Category: Application Notes

Surface Finish Inspection of Wood Flooring

Importance of Profiling Wood Finishes

In various industries, the purpose of a wood finish is to protect the wooden surface from various types of damage such as chemical, mechanical or biological and/or provide a specific visual aesthetic. For manufacturers and buyers alike, quantifying surface characteristics of their wood finishes can be vital to the quality control or optimization of finishing processes for wood. In this application, we will explore the various surface features that can be quantified using a Nanovea 3D Non-Contact Profilometer.

Quantifying the amount of roughness and texture that exists on a wooden surface can be essential to know in order to ensure it can meet the requirements of its application. Refining the finishing process or checking the quality of wooden surfaces based on a quantifiable, repeatable and reliable surface inspection method would allow manufacturers to create controlled surface treatments and buyers the ability to inspect and select wood materials to meet their needs.

Measurement Objective

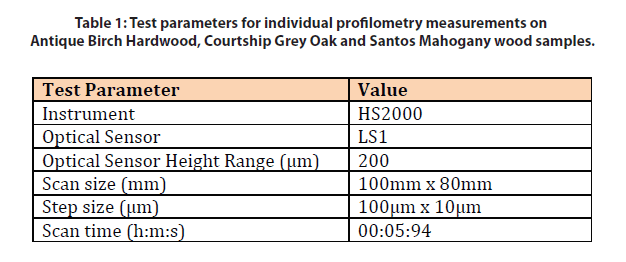

In this study, the high-speed Nanovea HS2000 profilometer equipped with a non-contact profiling line sensor was used to measure and compare the surface finish of three flooring samples: Antique Birch Hardwood, Courtship Grey Oak, and Santos Mahogany flooring. We showcase the capability of the Nanovea Non-Con-tact Profilometer in delivering both speed and precision when measuring three types of surface areas and a comprehensive in-depth analysis of the scans.

