INTRODUCTION

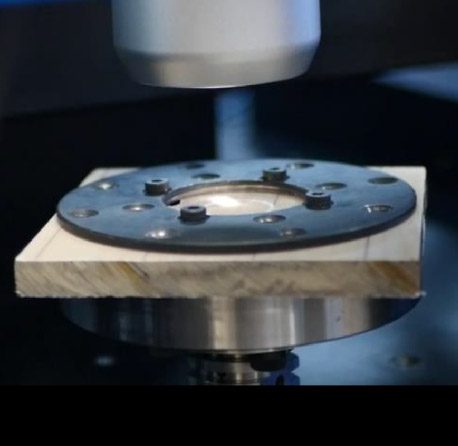

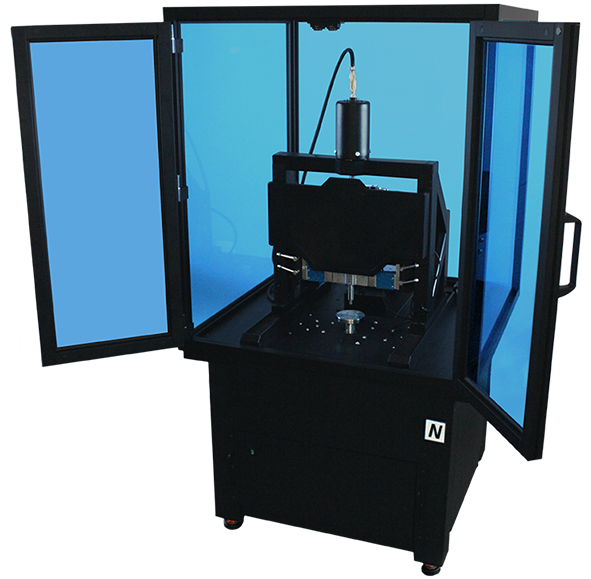

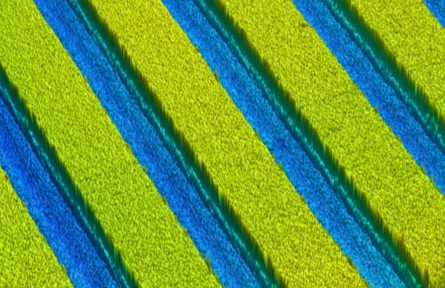

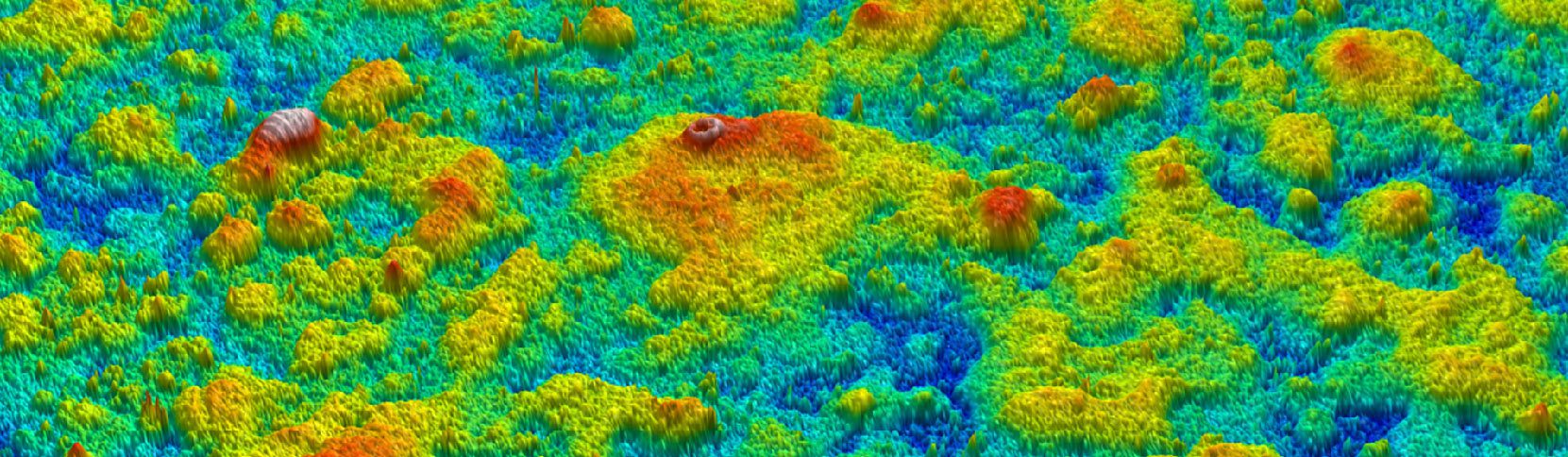

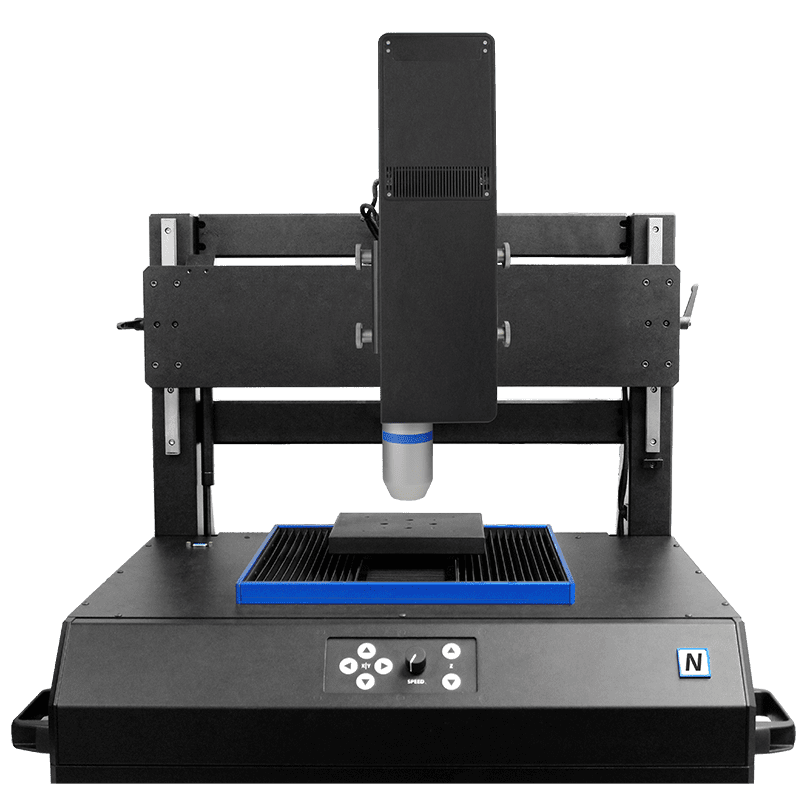

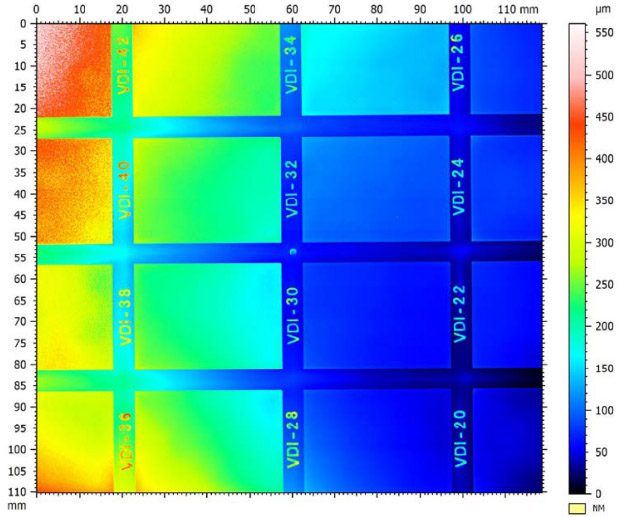

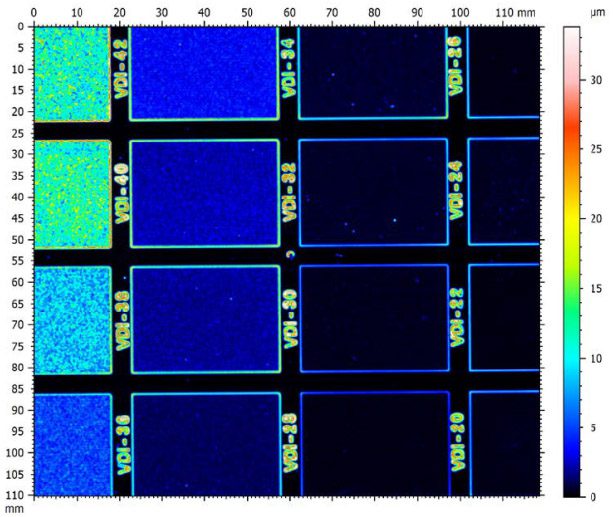

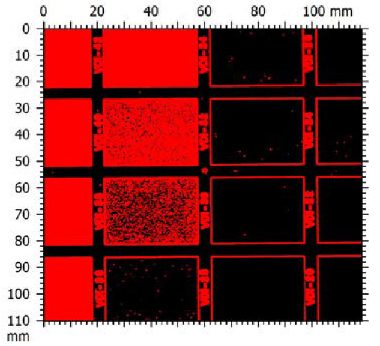

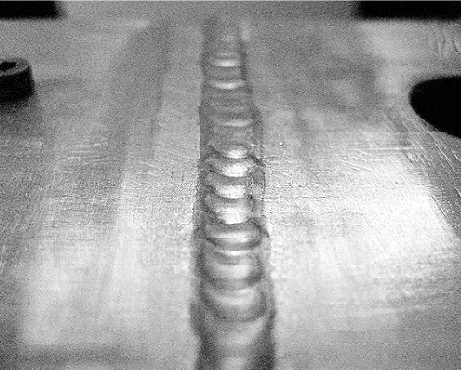

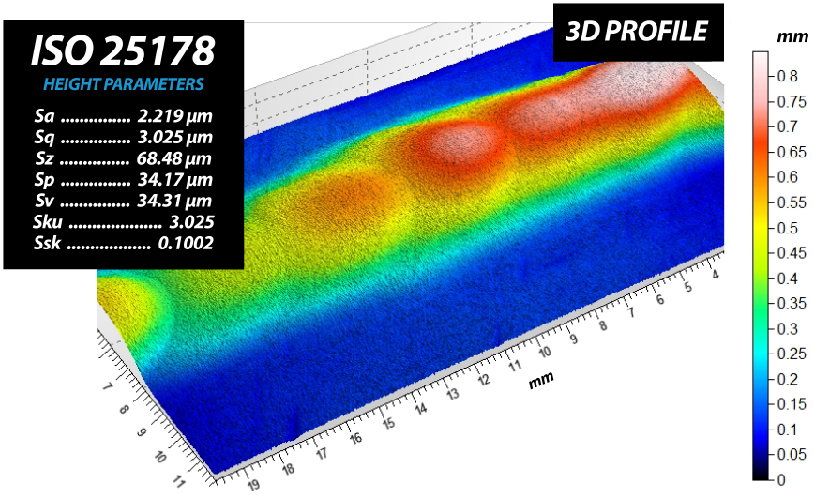

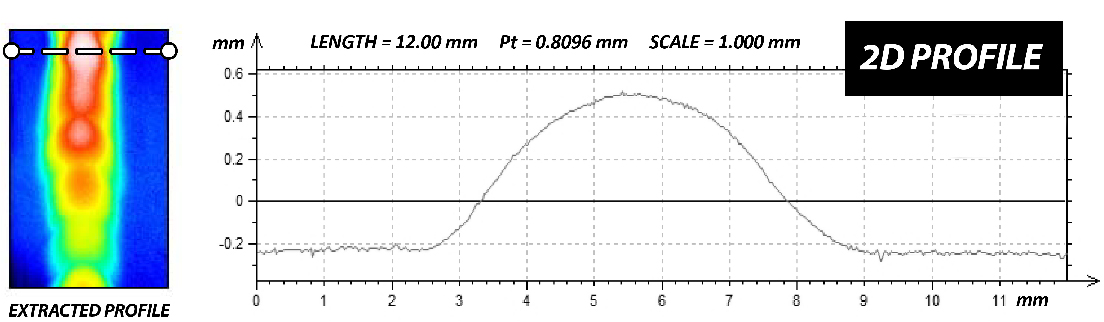

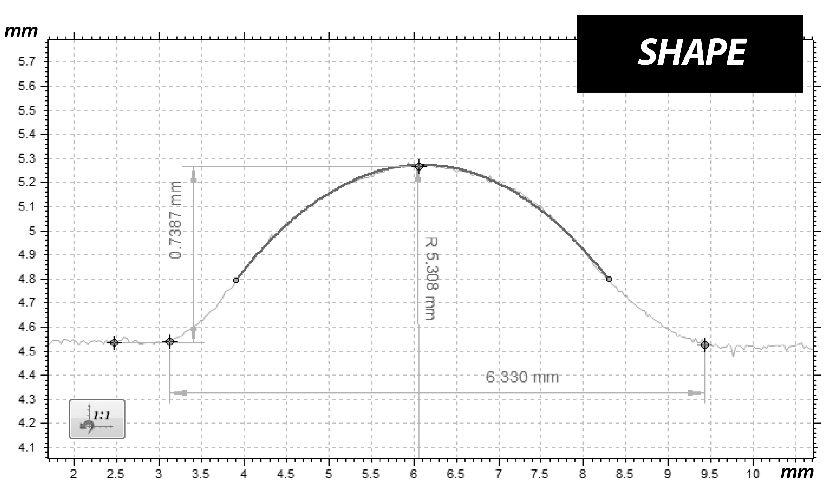

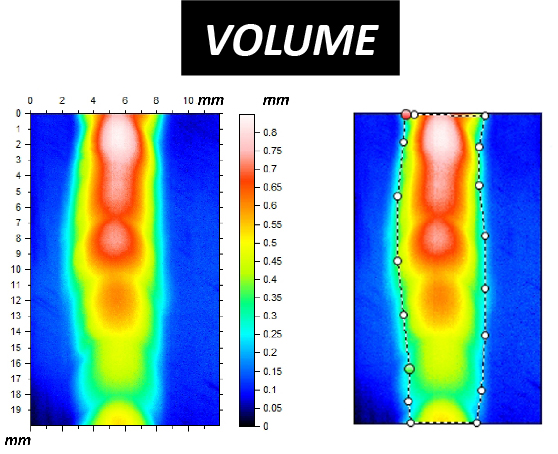

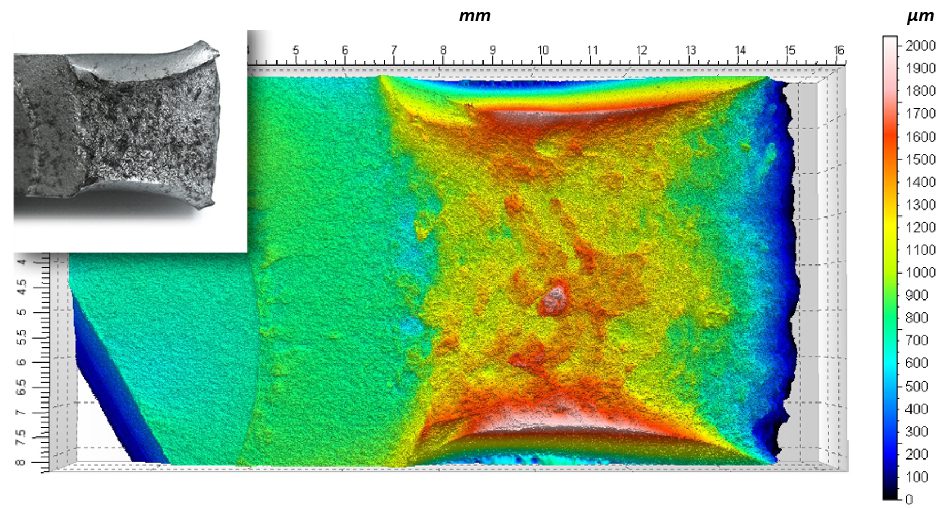

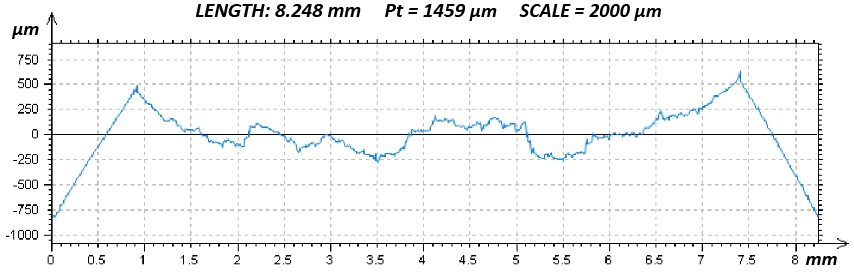

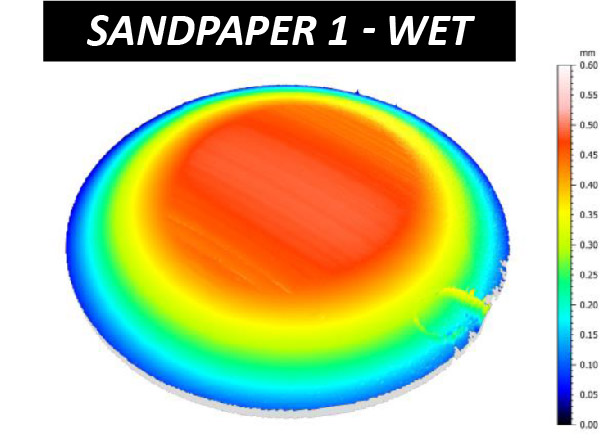

