LUBRICATION TESTING ADVANCEMENT: CONTINUOUS STRIBECK CURVE MEASUREMENT!

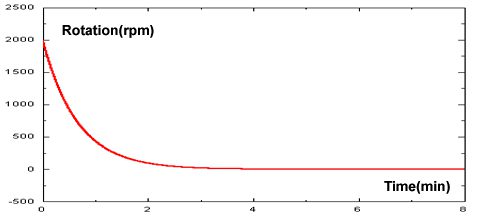

Irvine, Calif., Oct 24, 2013 – Nanovea demonstrates for the first time the ability to measure a continuous Stribeck Curve. Using the Nanovea Tribometer advanced speed control, from 2000 to 0.01 rpm, within 10 minutes software monitoring provides a complete Stribeck Curve. Prior to this advancement lubrication testing of a Stribeck Curve has been shown to be evaluated in a stepwise fashion requiring data stitching. This advancement provides precise data throughout lubricant regime evaluation and substantially reduces time and cost. The test also shows a great potential to be used in different industrial engineering applications.

Learn more in this months app note: Continuous Stribeck Curve Measurement Using Tribometer

NEXT WEEK VISIT NANOVEA AT MS&T 2013!

MS&T 2013 | October 29-30 Montreal, Quebec Canada. The MS&T partnership of ACerS, AIST, ASM, MetSoc and TMS brings together scientists, engineers, students, suppliers and more to discuss current research and technical applications, and to shape the future of materials science and technology. NACE International will co-sponsor MS&T’13. ►www.matscitech.org

Continuous Stribeck Curve Measurement Using Tribometer

The Stribeck curves were measured using two lubricant oils with different kinetic viscosities for comparison. The Nanovea Pin-On-Disk Tribometer equipped with the lubrication module was used. The rotational speed decreased at an exponential rate from 2000 to 0.01 rpm to showcase the continuous Stribeck Curve measurement and the precise sensitivity of the Tribometer capabilities.

Continuous Stribeck Curve Measurement Using Tribometer

Here are examples of materials we tested this month:

Mechanical:

• Nanoindentation DMA of polymer films

• Nanoindentation compression of micro features

• Nanoindentation creep of composites

• Nano Scratch of micro wire coatings

• Micro Scratch of anodized coatings

• Macroindentation multi cycle failure of micro parts

• Macro Scratch of epoxy coatings

3D Non-Contact Profilometry:

• Roughness of anodized coatings

• Laser micro etching texture measurement

• Flatness of DNA trays

• Step Height of automotive parts

• Dimensions of wafer grid

Tribology:

• Wear Testing anodized coatings

• Wear Testing epoxy coatings

• Stribeck Curve analysis of oil samples

Anodized Coatings Macro Scratch Testing

The process of scratching is simulated in a controlled and monitored manner to observe adhesive or cohesive failures. In this application, the Nanovea Mechanical Tester in its macro scratch testing mode is used to measure the load required to cause failure to anodized coatings produced by different processes.

VISIT NANOVEA DISTRIBUTOR AT NANOTECH DUBAI

October 28-30 | Dubai, UAE. Nanotech Dubai brings together leading scientists, researchers, engineers, practitioners, technology developers and policy makers in nanotechnology to exchange information on their latest research progress, innovation and business opportunities. It’s among the most important events in terms of international regulatory policies. ►Nanotech Dubai 2013

Coating Failure Analysis Using Micro Scratch Testing

We must simulate the process of scratch testing in a controlled and monitored manner to observe coating failure analysis. In this application, the Nanovea Mechanical Tester, in its micro scratch mode, is used to measure the load required to cause the coating failure to three separately processed DLC coatings. A 90° Cone, 20μm diamond tipped stylus is used at a progressive load ranging from 0.01 mN to 15 N to scratch the DLC coating. The point where the coating fails by cracking is taken as the point of failure.

Mechanical Stability of Grease Using Tribometer

The Nanovea Pin-On-Disk Tribometer will be used in rotative mode, linear could have also been used. A steel ball tip will be used against a steel sample coated with lithium complex grease. The load used will be at 5N with a constant speed of 150rpm. Two separately formulated lithium complex greases will be tested for comparative evaluation.

Here are examples of materials we tested this month:

Mechanical:

• Nanoindentation stress strain of steels

• Nanoindentation yield strength of micro parts

• Nanoindentation stiffness of polymers

• Nano Scratch of optical coating

• Micro Scratch of paint coatings

• Macroindentation of dlc coatings

• Macro Scratch of dlc coatings

3D Non-Contact Profilometry:

• Topography of gel surfaces

• Roughness of injection molds

• Texture of silicone samples

• Flatness & Co-Planarity of wafer arrays

• Step Height of photomask

• Dimensions of micro parts

• Submerged Wear Testing of dlc coatings

• Wear Testing silicon coatings

• Friction Testing smart glass samples

Flatness Measurement of Wafer Using 3D Profilometry

In this application the Nanovea ST400 Profilometer is used to measure the section of a wafer array. The area measured was selected at random, and assumed large enough in that it could be extrapolated to make assumptions about a much larger surface. Surface flatness measurement, planarity & other surface parameters are used to analyze the surface.