Anodized Coatings Macro Scratch Testing

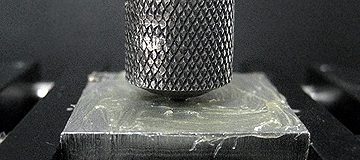

The process of scratching is simulated in a controlled and monitored manner to observe adhesive or cohesive failures. In this application, the Nanovea Mechanical Tester in its macro scratch testing mode is used to measure the load required to cause failure to anodized coatings produced by different processes.

Coating Failure Analysis Using Micro Scratch Testing

We must simulate the process of scratch testing in a controlled and monitored manner to observe coating failure analysis. In this application, the Nanovea Mechanical Tester, in its micro scratch mode, is used to measure the load required to cause the coating failure to three separately processed DLC coatings. A 90° Cone, 20μm diamond tipped stylus is used at a progressive load ranging from 0.01 mN to 15 N to scratch the DLC coating. The point where the coating fails by cracking is taken as the point of failure.

Mechanical Stability of Grease Using Tribometer

The Nanovea Pin-On-Disk Tribometer will be used in rotative mode, linear could have also been used. A steel ball tip will be used against a steel sample coated with lithium complex grease. The load used will be at 5N with a constant speed of 150rpm. Two separately formulated lithium complex greases will be tested for comparative evaluation.

Here are examples of materials we tested this month:

Mechanical:

• Nanoindentation stress strain of steels

• Nanoindentation yield strength of micro parts

• Nanoindentation stiffness of polymers

• Nano Scratch of optical coating

• Micro Scratch of paint coatings

• Macroindentation of dlc coatings

• Macro Scratch of dlc coatings

3D Non-Contact Profilometry:

• Topography of gel surfaces

• Roughness of injection molds

• Texture of silicone samples

• Flatness & Co-Planarity of wafer arrays

• Step Height of photomask

• Dimensions of micro parts

• Submerged Wear Testing of dlc coatings

• Wear Testing silicon coatings

• Friction Testing smart glass samples

Flatness Measurement of Wafer Using 3D Profilometry

In this application the Nanovea ST400 Profilometer is used to measure the section of a wafer array. The area measured was selected at random, and assumed large enough in that it could be extrapolated to make assumptions about a much larger surface. Surface flatness measurement, planarity & other surface parameters are used to analyze the surface.

Nanomechanical Testing of Thermal Transfer Print

We must simulate the process of scratching in a controlled and monitored manner to observe sample behavior effects. In this application, the Nanovea Mechanical Tester, in nano scratch testing mode, is used to measure the nanomechanical load required to cause failure to 3 micron wax/resin prints on coated paper. A 2μm 90° cone diamond tip stylus is used at a progressive load ranging from 0.10 mN to 0.20 mN to scratch the printed surface. Points of failure will be reviewed. In addition, we have also used nanoindentation mode to obtain hardness and elastic modulus of the sample prints.

Surface Measurement Using 3D Profilometry

In this application the Nanovea ST400 Profilometer is used for surface measurement of an exposed piece of carbon fiber. The area measured was selected at random, and assumed large enough in that it could be extrapolated to make assumptions about a

much larger surface. Surface roughness, surface area, wavelength, fractal analysis and other surface parameters are used to characterize the surface.

Here are examples of materials we tested this month:

Mechanical:

• Nanoindentation of glass samples

• Nanoindentation compression of micro features

• Nanoscratch of soft films

• Nanowear of biomedical samples

• Microindentation mapping of welds

3D Non-Contact Profilometry:

• Finish of micro seals

• Texture of micro patterns

• Roughness of transparent gel films

• Flatness of glass samples

• Dimensions of lens samples

• Deposited grid Step Height measurement

Tribology:

• High Temp Wear of various spray coatings

• Friction of submerged polymer samples

NANOVEA PROUD SPONSOR OF EUROMAT

September 8-13 | Sevilla, Spain. Held every two years since 1989, the Euromat conferences gather academics and researchers from the industry with a large scope on materials science and technology and their application. The extraordinary positive evolution of the conferences in the recent editions is indicative of the materials scientist community’s excellent health.

Learn more ►Euromat 2013

Corrosion Measurement Using 3D Profilometry

In this application the Nanovea ST400 Profilometer is used to measure the surface of a corrosion pitted stainless steel coupon. The area measured was selected at random, and assumed large enough in that it could be extrapolated to make assumptions

about a much larger surface. Density, area, volume, size and shape will be used here to quantify the level of corrosion.