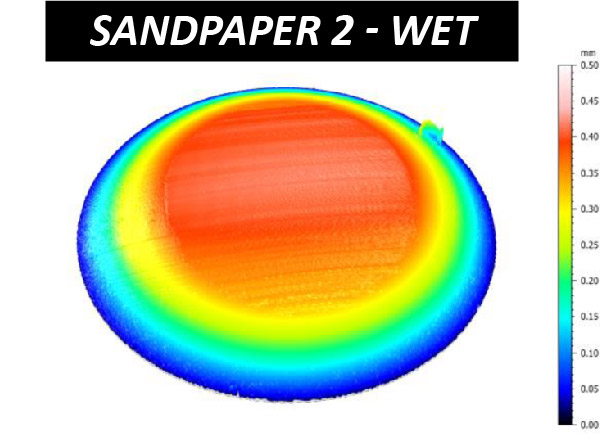

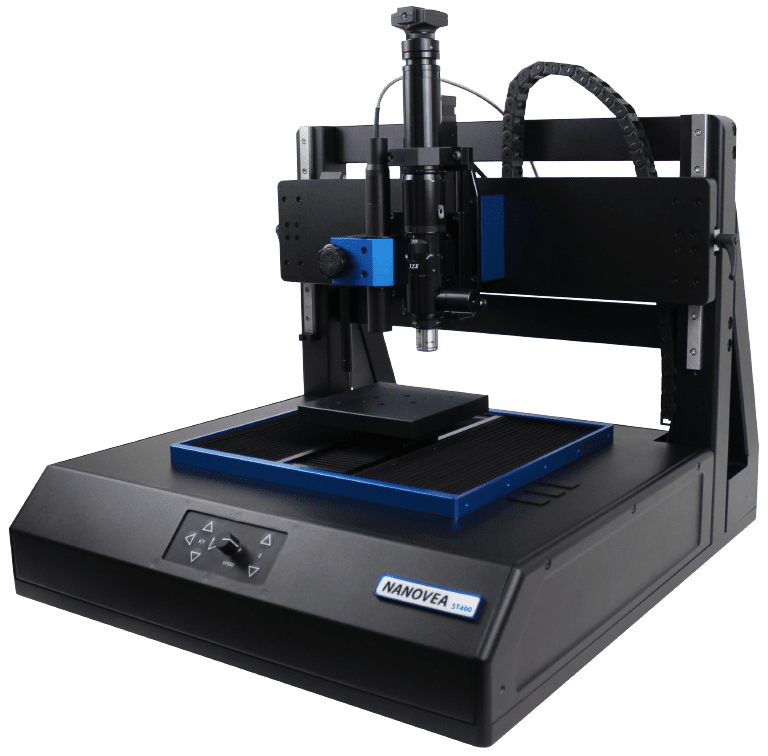

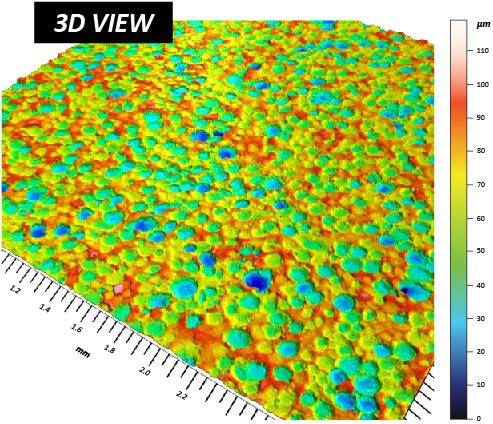

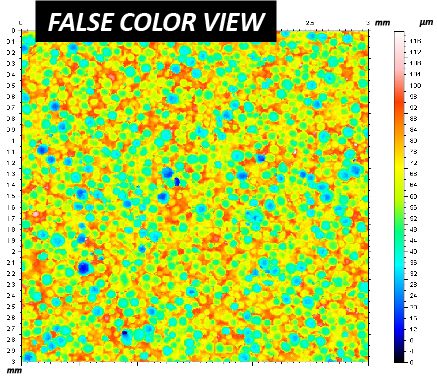

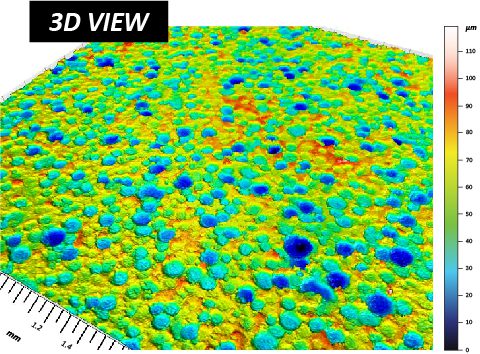

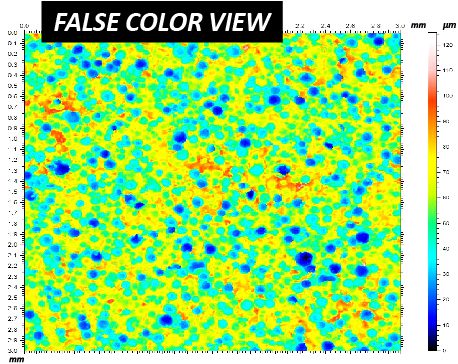

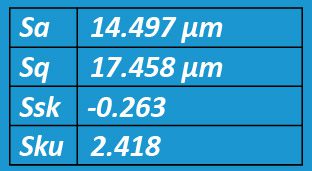

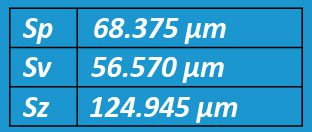

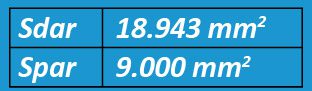

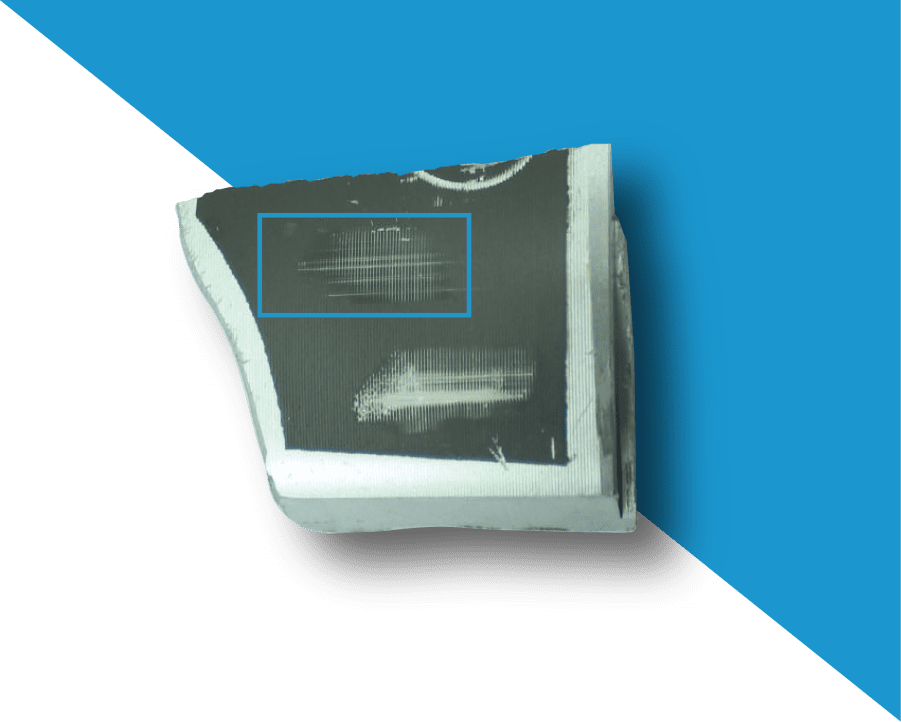

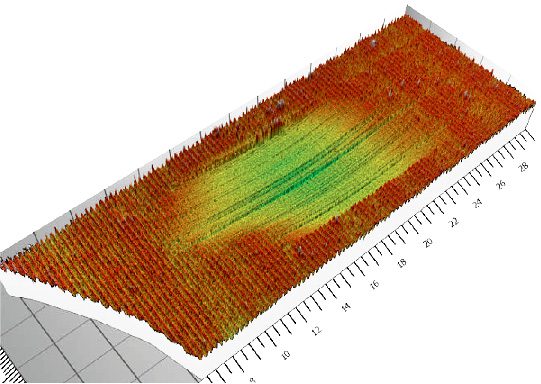

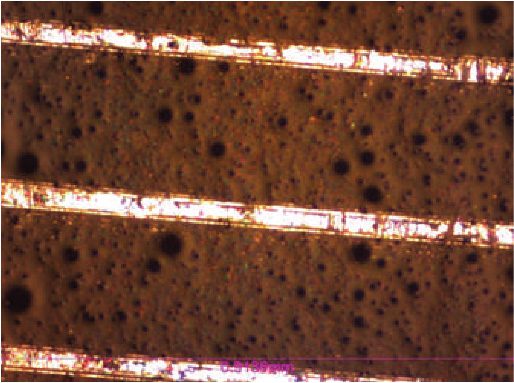

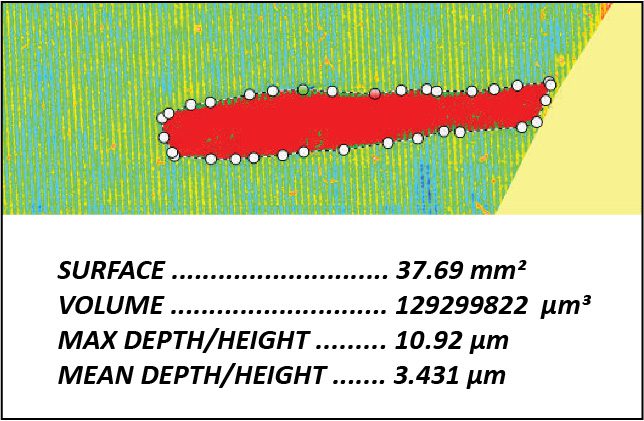

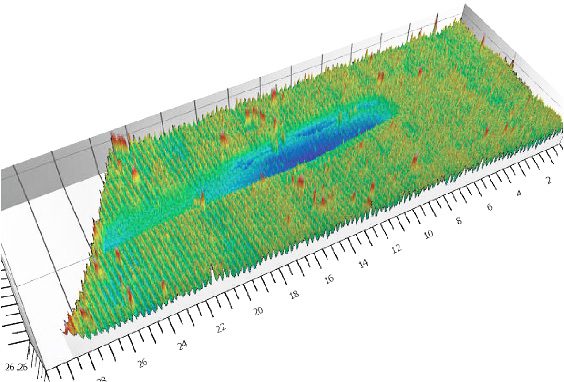

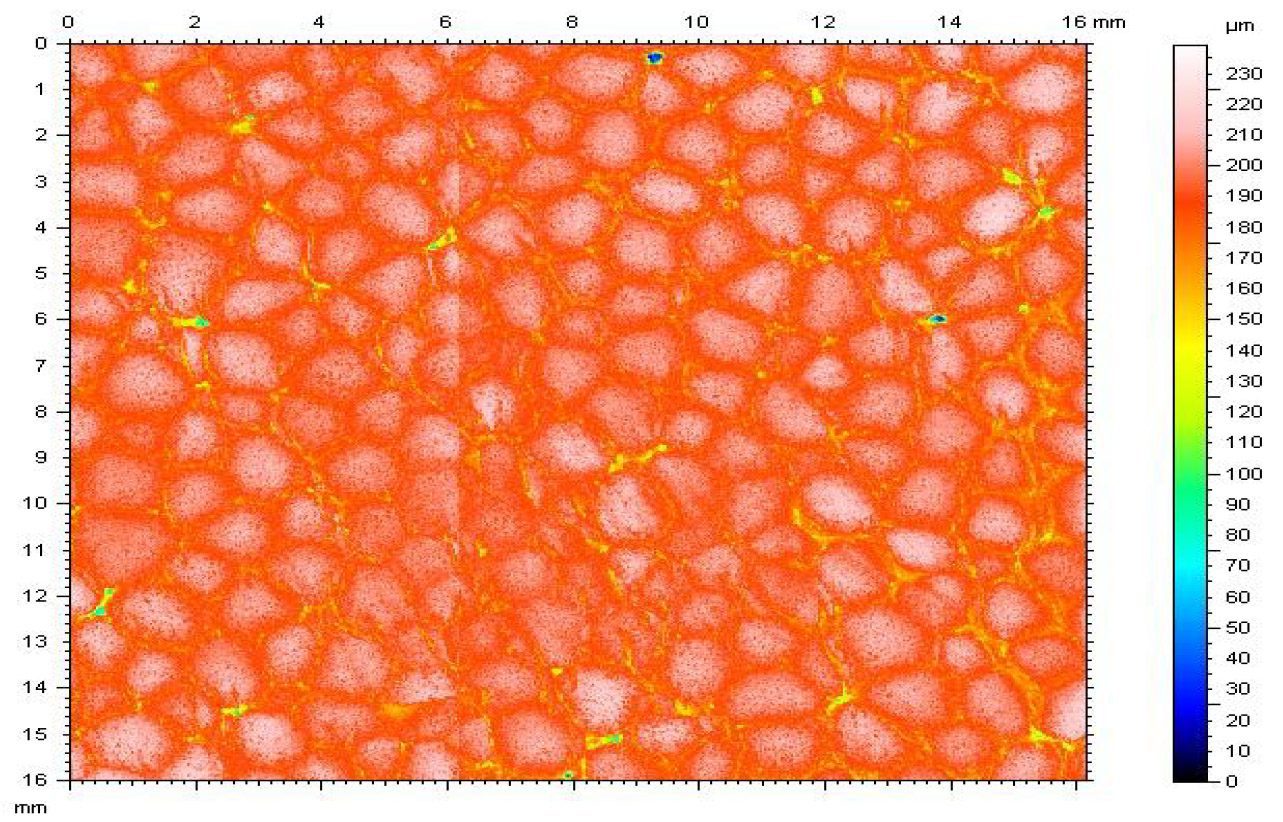

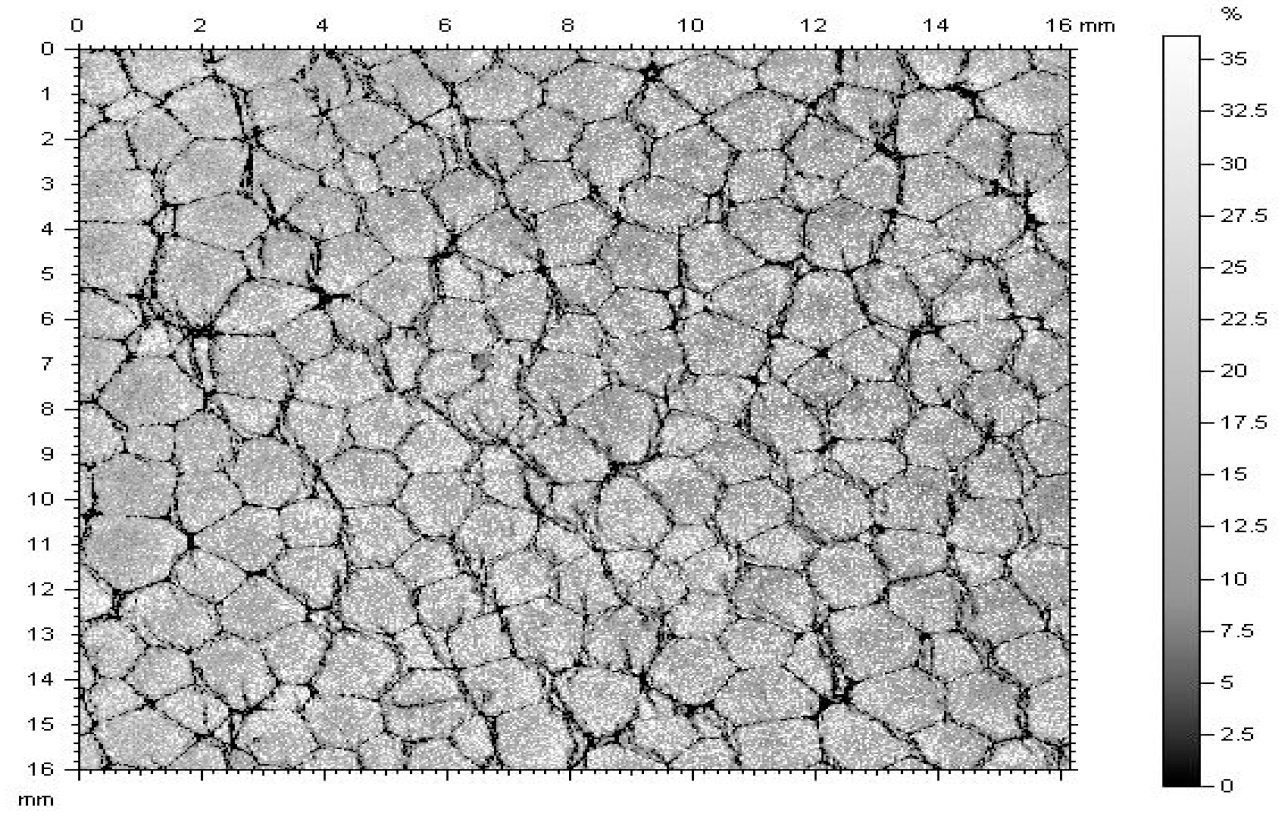

