INTRODUCTION

Protective and decorative properties of paint play a significant role in a variety of industries, including automotive, marine, military, and construction. To achieve desired properties, such as corrosion resistance, UV protection, and abrasion resistance, paint formulas and architectures are carefully analyzed, modified, and optimized.

IMPORTANCE OF 3D NON-CONTACT PROFILOMETER FOR DRYING PAINT SURFACE MORPHOLOGY ANALYSIS

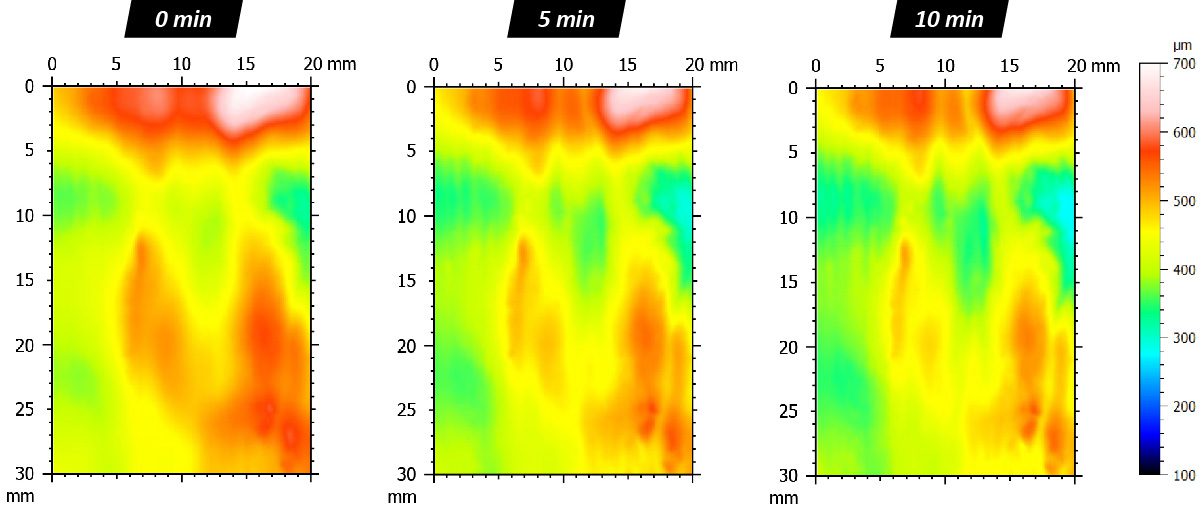

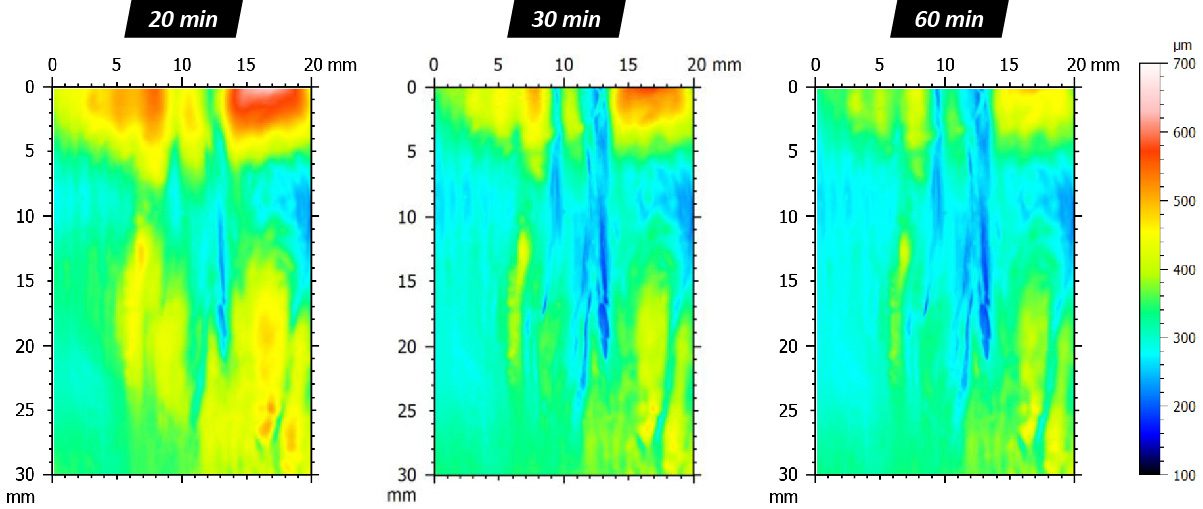

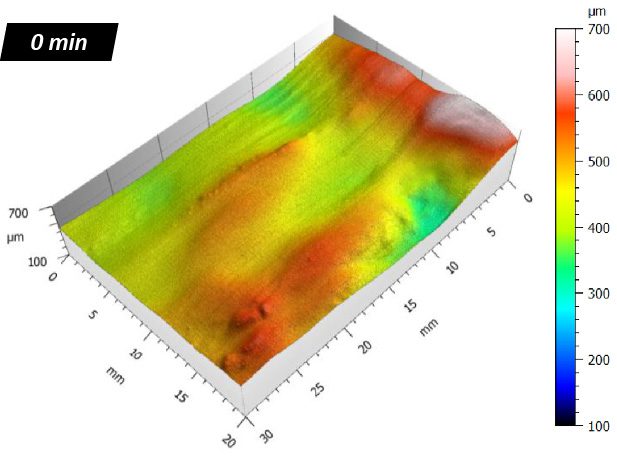

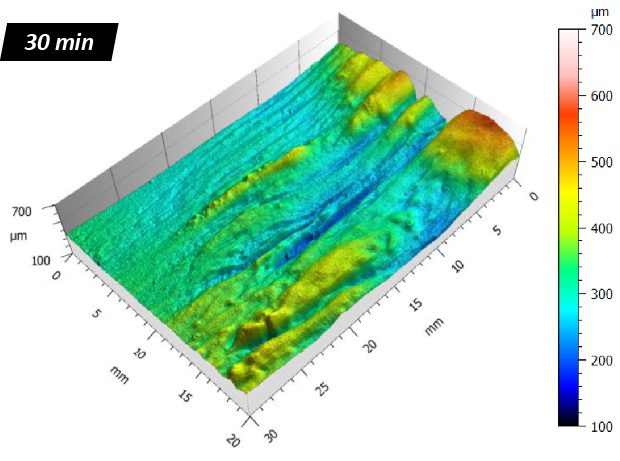

