MICRO SCRATCH | MICRO ADHESION TESTING

Mechanical Testers | Lab Services | Nano Module | Micro Module | Application Notes

Micro Scratch Process:

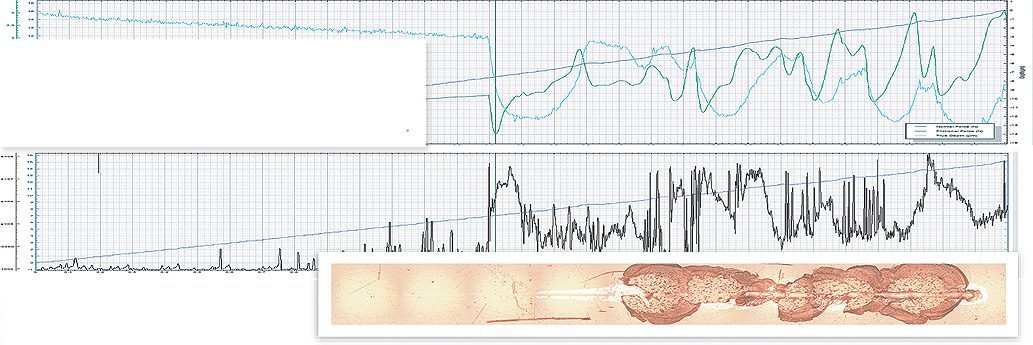

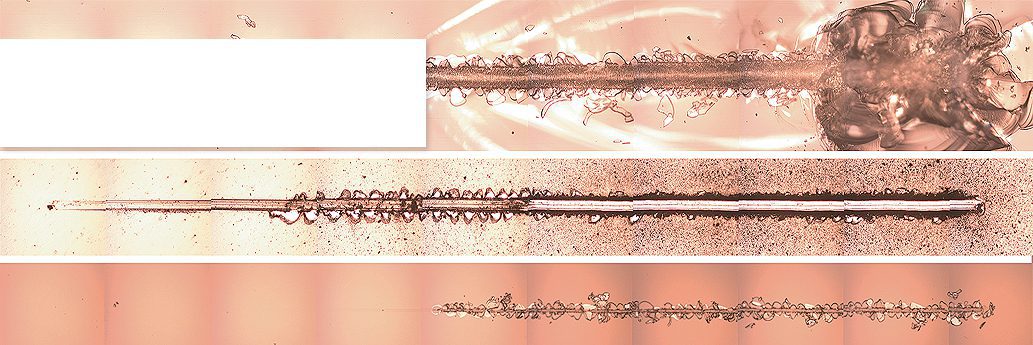

During Micro Scratch Testing, a conical spherical tip, diamond or WC, is drawn across the coated surface with an increasing load, resulting in various types of failure at specific critical loads. Micro Scratch Adhesion Testing identifies critical loads optically using a built-in video microscope. These critical loads are used to quantify the adhesive and cohesive properties of different film/substrate combinations. In addition, failure points can be determined using frictional force and depth measurements. Depth measurements provide the plastic and elastic portion of the deformation. Constant load scratch testing can be used, in mapping, to check the surface uniformity. True Depth Measurements based on (European Patent No. 0663068) providing accurate elastic and plastic deformation.

Standards:

- ASTM D7187

- ASTM C1624

- ASTM D7027

- ASTM G171

- ISO 20502

- ISO 1518

- DIN EN 1071

- DVM-0058-PA

Properties Analyzed During Micro Scratch:

- Cohesive & Adhesive failure

- Adhesion Strength

- Marring (Resistance) and Crack/Fracture initiation

- Plastic & Elastic Deformation depth and others

Micro Scratch Software Features:

- Recipes

- Export Raw Data and Images

- Real Time Display

- Automatic Reporting

- Multi-Language Support

- Failure Comparison

- Mapping

- Full Scratch Image for post inspection using tracking zoomed view

- Tracking Zoomed View for easy post inspection with data depth, friction and AE analysis

Advanced Micro Scratch Automation:

- Broadview Map Selection Tool: Advanced Mapping on stitched image

- Automated multi-sample testing (handles height variance of up to 50mm)

- Navigation Plus: User Friendly surface navigation imaging

- Quick Approach, Auto Surface Detection and Auto Analysis

- Direct Easy Calibration Tools for Load & Depth

- Single Indent Area Function (European Patent No. 3076153)

- Quantifiable quality check for indenter (European Patent No. 3076153)

- Wizard (Patent Pending): Automatic Test Parameter generator

- Savable recipes of all macros programmed

Indenters: (Diamond, WC and many other materials)

- Vickers

- Cube Corner

- Conical-Spherical

- Knife

Sample(s) Holders and Environmental Conditions:

- 275°C & 450 °C Oven

- Down to -10°C Cooling Chamber

- Humidity Chamber

- Liquid Cups

- Custom Sample & Indenter Holders

Additional Micro Module Modes:

Microindentation | MicroHardness Testing