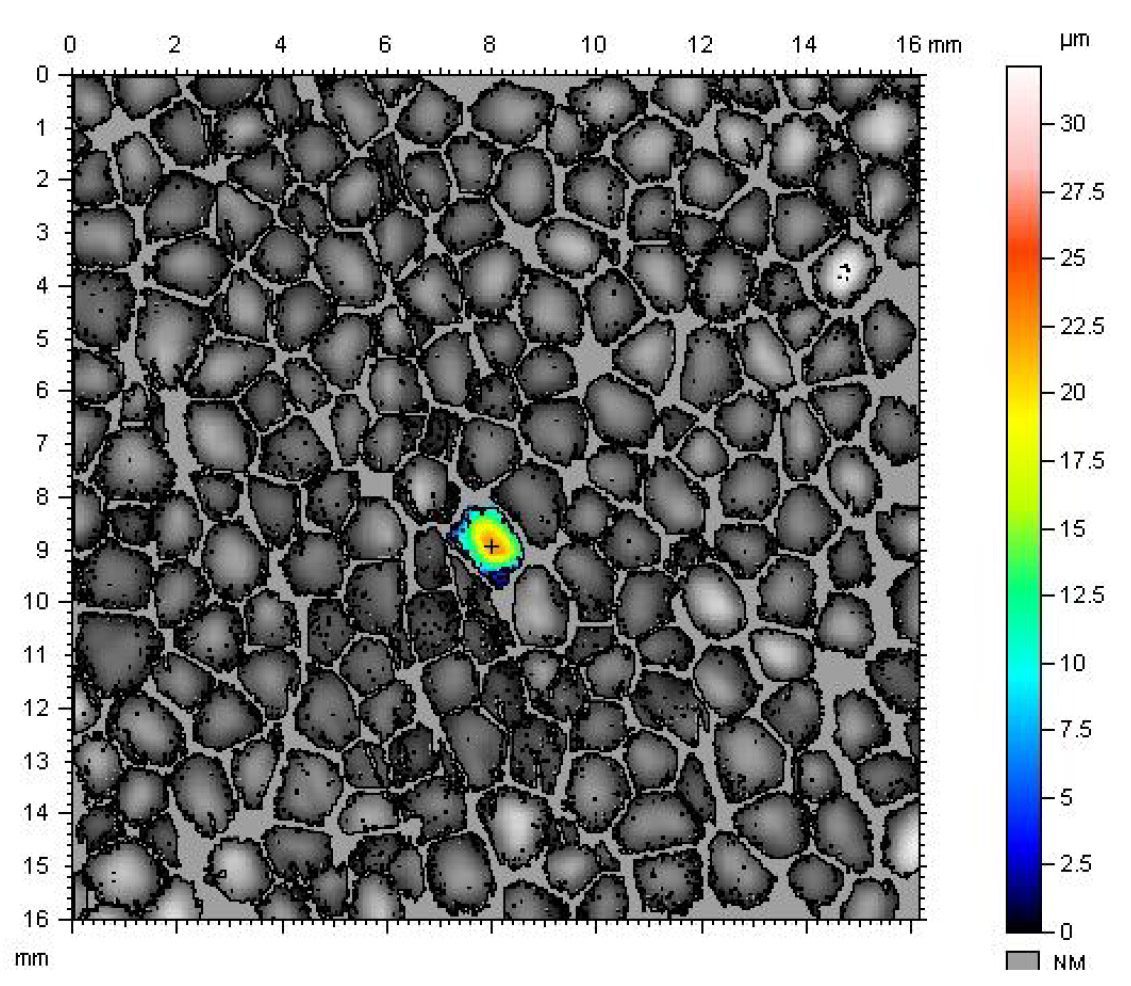

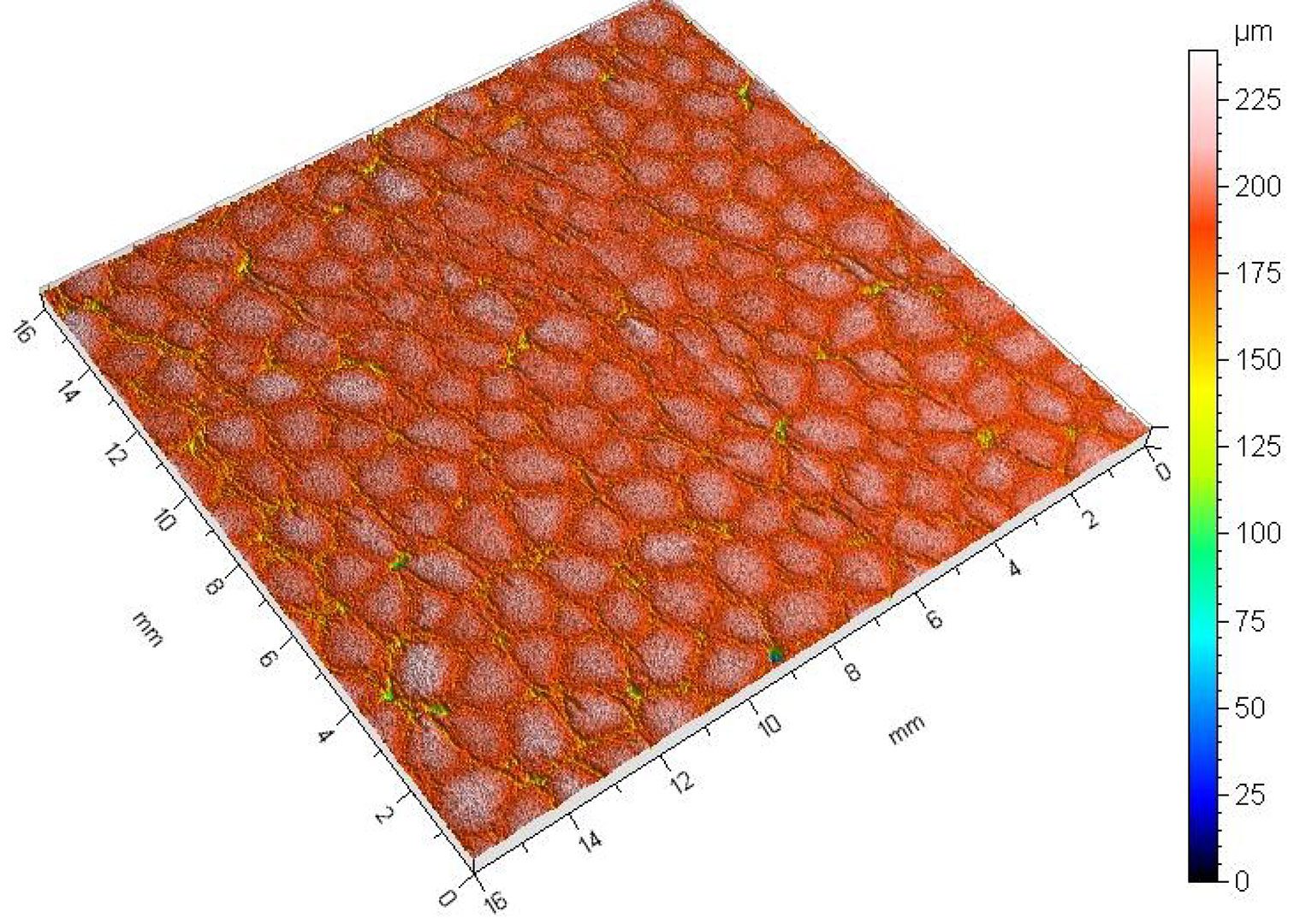

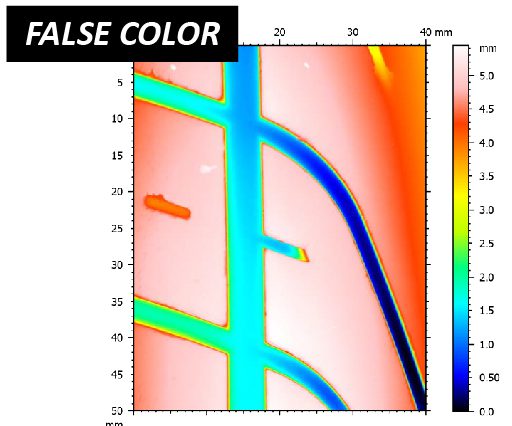

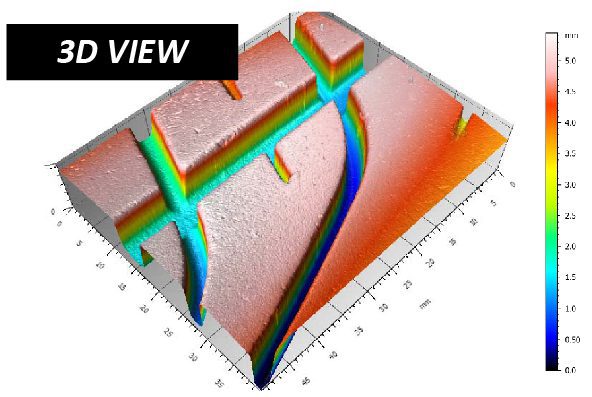

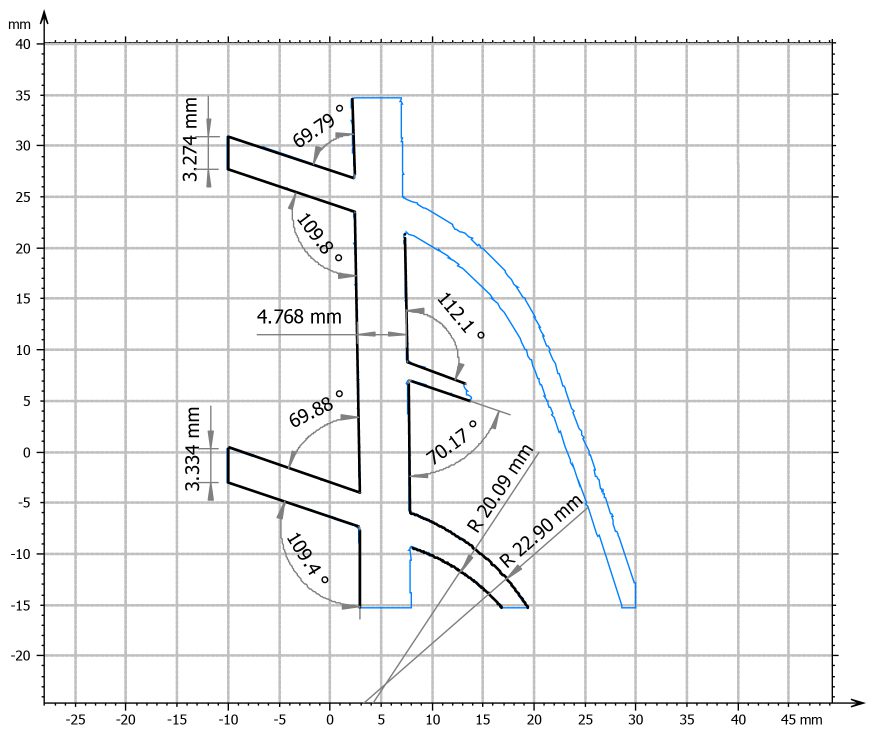

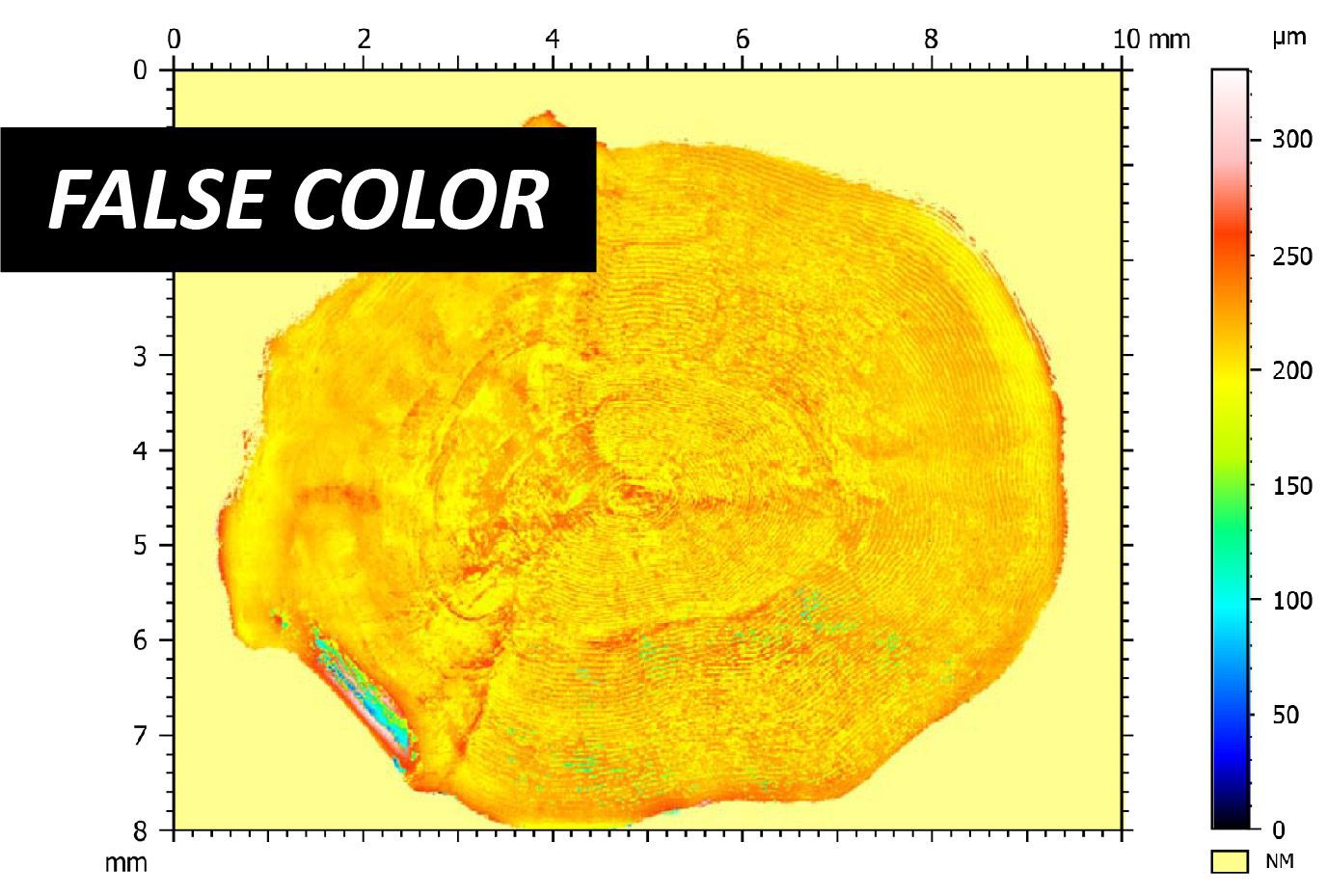

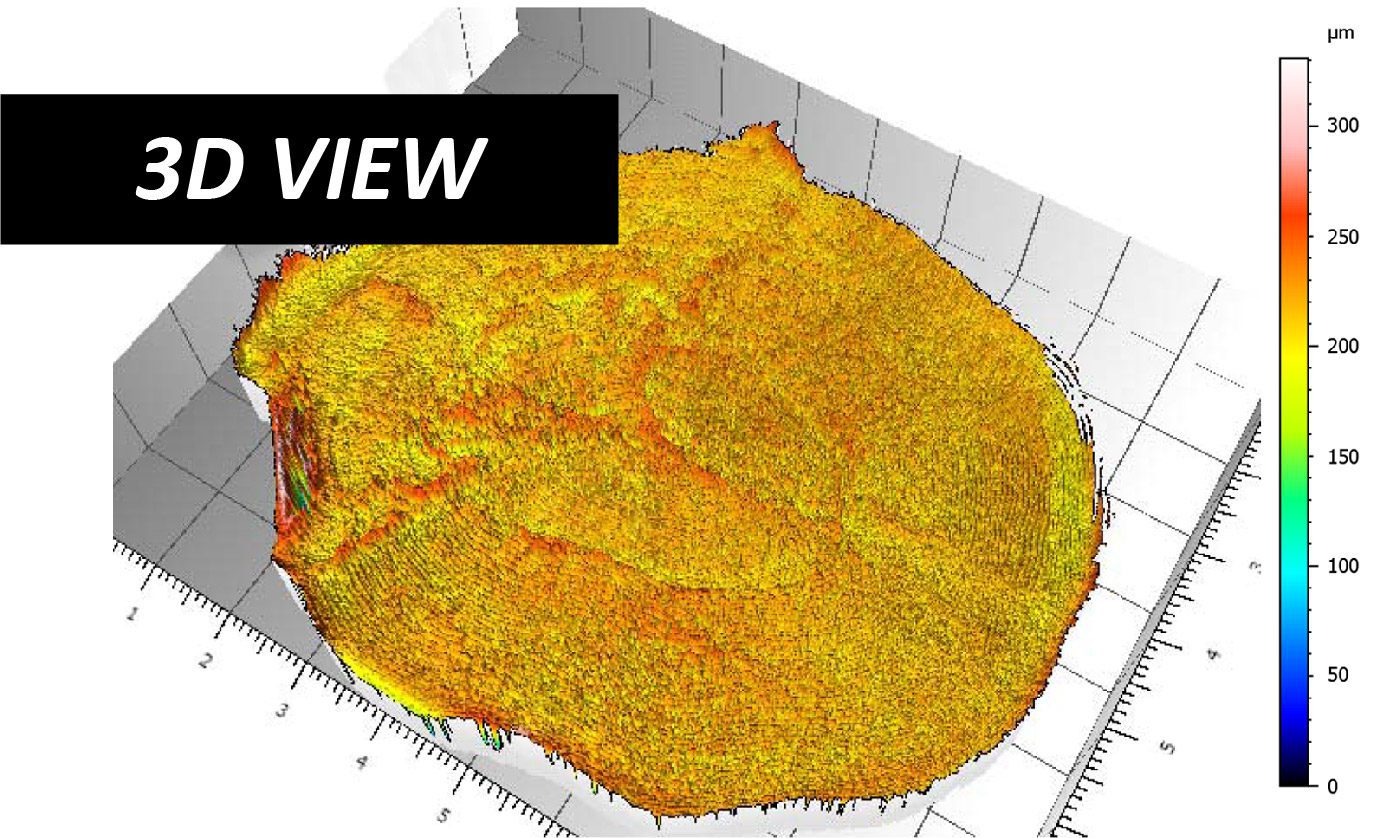

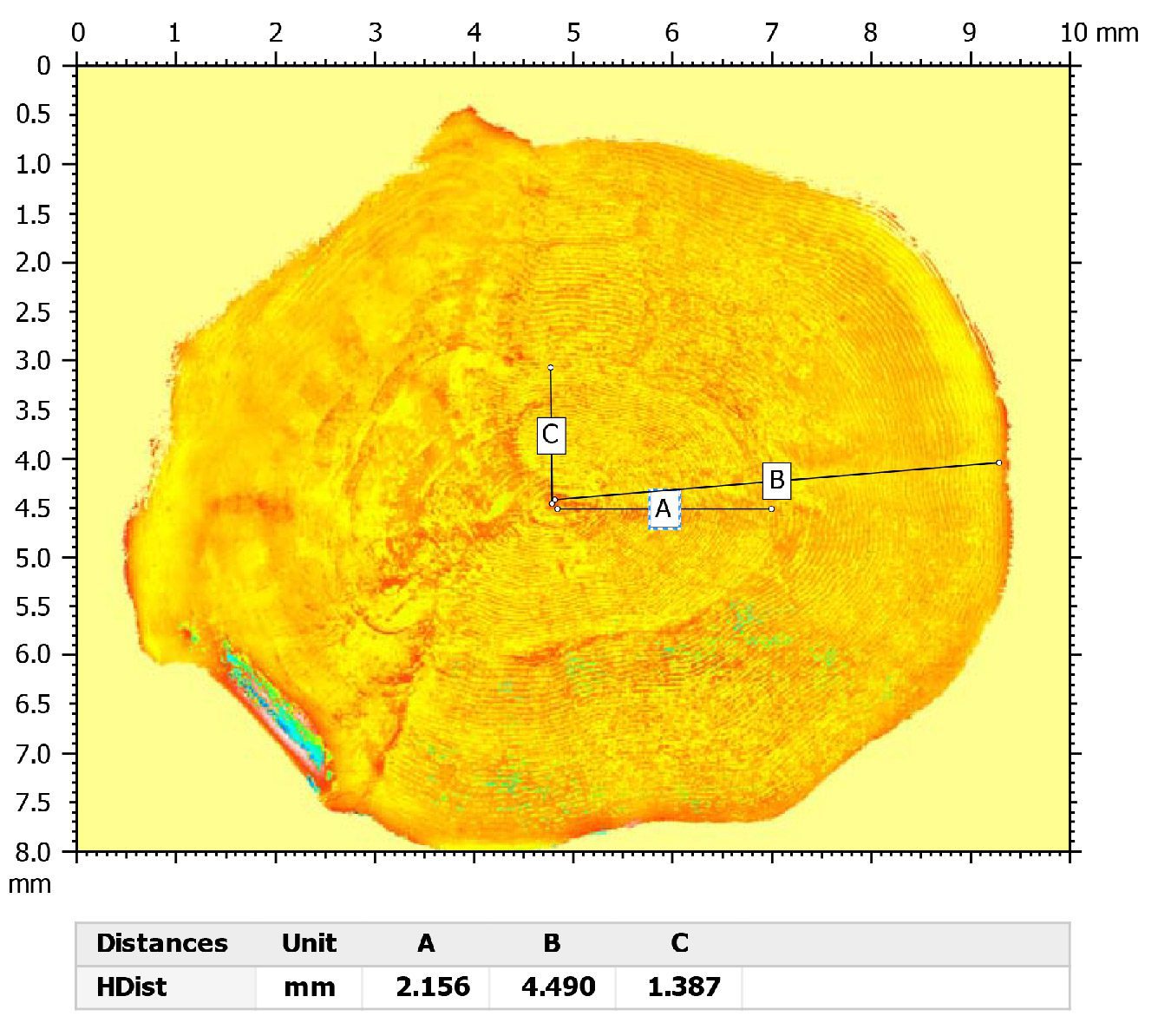

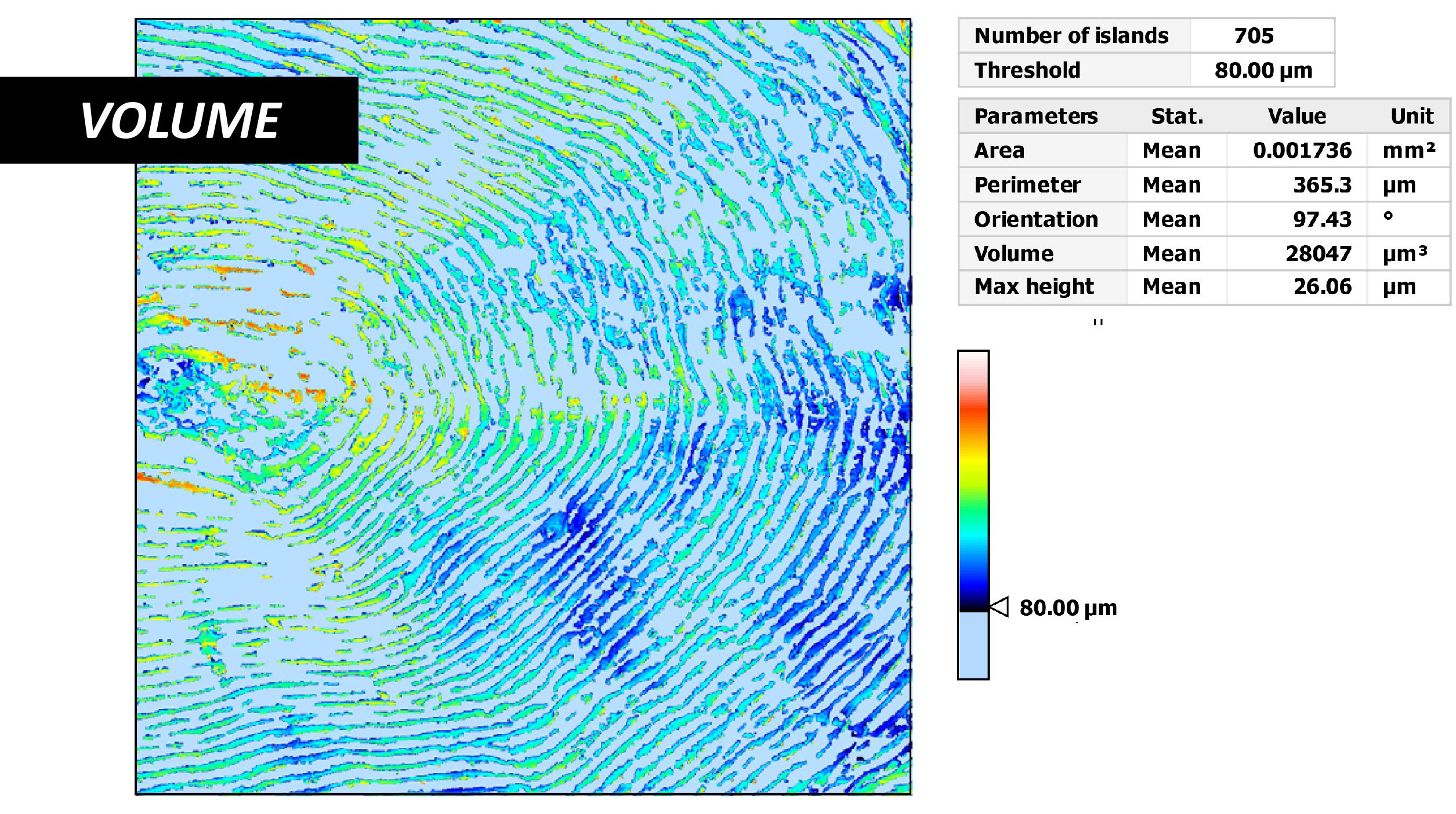

Flooring materials are designed to be durable, but they often suffer wear and tear from everyday activities such as movement and furniture use. To ensure their longevity, most types of flooring have a protective wear layer that resists damage. However, the thickness and durability of the wear layer vary depending on the flooring type and level of foot traffic. In addition, different layers within the flooring structure, such as UV coatings, decorative layers, and glaze, have varying wear rates. That’s where progressive wear mapping comes in. Using the NANOVEA T2000 Tribometer with an integrated 3D Non-Contact Profilometer, precise monitoring, and analysis of the performance and longevity of flooring materials can be done. By providing detailed insight into the wear behavior of various flooring materials, scientists and technical professionals can make more informed decisions when selecting and designing new flooring systems.

