Category: Profilometry Testing

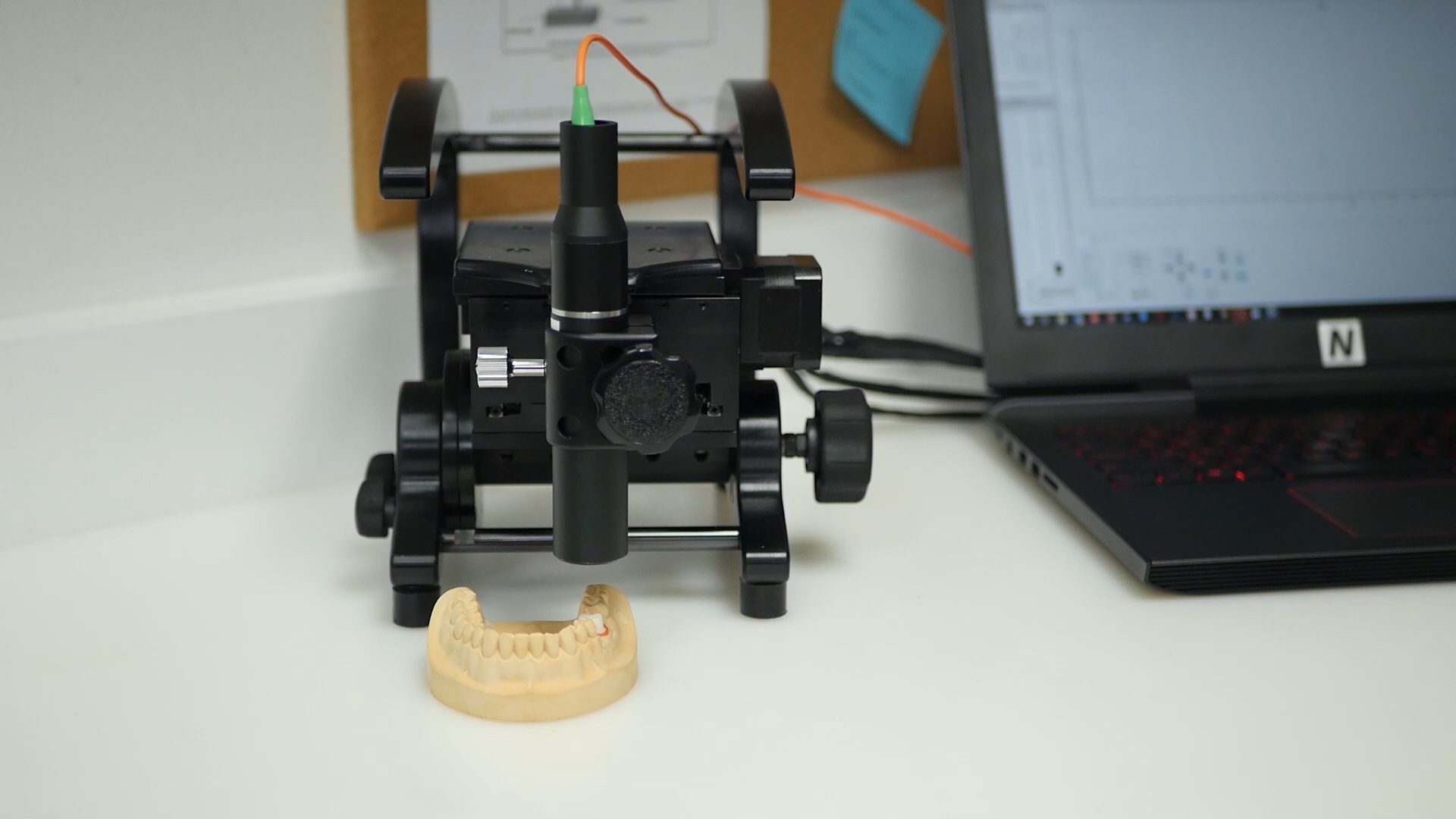

Portability and Flexibility of the Jr25 3D Non-contact Profilometer

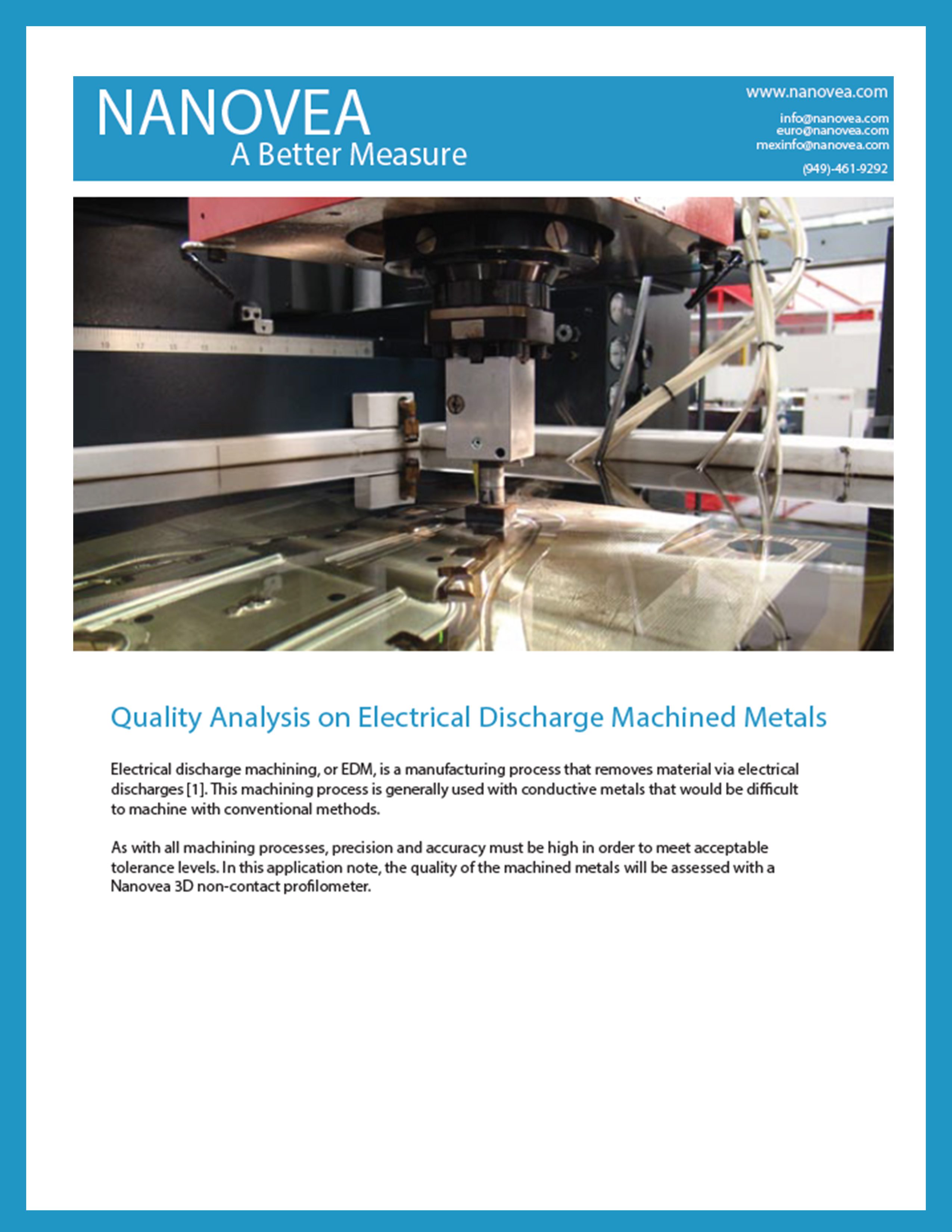

Quality Analysis on Electrical Discharge Machined Metals

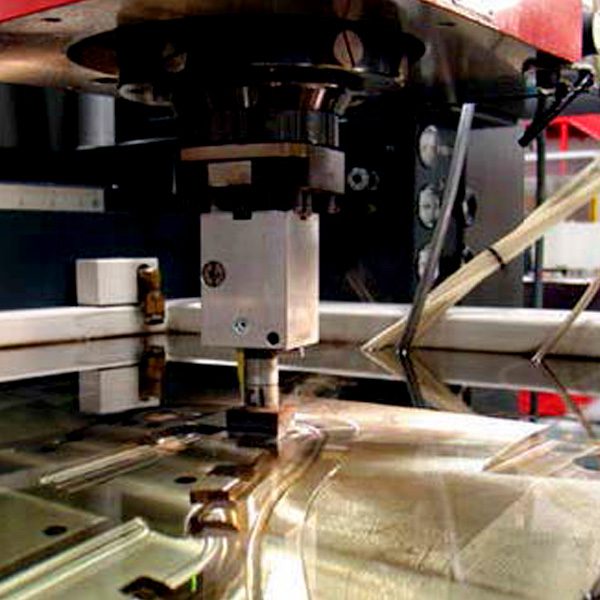

Electrical discharge machining, or EDM, is a manufacturing process that removes material via electrical

discharges [1]. This machining process is generally used with conductive metals that would be difficult

to machine with conventional methods.

As with all machining processes, precision and accuracy must be high in order to meet acceptable

tolerance levels. In this application note, the quality of the machined metals will be assessed with a

Nanovea 3D non-contact profilometer.

A Better Look at Paper

