Category: Application Notes

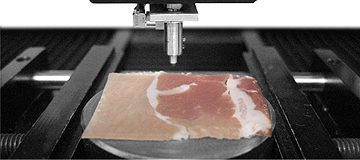

Biomechanical Hardness Evaluation of Tissue

The ability to accurately measure mechanical properties in the fields of Life Science has recently become an important aspect of many current studies. In some cases, understanding the mechanical properties of soft biological surfaces have helped uncover the mechanical effects of diseases. Understanding mechanical properties provides a context for identifying the local mechanical behavior linked to specific changes. It is also critical in the development of artificial bio-materials. In this application, the Nanovea Mechanical Tester, in Nanoindentation mode, is used to study the biomechanical hardness and elastic modulus of 3 separate areas of prosciutto (fat, light meat and dark meat).

Petroleum Jelly Surface Measurement Using 3D Profilometry

Non-contact surface measurement has the advantage that eliminates the possibility of surface alteration of a given application (deformed, scratched or moved). This may be critical, for example, when measuring soft surfaces of films, gels and many others. Additionally, many of these soft surfaces will have transparent or absorptive surfaces leading to measurement error with some optical techniques. In this application the Nanovea ST400 Profilometer is used to measure the extremely soft and

transparent surface of lip balm made of a petroleum jelly.

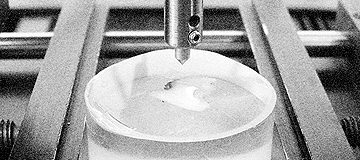

Tooth Hardness Evaluation Using Nanoindentation

In this application, the Nanovea Mechanical Tester, in Nanoindentation mode, is used to study the hardness and elastic modulus of the dentin, decay and pulp of a tooth. The most critical aspect with Nanoidentation testing is securing the sample, here we took a sliced tooth and epoxy mounted leaving all three area of interest exposed for testing.

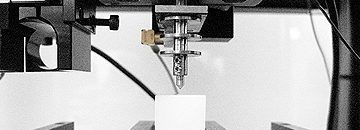

3 Point Bend Test Using Microindentation

In this application, the Nanovea Mechanical Tester, in Microindentation mode, is used to measure the flexural strength (using 3 Point Bend) of various sized rod samples (pasta) to show a range of data. 2 different diameters were chosen to demonstrate both elastic and brittle characteristics. Using a flat tip indenter to apply a point load, we determine stiffness (Young’s Modulus) and identify the critical loads at which the sample will fracture.

Morphology Measurement of Heated Polymer

In this application the Nanovea ST400 Profilometer is used for morphology measurement of polymer before and after being subjected to heat deformation. The deformation could be characterized in several ways; here we will show the change in surface area, relative volume increase and decrease and flatness as defined by ISO 12781

Texture Consistency Measurement Using 3D Profilometry

In this application the Nanovea ST400 Profilometer is used to measure the texture consistency of linoleum flooring. The intended surface texture here should be a repetitive structure with the same relative size. Measuring a small area should show how consistent this texture is being produced.

Surface Boundary Measurement Using 3D Profilometry

In this application the Nanovea ST400 Profilometer is used for surface boundary measurement of Styrofoam. Boundaries were established by combining a reflected intensity file along with the topography, which are simultaneously acquired using the Profilometer. This data was then used to calculate different shape and size information of each Styrofoam “grain”.

Nanoindentation of Polymer at Elevated Temperature

In this application, the Nanovea Mechanical Tester, in Nanoindentation mode with a temperature heating plate ( up to 120°C ) is used to study the comparative Polymer Hardness, Polymer Young’s Modulus and Polymer Creep analysis properties between High Density Polyethylene (HDPE) and Low Density Polyethylene (LDPE). The temperature was measured directly on the surface of the polymer with a thermocouple.

Surface Roughness Statistical Analysis Using 3D Profilometry

In this application the Nanovea ST400 Profilometer is used to measure over 30 coupons with similar surface features with only slight differences. The surfaces were analyzed for parameters such as surface roughness, maximum height, maximum peak height and root mean square. A statistical analysis was then performed using histograms, tables, control charts, box plots and

scatter plots.

Surface Roughness Statistical Analysis Using 3D Profilometry

Fabric Surface Area Measurement Using 3D Profilometry

In this application the Nanovea ST400 Profilometer was used for surface area measurement of a fabric surface to determine amount of projected and developed surface areas as well as a contour analysis of the texture on the surface.