Category: Application Notes

Corrosion Surface Analysis Using 3D Profilometry

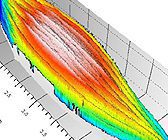

In this application the Nanovea PS50 Profilometer is used to analyze the surface morphology of the

samples after service in corrosive environment. Surface roughness, materials loss and pits on the

sample surface are measured to provide more insight in the corrosion mechanism.

Automated Multi Sample Scratch Testing

In this application, the Nanovea Mechanical Tester is used to evaluate the adhesion of six coated samples

using the multi sample scratch test. We would like to showcase the capacity of Nanovea Mechanical

Tester in performing automated scratch tests on multiple samples with high efficiency and

reproducibility.

Scratch Hardness Measurement Using Tribometer

In this study, the Nanovea Tribometer is used to measure the scratch hardness of different metals. The

capacity of performing scratch hardness measurement with high precision and reproducibility makes

Nanovea Tribometer a more complete system for tribological and mechanical evaluations.

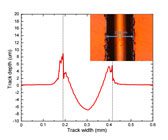

Steel Surface Characterization Using 3D Profilometry

The camera is used initially to stitch an image area, 6mm2, and then visually select an area of interest, 2mm2, for measurement. The Nanovea ST400 Profilometer is then used to create a height map of the surface and the roughness and pitting were studied.

Fish Scale Surface Characterization Using 3D Profilometry

In this application the Nanovea ST400 Profilometer is used to scan the entire surface of the scale, along with a smaller higher resolution scan in the center of the scale The outer and inner side surface roughness of the scale was also measured for comparison.

Surface Characterization of Fish Scale Using 3D Profilometry

Mechanical & Tribological Properties of Carbon Fiber

Combined with the wear test by Tribometer and surface analysis by Optical 3D Profilometer, we

showcase the versatility and accuracy of the Nanovea instruments in testing composite materials

with directional mechanical properties.

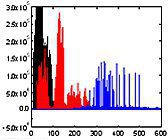

Wear Testing Glass With Acoustic Emissions Monitoring

The wear behavior of three types of glass (Regular glass, Galaxy S3 glass and Sapphire coated glass) is compared in a controlled and monitored manner using the Nanovea Tribometer equipped with an AE detector. In this study, we would like to show the application of AE detection during wear and its correlation with the evolution of coefficient of friction (COF).

Mechanical Properties of Smartphone Glass

In this study, the Nanovea Mechanical Tester is used to perform a comprehensive study of the tribo-mechanical

properties of a smartphone lens, including the hardness, Young’s modulus and fracture toughness as well as scratch and wear resistance, in order to showcase the versatility and accuracy of the Nanovea Mechanical Tester in glass sample testing.

Tribological Properties of PTFE Using Tribometer

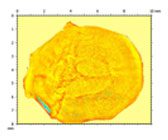

Seed Surface Topography Using 3D Profilometry

In this application the Nanovea ST400 Profilometer is used to measure the surface of a tomato seed and romaine lettuce seed. The entire surface of each seed was scanned with a high resolution. Various analyses will be used to characterize the surfaces

including surface roughness, contour analysis, and texture direction.