Category: Uncategorized

LUBRICATION TESTING ADVANCEMENT: CONTINUOUS STRIBECK CURVE MEASUREMENT!

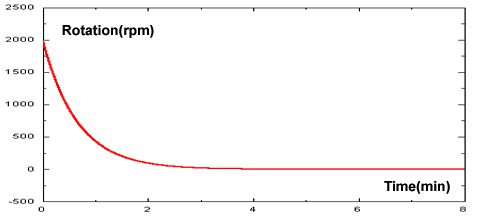

Irvine, Calif., Oct 24, 2013 – Nanovea demonstrates for the first time the ability to measure a continuous Stribeck Curve. Using the Nanovea Tribometer advanced speed control, from 2000 to 0.01 rpm, within 10 minutes software monitoring provides a complete Stribeck Curve. Prior to this advancement lubrication testing of a Stribeck Curve has been shown to be evaluated in a stepwise fashion requiring data stitching. This advancement provides precise data throughout lubricant regime evaluation and substantially reduces time and cost. The test also shows a great potential to be used in different industrial engineering applications.

Learn more in this months app note: Continuous Stribeck Curve Measurement Using Tribometer

Here are examples of materials we tested this month:

Mechanical:

• Nanoindentation DMA of polymer films

• Nanoindentation compression of micro features

• Nanoindentation creep of composites

• Nano Scratch of micro wire coatings

• Micro Scratch of anodized coatings

• Macroindentation multi cycle failure of micro parts

• Macro Scratch of epoxy coatings

3D Non-Contact Profilometry:

• Roughness of anodized coatings

• Laser micro etching texture measurement

• Flatness of DNA trays

• Step Height of automotive parts

• Dimensions of wafer grid

Tribology:

• Wear Testing anodized coatings

• Wear Testing epoxy coatings

• Stribeck Curve analysis of oil samples

Here are examples of materials we tested this month:

Mechanical:

• Nanoindentation stress strain of steels

• Nanoindentation yield strength of micro parts

• Nanoindentation stiffness of polymers

• Nano Scratch of optical coating

• Micro Scratch of paint coatings

• Macroindentation of dlc coatings

• Macro Scratch of dlc coatings

3D Non-Contact Profilometry:

• Topography of gel surfaces

• Roughness of injection molds

• Texture of silicone samples

• Flatness & Co-Planarity of wafer arrays

• Step Height of photomask

• Dimensions of micro parts

• Submerged Wear Testing of dlc coatings

• Wear Testing silicon coatings

• Friction Testing smart glass samples

Here are examples of materials we tested this month:

Mechanical:

• Nanoindentation of glass samples

• Nanoindentation compression of micro features

• Nanoscratch of soft films

• Nanowear of biomedical samples

• Microindentation mapping of welds

3D Non-Contact Profilometry:

• Finish of micro seals

• Texture of micro patterns

• Roughness of transparent gel films

• Flatness of glass samples

• Dimensions of lens samples

• Deposited grid Step Height measurement

Tribology:

• High Temp Wear of various spray coatings

• Friction of submerged polymer samples

NANOVEA PROUD SPONSOR OF EUROMAT

September 8-13 | Sevilla, Spain. Held every two years since 1989, the Euromat conferences gather academics and researchers from the industry with a large scope on materials science and technology and their application. The extraordinary positive evolution of the conferences in the recent editions is indicative of the materials scientist community’s excellent health.

Learn more ►Euromat 2013

NANOVEA’S MOST ADVANCED 3D PROFILOMETER EVER

Nanovea has taken the High Speed HS1000 3D Profilometer to the next optional level. In place of the standard Optical Pen the Line Sensor, in Nanoview option, has been combined with both linear and rotational staging.

SPECIFICATIONS:

Speed: 1800 “Lines” or 324,000 “Points” per second

Line Length: 1.33mmNumber of Points: 180

Spot Size: 3.6um Pitch: 7.4um

Working Distance: 5mm

Z Measurement Range: 110um

Resolution: 20nm

Here are examples of materials we tested this month:

Mechanical:

• Nanoindentation DMA of soft polymer

• Cermaic fracture toughness using Nanoindentation

• Nanoscratch of micro features

• Microindentation 3 Point Bend Test on pasta

• Microscratch of spray coatings

3D Non-Contact Profilometry:

• Finish of micro parts

• Texture of composite fabrics

• Roughness of various seals

• Topography of gel surfaces

• Dimensions of micro parts

Tribology:

• 24 hour Wear of various PVD coatings

Here are examples of materials we tested this month:

Mechanical:

• Nanoindentation of dental materials

• Nanoindentation compression of microbumps

• Nanoscratch of stent

• Nanoscratch of dental materials

• Microindentation multi cycle of various metals

3D Non-Contact Profilometry:

• Roughness of tablet press punch

• Step height of titanium oxide films

• Dimensions of metal chamfered edge

Tribology:

• Wear testing of enriched teflon

• Wear testing of nylon composite

Here are examples of materials we tested this month:

Mechanical:

• Nanoindentation of micropads

• Nanoindentation of various polymer coatings

• Nanoscratch of microwire

• Nanoscratch of paint coatings

• Microindentation fracture of micro ceramic parts

• Microscratch of thermal coatings

3D Non-Contact Profilometry:

• Finish of machined parts

• Texture of molded surfaces

• Roughness of nitinol wire

• Roughness of spray coatings

• CoPlanarity of microfluidic trays

• Dimension of micropatterns

Tribology:

• Wear testing of enriched teflon

• Wear testing of nylon composite

Here are examples of materials we tested this month:

Mechanical:

• Nanoindentation of wire cross sections

• Nanoindentation of Y2O3 thin films

• Nanoscratch of thin polymer films

• Nanoscratch of catheters

• Microindentation of oil-well cement

3D Non-Contact Profilometry:

• Roughness of catheters

• Finish of processed leather

• Topography of thin film particle contaminants

• Coplanarity of ball grid arrays

• Step height of microchannels

• Stribeck Curve evaluation of various lubrication