. Using a flat tip indenter to apply a point load, we determine stiffness (Young’s Modulus) and identify the critical loads at which the sample will fracture.

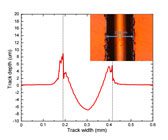

Micro Scratch Depth Measurement Using 3D Profilometry

In this application the Nanovea ST400 Profilometer is used for depth measurement of a row of micro scratches created using Nanovea’s Mechanical Tester in scratch mode. In seconds the Profilometer, with a single line pass in 2D mode, provides area and depth measurement.