ASTM G99 Tips Perspective Continuous Wear Contact

In this application, the Nanovea Tribometer is used to measure the wear rate of a 6mm diameter Stainless Steel and Tungsten Carbide ball tip; many other custom materials and or sizes can be used. The rotative wear test (ASTM G99) was used for a 1hour duration. Then a surface profile was measured using the PS50 Profilometer and micrograph was taken to evaluate surface wear loss between each ball tip for comparison.

NANOVEA’S MOST ADVANCED 3D PROFILOMETER EVER

Nanovea has taken the High Speed HS1000 3D Profilometer to the next optional level. In place of the standard Optical Pen the Line Sensor, in Nanoview option, has been combined with both linear and rotational staging.

SPECIFICATIONS:

Speed: 1800 “Lines” or 324,000 “Points” per second

Line Length: 1.33mmNumber of Points: 180

Spot Size: 3.6um Pitch: 7.4um

Working Distance: 5mm

Z Measurement Range: 110um

Resolution: 20nm

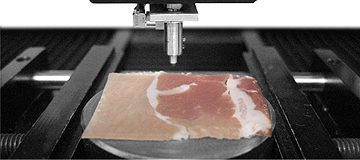

Biomechanical Hardness Evaluation of Tissue

The ability to accurately measure mechanical properties in the fields of Life Science has recently become an important aspect of many current studies. In some cases, understanding the mechanical properties of soft biological surfaces have helped uncover the mechanical effects of diseases. Understanding mechanical properties provides a context for identifying the local mechanical behavior linked to specific changes. It is also critical in the development of artificial bio-materials. In this application, the Nanovea Mechanical Tester, in Nanoindentation mode, is used to study the biomechanical hardness and elastic modulus of 3 separate areas of prosciutto (fat, light meat and dark meat).

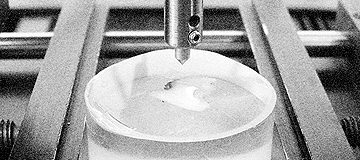

Petroleum Jelly Surface Measurement Using 3D Profilometry

Non-contact surface measurement has the advantage that eliminates the possibility of surface alteration of a given application (deformed, scratched or moved). This may be critical, for example, when measuring soft surfaces of films, gels and many others. Additionally, many of these soft surfaces will have transparent or absorptive surfaces leading to measurement error with some optical techniques. In this application the Nanovea ST400 Profilometer is used to measure the extremely soft and

transparent surface of lip balm made of a petroleum jelly.

Tooth Hardness Evaluation Using Nanoindentation

In this application, the Nanovea Mechanical Tester, in Nanoindentation mode, is used to study the hardness and elastic modulus of the dentin, decay and pulp of a tooth. The most critical aspect with Nanoidentation testing is securing the sample, here we took a sliced tooth and epoxy mounted leaving all three area of interest exposed for testing.

Here are examples of materials we tested this month:

Mechanical:

• Nanoindentation DMA of soft polymer

• Cermaic fracture toughness using Nanoindentation

• Nanoscratch of micro features

• Microindentation 3 Point Bend Test on pasta

• Microscratch of spray coatings

3D Non-Contact Profilometry:

• Finish of micro parts

• Texture of composite fabrics

• Roughness of various seals

• Topography of gel surfaces

• Dimensions of micro parts

Tribology:

• 24 hour Wear of various PVD coatings

Here are examples of materials we tested this month:

Mechanical:

• Nanoindentation of dental materials

• Nanoindentation compression of microbumps

• Nanoscratch of stent

• Nanoscratch of dental materials

• Microindentation multi cycle of various metals

3D Non-Contact Profilometry:

• Roughness of tablet press punch

• Step height of titanium oxide films

• Dimensions of metal chamfered edge

Tribology:

• Wear testing of enriched teflon

• Wear testing of nylon composite

3 Point Bend Test Using Microindentation

In this application, the Nanovea Mechanical Tester, in Microindentation mode, is used to measure the flexural strength (using 3 Point Bend) of various sized rod samples (pasta) to show a range of data. 2 different diameters were chosen to demonstrate both elastic and brittle characteristics. Using a flat tip indenter to apply a point load, we determine stiffness (Young’s Modulus) and identify the critical loads at which the sample will fracture.

Morphology Measurement of Heated Polymer

In this application the Nanovea ST400 Profilometer is used for morphology measurement of polymer before and after being subjected to heat deformation. The deformation could be characterized in several ways; here we will show the change in surface area, relative volume increase and decrease and flatness as defined by ISO 12781

Here are examples of materials we tested this month:

Mechanical:

• Nanoindentation of micropads

• Nanoindentation of various polymer coatings

• Nanoscratch of microwire

• Nanoscratch of paint coatings

• Microindentation fracture of micro ceramic parts

• Microscratch of thermal coatings

3D Non-Contact Profilometry:

• Finish of machined parts

• Texture of molded surfaces

• Roughness of nitinol wire

• Roughness of spray coatings

• CoPlanarity of microfluidic trays

• Dimension of micropatterns

Tribology:

• Wear testing of enriched teflon

• Wear testing of nylon composite