Category: Linear Tribology

Brush Bristle Stiffness Performance Using Tribometer

Brushes are among the most basic and widely used tools in the world. They can be used to remove material (toothbrush, archaeological brush, bench grinder brush), apply material (paintbrush, makeup brush, gilding brush), comb filaments, or add a pattern. As a result of the mechanical and abrasive forces on them, brushes constantly have to be replaced after moderate use. For example toothbrush heads should be replaced every three to four months because of fraying as a result of repeated usage. Making the toothbrush fiber filaments too stiff risks wearing away the actual tooth instead of soft plaque. Making the toothbrush fibers too soft makes the brush lose its form faster. Understanding the changing bend of the brush, as well as the wear and overall change in shape in the filaments under different loading conditions is necessary to design brushes that better fulfill their application.

Low Temperature Tribology

A reliable measurement of low temperature tribology, static and dynamic coefficient of friction, COF, as well as wear behavior is needed in order to better understand the tribological performance of materials for sub-zero applications. It provides a useful tool to correlate the frictional property with the influence of various factors, such as reactions at the interface, interlocking surface features, cohesion of surface films, and even microscopic solid static junctions between surfaces at low temperatures.

Mechanical & Tribological Properties of Carbon Fiber

Combined with the wear test by Tribometer and surface analysis by Optical 3D Profilometer, we

showcase the versatility and accuracy of the Nanovea instruments in testing composite materials

with directional mechanical properties.

Wear Testing Glass With Acoustic Emissions Monitoring

The wear behavior of three types of glass (Regular glass, Galaxy S3 glass and Sapphire coated glass) is compared in a controlled and monitored manner using the Nanovea Tribometer equipped with an AE detector. In this study, we would like to show the application of AE detection during wear and its correlation with the evolution of coefficient of friction (COF).

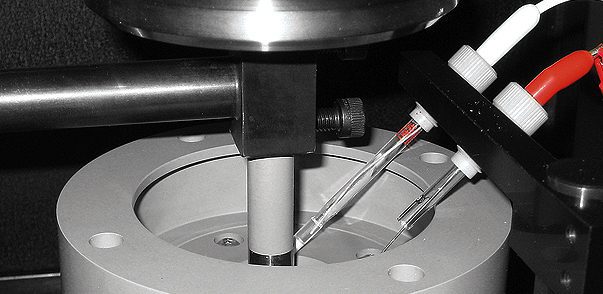

Tribocorrosion Wear Evaluation of Protective Coating

The tribocorrosion process of the DLC coatings on different types of steel substrates is simulated using the Nanovea Tribometer. In this study, we would like to showcase that Nanovea Tribometer equipped with the Tribocorrosion Module is an ideal tool for evaluating the performance of protective coatings used in wear and corrosion environment.