Category: Application Notes

Elastic-Plastic Response of Polymer Coating

In this application, we designed a new testing setup to simulate the repetitive impact on the protective

polymer coating and investigated its elastic-plastic response as a function of time using the Nanovea

Mechanical Tester in Microindentation mode.

Elastic-Plastic Response of Polymer Coating Under Repetitive Impact

Static Coefficient of Friction Measurement Using Tribometer

In this study, we would like to showcase the capacity of Nanovea Tribometer for measuring the static coefficient of friction. The coefficient of friction of an aluminum block against Glass and Teflon samples was measured and analyzed as examples.

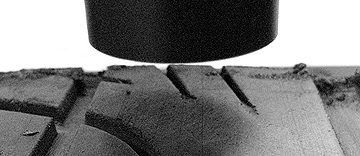

Contour Measurement of Rubber Tread Using 3D Profilometry

In this application the Nanovea ST400 Profilometer is used to measure the surface and treads of a rubber tire. The surface area measured was selected at random, and was large enough that it could be extrapolated to make assumptions about a much larger surface. Contour dimensions, depth, surface roughness, and developed area will be used here to quantify the rubber’s characteristics.

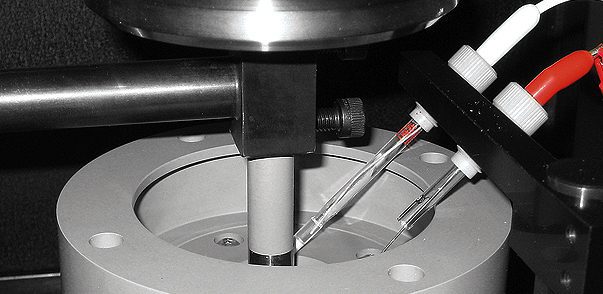

Tribocorrosion Wear Evaluation of Protective Coating

The tribocorrosion process of the DLC coatings on different types of steel substrates is simulated using the Nanovea Tribometer. In this study, we would like to showcase that Nanovea Tribometer equipped with the Tribocorrosion Module is an ideal tool for evaluating the performance of protective coatings used in wear and corrosion environment.

Pitting Corrosion density, area, volume, size and shape

In this application the Nanovea ST400 Profilometer is used to measure the surface of a corrosion pitted stainless steel coupon. The area measured was selected at random, and assumed large enough in that it could be extrapolated to make assumptions

about a much larger surface. Density, area, volume, size and shape will be used here to quantify the level of corrosion.

Initial Plastic Deformation To Wear Analysis

The wear process of a metal sample (Cu 110) and a polymer sample (teflon) is simulated in controlled and monitored manner using the Nanovea Mechanical Tester. In this study, we would like to showcase that the controlling and measuring the load and depth is ideal for wear analysis.

The Critical Effect Of Initial Plastic Deformation To Wear Analysis

Extreme Low Speed Friction Evaluation On Rubber

The coefficient of friction, COF, of rubber against different materials is measured in a controlled and monitored manner using the Nanovea Tribometer. In this study, we would like to showcase the capacity of the Tribometer for measuring the coefficient of friction of different materials at extreme low speeds.

Rubber Friction Evaluation At Extreme Low Speeds Using Tribometer

Surface Finish Measurement of Processed Leather

In this application, the Nanovea ST400 Profilometer is used to measure and compare the surface finish of 2 different but closely processed leather samples. Several surface parameters will be automatically calculated from the surface profile. Here we will focus on surface roughness, dimple depth, dimple pitch and dimple diameter for comparative evaluation.

Processed Leather Surface Finish Using 3D Profilometry

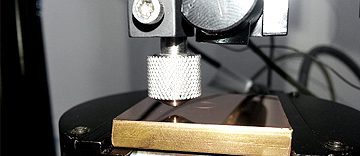

In-Situ Wear Measurement At High Temperature Using Tribometer

Wear measurement of alumina silicate ceramic is simulated at high temperature in a controlled and monitored manner using the Nanovea Tribometer. In this study, we would like to showcase the capacity of the Tribometer for in-situ monitoring the evolution of the wear process of materials at elevated temperatures.

In-Situ Wear Measurement At High Temperature Using Tribometer

Transparent Film on Transparent Substrate Measurement

The Nanovea PS50 Profilometer is used for roughness measurement, step height thickness and optical thickness of a thin transparent film on a transparent glass substrate. Step height will be obtained by measuring an area of the film and an area where the substrate is exposed for relative height difference, while optical thickness will be measured by using the Profilometer capability of measuring through the transparent film and detecting a reflecting both from the top surface of the film and the substrate simultaneously.

Transparent Film on Transparent Substrate Measurement Using 3D Profilometry