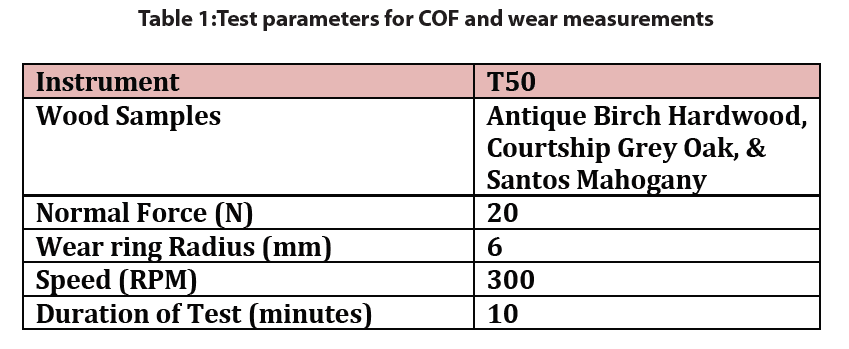

Test Procedure and Procedures

Results and Discussion

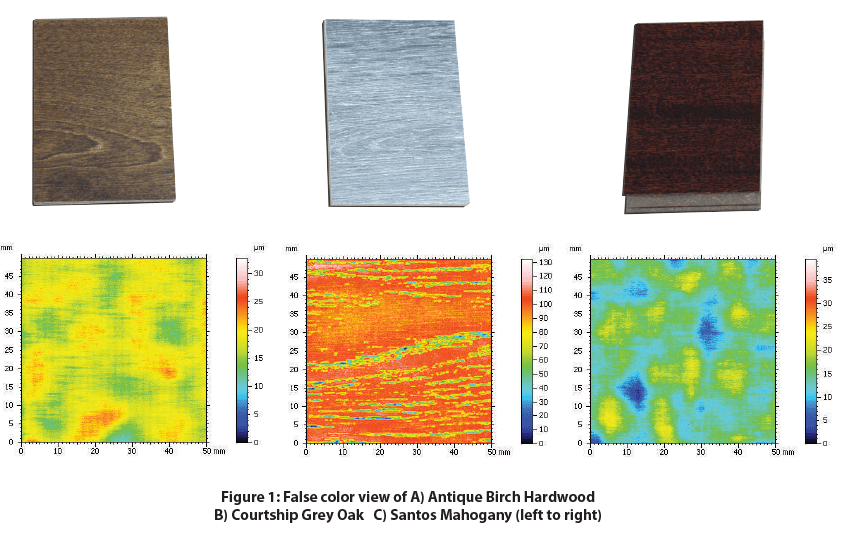

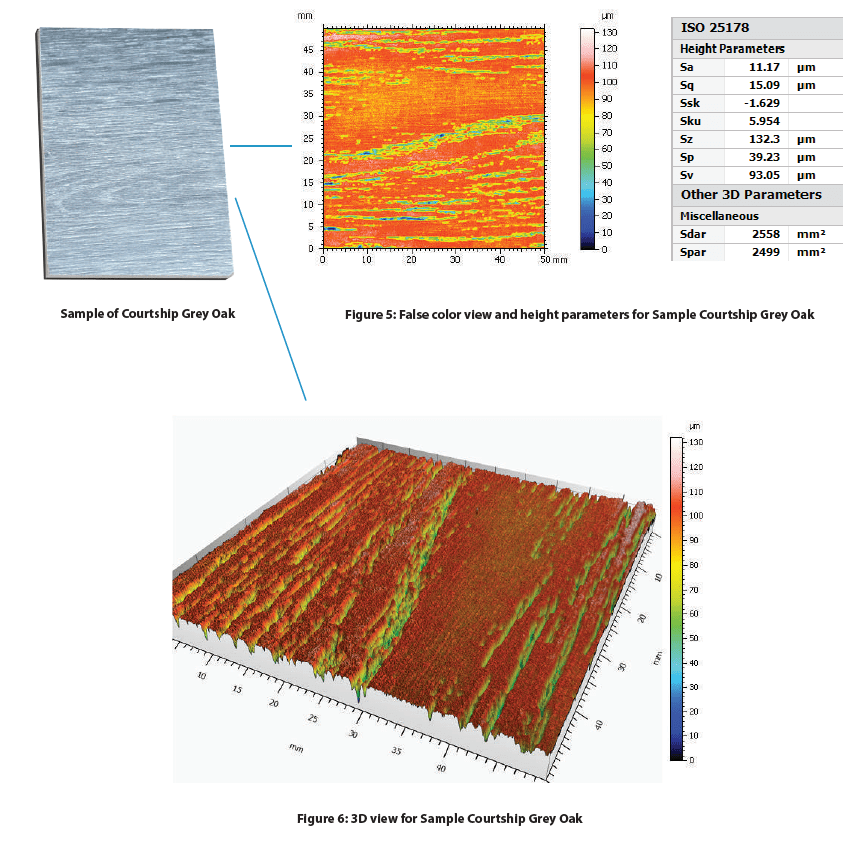

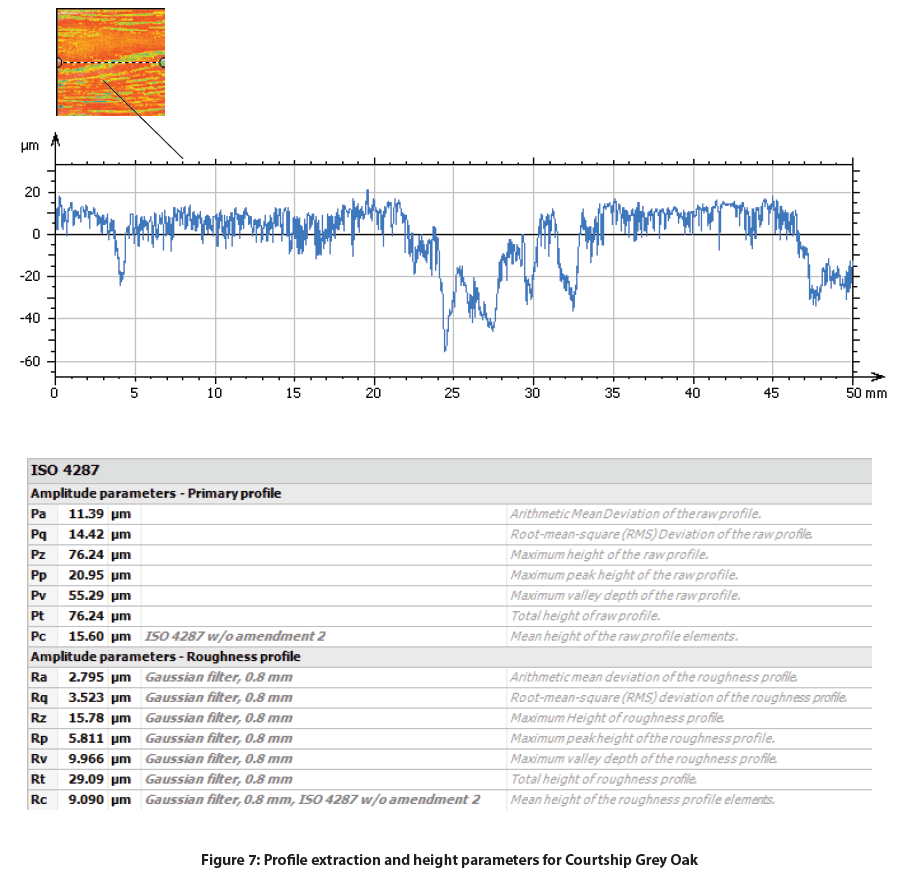

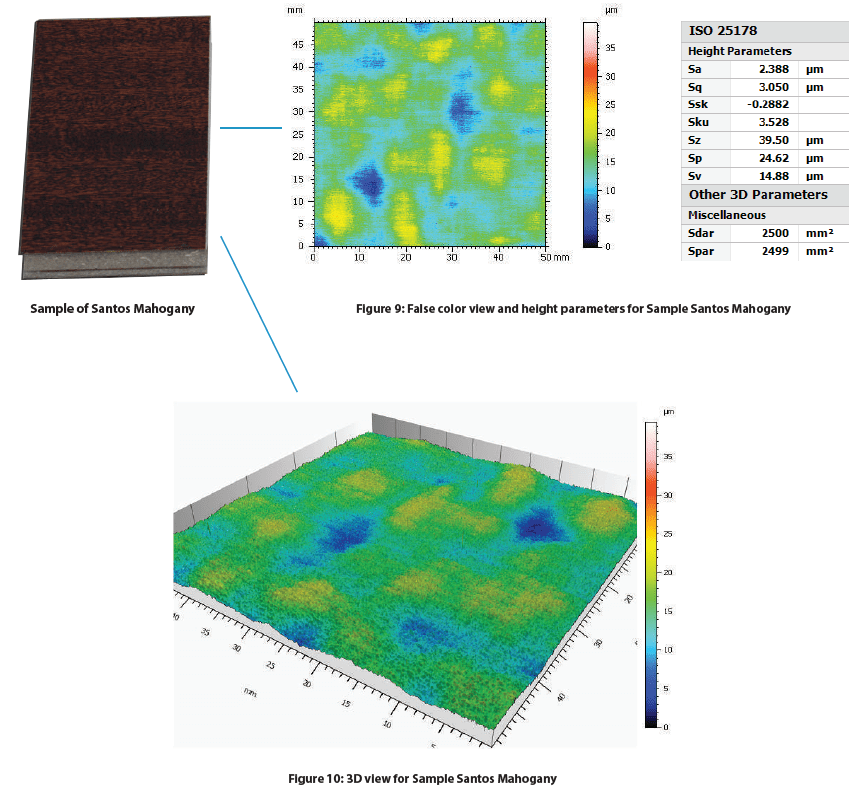

Sample description: Courtship Grey Oak and Santos Mahogany flooring are laminate flooring types. Courtship Grey Oak is a low gloss, textured slate gray sample with an EIR finish. Santos Mahogany is a high gloss, dark burgundy sample that was prefinished. Antique Birch Hardwood has a 7-layer aluminum oxide finish, providing everyday wear and tear protection.

Discussion

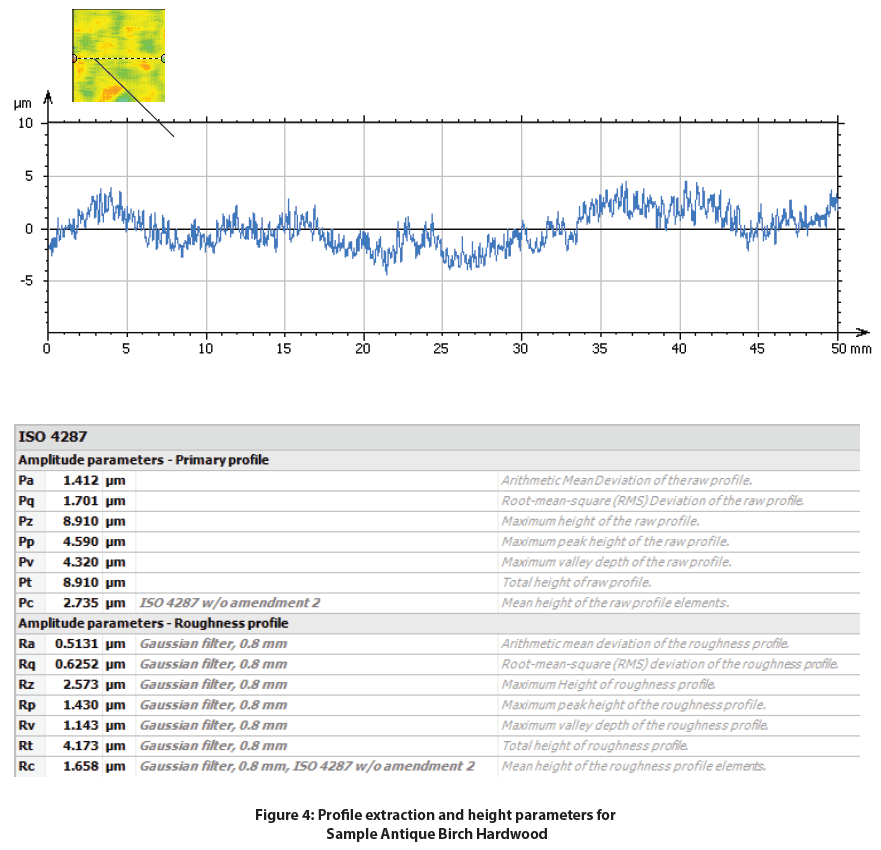

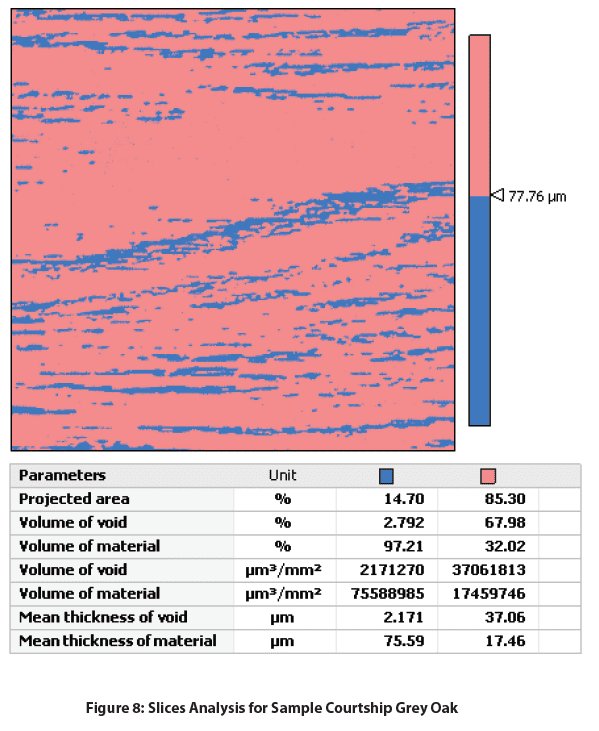

There is a clear distinction between all the samples’ Sa value. The smoothest was Antique Birch Hardwood with a Sa of 1.716 µm, followed by Santos Mahogany with a Sa of 2.388 µm, and significantly increasing for Courtship Grey Oak with a Sa of 11.17 µm. P-values and R-values are also common roughness values that can be used to assess the roughness of specific profiles along the surface. The Courtship Grey Oak possess-es a coarse texture full of crack-like features along the wood’s cellular and fiber direction. Additional analysis was done on the Courtship Grey Oak sample because of its textured surface. On the Courtship Grey Oak sample, slices were used to separate and calculate the depth and volume of the cracks from the flatter uniform surface.

Conclusion

In this application, we have shown how the Nanovea HS2000 high-speed profilometer can be used to inspect the surface finish of wood samples effectively and efficiently. Surface finish measurements can prove to be important to both manufactures and consumers of hardwood flooring in understanding how they can improve a manufacturing process or choose the appropriate product that performs best for a specific application.