A BETTER Look at Polycarbonate Lens

500nm Glass Step Height: Extreme Accuracy with Non-Contact Profilometry

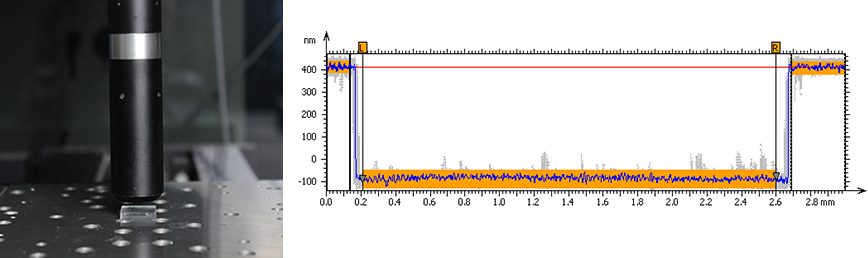

Surface characterization are current topics undergoing intense study. The surfaces of materials are important since they are the regions where physical and chemical interactions between the material and environment occur. Thus, being able to image the surface with high resolution has been desirable, since it allows scientists to visually observe the smallest surface details. Common surface imaging data includes topography, roughness, lateral dimensions, and vertical dimensions. Identifying the load bearing surface, spacing and step height of fabricated microstructures, and defects on the surface are some applications that can be obtained from surface imaging. All surface imaging techniques, however, are not created equal.

500nm Glass Step Height: Extreme Accuracy with Non-Contact Profilometry

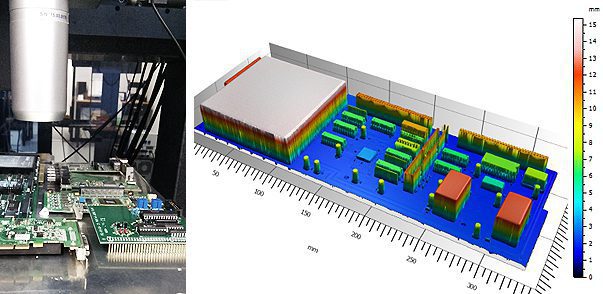

Automated Large Area Profilometry of PCB

Scaling up of manufacturing processes is necessary for industries to grow and keep up with constantly increasing demands. As manufacturing process scales up, the tools used in quality control also need to be scaled up. These tools must be fast to keep up with the production rate, while still maintaining high accuracy to meet product tolerance limits. Here, the Nanovea HS2000 Profilometer, with Line Sensor, showcases its value as a quality control instrument with its fast, automated, and high-resolution large area profilometry capabilities.

