Category: Uncategorized

Here are examples of materials we tested this month:

Mechanical:

• Nanoindentation of thin, hard oxide coatings

• Nanoindentation & scratch of hard titanium nitride coatings

• Microindentation compression of foams

• Microscratch of thin, hard oxide coating

3D Non-Contact Profilometry:

• Roughness & grain size analysis of dental implant

• Roughness of wood flooring finishes

• Roughness of building drywall

• Coplanarity of pin grid array under elevated temperature

Tribology:

• Wear testing of cryogenically hardened steel

• Friction testing doggie treats

• Tribocorrosion of dlc coatings

Profilometer For Large Area Measurements

Meet the ST500 Profilometer. After years of success with the ST400 and HS1000 Nanovea introduces the ST500 providing high speed large area measurement without stitching. The ST500 has a 400 mm X-Y Axis Travel, a 50 mm Z Axis with a maximum speed up to 200 mm/s. The system can be equipped with either an optical pen or line scanner for ultra fast measurement (384,000 points per second). Unlike other technologies, each point is a direct, full depth of field during large area measurement without the need of refocusing. A video zoom camera can also be used to provide automatic function to large area measurement complete on a desktop user friendly platform. See app note for example.

Here are examples of materials we tested this month:

Mechanical:

• Nanoindentation & Scratch of blank coins

• Nanoindentation of electroplated coating

• Nanoindetation dma of epoxy adhesive coating

3D Non-Contact Profilometry:

• Roughness of tablet press punch

• Step height of titanium oxide films

• Dimensions of metal chamfered edge

Tribology:

• Wear testing of enriched teflon

• Wear testing of nylon composite

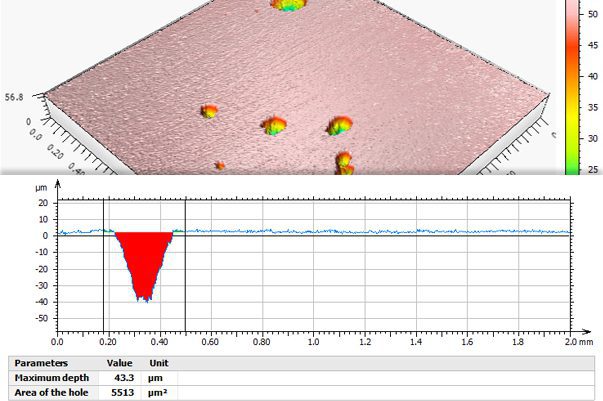

Corrosion Profilometry Is Application Of The Year

With the Nace Corrosion Conference only weeks away Nanovea highlights pitting corrosion measurement as its most popular profilometry application of 2014. The Nanovea Profilometer has quickly become the choice in the corrosion community for its accurate and reliable measurement. Primary area of interest include pitting depth, volume, area and density. Learn more in this months app note below.

Understanding the Breakthrough N3 Line!

| M3 Review Automated Nanoindentation |

T3 Review Automated Wear |

P3 Review Automated Roughness |

Here are examples of materials we tested this month:

Mechanical:

• Nanoindentation of silicon

• Nanoindentation of rubber particles

• Microscratch of metallic epoxy coatings

• Macroscratch of DLC coatings

• Microindentation UTS of titanium

3D Non-Contact Profilometry:

• Roughness of catheters

• Texture of diamond sandpaper

• Finish consistency coatings

• Topography of corroded samples

• Coplanarity of pin grid arrays

• Flatness of laser cut surface

• Motor oil lubricant friction testing

• Wear testing of DLC coatings

• Wear testing steel (Extended high temperature)

• Wear testing of DLC coatings

Here are examples of materials we tested this month:

Mechanical:

• Nanoindentation, scratch & wear of silver and aluminum coatings

• Nanoindentation of polycrystalline diamond

• Nano scratch of polystyrene coatings

• Nano scratch of teflon coated wires

• Macro scratch testing of DLC coatings

3D Non-Contact Profilometry:

• Roughness of polished metal samples

• Texture of bandage fabric

• Dimensions of sphere tips

• Coplanarity of pin grid array

• Flatness of metal parts

• Topography of rock fossil

Tribology:

• Friction testing rubber samples

• Friction testing medical parts

• Wear testing dlc coatings

• Wear metallic coatings

• Stribeck Curve of heated lubrication samples

R&D Recognizes Nanovea’s Measurement Achievement

R&D Magazine has recognized Nanovea’s breakthrough method of reliably acquiring both yield strength (YS) and ultimate tensile strength (UTS) measurement through the indentation technique; which has significant advantages when compared to the traditional tensile testing. Read the full article at R&D Magazine

Here are examples of materials we tested this month:

Mechanical:

• Nanoindentation of multi-layered rubber tubing

• Nanoindentation of dlc coating

• Nanoscratch of thin copper & alumina coating

• Microindentation ultimate tensile strength of steel samples

• Microscratch brittle metallic coatings

• Macroindentation compression of hard particles

3D Non-Contact Profilometry:

• Roughness of large silicon ingot

• Isotropy of textured cable

• Dimensions of MEMS

• Topography of golf ball

• Topography of fish scale

• Area of textured metal

• Friction testing textured cable

• Friction testing lubrication

• Wear testing dlc coating

• Wear testing treated steel