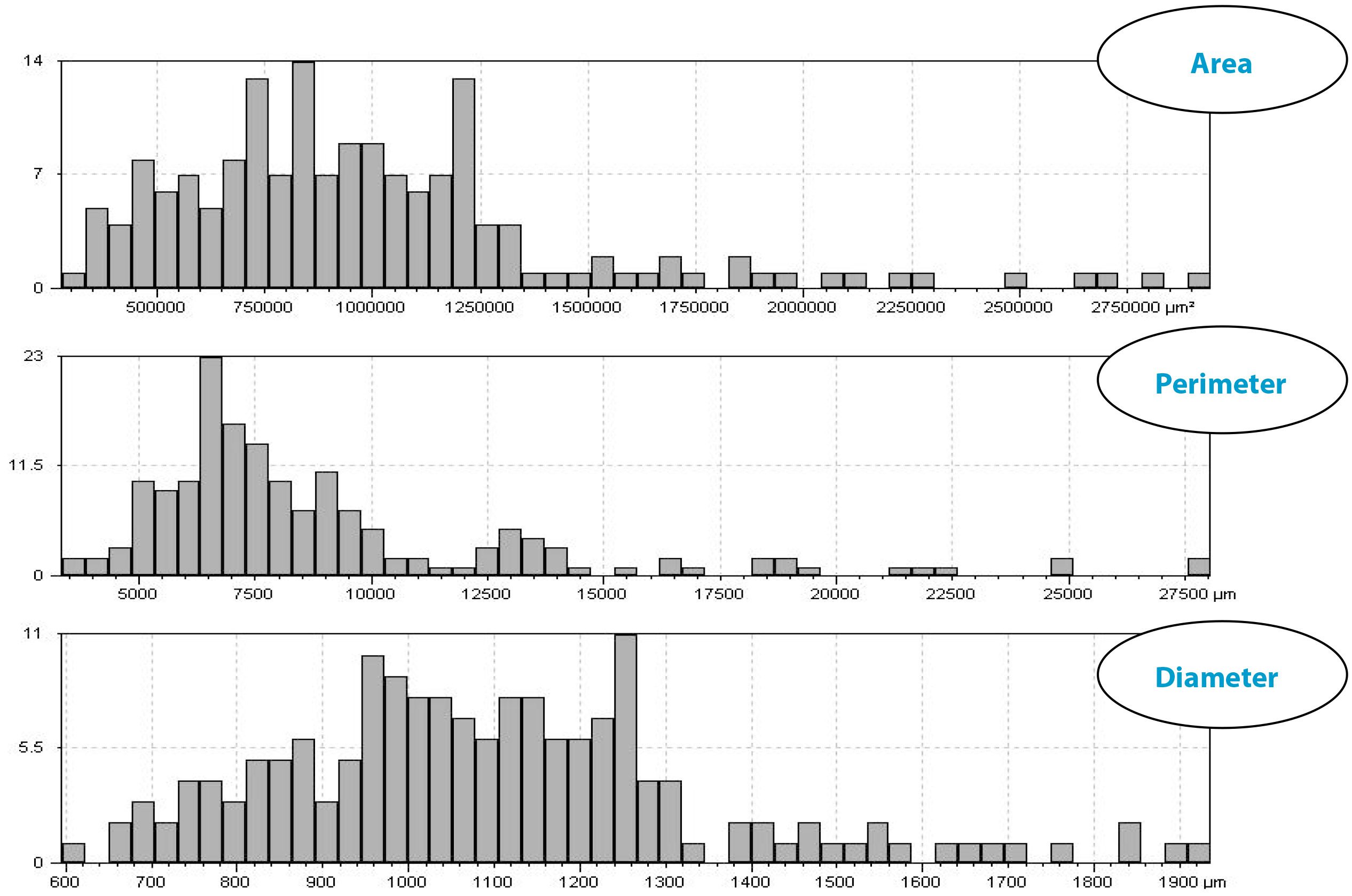

IMPORTANCE OF PROGRESSIVE WEAR MAPPING FOR FLOOR PANELS

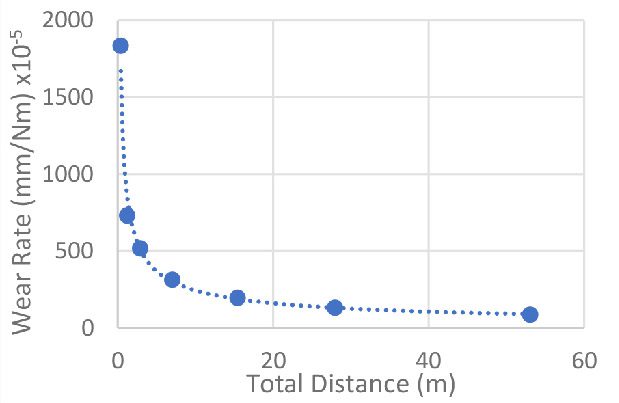

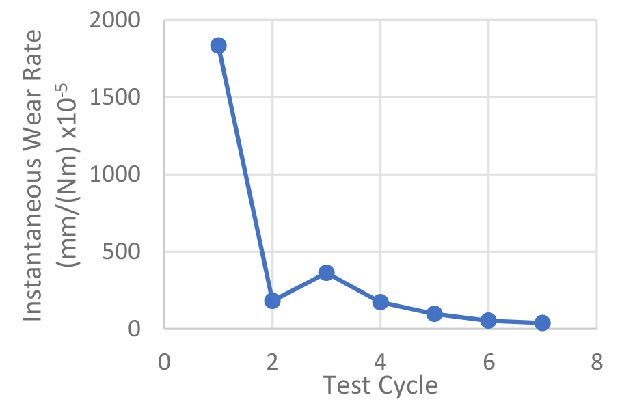

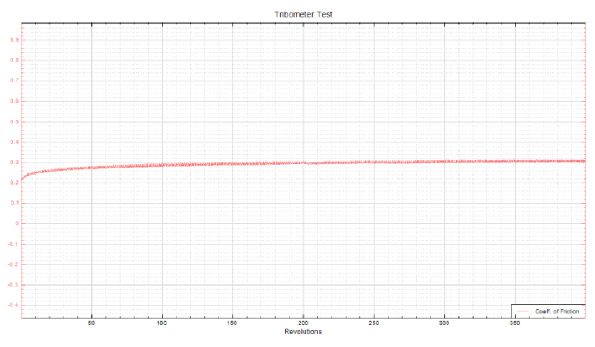

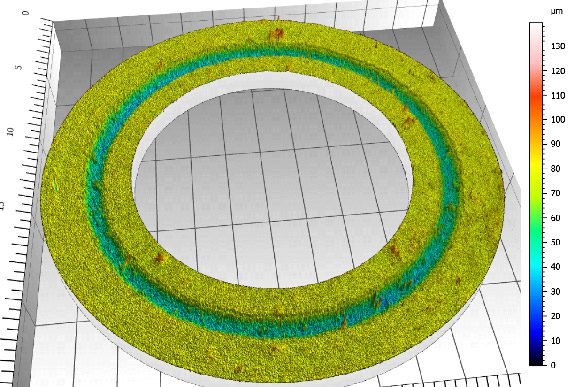

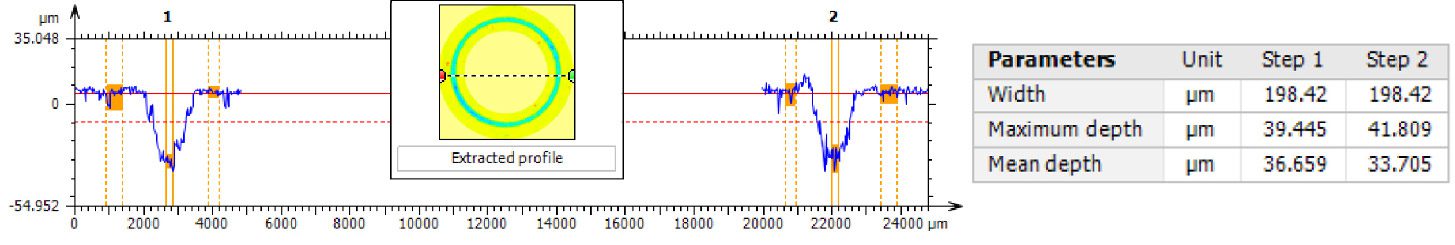

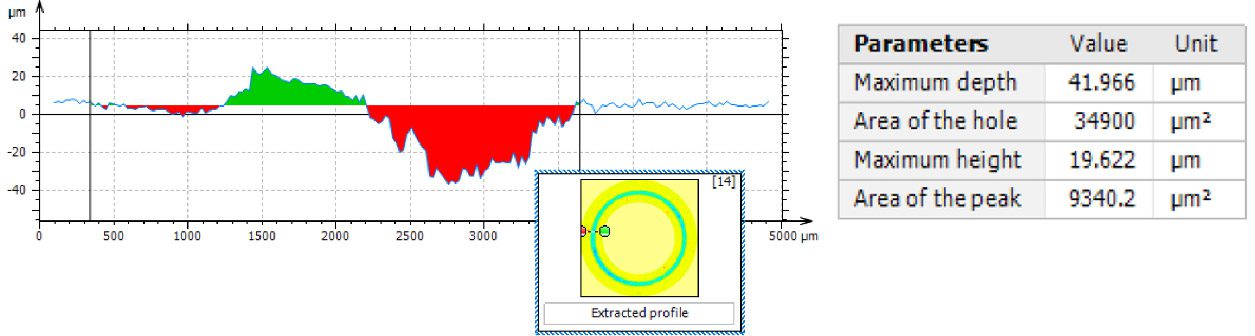

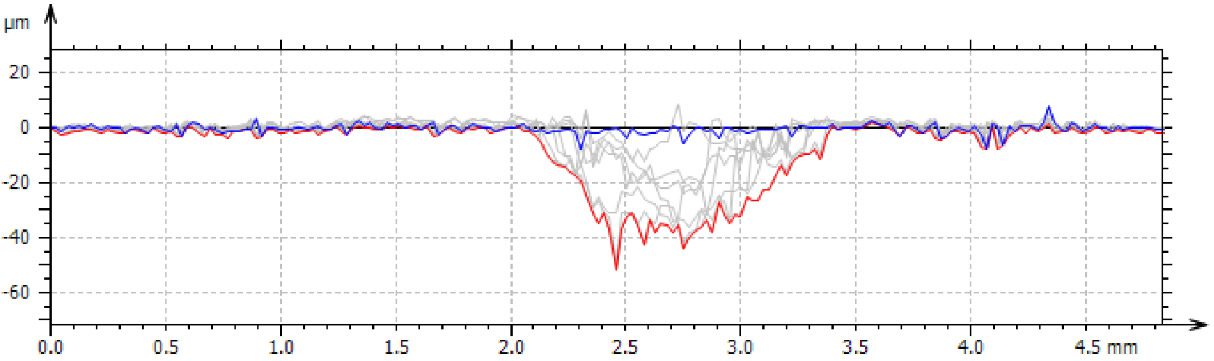

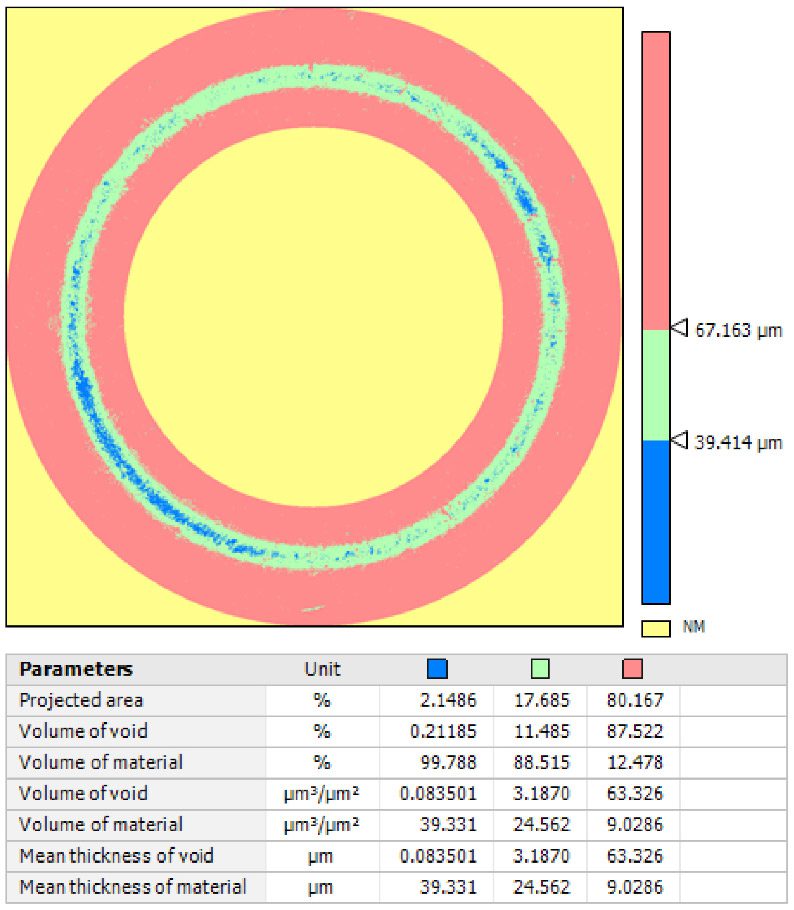

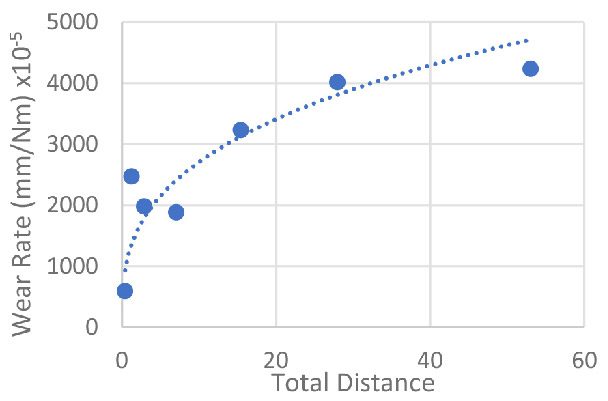

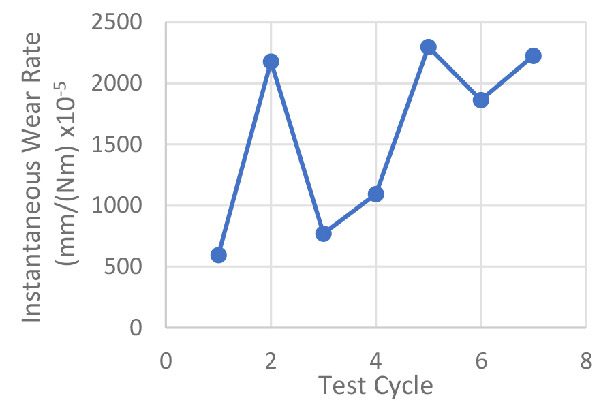

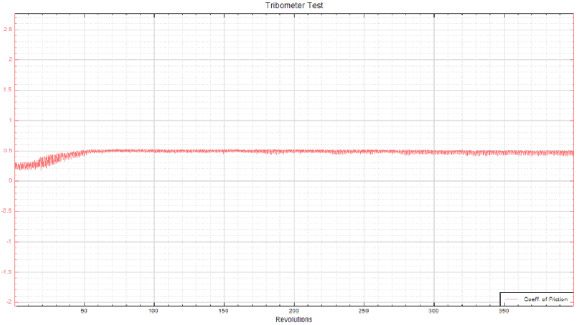

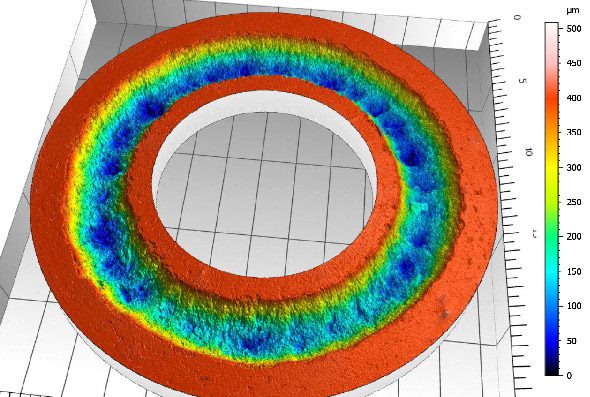