NOW, LET'S TALK ABOUT YOUR APPLICATION

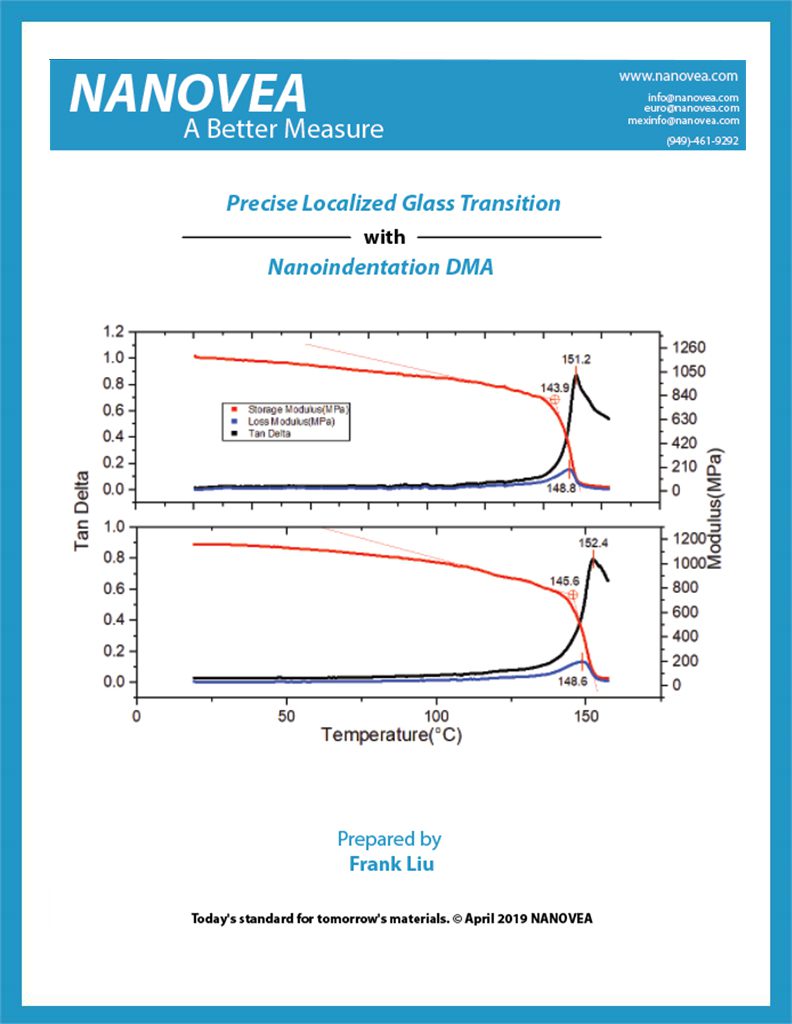

Precise Localized Glass Transition with Nanoindentation DMA

Learn more

Stress Relaxation Measurement using Nanoindentation

Learn more

NOW, LET'S TALK ABOUT YOUR APPLICATION

Wood Wear Test with the Nanovea Tribometer

Importance of Comparing Wood Finish Wear & COF

Wood has been used for thousands of years as a building material for homes, furniture, and flooring. It has a combination of natural beauty, and durability, making it an ideal candidate for flooring. Unlike carpet, hardwood floors keep their color for a long time and can be easily cleaned and maintained, however, being a natural material, most wood flooring requires the application of a surface finish to protect the wood from various kinds of damage such as scuffing and chipping over time. In this study, a Nanovea Tribometer was used to measure the wear rate and coefficient of friction (COF) to better understand the comparative performance of three wood finishes.

The service behavior of a wood species used for flooring is often related to its wear resistance. The change in the individual cellular and fiber structure of different species of wood contributes to their different mechanical and tribological behaviors. Actual service tests of wood as flooring materials are expensive, difficult to duplicate, and require long periods of testing time. As a result, it becomes valuable to develop a simple wear test that can produce reliable, reproducible, and straight forward.

Measurement Objective

In this study, we simulated and compared the wear behaviors of three types of wood to showcase the capability of the Nanovea Tribometer in evaluating the tribological properties of wood in a controlled and monitored manner.

