INTRODUCTION

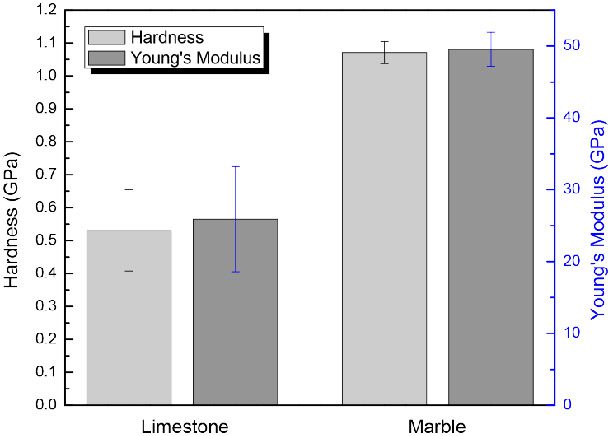

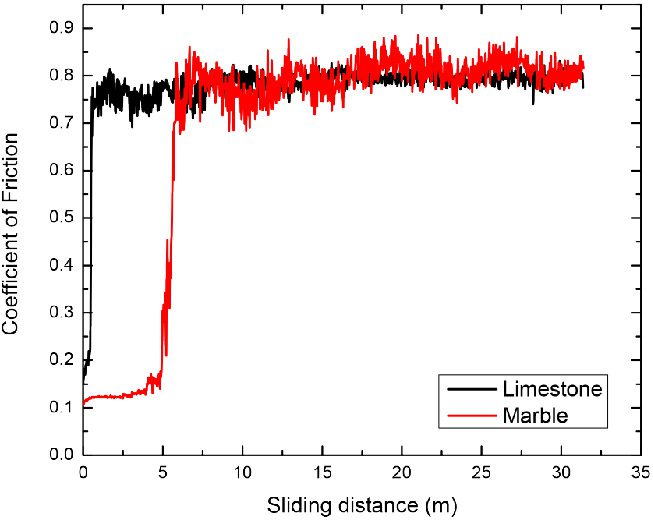

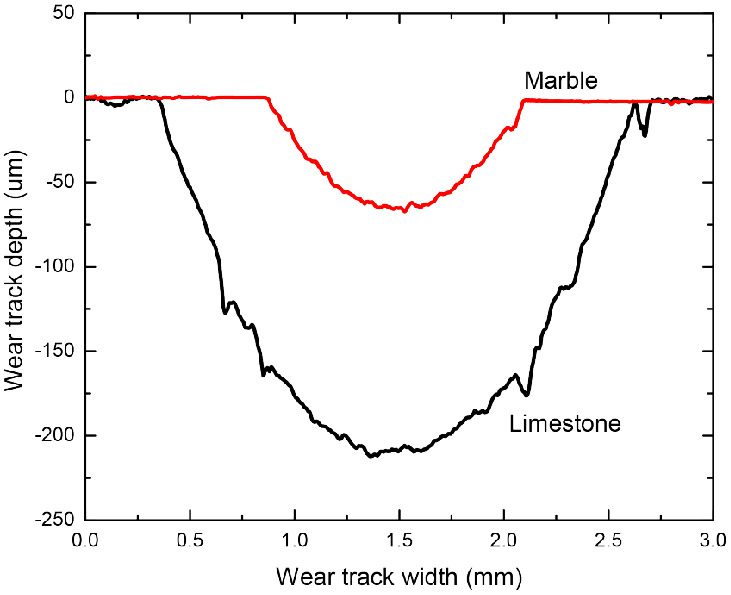

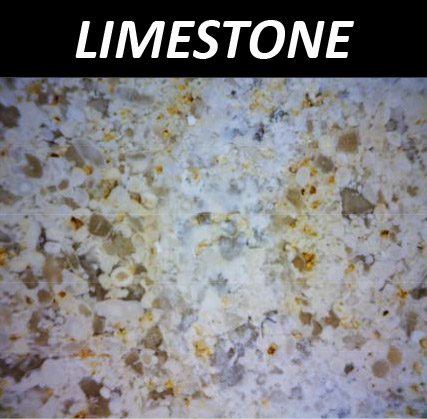

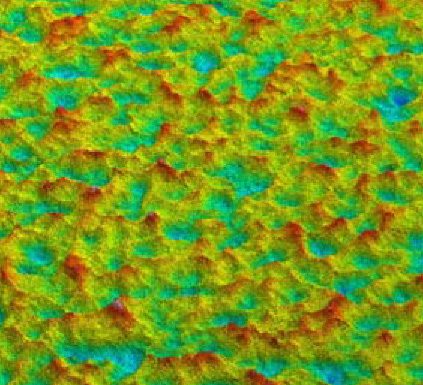

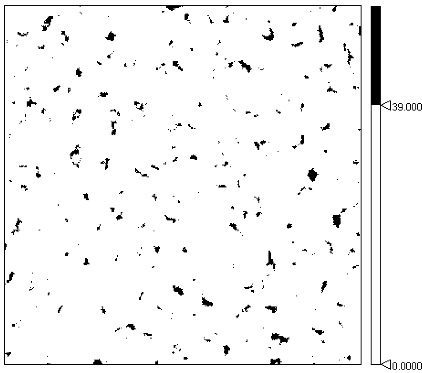

Rocks are composed of grains of minerals. The type and abundance of these minerals, as well as the chemical bonding strength between the mineral grains, determine the mechanical and tribological properties of the rocks. Depending on the geological rock cycles, rocks can undergo transformations and are typically classified into three major types: igneous, sedimentary, and metamorphic. These rocks exhibit different mineral and chemical compositions, permeabilities, and particle sizes, and such characteristics contribute to their varied wear resistance. Rock tribology explores the wear and friction behaviors of rocks in various geological and environmental conditions.