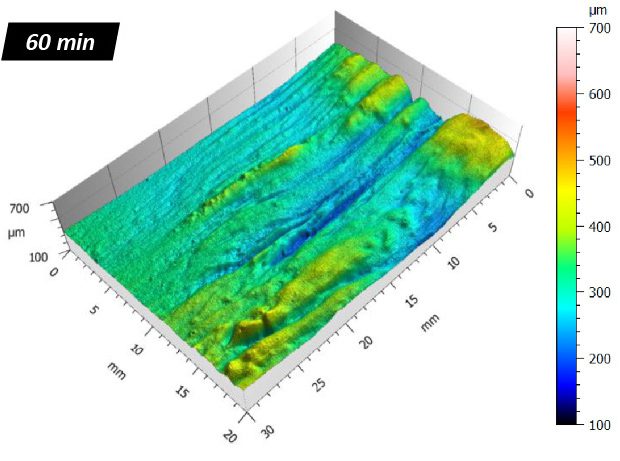

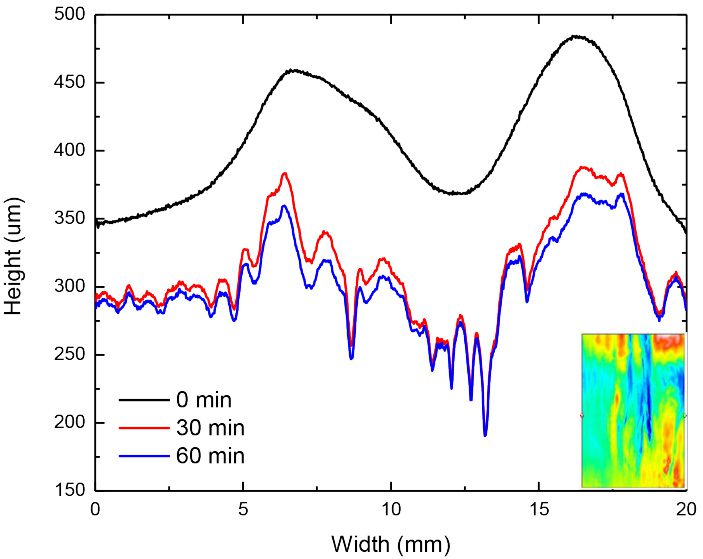

Paint is usually applied in liquid form and undergoes a drying process, which involves the evaporation of solvents and the transformation of the liquid paint into a solid film. During the drying process, the paint surface progressively changes its shape and texture. Different surface finishes and textures can be developed by using additives to modify the surface tension and flow properties of the paint. However, in cases of a poorly formulated paint recipe or improper surface treatment, undesired paint surface failures may occur.