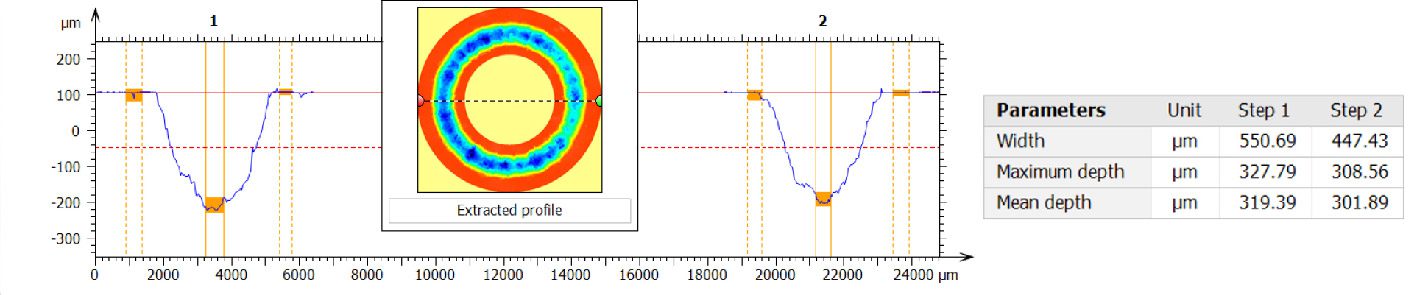

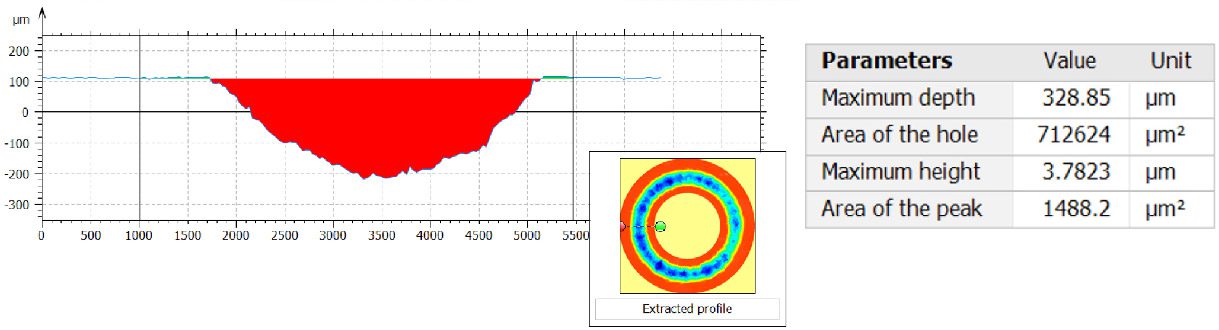

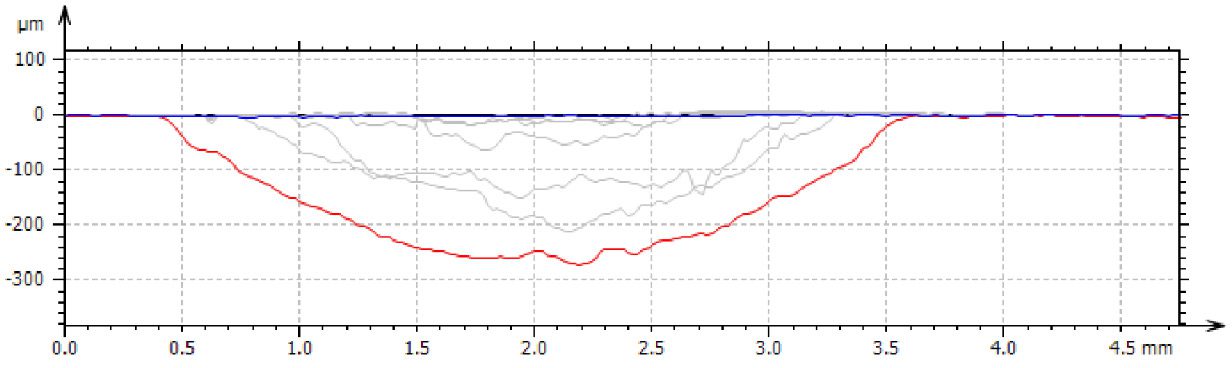

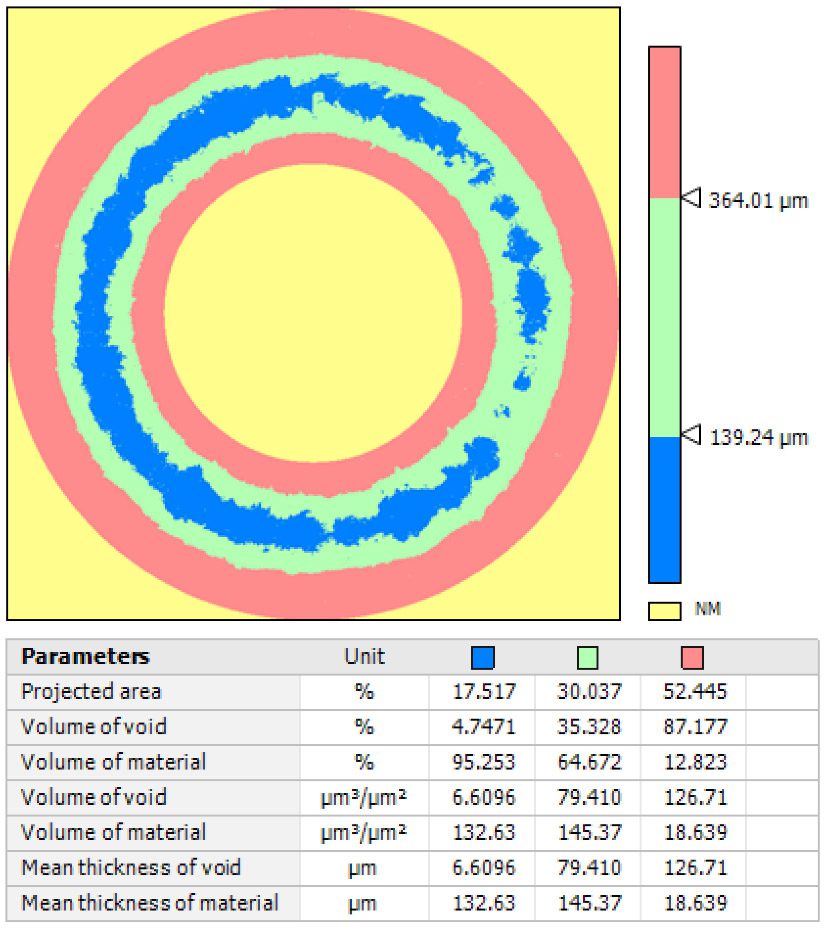

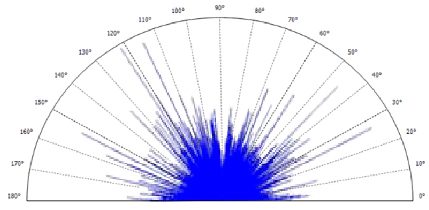

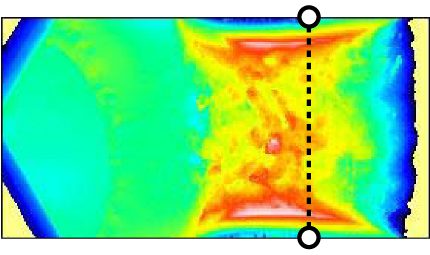

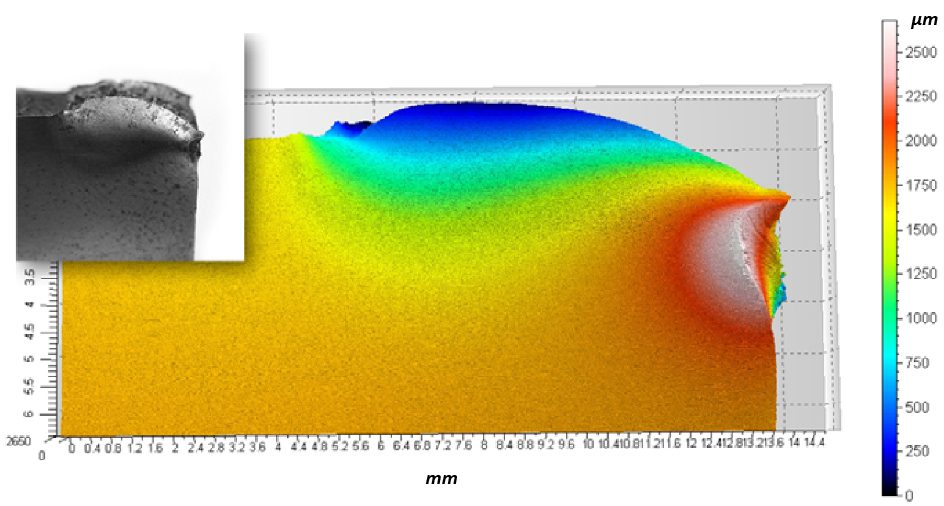

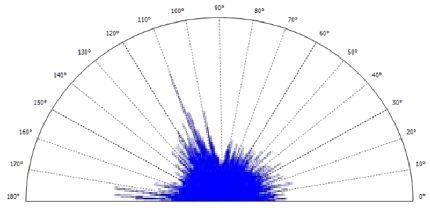

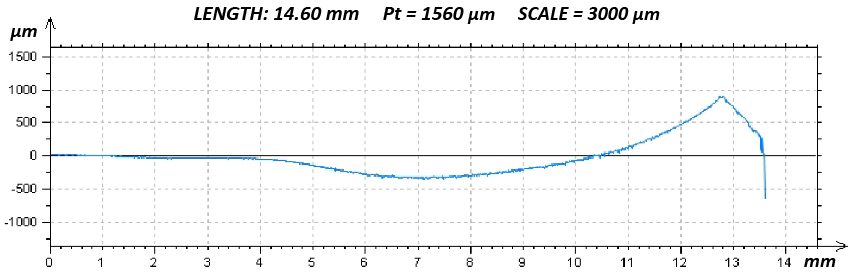

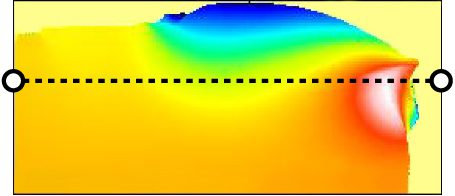

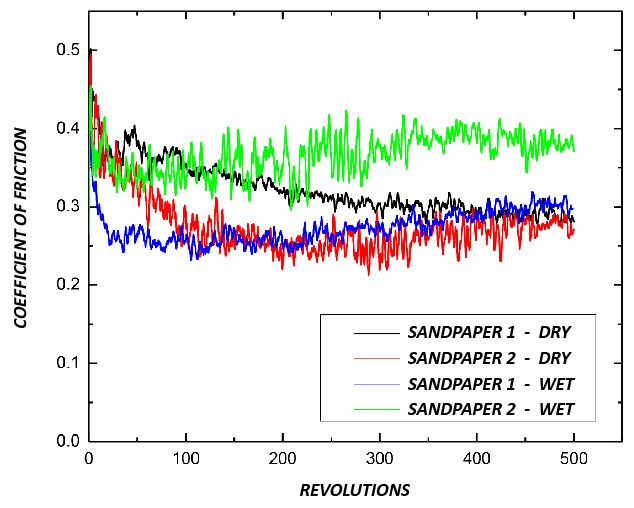

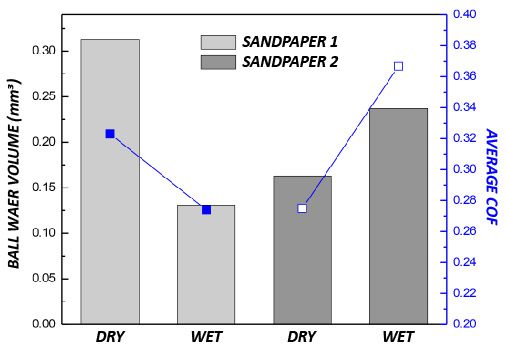

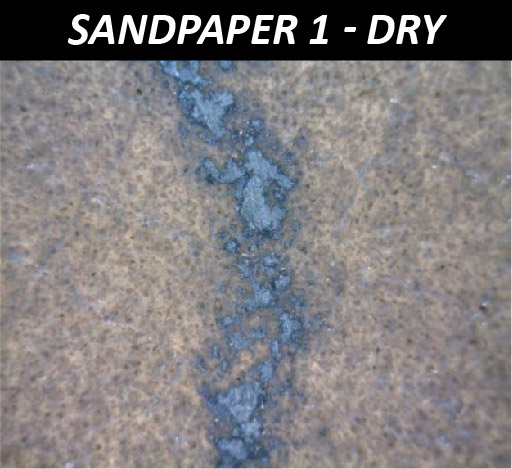

