Category: Scratch Testing | Cohesive Failure

Mechanical Properties of Silicon Carbide Wafer Coatings

Understanding the mechanical properties of silicon carbide wafer coatings is critical. The fabrication process for microelectronic devices can have over 300 different processing steps and can take anywhere from six to eight weeks. During this process, the wafer substrate must be able to withstand the extreme conditions of manufacturing, since a failure at any step would result in the loss of time and money. The testing of hardness, adhesion/scratch resistance and COF/wear rate of the wafer must meet certain requirements in order to survive the conditions imposed during the manufacturing and application process to insure a failure will not occur.

Micro Scrape Test Of Polymeric Coating

Scratch testing has developed to be one of the most widely applied methods to evaluate the cohesive and adhesive strength of the coatings. The critical load, at which a certain type of coating failure occurs as the applied load progressively increases, is widely regarded as a reliable tool to determine and compare the adhesive and cohesive properties of the coatings. The most commonly used indenter for scratch testing is the conical Rockwell diamond indenter. However, when the scratch test is performed on the soft polymeric coating deposited on a brittle substrate such as silicon wafer, the conical indenter tends to plough through the coating forming grooves rather than creating cracks or delamination. Cracking of the brittle silicon wafer takes place when the load further increases. Therefore, it is vital to develop a new technique to evaluate the cohesion or adhesion properties of soft coatings on a brittle substrate.

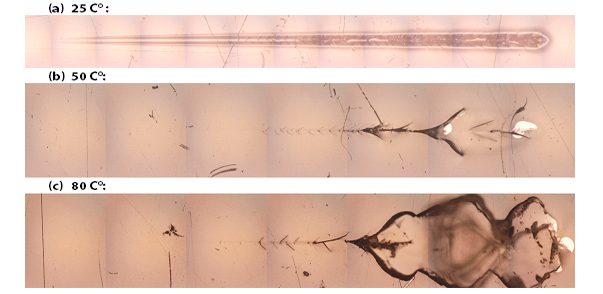

ASTM D7187 Temperature Effect Using Nanoscratching

ASTM D7187, the resistance of the paint to scratch and mar plays a vital role in its end use. Automotive paint susceptible to scratches makes it difficult and costly to maintain and repair. Different coating architectures of the primer, basecoat, and clearcoat have been developed to achieve the best scratch/mar resistance. Nanoscratch testing has been developed as a standard test method to measure the mechanistic aspects of scratch/mar behavior of paint coatings as described in ASTM D7187. Different elementary deformation mechanisms, namely elastic deformation, plastic deformation and fracture, occur at different loads during the scratch test. It provides a quantitative assessment of the plastic resistance and fracture resistance of the paint coatings.

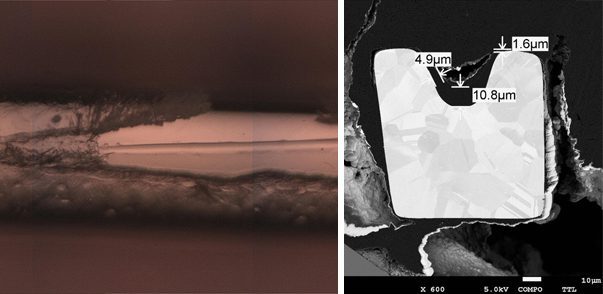

Grooved Stent Coating Failure Using Nano Scratch Testing

Drug–eluting stent is a novel approach in stent technology. It possesses a biodegradable and biocompatible polymer coating that releases medicine slowly and continuously at the local artery to inhibit intimal thickening and prevent the artery from being blocked again. One of the major concerns is the delamination of the polymer coating that carries the drug-eluting layer from the metal stent substrate. In order to improve the adhesion of this coating to the substrate, the stent is designed in different shapes. Specifically in this study, the polymer coating locates at the bottom of the groove on the mesh wire, which brings enormous challenge to the adhesion measurement. A reliable technique is in need to quantitatively measure the interfacial strength between the polymer coating and the metal substrate. The special shape and the small diameter of the stent mesh (comparable to a human hair) require ultrafine X-Y lateral accuracy to locate the test position and proper control and measurement of the load and depth during the test.

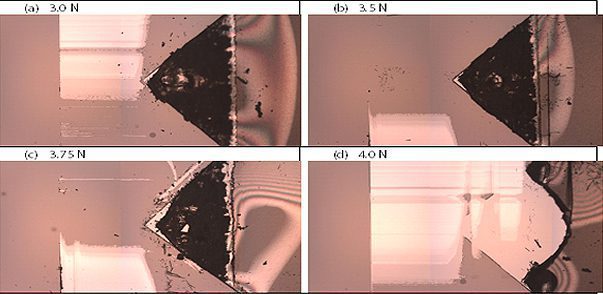

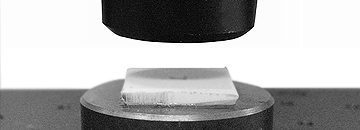

Macro Adhesion Failure of DLC

bits and bearings. Under such extreme conditions, sufficient cohesive and adhesive strength of the coating/substrate system becomes vital. In order to select the best metal substrate for the target application and to establish a consistent coating process for DLC, it is critical to develop a reliable technique to quantitatively assess cohesion and adhesion failure of different DLC coating systems.

Cohesive & Adhesive Strength of DLC Using Macro Scratch Testing

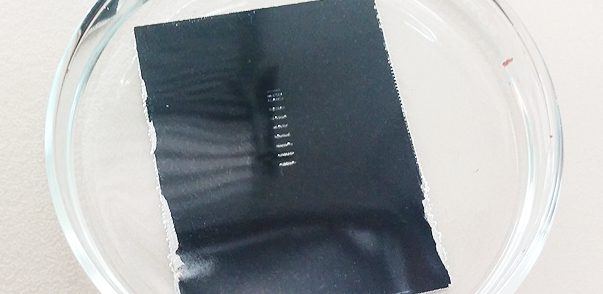

Corrosion Resistance of Coating After Scratch Testing

The corrosion resistant coatings should possess sufficient mechanical strength as they are often exposed to abrasive and erosive application environments. For example, the abrasive oil sands constantly wear away the inside of pipe, which progressively compromise the pipe’s integrity and potentially result in failure. In auto industry, corrosion takes place at the location of scratches on the auto

paint, especially during freezing winter when salts are applied on road. Therefore, a quantitative and reliable tool for measuring the

influence of scratch testing on protective coatings and its corrosion resistance is in need, in order to select the most proper coating for the intended application.

Micro Scratch Depth Measurement Using 3D Profilometry

In this application the Nanovea ST400 Profilometer is used for depth measurement of a row of micro scratches created using Nanovea’s Mechanical Tester in scratch mode. In seconds the Profilometer, with a single line pass in 2D mode, provides area and depth measurement.