Discussion

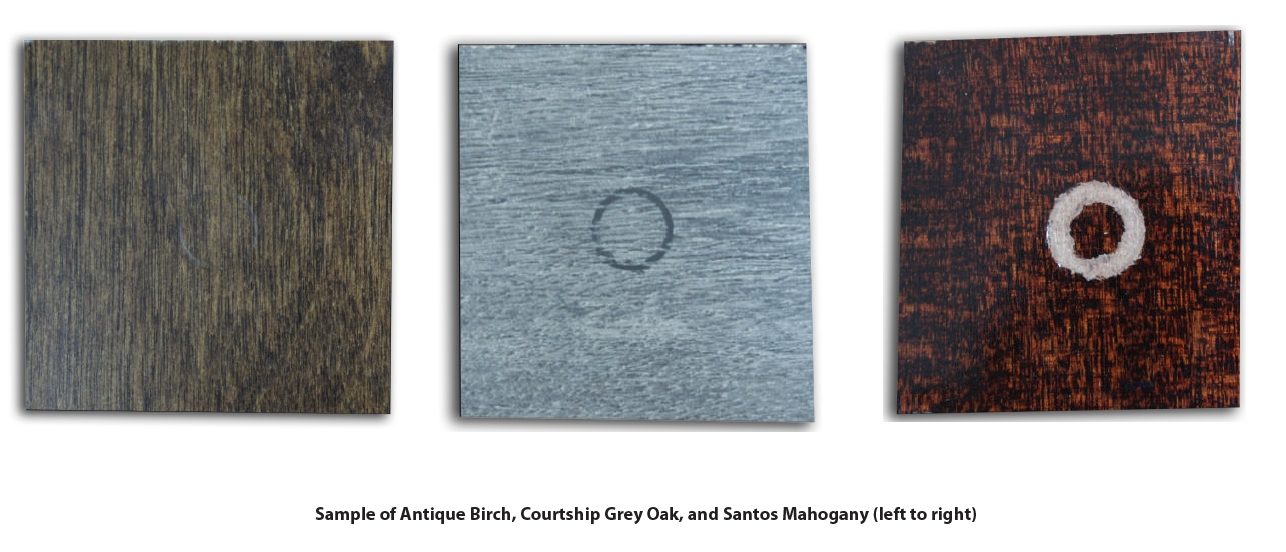

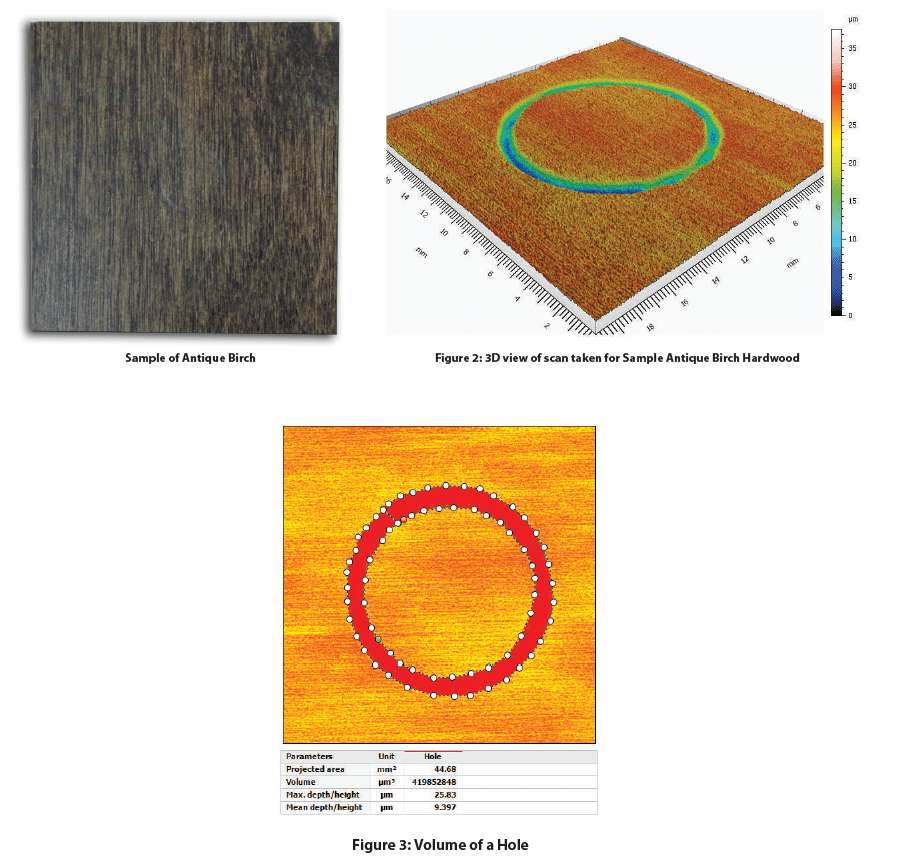

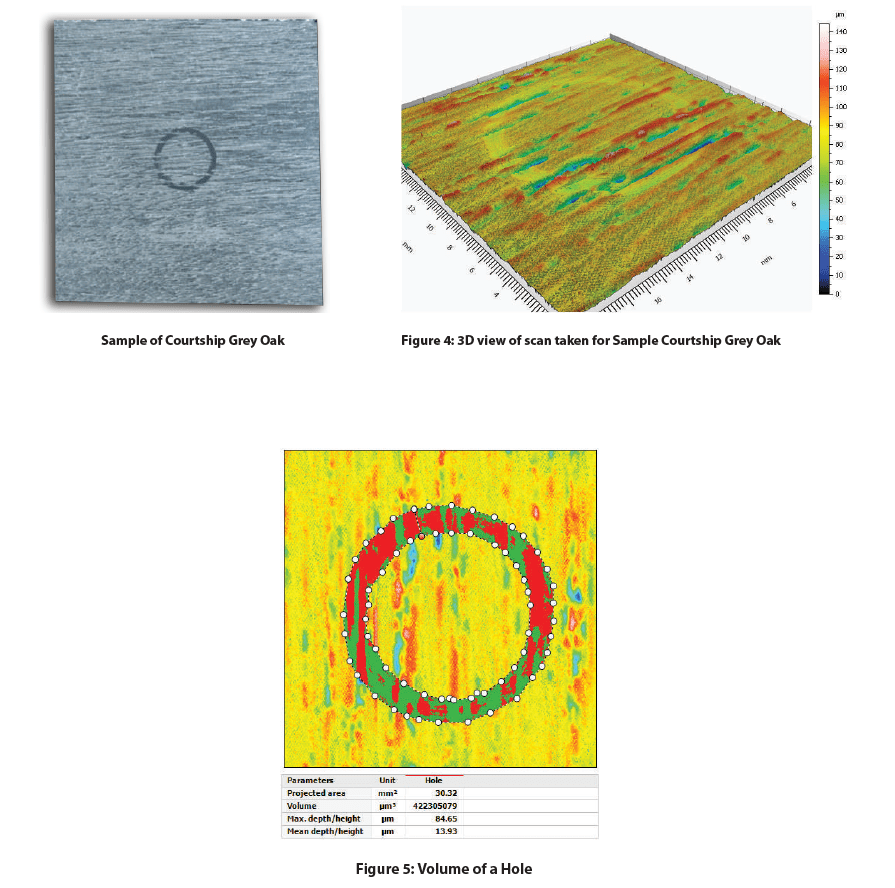

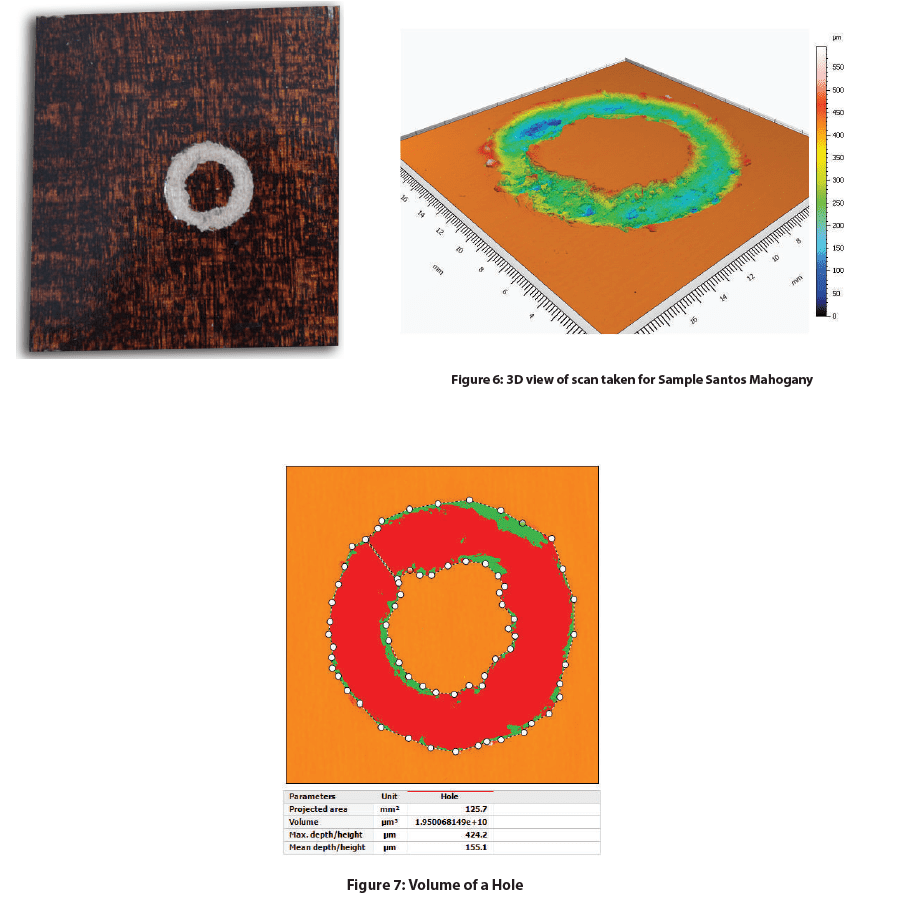

Sample Description: Antique Birch Hardwood has a 7-layer aluminum oxide finish, providing everyday wear and tear protection. Courtship Grey Oak, & Santos Mahogany are both laminate flooring types that vary in surface finish and gloss. The Courtship Grey Oak is a slate gray color, EIR finish, and low gloss. On the other hand, Santos Mahogany is a dark burgundy color, prefinished, and high gloss which allows surface scratches and defects to be more easily hidden.

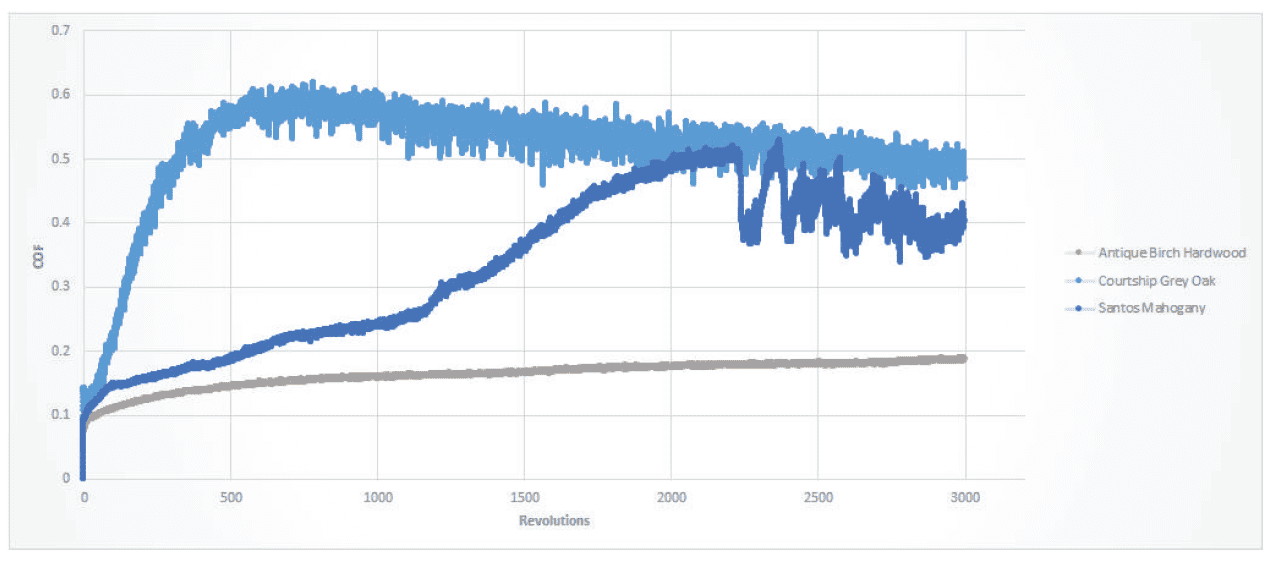

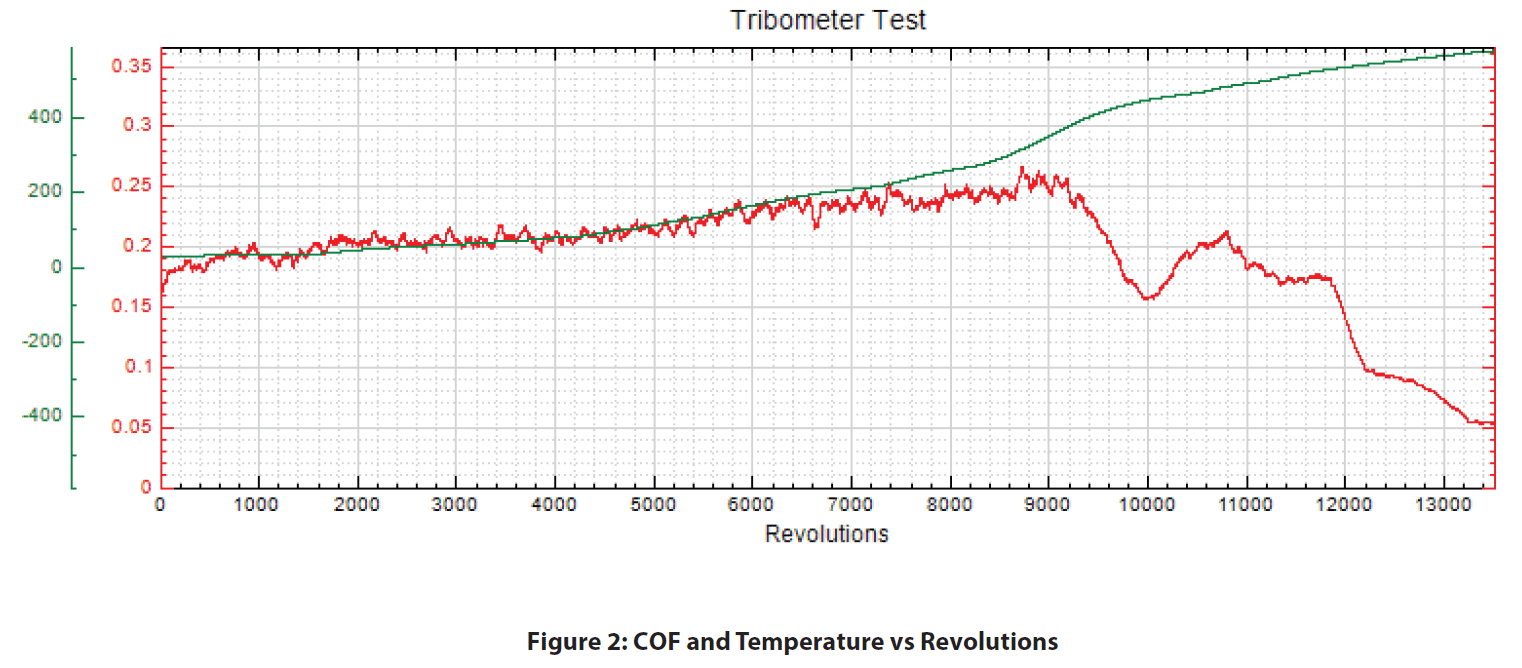

The evolution of COF during the wear tests of the three wood flooring samples are plotted in Fig. 1. The Antique Birch Hardwood, Courtship Grey Oak, & Santos Mahogany samples all showed different COF behavior.