IMPORTANCE OF ROCK TRIBOLOGY

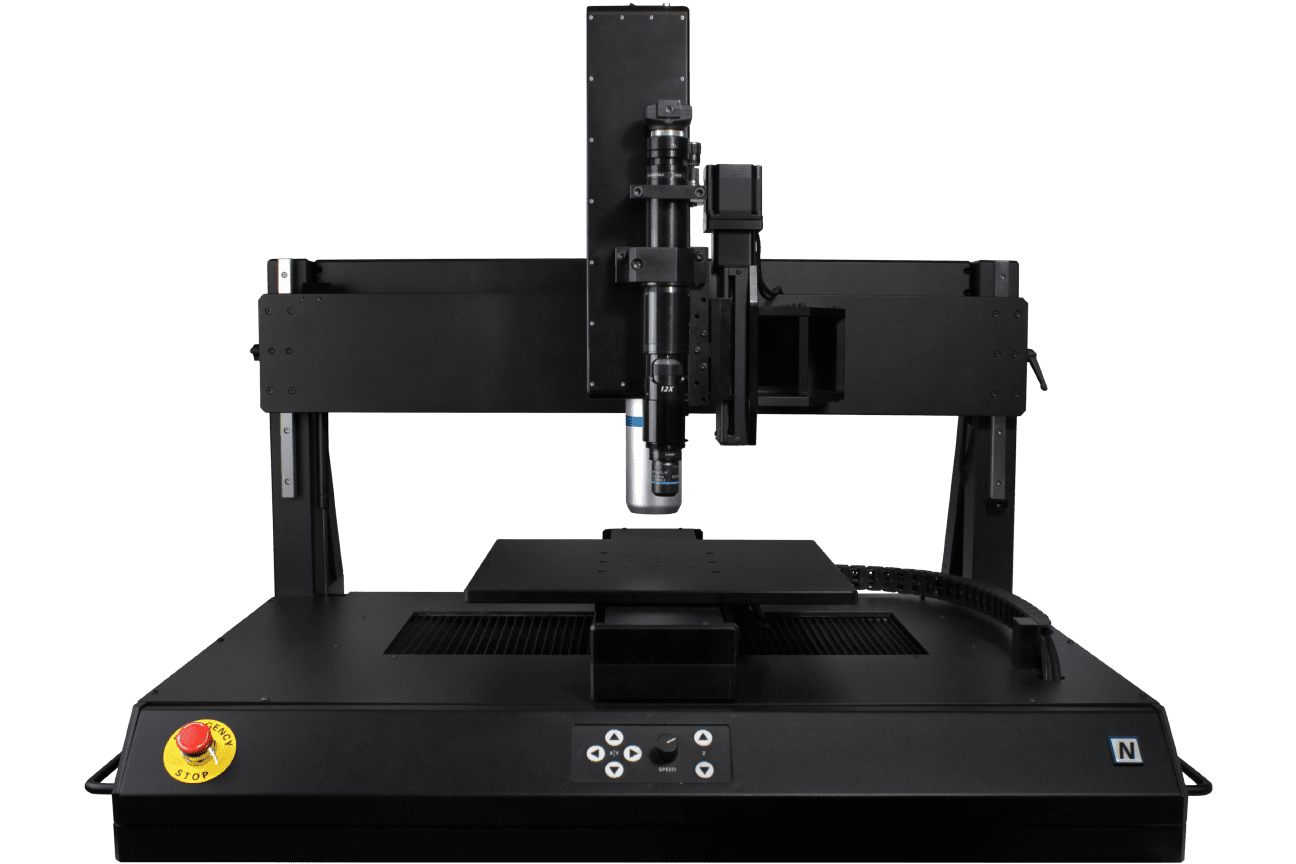

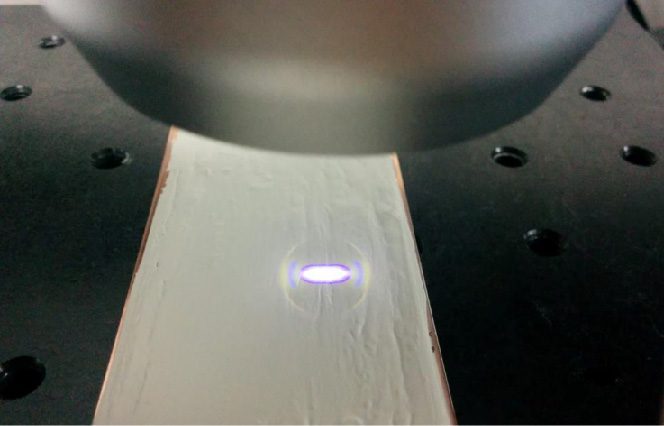

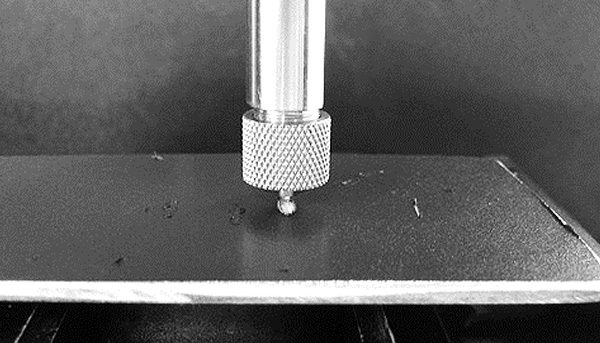

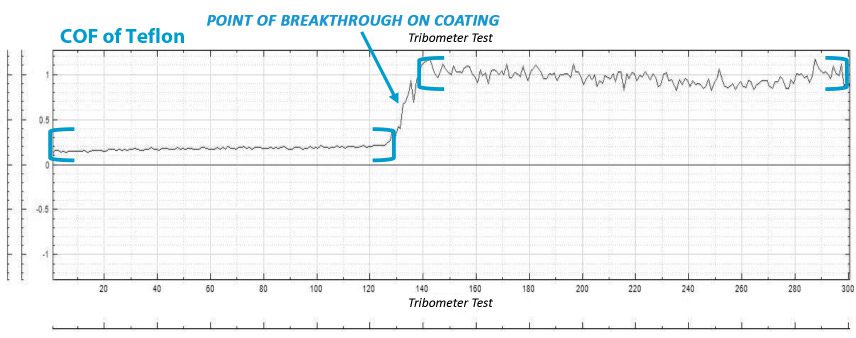

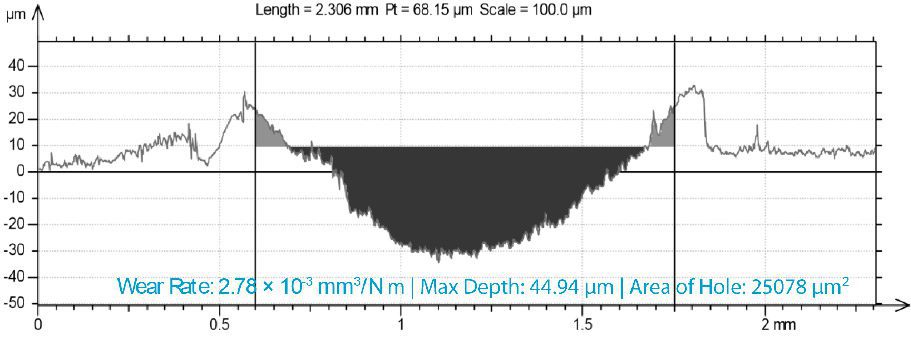

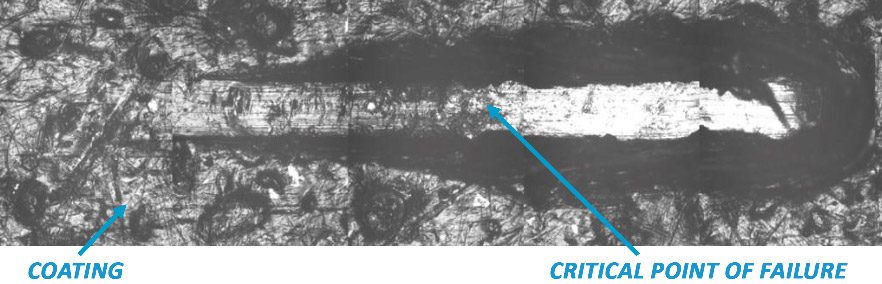

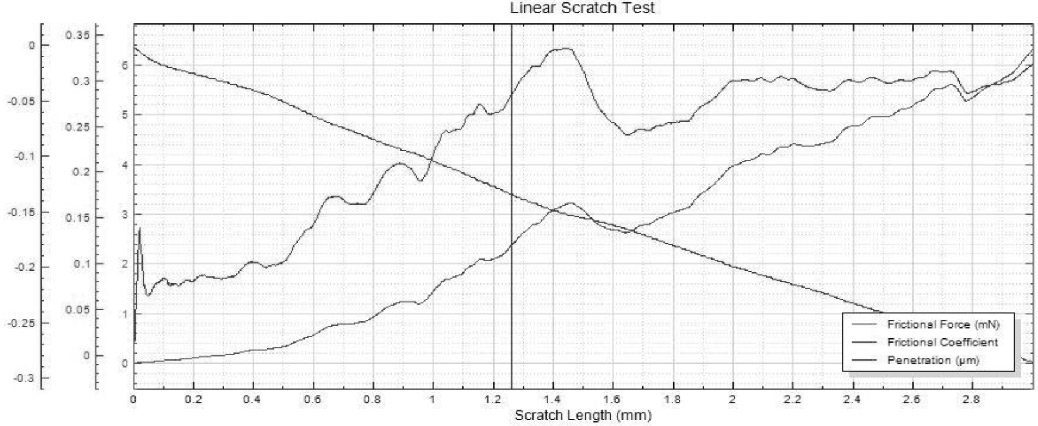

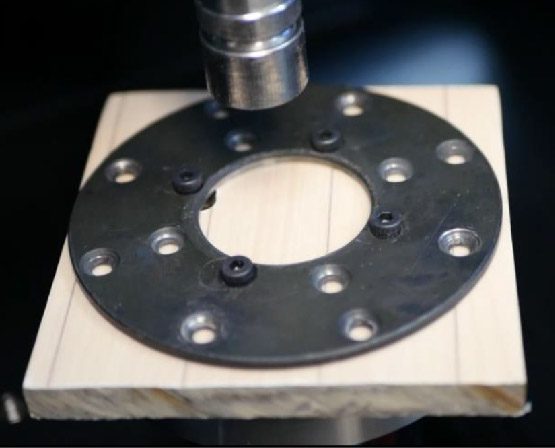

