Machined Parts Inspection

MACHINED PARTS

inspection from CAD model using 3D profilometry

Author:

Duanjie Li, PhD

Revised by

Jocelyn Esparza

INTRODUCTION

The demand for precision machining able to create complex geometries has been on the rise across a spectrum of industries. From aerospace, medical and automobile, to tech gears, machinery and musical instruments, the continuous innovation and evolution push expectations and accuracy standards to new heights. Consequently, we see the rise of the demand for rigorous inspection techniques and instruments to ensure the highest quality of the products.

Importance of 3D Non-Contact Profilometry for Parts Inspection

Comparing properties of machined parts to their CAD models is essential to verify tolerances and adherence to production standards. Inspection during the service time is also crucial as wear and tear of the parts may call for their replacement. Identification of any deviations from the required specifications in a timely manner will help avoid costly repairs, production halts and tarnished reputation.

Unlike a touch probe technique, the NANOVEA Optical Profilers perform 3D surface scans with zero contact, allowing for quick, precise and non-destructive measurements of complex shapes with the highest accuracy.

CAD MODEL

A precise measurement of the dimension and surface roughness of the machined part is critical to make sure it meets the desired specifications, tolerances and surface finishes. The 3D model and the engineering drawing of the part to be inspected are presented below.

FALSE COLOR VIEW

The false color view of the CAD model and the scanned machined part surface are compared in FIGURE 3. The height variation on the sample surface can be observed by the change in color.

Three 2D profiles are extracted from the 3D surface scan as indicated in FIGURE 2 to further verify the dimensional tolerance of the machined part.

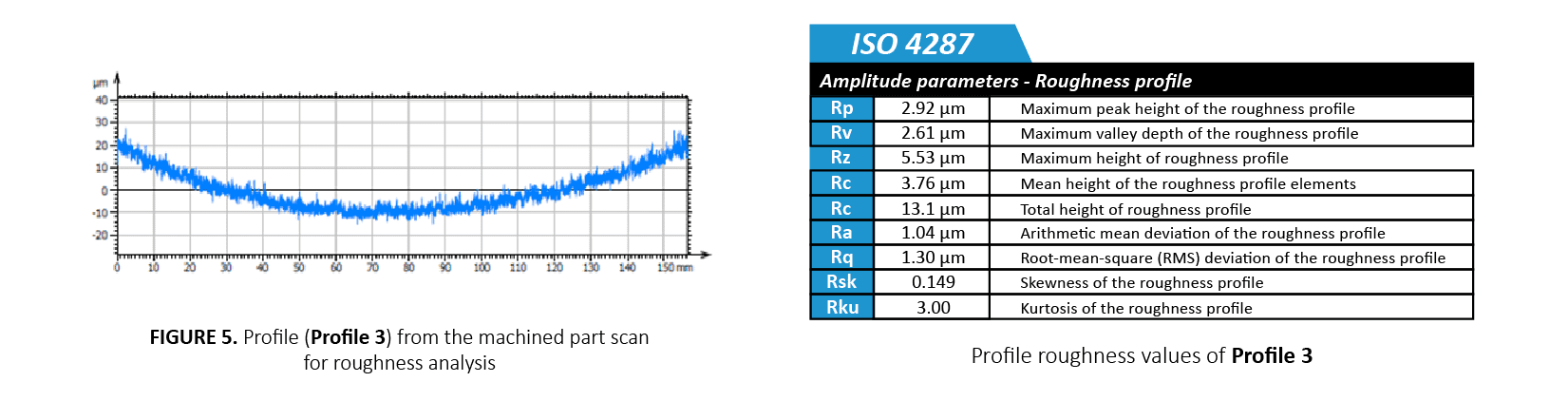

PROFILES COMPARISON & RESULTS

Profile 1 through 3 are shown in FIGURE 3 through 5. Quantitative tolerance inspection is carried out by comparing the measured profile with the CAD model to uphold rigorous manufacturing standards. Profile 1 and Profile 2 measure the radius of different areas on the curved machined part. The height variation of Profile 2 is 30 µm over a length of 156 mm which meets the desired ±125 µm tolerance requirement.

By setting up a tolerance limit value, the analysis software can automatically determine pass or fail of the machined part.

