Tooth Hardness Evaluation using Nanoindentation

Importance of Nanoindentation for Bio Materials

With many traditional mechanical tests (Hardness, Adhesion, Compression, Puncture, Yield Strength, etc.), today’s quality control environments with advanced sensitive materials, from gels to brittle materials, now require greater precision and reliability control. Traditional mechanical instrumentation fails to provide the sensitive load control and resolution required; designed to be used for bulk materials. As the size of material being tested became of greater interest, the development of Nanoindentation provided a reliable method to obtain essential mechanical information on smaller surfaces such as the research being done with biomaterials. The challenges specifically associated with biomaterials have required the development of mechanical testing capable of accurate load control on extremely soft to brittle materials. Also, multiple instruments are needed to perform various mechanical tests which can now be performed on a single system. Nanoindentation provides a wide range of measurement with precise resolution at nano controlled loads for sensitive applications.

Measurement Objective

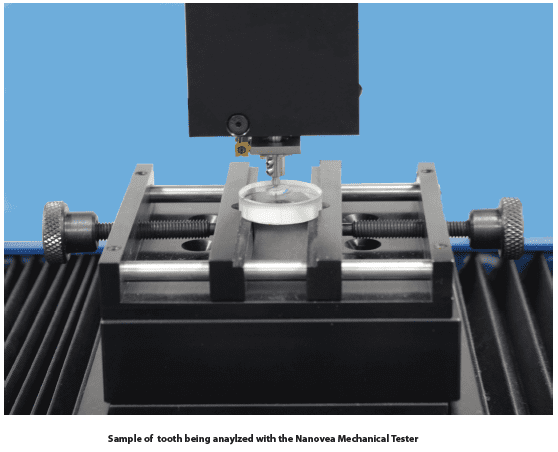

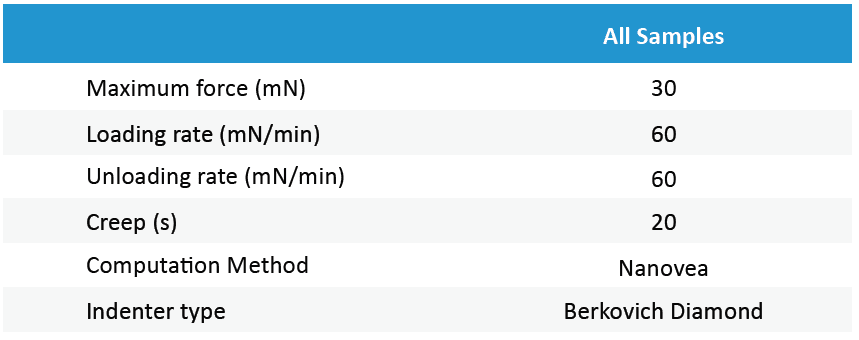

In this application, the Nanovea Mechanical Tester, in Nanoindentation mode, is used to study the hardness and elastic modulus of the dentin, decay, and pulp of a tooth. The most critical aspect with Nanoindentation testing is securing the sample, here we took a sliced tooth and epoxy mounted leaving all three areas of interest exposed for testing.