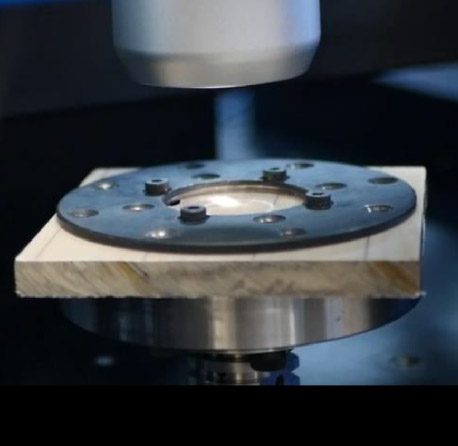

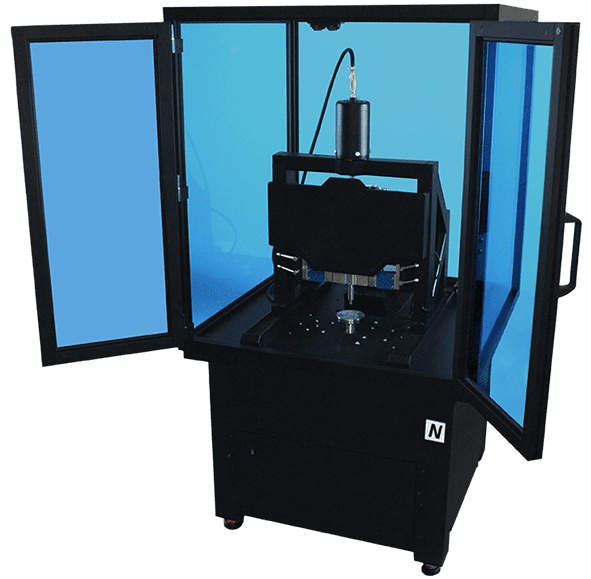

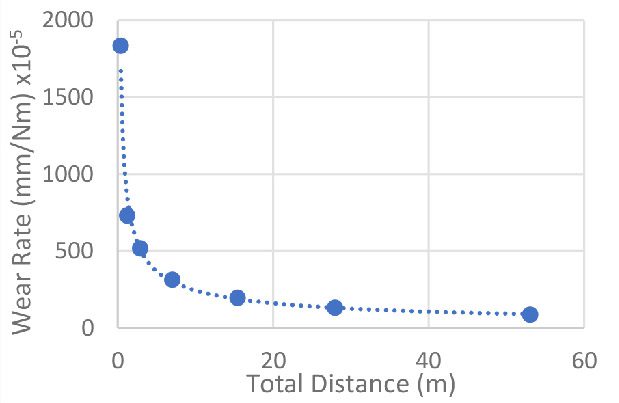

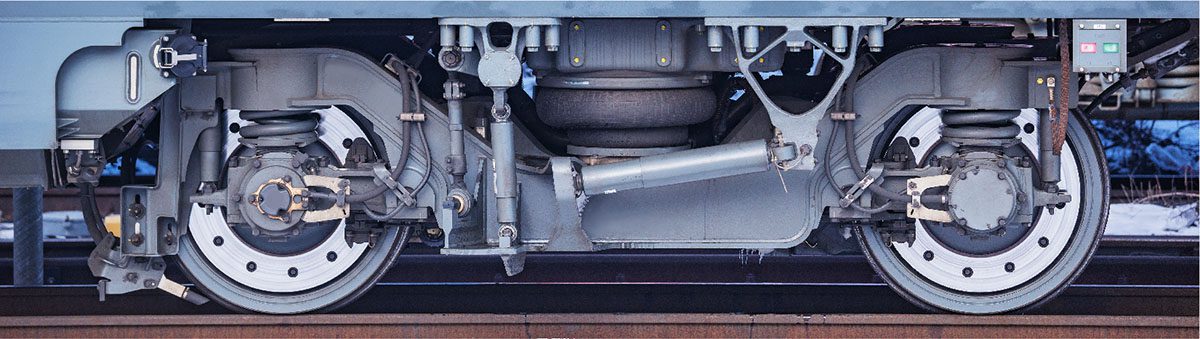

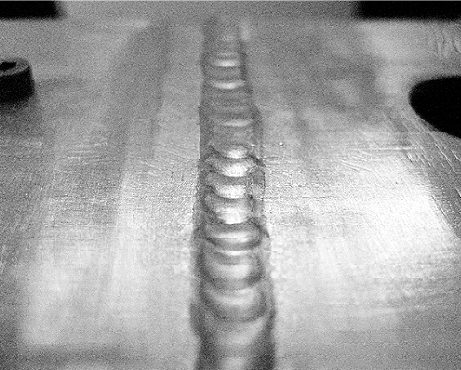

Various types of wear against rocks, including abrasion and friction, occur during the drilling process of wells, leading to significant direct and consequential losses attributed to the repair and replacement of drill bits and cutting tools. Therefore, the study of drillability, boreability, cuttability, and abrasivity of rocks are critical in the oil, gas, and mining industries. Rock tribology research plays a pivotal role in the selection of the most efficient and cost-effective drilling strategies, thereby enhancing overall efficiency and contributing to the conservation of materials, energy, and the environment. Additionally, minimizing surface friction is highly advantageous in reducing the interaction between the drilling bit and the rock, resulting in decreased tool wear and improved drilling/cutting efficiency.