It can be observed in the graph above that Antique Birch Hardwood was the only sample that demonstrated a steady COF for the duration of an entire test. The Courtship Grey Oak’s sharp increase in COF and then gradual decrease could be indicative that the sample’s surface roughness largely contributed to its COF behavior. As the sample wore, the surface roughness decreased and became more homogenous which explains the decrease in COF as the sample surface became smoother from mechanical wear. The COF on Santos Mahogany displays a smooth gradual increase in COF at the beginning of the test and then transitioned abruptly into a choppy COF trend. This could indicate that once the laminate coating started to wear through, the steel ball (counter material) made contact with the wood substrate which wore in a quicker and turbulent manner creating the noisier COF behavior towards the end of the test.

Antique Birch Hardwood:

Courtship Grey Oak:

Santos Mahogany

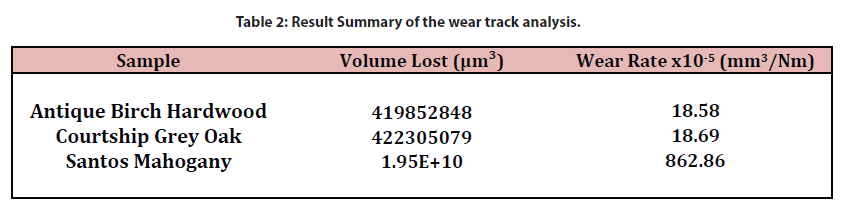

Table 2 summarizes the results of the wear track scans and analysis on all wood flooring samples after the wear tests were performed. Detailed information and images for each sample can be seen in Figures 2-7. Based on the Wear Rate comparison between all three samples, we can deduct that Santos Mahogany proved to be less resilient to mechanical wear than the other two samples. Antique Birch Hardwood and Courtship Grey Oak had very similar wear rates although their wear behavior during their tests differed significantly. Antique Birch Hardwood had a gradual and more uniform wear trend while Court-ship Grey Oak showed a shallow and pitted wear track due to the pre-existing surface texture and finish

Conclusion

In this study, we showcased the capacity of Nanovea’s Tribometer in evaluating the coefficient of friction and wear resistance of three types of wood, Antique Birch Hardwood, Courtship Grey Oak, and Santos Mahogany in a controlled and monitored manner. The superior mechanical properties of the Antique Birch Hardwood leads to its better wear resistance. The texture and homogeneity of the wood surface play an important role in the wear behavior. The Courtship Grey Oak surface texture such as gaps or cracks between the wood cell fibers may become the weak spots where the wear initiates and propagates.

NOW, LET'S TALK ABOUT YOUR APPLICATION

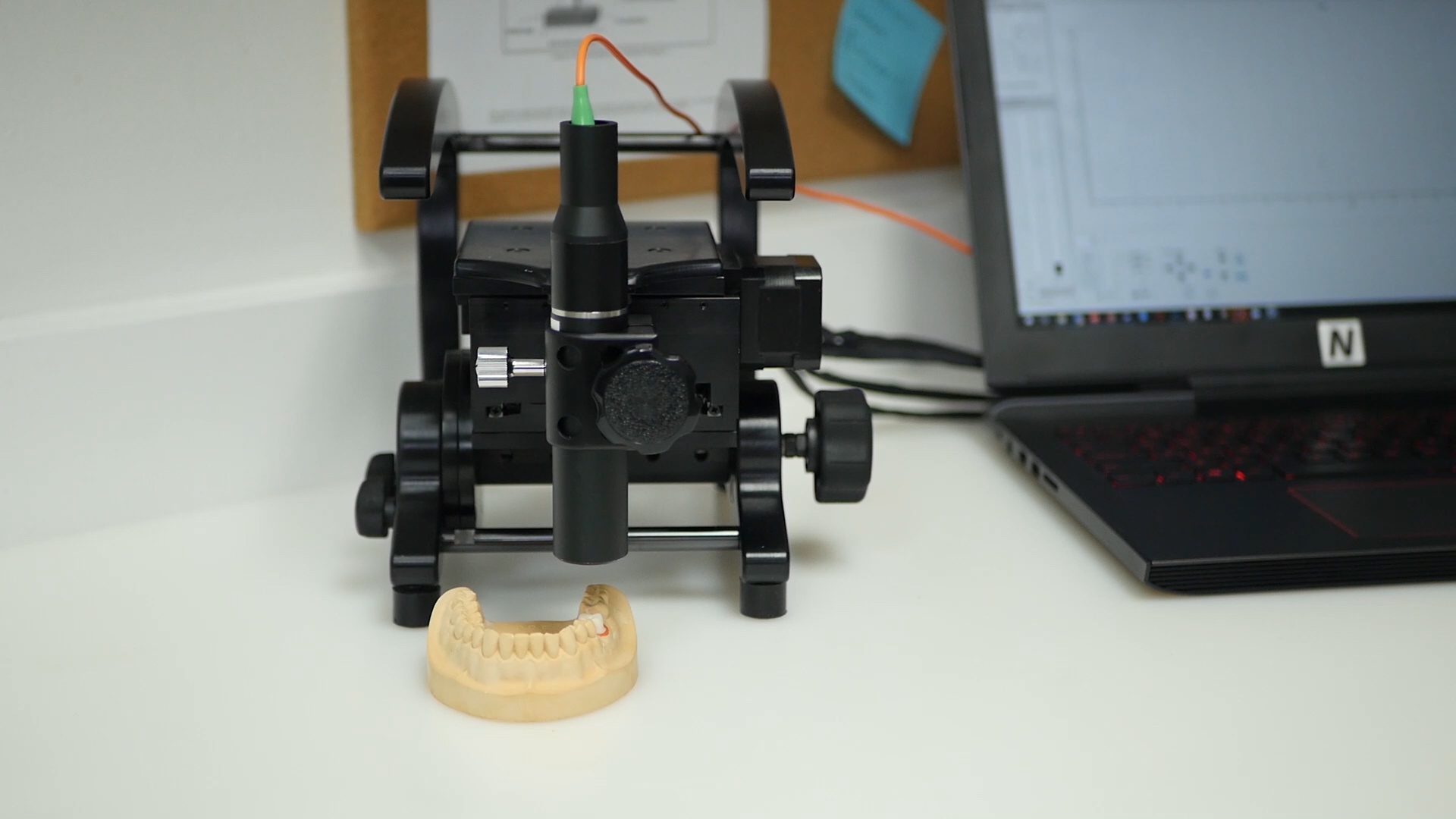

Portability and Flexibility of the Jr25 3D Non-contact Profilometer

Understanding and quantifying a sample’s surface is crucial for many applications including quality control and research. To study surfaces, profilometers are often used to scan and image samples. A large problem with conventional profilometry instruments is the inability to accommodate for non conventional samples. Difficulties in measuring non conventional samples can occur due to sample size, geometry, inability to move the sample, or other inconvenient sample preparations. Nanovea’s portable 3D non-contact profilometers, the JR series, is able to solve most of these problems with its ability to scan sample surfaces from varying angles and its portability.

Compression on Soft, Flexible Materials

Importance of testing soft, flexible materials

An example of very soft and flexible samples is a microelectromechanical system. MEMS are used in everyday commercial products like printers, mobile phones, and cars [1]. Their uses also include special functions, such as biosensors [2] and energy harvesting [3]. For their applications, MEMS must be able to reversibly transition between their original configuration to a compressed configuration repeatedly [4]. To understand how the structures will react to mechanical forces, compression testing can be conducted. Compression testing can be utilized to test and tune various MEMS configurations as well as testing upper and lower force limits for these samples.

