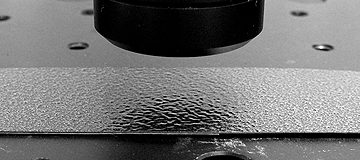

Surface Finish Measurement of Processed Leather

In this application, the Nanovea ST400 Profilometer is used to measure and compare the surface finish of 2 different but closely processed leather samples. Several surface parameters will be automatically calculated from the surface profile. Here we will focus on surface roughness, dimple depth, dimple pitch and dimple diameter for comparative evaluation.

Processed Leather Surface Finish Using 3D Profilometry

Here are examples of materials we tested this month:

Mechanical:

• Nanoindentation of nickel coatings

• Nanoindentation compression of adhesive

• Nanoscratch of ceramic coatings

• Microindentation of seawater aged rubber

• Microscratch of anodized coatings

3D Non-Contact Profilometry:

• Leather roughness measurement

• Form consistency of stamped metal

• Topography consistency of woven fabric

• Texture of molded plastic surfaces

• Depth of extrusion die pits

Tribology:

• Wear rate of Ti-MoS2 and WC coatings in dry, liquid and high temp conditions

In-Situ Wear Measurement At High Temperature Using Tribometer

Wear measurement of alumina silicate ceramic is simulated at high temperature in a controlled and monitored manner using the Nanovea Tribometer. In this study, we would like to showcase the capacity of the Tribometer for in-situ monitoring the evolution of the wear process of materials at elevated temperatures.

In-Situ Wear Measurement At High Temperature Using Tribometer

Transparent Film on Transparent Substrate Measurement

The Nanovea PS50 Profilometer is used for roughness measurement, step height thickness and optical thickness of a thin transparent film on a transparent glass substrate. Step height will be obtained by measuring an area of the film and an area where the substrate is exposed for relative height difference, while optical thickness will be measured by using the Profilometer capability of measuring through the transparent film and detecting a reflecting both from the top surface of the film and the substrate simultaneously.

Transparent Film on Transparent Substrate Measurement Using 3D Profilometry

Here are examples of materials we tested this month:

Mechanical:

• Nanoindentation mapping of micro parts

• Nanoindentation fracture of ceramic samples

• Nano Scratch of coated glass

• Nano Scratch failure of implant coatings

• Macroindentation of anodized coatings

• Micro Scratch of acrylic urethane coatings

• Macro Scratch of rock samples

3D Non-Contact Profilometry:

• Roughness of micro channels

• Roughness of curved plastics

• Texture of micro emboss

• Finish of powder coatings

• Coplanarity of micro features

• Dimensions of micro parts

Tribology:

• Linear Wear Testing of engine parts

• Rotative Wear Testing of ceramic samples

COLLABORATION TO IMPROVE TABER ABRASION TESTING

Traditionally, Taber abrasion testing is carried out to evaluate the wear resistance of Industrial Coatings according to ASTM D4060 Standard. However, as mentioned in the ASTM D4060 standard, “For some materials, abrasion tests utilizing the Taber Abraser may be subject to variation due to changes in the abrasive characteristics of the wheel during testing.” This may result in poor reproducibility of test results and create difficulty in comparing values reported from different laboratories. Moreover, in Taber abrasion test, abrasion resistance is calculated as loss in weight at a specified number of abrasion cycles. However, for example acrylic urethane floor paints have a recommended dry film thickness of 37.5-50 μm. The aggressive abrasion process by Taber Abraser can quickly wear through the acrylic urethane coating and create mass loss to the substrate, which leads to substantial errors in the calculation of the paint weight loss. The implant of abrasive particles in the paint during the abrasion test also contributes to the errors. Therefore, a well-controlled quantifiable and reliable measurement is crucial to ensure reproducible wear evaluation; such as a Tribometer.

Learn more in this months app note: Industrial Coating Scratch & Wear Evaluation

Powder Coating Finish Measurement Using 3D Profilometry

In this application, the Nanovea ST400 Profilometer is used to measure and compare the surface finish of four different Powder Coating samples. Several surface parameters will be automatically calculated from the coating profile. Here we will focus on Surface Roughness, Peak to Valley and Surface Area for comparative evaluation.

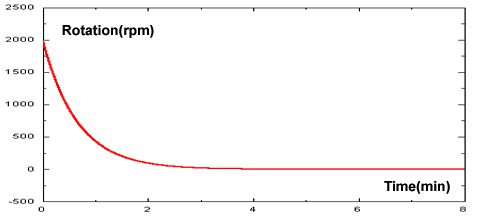

LUBRICATION TESTING ADVANCEMENT: CONTINUOUS STRIBECK CURVE MEASUREMENT!

Irvine, Calif., Oct 24, 2013 – Nanovea demonstrates for the first time the ability to measure a continuous Stribeck Curve. Using the Nanovea Tribometer advanced speed control, from 2000 to 0.01 rpm, within 10 minutes software monitoring provides a complete Stribeck Curve. Prior to this advancement lubrication testing of a Stribeck Curve has been shown to be evaluated in a stepwise fashion requiring data stitching. This advancement provides precise data throughout lubricant regime evaluation and substantially reduces time and cost. The test also shows a great potential to be used in different industrial engineering applications.

Learn more in this months app note: Continuous Stribeck Curve Measurement Using Tribometer

Continuous Stribeck Curve Measurement Using Tribometer

The Stribeck curves were measured using two lubricant oils with different kinetic viscosities for comparison. The Nanovea Pin-On-Disk Tribometer equipped with the lubrication module was used. The rotational speed decreased at an exponential rate from 2000 to 0.01 rpm to showcase the continuous Stribeck Curve measurement and the precise sensitivity of the Tribometer capabilities.

Continuous Stribeck Curve Measurement Using Tribometer

Here are examples of materials we tested this month:

Mechanical:

• Nanoindentation DMA of polymer films

• Nanoindentation compression of micro features

• Nanoindentation creep of composites

• Nano Scratch of micro wire coatings

• Micro Scratch of anodized coatings

• Macroindentation multi cycle failure of micro parts

• Macro Scratch of epoxy coatings

3D Non-Contact Profilometry:

• Roughness of anodized coatings

• Laser micro etching texture measurement

• Flatness of DNA trays

• Step Height of automotive parts

• Dimensions of wafer grid

Tribology:

• Wear Testing anodized coatings

• Wear Testing epoxy coatings

• Stribeck Curve analysis of oil samples