R&D Recognizes Nanovea’s Measurement Achievement

R&D Magazine has recognized Nanovea’s breakthrough method of reliably acquiring both yield strength (YS) and ultimate tensile strength (UTS) measurement through the indentation technique; which has significant advantages when compared to the traditional tensile testing. Read the full article at R&D Magazine

Automated Multi Sample Scratch Testing

In this application, the Nanovea Mechanical Tester is used to evaluate the adhesion of six coated samples

using the multi sample scratch test. We would like to showcase the capacity of Nanovea Mechanical

Tester in performing automated scratch tests on multiple samples with high efficiency and

reproducibility.

Scratch Hardness Measurement Using Tribometer

In this study, the Nanovea Tribometer is used to measure the scratch hardness of different metals. The

capacity of performing scratch hardness measurement with high precision and reproducibility makes

Nanovea Tribometer a more complete system for tribological and mechanical evaluations.

Steel Surface Characterization Using 3D Profilometry

The camera is used initially to stitch an image area, 6mm2, and then visually select an area of interest, 2mm2, for measurement. The Nanovea ST400 Profilometer is then used to create a height map of the surface and the roughness and pitting were studied.

Here are examples of materials we tested this month:

Mechanical:

• Nanoindentation of multi-layered rubber tubing

• Nanoindentation of dlc coating

• Nanoscratch of thin copper & alumina coating

• Microindentation ultimate tensile strength of steel samples

• Microscratch brittle metallic coatings

• Macroindentation compression of hard particles

3D Non-Contact Profilometry:

• Roughness of large silicon ingot

• Isotropy of textured cable

• Dimensions of MEMS

• Topography of golf ball

• Topography of fish scale

• Area of textured metal

• Friction testing textured cable

• Friction testing lubrication

• Wear testing dlc coating

• Wear testing treated steel

The Profilometer Becomes a Tool For Zoology Research!

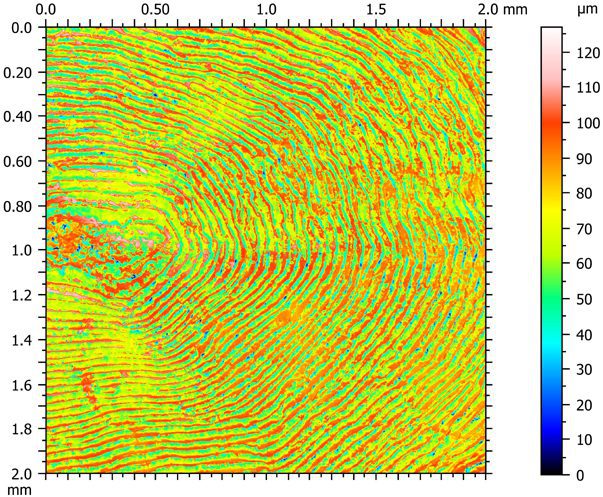

Above is a 3D surface measurement of a fish scale with interest to identify front and back surface characteristics. Zoology Research is yet another example of the endless possible applications for the accuracy of the Nanovea Profilometer. Learn more in this months application note.

Fish Scale Surface Characterization Using 3D Profilometry

In this application the Nanovea ST400 Profilometer is used to scan the entire surface of the scale, along with a smaller higher resolution scan in the center of the scale The outer and inner side surface roughness of the scale was also measured for comparison.

Surface Characterization of Fish Scale Using 3D Profilometry

Mechanical & Tribological Properties of Carbon Fiber

Combined with the wear test by Tribometer and surface analysis by Optical 3D Profilometer, we

showcase the versatility and accuracy of the Nanovea instruments in testing composite materials

with directional mechanical properties.

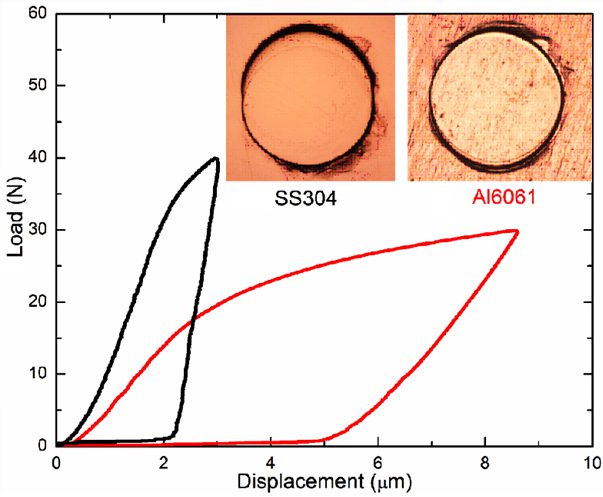

Breakthrough Measurement Proven on Steel & Aluminum

For the first time, Nanovea has developed a breakthrough method of reliably acquiring both yield strength (YS) and ultimate tensile strength (UTS) through the indentation technique; which has significant advantages when compared to the traditional tensile testing. Learn more in this months updated application note.

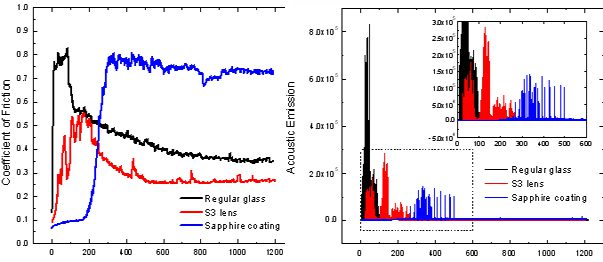

Using Acoustic Emission (AE) During Wear Testing

During Tribometer wear testing, the constant rubbing process of the counterface against the test sample creates a series of events, such as deformation, cracking, abrasion, phase transformation and material removal. These rapid stress-releasing events are the sources of AE. A quantifiable and reliable measurement of AE can provide more insight in the wear failure mechanism. Learn more in this months application note.