Measurement Objective

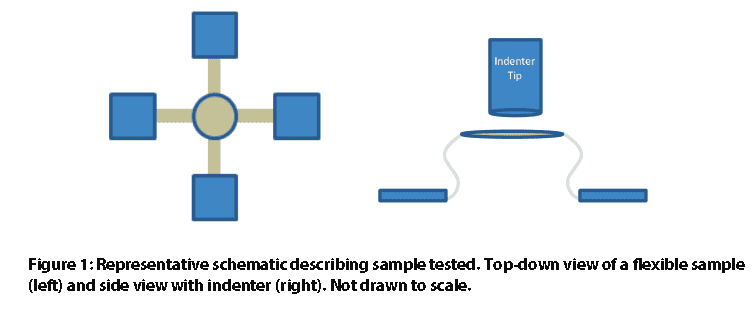

In this case study, Nanovea conducted compression testing on two uniquely di erent flexible, spring-like samples. We showcase our ability to conduct compression at very low loads and record large displacement while accurately obtaining data at low loads and how this can be applied to the MEMS industry. Due to privacy policies, the samples and their origin will not be revealed in this study

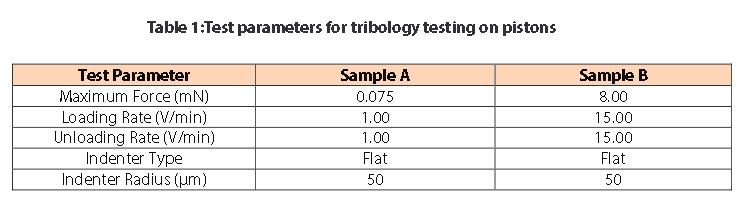

Measurement Parameters

Note: The loading rate of 1 V/min is proportional to approximately 100μm of displacement when the indenter is in the air.

Results and Discussion

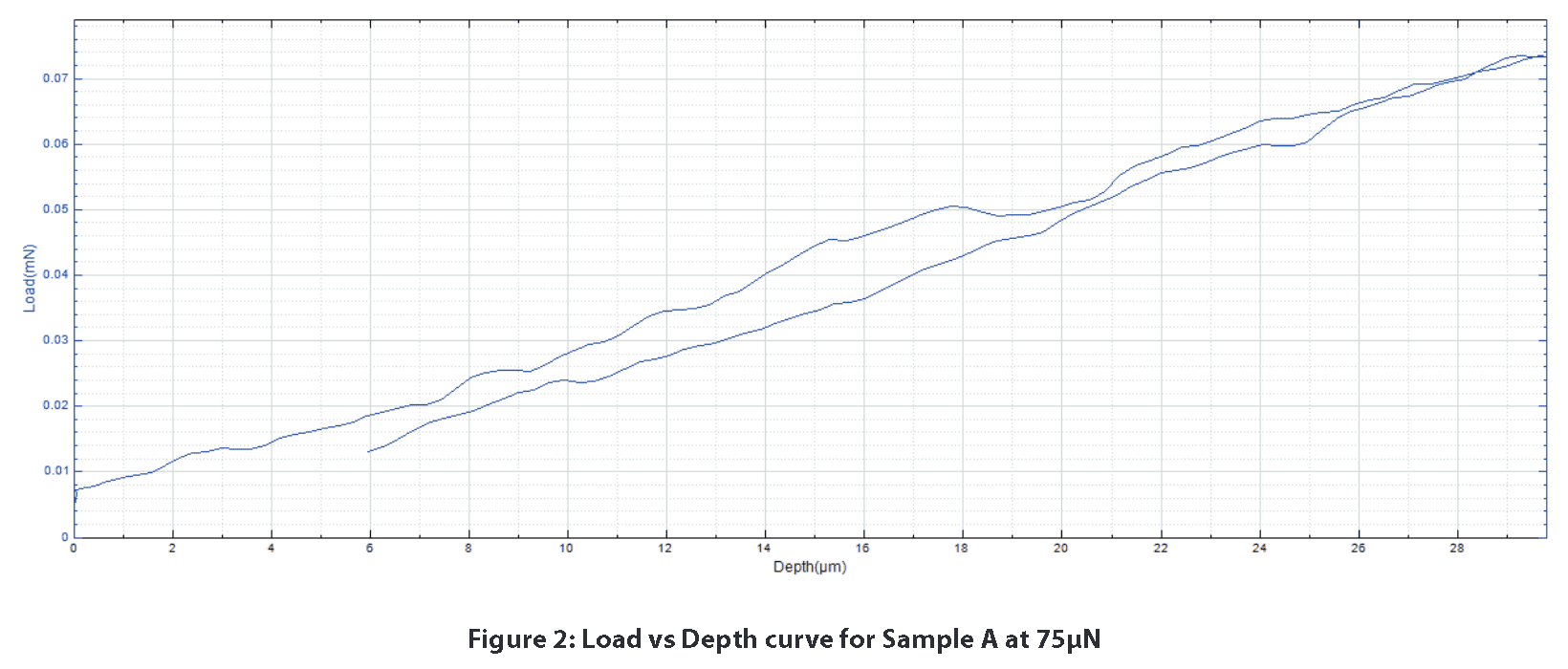

The sample’s response to mechanical forces can be seen in the load vs depth curves. Sample A only displays linear elastic deformation with the test parameters listed above. Figure 2 is a great example of the stability that can be achieved for a load vs. depth curve at 75μN. Due to the load and depth sensors stability, it would be easy to perceive any signi cant mechanical response from the sample.

Sample B displays a different mechanical response from Sample A. Past 750μm of depth, fracture-like behavior in the graph begins to appear. This is seen with the sharp drops in load at 850 and 975μm of depth. Despite traveling at a high loading rate for more than 1mm over a range of 8mN, our highly sensitive load and depth sensors allow the user to obtain the sleek load vs depth curves below.

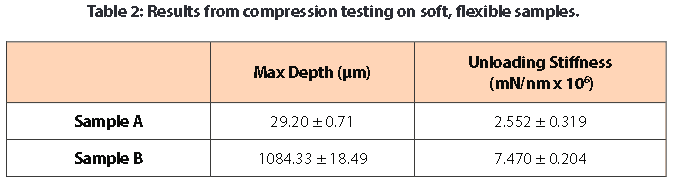

The stiffness was calculated from the unloading portion of the load vs depth curves. Stiffness reflects how much force is necessary to deform the sample. For this stiffness calculation, a pseudo Poisson’s ratio of 0.3 was used since the actual ratio of the material is not known. In this case, Sample B proved to be stiffer than Sample A.

Conclusion

Two diff erent flexible samples were tested under compression using the Nanovea Mechanical Tester’s Nano Module. The tests were conducted at very low loads (<80μN) and over a large depth range (>1mm). Nano-scaled compression testing with the Nano Module has shown the module’s ability to test very soft and flexible samples. Additional testing for this study could address how repeated cyclical loading a ects the elastic recovery aspect of the spring-like samples via the Nanovea Mechanical Tester’s multi-loading option.

For more information on this testing method, feel free to contact us at info@nanovea.com and for additional application notes please browse our extensive Application Note digital library.

References

[1] “Introduction and Application Areas for MEMS.” EEHerald, 1 Mar. 2017, www.eeherald.com/section/design-guide/mems_application_introduction.html.

[2] Louizos, Louizos-Alexandros; Athanasopoulos, Panagiotis G.; Varty, Kevin (2012). “Microelectromechanical Systems and Nanotechnology. A Platform for the Next Stent Technological Era”. Vasc Endovascular Surg.46 (8): 605–609. doi:10.1177/1538574412462637. PMID 23047818.

[3] Hajati, Arman; Sang-Gook Kim (2011). “Ultra-wide bandwidth piezoelectric energy harvesting”. AppliedPhysics Letters. 99 (8): 083105. doi:10.1063/1.3629551.

[4] Fu, Haoran, et al. “Morphable 3D mesostructures and microelectronic devices by multistable bucklingmechanics.” Nature materials 17.3 (2018): 268.

NOW, LET'S TALK ABOUT YOUR APPLICATION

Evaluating Brake Pads with Tribology

Importance of Evaluating Break Pad Performance

Brake pads are composites., a material made up of multiple ingredients, that must be able to satisfy a large number of safety requirements. Ideal brake pads have high coefficient of friction (COF), low wear rate, minimal noise, and remain reliable under varying environments. To ensure the quality of brake pads are able to satisfy their requirements, tribology testing can be used to identify critical specifications.

The importance of the reliability of brake pads is placed very high; the safety of passengers should never be neglected. Therefore, it is key to replicate operating conditions and identify possible points of failure.