Results and Discussion

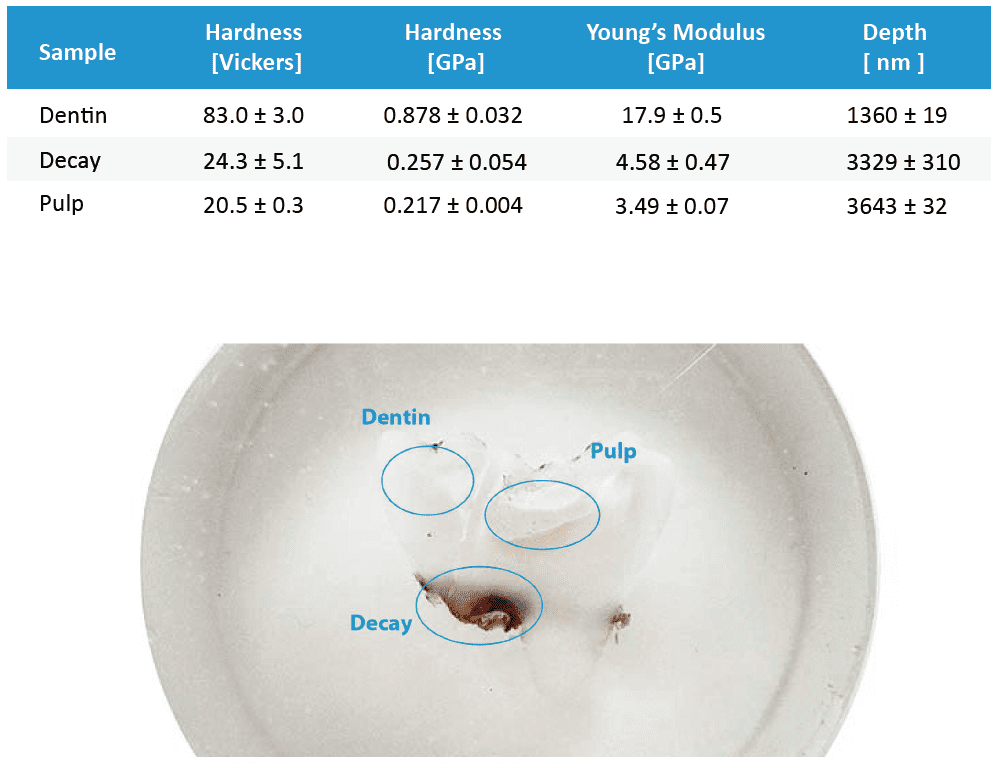

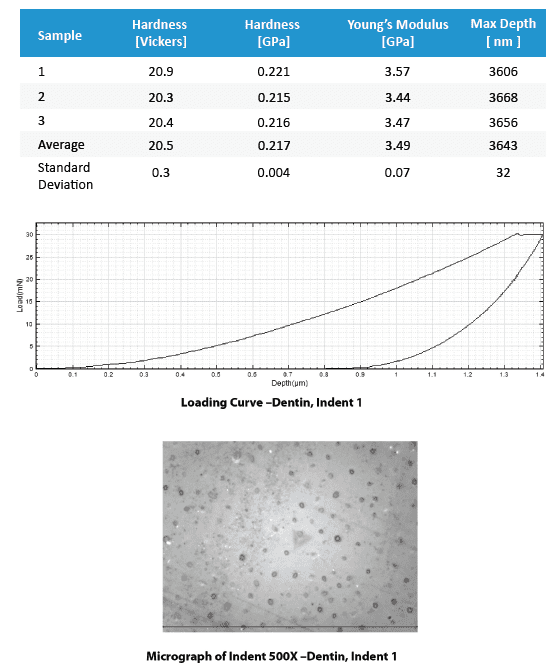

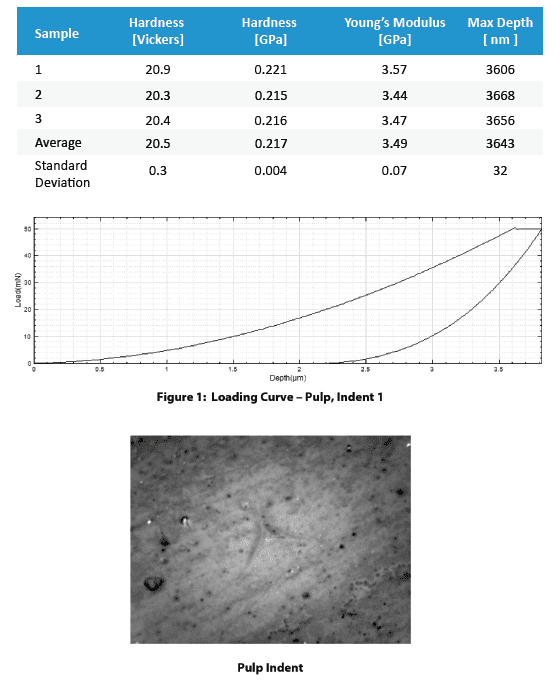

This section includes a summary table that compares the main numerical results for the different samples, followed by the full result listings, including each indentation performed, accompanied by micrographs of the indentation, when available. These full results present the measured values of Hardness and Young’s modulus as the penetration depth with their averages and standard deviations. It should be considered that large variation in the results can occur in the case that the surface roughness is in the same size range as the indentation.

Summary table of main numerical results:

Conclusion

In conclusion, we have shown how the Nanovea Mechanical Tester, in Nanoindentation mode, provides precise measurement of the mechanical properties of a tooth. The data can be used in the development of fillings that will better match the mechanical characteristics of a real tooth. The positioning capability of the Nanovea Mechanical Tester allows full mapping of the hardness of the teeth across the various zones.