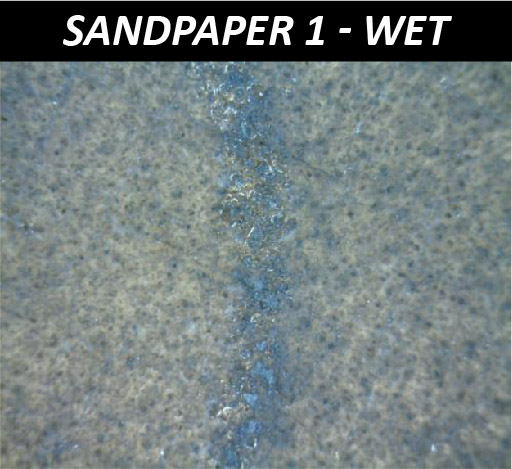

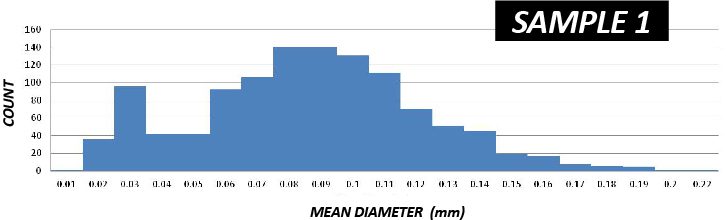

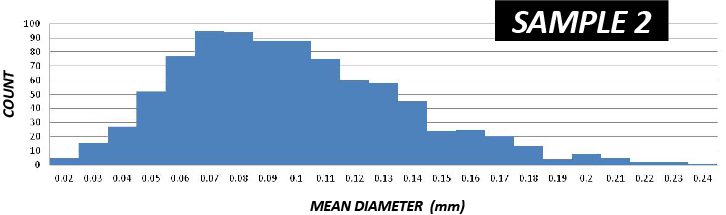

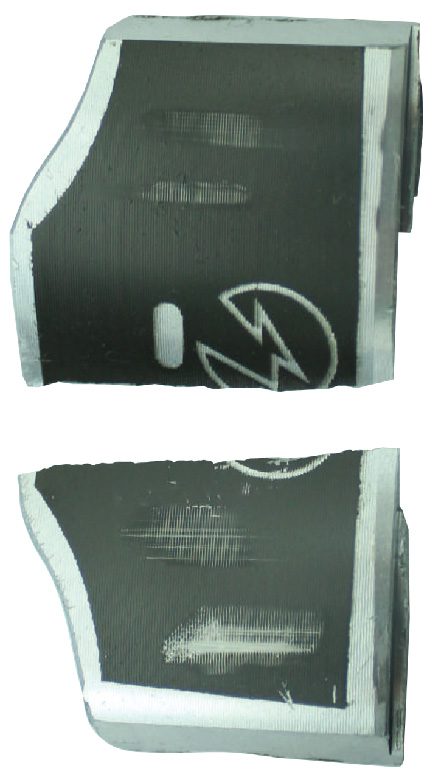

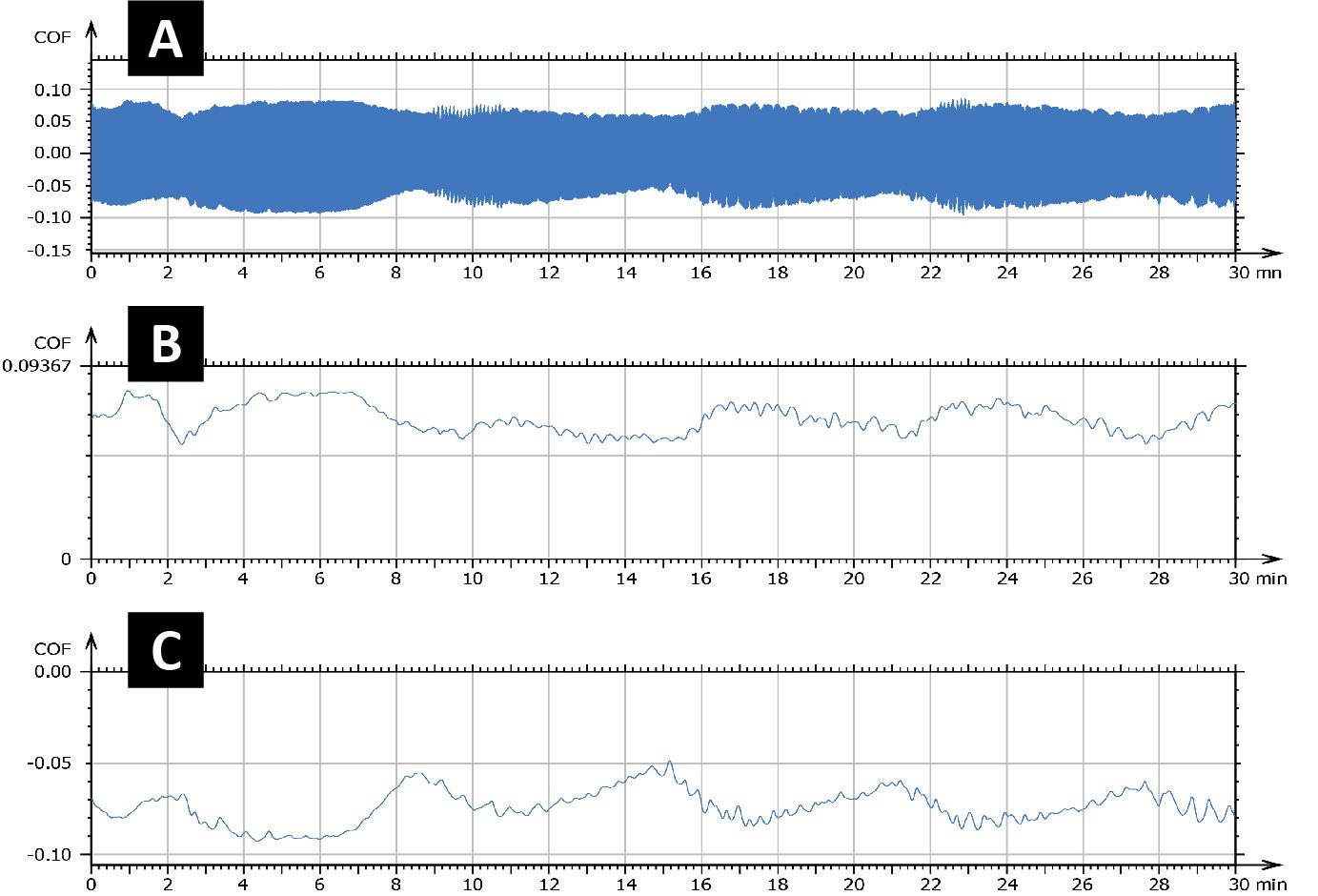

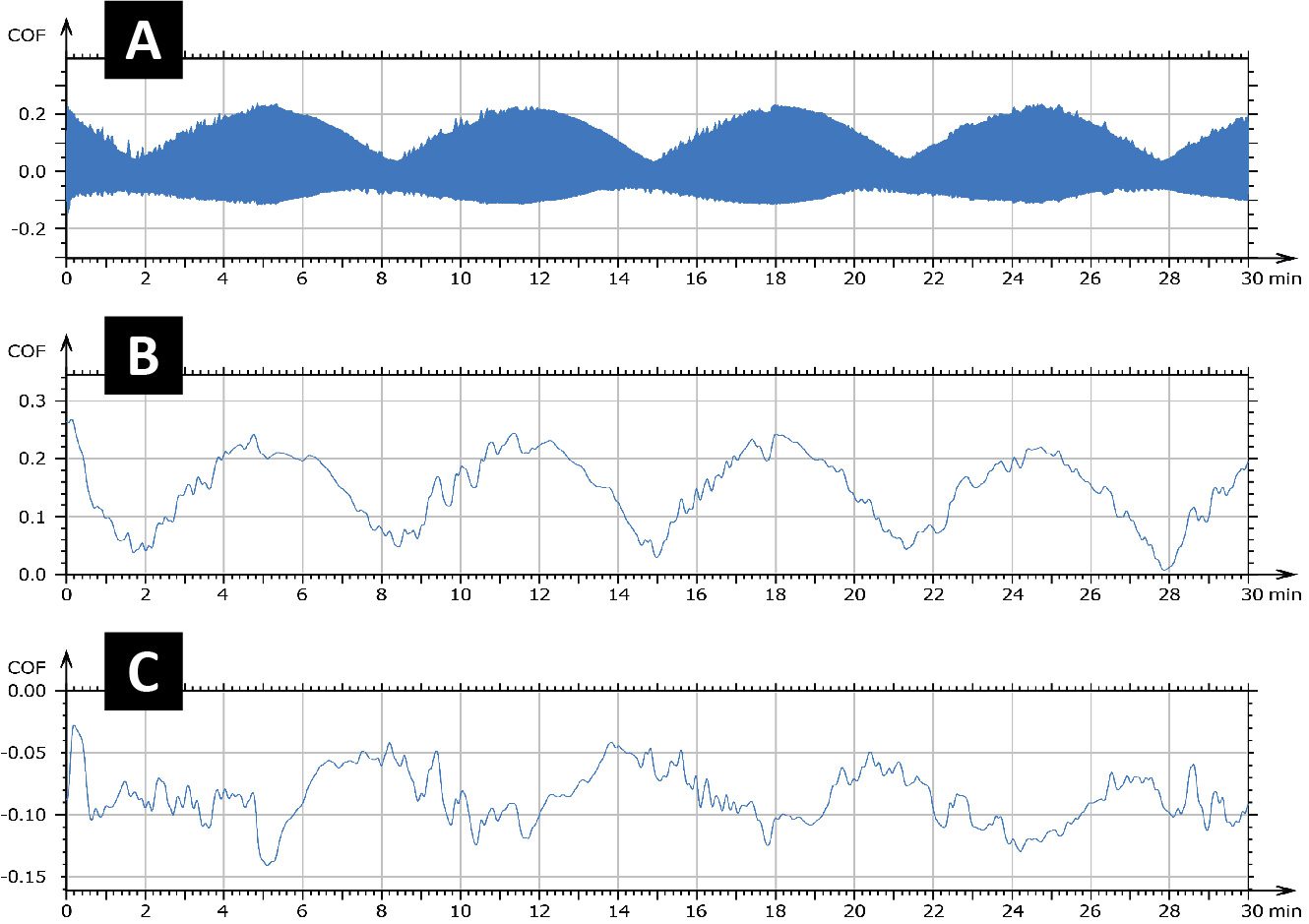

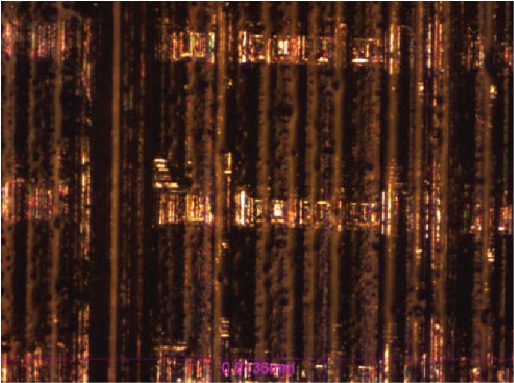

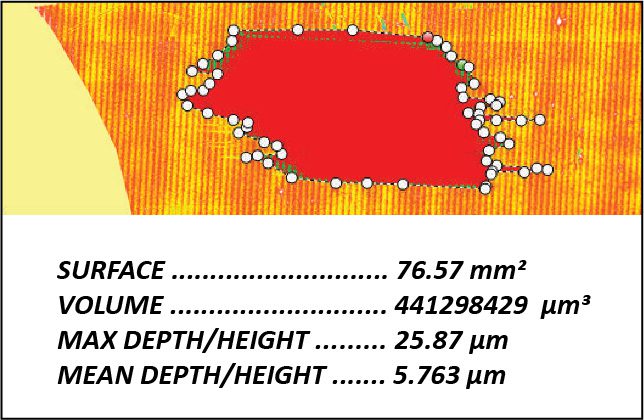

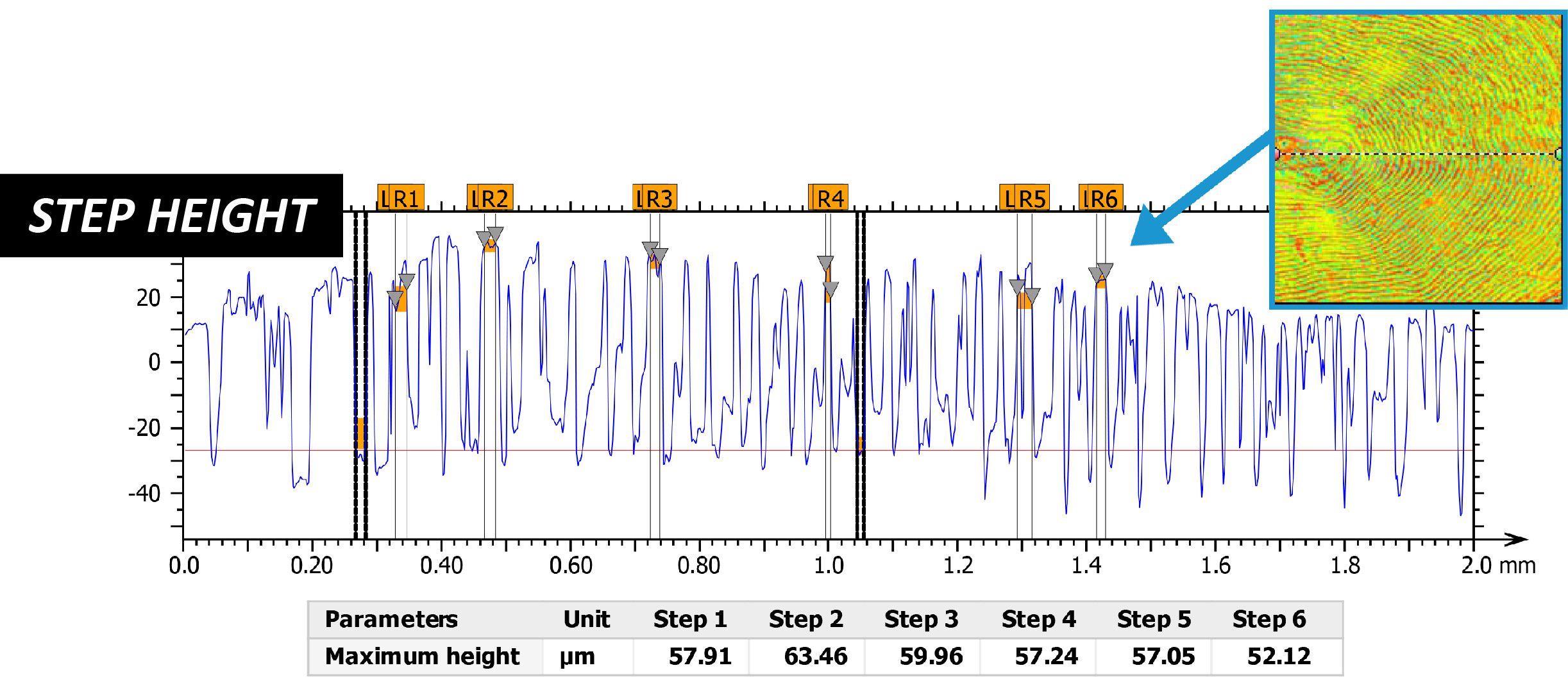

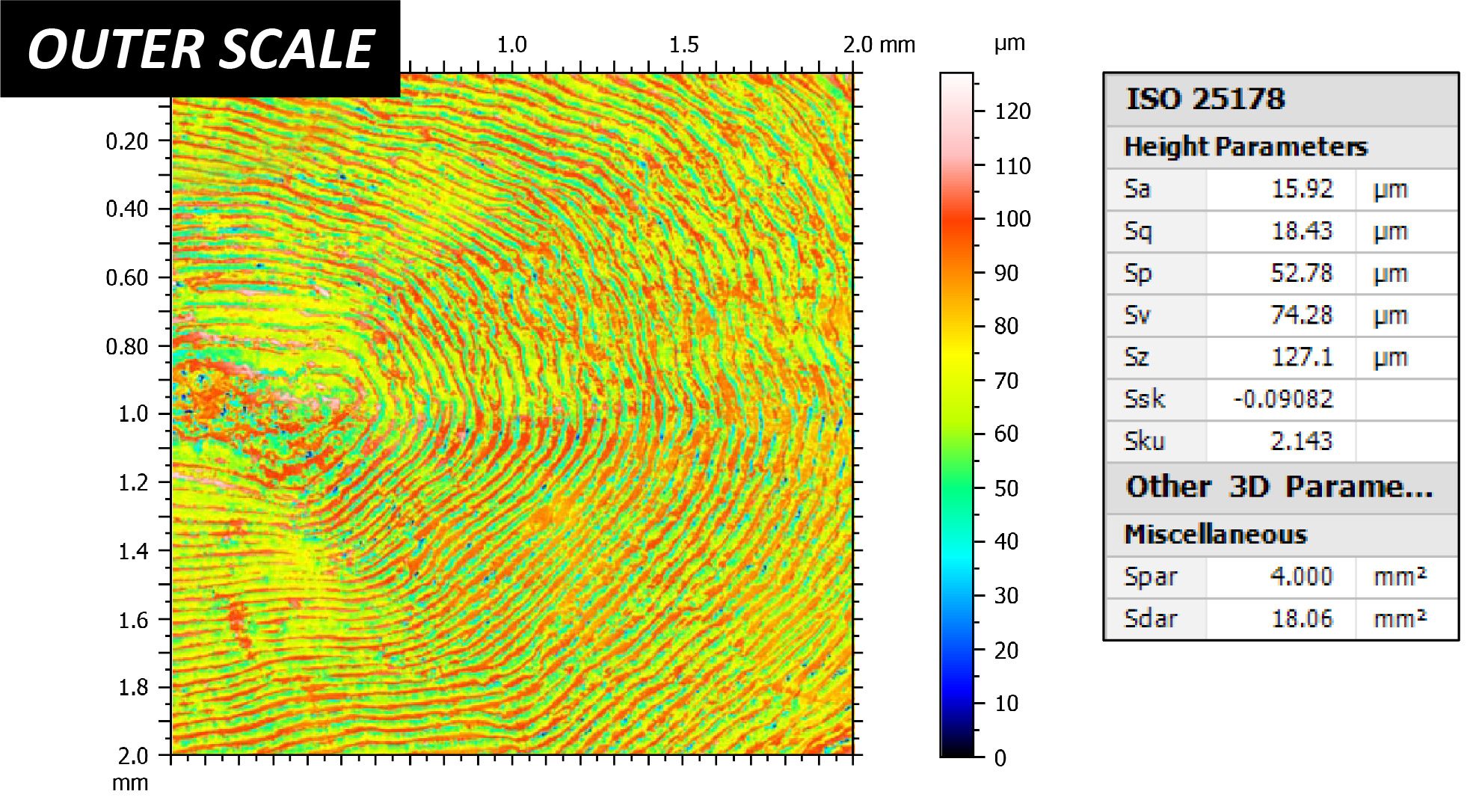

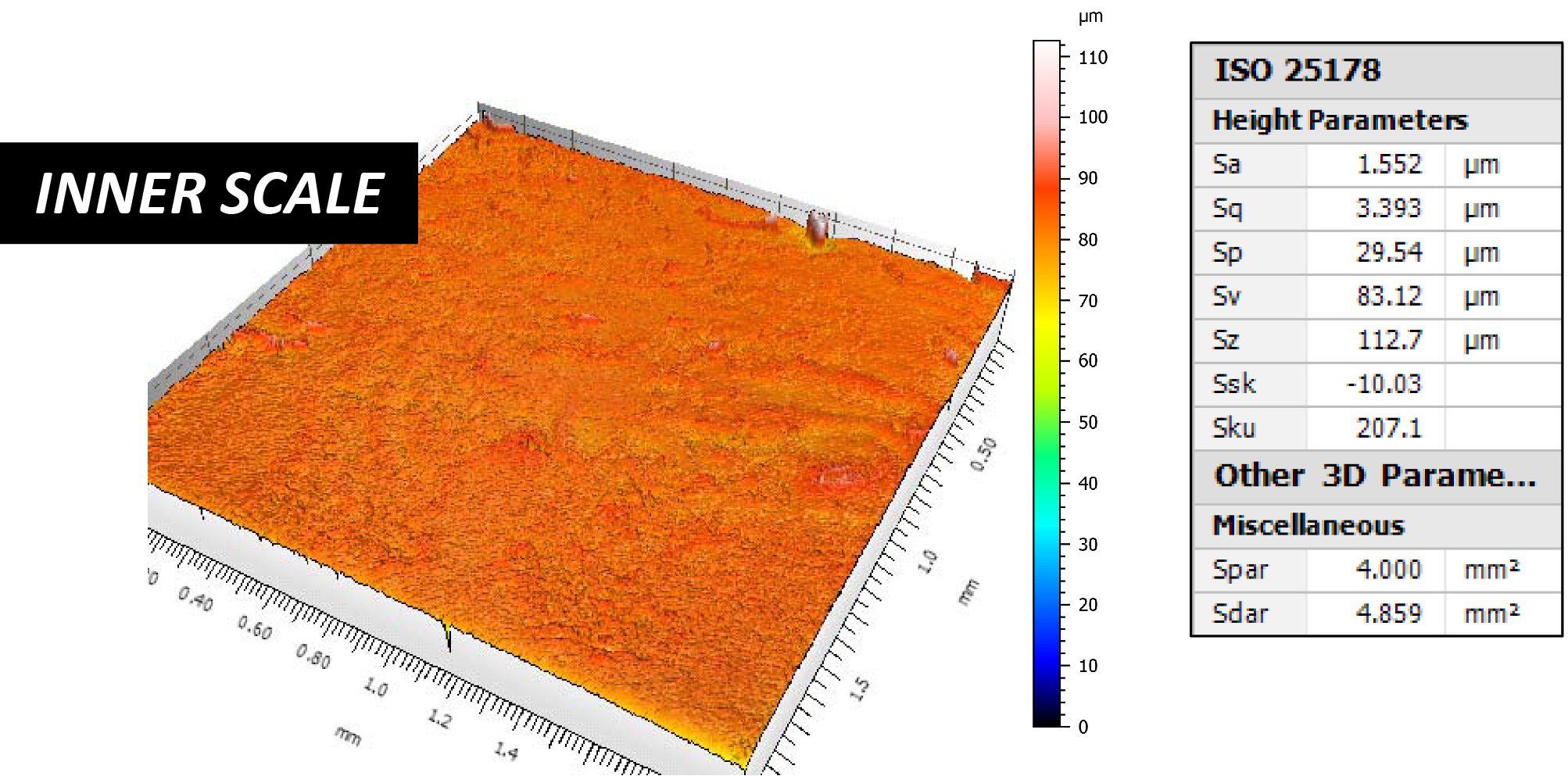

Flooring testing has traditionally centered on the wear rate of a sample to determine its durability against wear. However, progressive wear mapping allows analyzing the sample’s wear rate throughout the test, providing valuable insights into its wear behavior. This in-depth analysis allows for correlations between friction data and wear rate, which can identify the root causes of wear. It should be noted that wear rates are not constant throughout wear tests. Thus, observing the progression of wear gives a more accurate assessment of the sample’s wear. Progressing beyond traditional testing methods, the adoption of progressive wear mapping has contributed to significant advancements in the field of flooring testing.