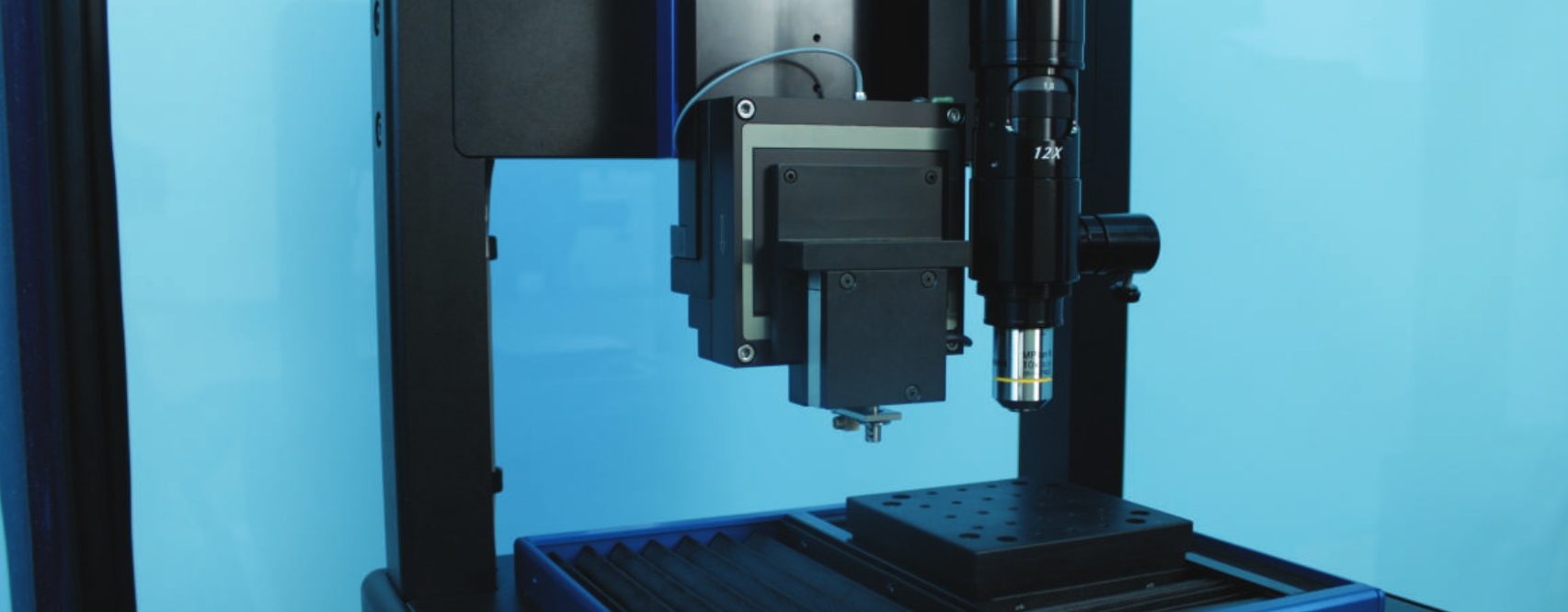

With the Nanovea Tribometer, a constant load is applied between a pin, ball, or flat and a constantly moving counter material. The friction between the two material is collected with a stiff load cell, allowing the collection of material properties at different loads and speeds and tested in high temperature, corrosive, or liquid environments.

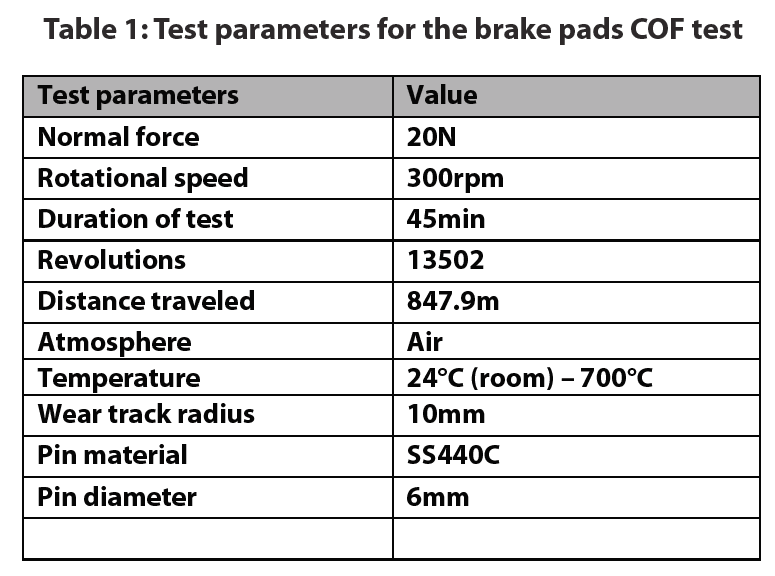

Measurement Objective

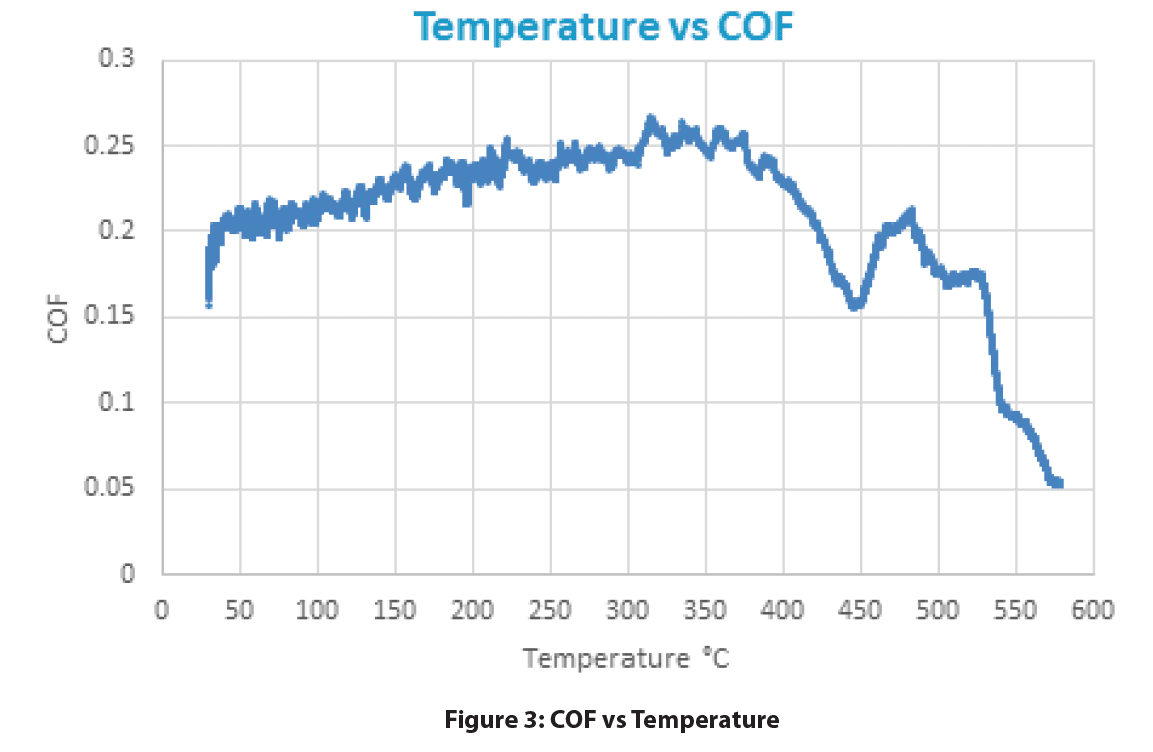

In this study, the coefficient of friction of the brake pads were studied under a continuously increasing temperature environment from room temperature to 700°C. The environmental temperature was raised in-situ until noticeable failure of the brake pad was observed. A thermocouple was attached to the backside of the pin to measure the temperature near the sliding interface.

Results and Discussion

This study focuses mainly on the temperature at which brake pads start to fail. The COF obtained do not represent real-life values; the pin material is not the same as brake rotors. It should also be noted that the temperature data collected is the temperature of the pin and not the sliding interface temperature

At the start of the test (room temperature), the COF between the SS440C pin and brake pad gave a consistent value of approximately 0.2. As the temperature increased, the COF steadily increased and peaked at a value of 0.26 near 350°C. Past 390°C, the COF quickly starts decreasing. The COF began to increase back to 0.2 at 450°C but starts decreasing to a value of 0.05 shortly after.

The temperature at which the brake pads consistently failed is identified at temperatures above 500°C. Past this temperature, the COF was no longer able to retain the starting COF of 0.2.

Conclusion

The brake pads have shown consistent failure at a temperature past 500°C. Its COF of 0.2 slowly rises to a value of 0.26 before dropping down to 0.05 at the end of the test (580°C). The difference between 0.05 and 0.2 is a factor of 4. This means that the normal force at 580°C must be four times greater than at room temperature to achieve the same stopping force!

While not included in this study, the Nanovea Tribometer is also able to conduct testing to observe another important property of brake pads: wear rate. By utilizing our 3D non-contact profilometers, the volume of the wear track can be obtained to calculate how quickly samples wear. Wear testing can be conducted with the Nanovea Tribometer under different test conditions and environments to best simulate operating conditions.

NOW, LET'S TALK ABOUT YOUR APPLICATION

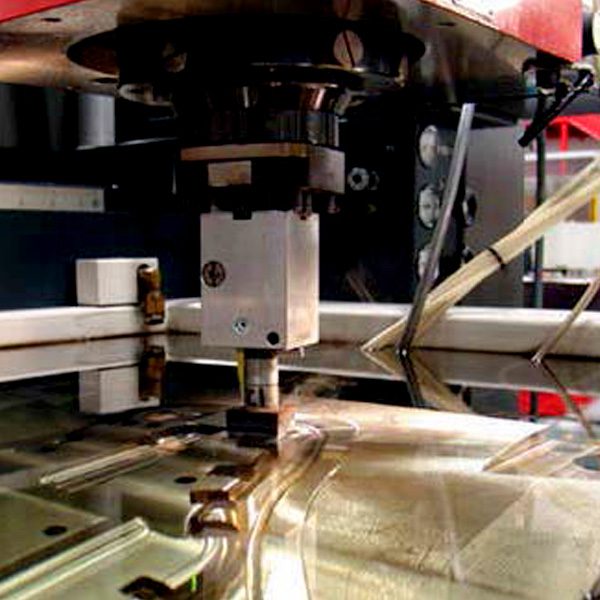

Quality Analysis on Electrical Discharge Machined Metals

Electrical discharge machining, or EDM, is a manufacturing process that removes material via electrical

discharges [1]. This machining process is generally used with conductive metals that would be difficult

to machine with conventional methods.

