Category: Mechanical Testing

Teflon Mechanical Properties at High Temperature

At elevated temperatures, heat changes teflon mechanical properties such as the hardness and viscoelasticity, which may result in mechanical failures. A reliable measurement of the thermo-mechanical behavior of polymeric materials is in need to quantitatively evaluate the candidate materials for high temperature applications. The Nano module of the Nanovea Mechanical Tester studies the Hardness, Young’s Modulus and Creep by applying the load with a high-precision piezo and measuring the evolution of force and displacement. An advanced oven creates a uniform temperature surrounding the indentation tip and the sample surface throughout the nanoindentation test so as to minimize the effect of thermal drift.

Teflon Mechanical Properties at High Temperature Using Nanoindentation

Macro Adhesion Failure of DLC

bits and bearings. Under such extreme conditions, sufficient cohesive and adhesive strength of the coating/substrate system becomes vital. In order to select the best metal substrate for the target application and to establish a consistent coating process for DLC, it is critical to develop a reliable technique to quantitatively assess cohesion and adhesion failure of different DLC coating systems.

Cohesive & Adhesive Strength of DLC Using Macro Scratch Testing

Corrosion Resistance of Coating After Scratch Testing

The corrosion resistant coatings should possess sufficient mechanical strength as they are often exposed to abrasive and erosive application environments. For example, the abrasive oil sands constantly wear away the inside of pipe, which progressively compromise the pipe’s integrity and potentially result in failure. In auto industry, corrosion takes place at the location of scratches on the auto

paint, especially during freezing winter when salts are applied on road. Therefore, a quantitative and reliable tool for measuring the

influence of scratch testing on protective coatings and its corrosion resistance is in need, in order to select the most proper coating for the intended application.

Thermomechanical Analysis of Solder Using Nanoindentation

Solder joints are subjected to thermal and/or external stress when the temperature exceeds 0.6 Tm where Tm is the melting point of the material in Kelvin. The creep behavior of solders at elevated temperatures can directly influence the reliability of solder interconnections. As a result, a reliable and quantitative thermomechanical analysis of the solder at different temperatures is in need. The Nano module of the Nanovea Mechanical Tester applies the load by a high-precision piezo and directly measures the evolution of force and displacement. The advanced heating oven provides a uniform temperature at the tip and sample surface, which ensures measuring accuracy and minimizes the influence of thermal drift.

Thermomechanical Analysis of Solder Using Nanoindentation

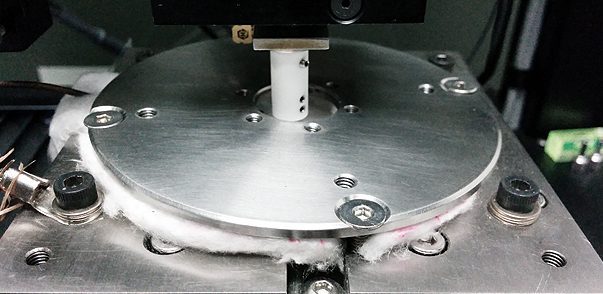

High Temperature Scratch Hardness Using Tribometer

Materials are selected based on the service requirements. For applications involving significant temperature changes and thermal gradients, it is critical to investigate the mechanical properties of materials at high temperatures to be fully aware of the mechanical limits. Materials, especially polymers, usually soften at high temperatures. A lot of mechanical failures are caused by creep deformation and thermal fatigue taking place only at elevated temperatures. Therefore, a reliable technique for measuring high temperature scratch hardness is in need to ensure proper selection of the materials for high temperature applications.

High Temperature Scratch Hardness Using Tribometer

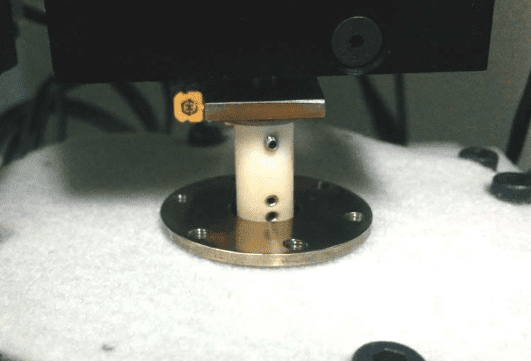

Gold Coating Adhesion on Quartz Crystal Substrate

As an extremely accurate device, the Quartz Crystal Microbalance (QCM) measures the mass change down to 0.1 nanogram. Any mass loss or delamination of the electrodes on the quartz plate will be detected by the quartz crystal and cause significant measurement errors. As a result, the intrinsic quality of the electrode gold coating and the interfacial integrity of the coating/substrate system play an essential role in performing accurate and repeatable mass measurement. The Micro scratch test is a widely used comparative measurement to evaluate the relative cohesion or adhesion properties of coatings based on comparison of the critical loads at which failures appear. It is a superior tool for reliable quality control of QCMs.

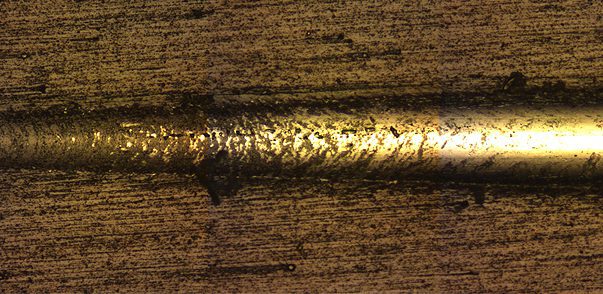

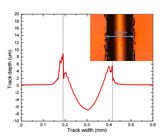

Scratch Hardness Measurement Using Tribometer

In this study, the Nanovea Tribometer is used to measure the scratch hardness of different metals. The

capacity of performing scratch hardness measurement with high precision and reproducibility makes

Nanovea Tribometer a more complete system for tribological and mechanical evaluations.

Mechanical & Tribological Properties of Carbon Fiber

Combined with the wear test by Tribometer and surface analysis by Optical 3D Profilometer, we

showcase the versatility and accuracy of the Nanovea instruments in testing composite materials

with directional mechanical properties.

Bio-Tribology of Endocardial Leads in Hanks’ Solution

In this study, we simulated and compared the nan friction and wear behaviors of endocardial pacing leads made of different materials, in Hanks Solution, using the Nanovea Mechanical and Tribometer, respectively.

Nano-Micro Bio-Tribology of Endocardial Leads in Hanks’ Solution

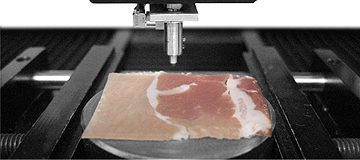

Biomechanical Hardness Evaluation of Tissue

The ability to accurately measure mechanical properties in the fields of Life Science has recently become an important aspect of many current studies. In some cases, understanding the mechanical properties of soft biological surfaces have helped uncover the mechanical effects of diseases. Understanding mechanical properties provides a context for identifying the local mechanical behavior linked to specific changes. It is also critical in the development of artificial bio-materials. In this application, the Nanovea Mechanical Tester, in Nanoindentation mode, is used to study the biomechanical hardness and elastic modulus of 3 separate areas of prosciutto (fat, light meat and dark meat).