Video Clip or App Note: Automated Large Area Profilometry of PCB

Mechanical Properties of Silicon Carbide Wafer Coatings

Understanding the mechanical properties of silicon carbide wafer coatings is critical. The fabrication process for microelectronic devices can have over 300 different processing steps and can take anywhere from six to eight weeks. During this process, the wafer substrate must be able to withstand the extreme conditions of manufacturing, since a failure at any step would result in the loss of time and money. The testing of hardness, adhesion/scratch resistance and COF/wear rate of the wafer must meet certain requirements in order to survive the conditions imposed during the manufacturing and application process to insure a failure will not occur.

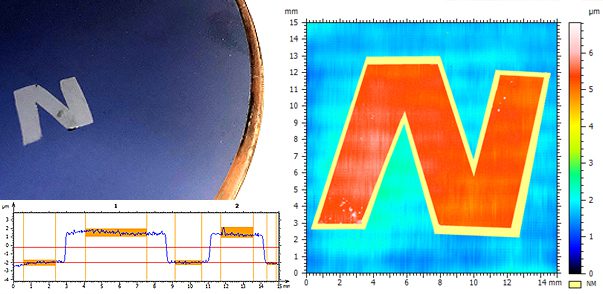

Wafer Coating Thickness Measurement Using 3D Profilometry

Wafer Coating Thickness Measurement is critical. Silicon wafers are widely used in the making of integrated circuits and other micro devices used in a vast number of industries. A constant demand for thinner and smoother wafers and wafer coatings makes the Nanovea 3D non-contact Profilometer a great tool to quantify coating thickness and roughness of just about any surface. The measurements in this article were taken from a coated wafer sample in order to demonstrate the capabilities of our 3D Non-Contact Profilometer.

Flatness Measurement of Screen Using Fast 3D Profilometry

Flatness measurement is an important geometric surface quality in the manufacture of precision parts and assemblies. Flatness of the surface plays a vital role in the end use of the product. For example, the parts that are connected in an air-tight or liquid-tight manner across a surface area require stringent surface conditions of superior flatness at the contact face. Flatness of the screen is critical to the functionality and aesthetics of electronic devices such as cellphones, pads and laptops. Any imperfection of the screen flatness can create negative user impression and experience of the product.

See Video Clip or Read Report: Flatness Measurement of Screen Using Fast 3D Profilometry

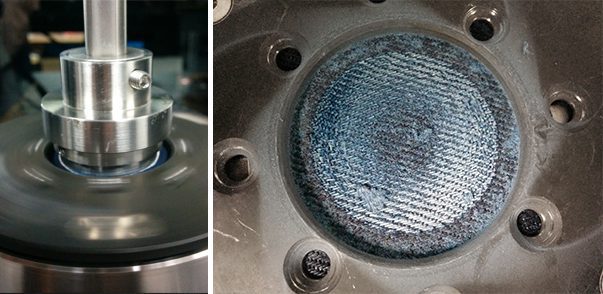

Textile Abrasion Wear By Tribometer

The measurement of textile abrasion resistance of fabrics is very challenging. Many factors play a role during the test, including the mechanical properties of the fibers, the structure of the yarns and the weave of the fabrics. This may result in poor reproducibility of test results and create difficulty in comparing values reported from different laboratories. Wear performance of the fabrics is critical to the manufacturers, distributors, and retailers in the textile production chain. A well-controlled quantifiable and reproducible Tribometer wear resistance measurement is crucial to ensure reliable quality control of the fabric production.