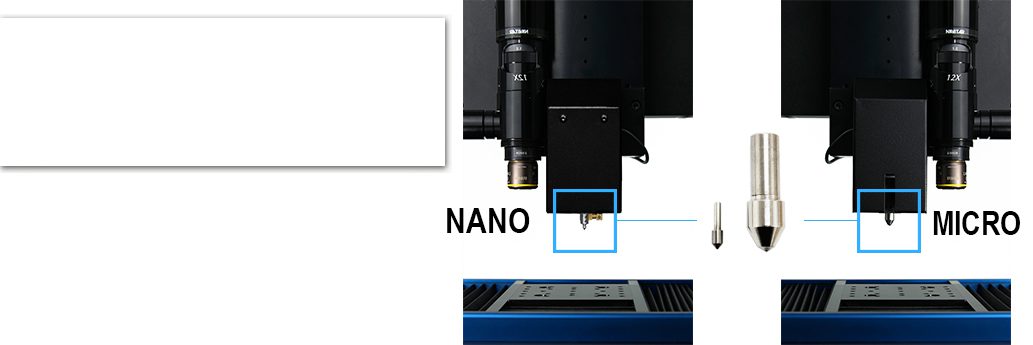

NANO MODULE INTRO

Mechanical Testers | Micro Module | Application Notes

Designed with the vision of providing clients high accuracy with ease of use, longevity with low maintenance cost; the nano module achieves this with its unique combination of piezo actuator, ultra sensitive load cell and a large surface capacitor ring, all vertically aligned for maximum stiffness. The unique use of independent depth and load sensors ensure high accuracy in all conditions but also provide excellent point of contact detection as the load applied is measured directly by the independent sensor when the indenter first touches the surface. The module also provides true closed control feedback loop using data from independent depth or load sensor. This feature is essential to react quickly and accurately to fast events such as during scratch and wear testing or when fractures occur during indentation. The measurement of the actual load applied ensures also accuracy during fast DMA testing and allows automatic. The ultra sensitive load cell is also straightforward to calibrate with a direct weight scale. Therefore, every Nano module can be quickly calibrated, by the user, in less than 15minutes for Load, Depth and Compliance. This ensures constant accuracy of the data through time and from one instrument to another. Nanovea achieves this high accuracy with some of the best comparative noise levels in the industry.

The module provides nanometer scale testing during indentation, scratch and wear testing modes. Each mode of testing provides wide range of testing that can provide properties such as hardness, creep, elastic modulus, stress-strain curves, yield strength, fatigue, loss and storage modulus, fracture toughness, wear rate, friction coefficient, scratch and marring resistance, plastic/elastic deformation among other tests. In combination with integrated x-y motorized table, one can test at very specific locations or do a full mapping of properties across a chosen area. In fact, the unique design of the nano module with the piezo actuator allows accurate indents to be performed in less than 3 seconds making mapping possible within minutes. The Nano module is ideal for accurately characterizing thin industrial coatings or films. Examples include thin polymer coatings for the medical device industry and various thin coatings for the solar and optical lens industries. Another major application of the nano module is the marring of top surfaces such as varnish clear coats used in the automobile industry and other protective coatings used on portable devices such as mobile electronics.

The Nano Module has been designed for high thermal stability with raw data uncorrected thermal drift of < 0.02 nm/sec. At high temperature, the oven provides uniform temperature of the tip and the sample for increased accuracy and lower levels of drift with no compensation. When used with the high temperature oven, the Nano module is designed with MACOR with low thermal expansion coefficient material of < 10-6 / °C . This reduces any thermal drift at high temperature.

NANO TESTING MODES

Nanoindentation | Nano Hardness Testing