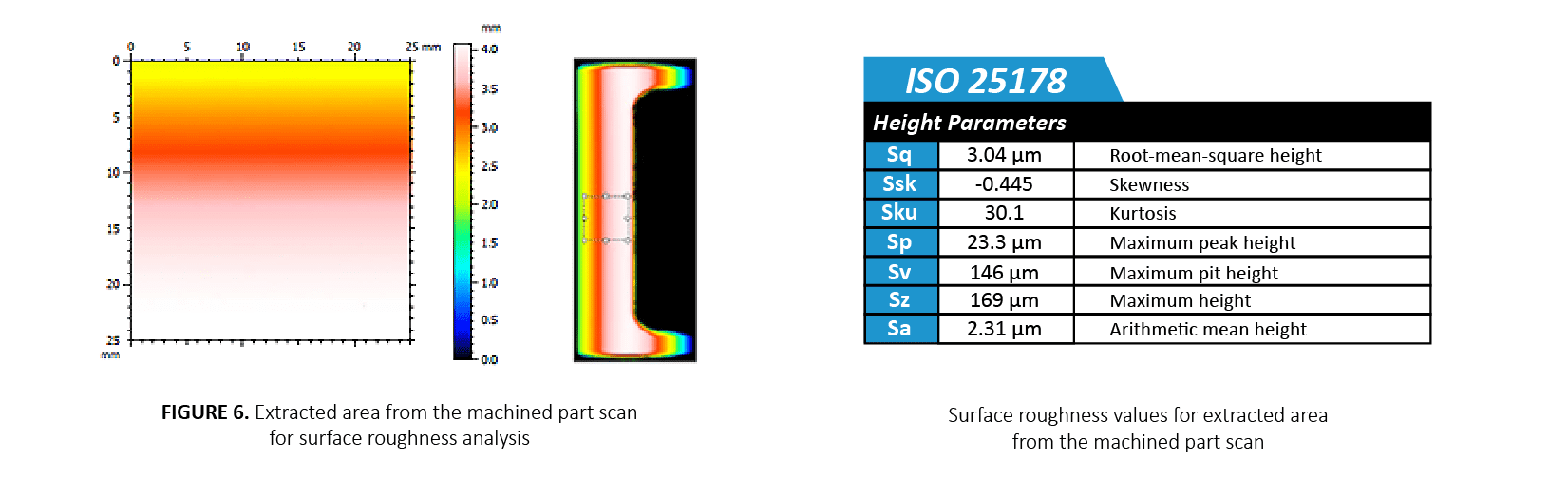

The roughness and uniformity of the machined part’s surface play an important role in ensuring its quality and functionality. FIGURE 6 is an extracted surface area from the parent scan of the machined part which was used to quantify the surface finish. The average surface roughness (Sa) was calculated to be 2.31 µm.

CONCLUSION

In this study, we have showcased how the NANOVEA HS2000 Non-Contact Profiler equipped with a high speed sensor performs comprehensive surface inspection of dimensions and roughness.

High-resolution scans enable users to measure detailed morphology and surface features of machined parts and to quantitatively compare them with their CAD models. The instrument is also capable of detecting any defects including scratches and cracks.

The advanced contour analysis serves as an unparalleled tool not only to determine whether the machined parts satisfy the set specifications, but also to evaluate the failure mechanisms of the worn components.

The data shown here represents only a portion of the calculations possible with the advanced analysis software that comes equipped with every NANOVEA Optical Profiler.

Categories

- Application Notes

- Block on Ring Tribology

- Corrosion Tribology

- Friction Testing | Coefficient of Friction

- High Temperature Mechanical Testing

- High Temperature Tribology

- Humidity and Gases Tribology

- Humidity Mechanical Testing

- Indentation | Creep and Relaxation

- Indentation | Fracture Toughness

- Indentation | Hardness and Elastic

- Indentation | Loss and Storage

- Indentation | Stress vs Strain

- Indentation | Yield Strength and Fatigue

- Laboratory Testing

- Linear Tribology

- Liquid Mechanical Testing

- Liquid Tribology

- Low Temperature Tribology

- Mechanical Testing

- Press Release

- Profilometry | Flatness and Warpage

- Profilometry | Geometry and Shape

- Profilometry | Roughness and Finish

- Profilometry | Step Height and Thickness

- Profilometry | Texture and Grain

- Profilometry | Volume and Area

- Profilometry Testing

- Ring on Ring Tribology

- Rotational Tribology

- Scratch Testing | Adhesive Failure

- Scratch Testing | Cohesive Failure

- Scratch Testing | Multi-Pass Wear

- Scratch Testing | Scratch Hardness

- Scratch Testing Tribology

- Tribology Testing

- Uncategorized

Archives

- November 2025

- September 2023

- August 2023

- June 2023

- May 2023

- July 2022

- May 2022

- April 2022

- January 2022

- December 2021

- November 2021

- October 2021

- September 2021

- August 2021

- July 2021

- June 2021

- May 2021

- March 2021

- February 2021

- December 2020

- November 2020

- October 2020

- September 2020

- July 2020

- May 2020

- April 2020

- March 2020

- February 2020

- January 2020

- November 2019

- October 2019

- September 2019

- August 2019

- July 2019

- June 2019

- May 2019

- April 2019

- March 2019

- January 2019

- December 2018

- November 2018

- October 2018

- September 2018

- July 2018

- June 2018

- April 2018

- March 2018

- February 2018

- November 2017

- October 2017

- September 2017

- August 2017

- June 2017

- May 2017

- March 2017

- February 2017

- January 2017

- November 2016

- October 2016

- August 2016

- July 2016

- June 2016

- May 2016

- April 2016

- March 2016

- February 2016

- January 2016

- December 2015

- November 2015

- October 2015

- September 2015

- August 2015

- July 2015

- June 2015

- May 2015

- April 2015

- March 2015

- February 2015

- January 2015

- November 2014

- October 2014

- September 2014

- August 2014

- July 2014

- June 2014

- May 2014

- April 2014

- March 2014

- February 2014

- January 2014

- December 2013

- November 2013

- October 2013

- September 2013

- August 2013

- July 2013

- June 2013

- May 2013

- April 2013

- March 2013

- February 2013

- January 2013

- December 2012

- November 2012

- October 2012

- September 2012

- August 2012

- July 2012

- June 2012

- May 2012

- April 2012

- March 2012

- February 2012

- January 2012

- December 2011

- November 2011

- October 2011

- September 2011

- August 2011

- July 2011

- June 2011

- May 2011

- November 2010

- January 2010

- April 2009

- March 2009

- January 2009

- December 2008

- October 2008

- August 2007

- July 2006

- March 2006

- January 2005

- April 2004