As with all machining processes, precision and accuracy must be high in order to meet acceptable

tolerance levels. In this application note, the quality of the machined metals will be assessed with a

Nanovea 3D non-contact profilometer.

Viscoelastic Analysis of Rubber

Viscoelastic Analysis of Rubber

Learn more

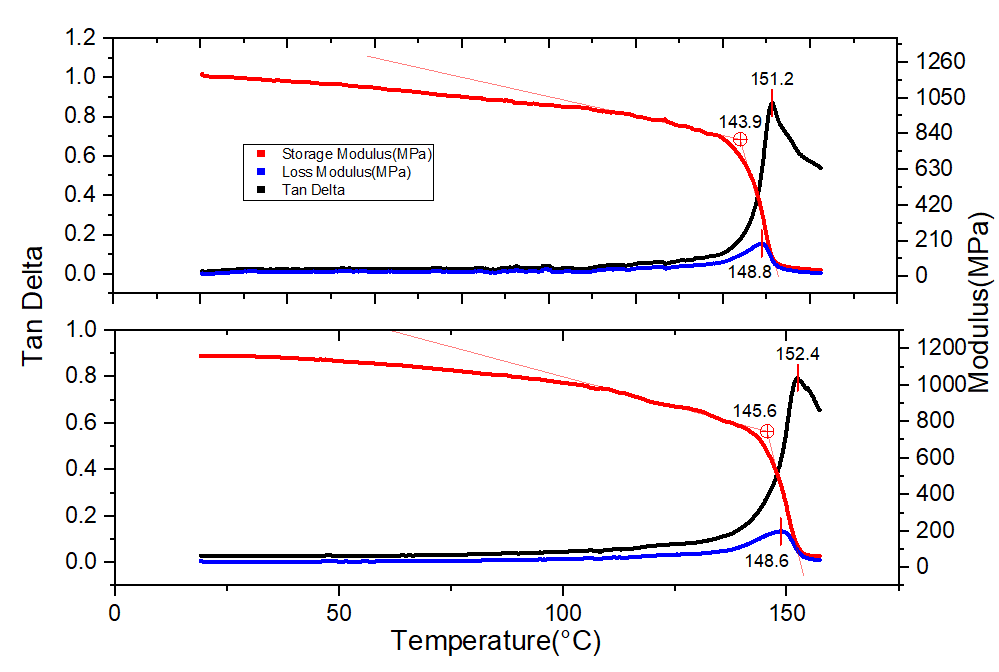

Tires are subjected to cyclical high deformations when vehicles are running on the road. When exposed to harsh road conditions, the service lifetime of the tires is jeopardized by many factors, such as the wear of the thread, the heat generated by friction, rubber aging, and others.

As a result, tires usually have composite layer structures made of carbon-filled rubber, nylon cords, and steel wires, etc. In particular, the composition of rubber at different areas of the tire systems is optimized to provide different functional properties, including but not limited to wear resistant thread, cushion rubber layer, and hard rubber base layer.

A reliable and repeatable test of the viscoelastic behavior of rubber is critical in quality control and R&D of new tires, as well as evaluation of the life span of old tires. Dynamic Mechanical Analysis(DMA) during Nanoindentation is a technique of characterizing the viscoelasticity. When controlled oscillatory stress is applied, the resulting strain is measured, allowing users to determine the complex modulus of the tested materials.

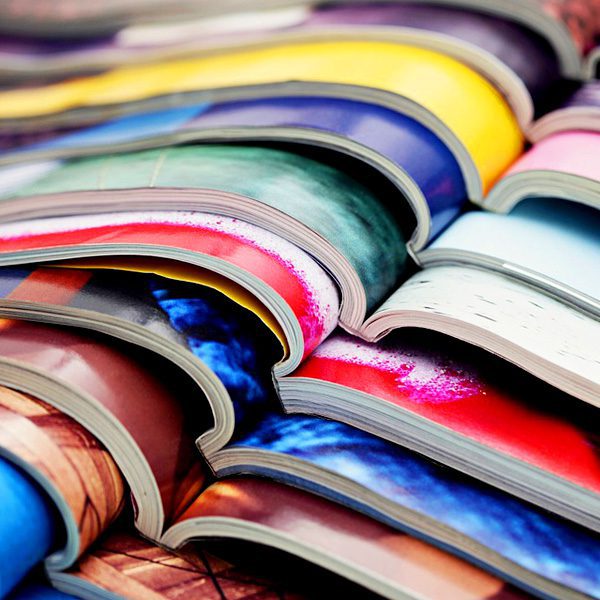

A Better Look at Paper

Paper has played a large role in information distribution since its invention in the 2nd century [1]. Paper consists of intertwined fibers, typically obtained from trees, that have been dried into thin sheets. As a medium for information storage, paper has allowed the spread of ideas, art, and history over long distances and through passing time.

Today, paper is commonly used for currency, books, toiletries, packaging, and more. Paper is processed in different ways to obtain properties to match their application. For example, the visually appealing, glossy paper from a magazine is different compared to rough, cold-pressed watercolor paper. The method in which paper is produced will affect the surface properties of the paper. This influences how ink (or other medium) will settle onto and appear on the paper. To inspect how different paper processes affect surface properties, Nanovea inspected the roughness and texture of various types of paper by conducting a large area scan with our 3D Non-Contact Profilometer.

Click to learn about the Surface Roughness of Paper!

A BETTER Look at Polycarbonate Lens

Categories

- Application Notes

- Block on Ring Tribology

- Corrosion Tribology

- Friction Testing | Coefficient of Friction

- High Temperature Mechanical Testing

- High Temperature Tribology

- Humidity and Gases Tribology

- Humidity Mechanical Testing

- Indentation | Creep and Relaxation

- Indentation | Fracture Toughness

- Indentation | Hardness and Elastic

- Indentation | Loss and Storage

- Indentation | Stress vs Strain

- Indentation | Yield Strength and Fatigue

- Laboratory Testing

- Linear Tribology

- Liquid Mechanical Testing

- Liquid Tribology

- Low Temperature Tribology

- Mechanical Testing

- Press Release

- Profilometry | Flatness and Warpage

- Profilometry | Geometry and Shape

- Profilometry | Roughness and Finish

- Profilometry | Step Height and Thickness

- Profilometry | Texture and Grain

- Profilometry | Volume and Area

- Profilometry Testing

- Ring on Ring Tribology

- Rotational Tribology

- Scratch Testing | Adhesive Failure

- Scratch Testing | Cohesive Failure

- Scratch Testing | Multi-Pass Wear

- Scratch Testing | Scratch Hardness

- Scratch Testing Tribology

- Tribology Testing

- Uncategorized

Archives

- November 2025

- September 2023

- August 2023

- June 2023

- May 2023

- July 2022

- May 2022

- April 2022

- January 2022

- December 2021

- November 2021

- October 2021

- September 2021

- August 2021

- July 2021

- June 2021

- May 2021

- March 2021

- February 2021

- December 2020

- November 2020

- October 2020

- September 2020

- July 2020

- May 2020

- April 2020

- March 2020

- February 2020

- January 2020

- November 2019

- October 2019

- September 2019

- August 2019

- July 2019

- June 2019

- May 2019

- April 2019

- March 2019

- January 2019

- December 2018

- November 2018

- October 2018

- September 2018

- July 2018

- June 2018

- April 2018

- March 2018

- February 2018

- November 2017

- October 2017

- September 2017

- August 2017

- June 2017

- May 2017

- March 2017

- February 2017

- January 2017

- November 2016

- October 2016

- August 2016

- July 2016

- June 2016

- May 2016

- April 2016

- March 2016

- February 2016

- January 2016

- December 2015

- November 2015

- October 2015

- September 2015

- August 2015

- July 2015

- June 2015

- May 2015

- April 2015

- March 2015

- February 2015

- January 2015

- November 2014

- October 2014

- September 2014

- August 2014

- July 2014

- June 2014

- May 2014

- April 2014

- March 2014

- February 2014

- January 2014

- December 2013

- November 2013

- October 2013

- September 2013

- August 2013

- July 2013

- June 2013

- May 2013

- April 2013

- March 2013

- February 2013

- January 2013

- December 2012

- November 2012

- October 2012

- September 2012

- August 2012

- July 2012

- June 2012

- May 2012

- April 2012

- March 2012

- February 2012

- January 2012

- December 2011

- November 2011

- October 2011

- September 2011

- August 2011

- July 2011

- June 2011

- May 2011

- November 2010

- January 2010

- April 2009

- March 2009

- January 2009

- December 2008

- October 2008

- August 2007

- July 2006

- March 2006

- January 2005

- April 2004