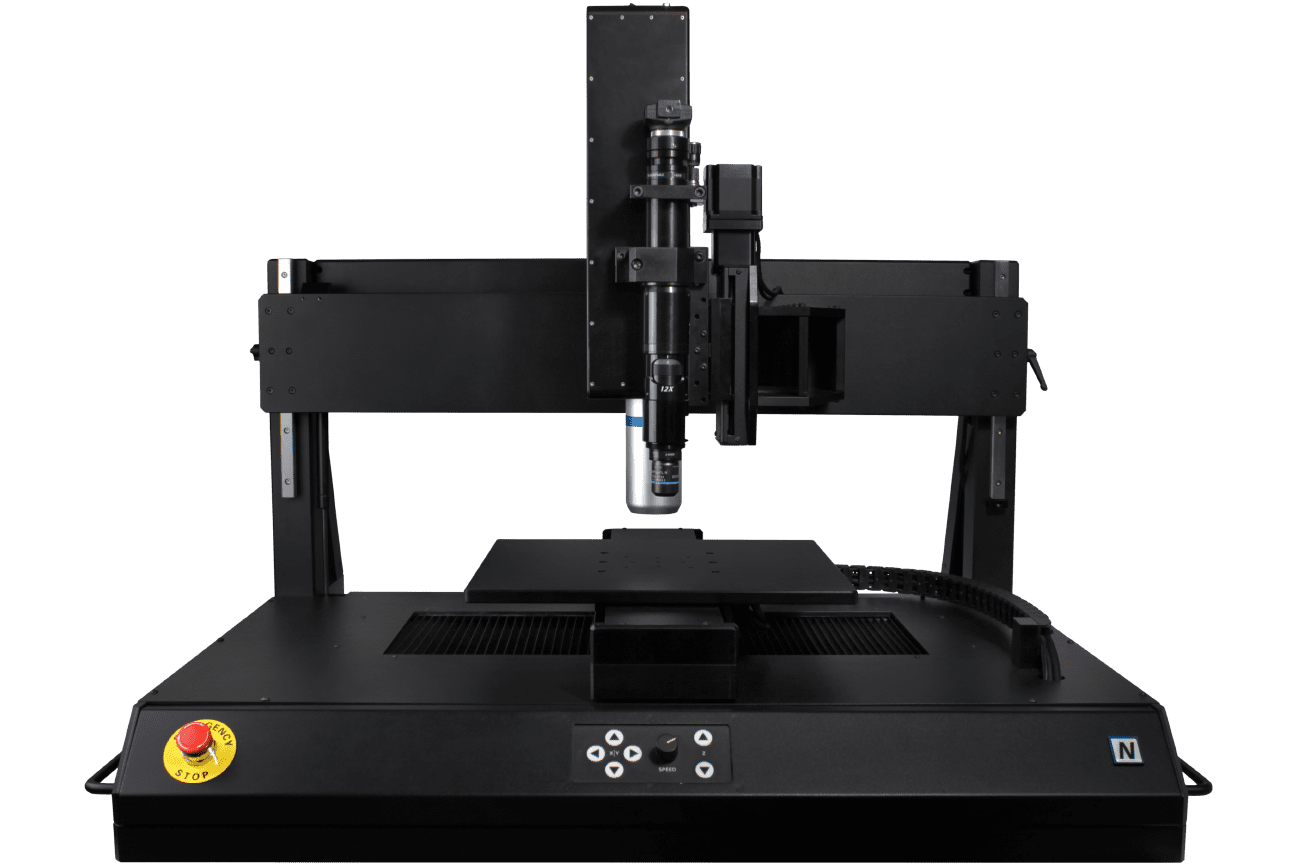

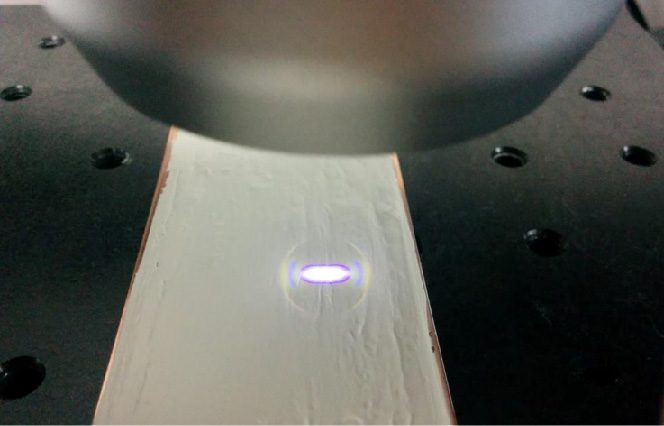

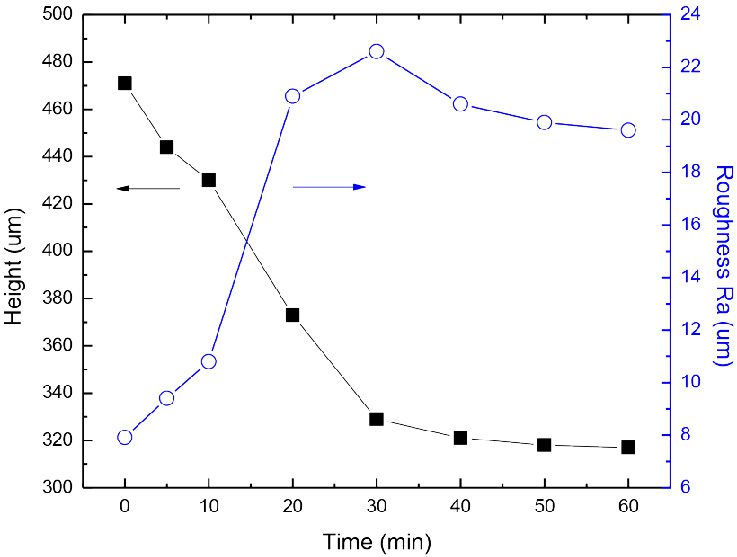

Accurate in situ monitoring of the paint surface morphology during the drying period can provide direct insight into the drying mechanism. Moreover, real-time evolution of surface morphologies is very useful information in various applications, such as 3D printing. The NANOVEA 3D Non-Contact Profilometers measure the paint surface morphology of materials without touching the sample, avoiding any shape alteration that may be caused by contact technologies such as a sliding stylus.