Using the same system, it is possible to test teeth material fracture toughness at higher loads up to 200N. A multi-cycle loading test can be used on more porous materials to evaluate the remaining level of elasticity. Using a flat cylindrical diamond tip can give yield strength information in each zone. In addition, with DMA “Dynamic Mechanical Analysis”, the viscoelastic properties including loss and storage moduli can be evaluated.

The Nanovea nano module is ideal for these tests because it uses a unique feedback response to control precisely the load applied. Because of this, the nano module can also be used to do accurate nano scratch testing. The study of scratch and wear resistance of tooth material and filling materials adds to the overall usefulness of the Mechanical tester. Using a sharp 2-micron tip to quantitatively compare marring on filling materials will allow better prediction of the behavior in real applications. Multi-pass wear or direct rotative wear testing are also common tests providing important information on the long term viability.

NOW, LET'S TALK ABOUT YOUR APPLICATION

Categories

- Application Notes

- Block on Ring Tribology

- Corrosion Tribology

- Friction Testing | Coefficient of Friction

- High Temperature Mechanical Testing

- High Temperature Tribology

- Humidity and Gases Tribology

- Humidity Mechanical Testing

- Indentation | Creep and Relaxation

- Indentation | Fracture Toughness

- Indentation | Hardness and Elastic

- Indentation | Loss and Storage

- Indentation | Stress vs Strain

- Indentation | Yield Strength and Fatigue

- Laboratory Testing

- Linear Tribology

- Liquid Mechanical Testing

- Liquid Tribology

- Low Temperature Tribology

- Mechanical Testing

- Press Release

- Profilometry | Flatness and Warpage

- Profilometry | Geometry and Shape

- Profilometry | Roughness and Finish

- Profilometry | Step Height and Thickness

- Profilometry | Texture and Grain

- Profilometry | Volume and Area

- Profilometry Testing

- Ring on Ring Tribology

- Rotational Tribology

- Scratch Testing | Adhesive Failure

- Scratch Testing | Cohesive Failure

- Scratch Testing | Multi-Pass Wear

- Scratch Testing | Scratch Hardness

- Scratch Testing Tribology

- Tribology Testing

- Uncategorized

Archives

- November 2025

- September 2023

- August 2023

- June 2023

- May 2023

- July 2022

- May 2022

- April 2022

- January 2022

- December 2021

- November 2021

- October 2021

- September 2021

- August 2021

- July 2021

- June 2021

- May 2021

- March 2021

- February 2021

- December 2020

- November 2020

- October 2020

- September 2020

- July 2020

- May 2020

- April 2020

- March 2020

- February 2020

- January 2020

- November 2019

- October 2019

- September 2019

- August 2019

- July 2019

- June 2019

- May 2019

- April 2019

- March 2019

- January 2019

- December 2018

- November 2018

- October 2018

- September 2018

- July 2018

- June 2018

- April 2018

- March 2018

- February 2018

- November 2017

- October 2017

- September 2017

- August 2017

- June 2017

- May 2017

- March 2017

- February 2017

- January 2017

- November 2016

- October 2016

- August 2016

- July 2016

- June 2016

- May 2016

- April 2016

- March 2016

- February 2016

- January 2016

- December 2015

- November 2015

- October 2015

- September 2015

- August 2015

- July 2015

- June 2015

- May 2015

- April 2015

- March 2015

- February 2015

- January 2015

- November 2014

- October 2014

- September 2014

- August 2014

- July 2014

- June 2014

- May 2014

- April 2014

- March 2014

- February 2014

- January 2014

- December 2013

- November 2013

- October 2013

- September 2013

- August 2013

- July 2013

- June 2013

- May 2013

- April 2013

- March 2013

- February 2013

- January 2013

- December 2012

- November 2012

- October 2012

- September 2012

- August 2012

- July 2012

- June 2012

- May 2012

- April 2012

- March 2012

- February 2012

- January 2012

- December 2011

- November 2011

- October 2011

- September 2011

- August 2011

- July 2011

- June 2011

- May 2011

- November 2010

- January 2010

- April 2009

- March 2009

- January 2009

- December 2008

- October 2008

- August 2007

- July 2006

- March 2006

- January 2005

- April 2004