Fabric Surface Area Measurement Using 3D Profilometry

In this application the Nanovea ST400 Profilometer was used for surface area measurement of a fabric surface to determine amount of projected and developed surface areas as well as a contour analysis of the texture on the surface.

Here are examples of materials we tested this month:

Mechanical:

• Nanoindentation hardness of epoxy coatings

• Nanoindentation hardness of silicone coatings

• Nanoscratch of silicone coatings

• Nanoscratch failure of stent coatings

• Nanowear friction of capillary tubes

• Microindentation compression of micro features

• Microindentation fracture of micro ceramics

3D Non-Contact Profilometry:

• Roughness of mini turbines

• Roughness of films

• Texture of hard rubber samples

• Flatness of plastic molds

• Flatness of seal

• Depth & Area of micro channels

• Topography of oxidized samples

• Dimension of micro aerospace parts

Tribology:

• Friction testing various lubrications on steel

• Wear testing various hard coatings

Surface Wear Subtraction Using 3D Profilometry

In this application the Nanovea ST400 Profilometer is used to measure the surface wear of a golf ball before and after wearing of the surface with sandpaper. The two profile measurements were then combined through software surface subtraction to analyze wear volume loss. This feature is ideal for applications such as but not limited to: wear, corrosion and lubrication failure.

Here are examples of materials we tested this month:

Mechanical:

• Nanoindentation hardness of optical fiber

• Nanoindentation compression of plant surface

• Nanoscratch of solar thin films

• Nanoscratch of optical fiber

• Microindentation hardness of tungsten carbide

• Micro Scratch of foil coating

• Macro Scratch of wood coating

3D Non-Contact Profilometry:

• Roughness of medical parts

• Roughness of films

• Texture consistency of molded plastic

• Finish of machined parts

• Depth & Area of micro scratches

• Topography & Form of spray coating

• Dimension of optical spheres

• Wear resistance of aluminum oxide coatings

• Wear testing tungsten carbide

• Wear testing chromium oxide

• Friction testing of catheter

• Friction testing of foaming liquid

Wood Coatings Wear Resistance using Tribometer

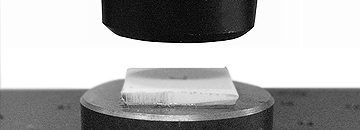

In this application, the Nanovea Tribometer is used to measure the wear resistance of a coated wood pencil. The linear wear test (ASTM G133) was used with a 3mm stainless steal ball tip; many other tips could have been used. The 1st test was performed for 4 hours and then a 2nd test was performed for 1.5 hours. After wear testing the 3D Profilometer integrated on the Tribometer was used to profile the wear track.

Micro Scratch Depth Measurement Using 3D Profilometry

In this application the Nanovea ST400 Profilometer is used for depth measurement of a row of micro scratches created using Nanovea’s Mechanical Tester in scratch mode. In seconds the Profilometer, with a single line pass in 2D mode, provides area and depth measurement.

Here are examples of materials we tested this month:

Mechanical:

• Nanoindentation compression of amorphous silica

• Nanoindentation yield strength of micro wire

• Nanoindentation fracture of micro ceramic

• Nanoscratch of catheter coatings

• Microindentation puncture of thin film

• Micro Scratch of glass samples

• Macro Scratch of clear coat samples

3D Non-Contact Profilometry:

• Elastomer molds roughness measurement

• Roughness of plastic electronic surfaces

• Finish of die cast samples

• Volume & Area of pitted surface

• Shape & Form of polymer samples

• Contour of micro circuit surface

Tribology:

• 12 & 24hr Wear & Friction testing of ceramic, polymer and alloy samples in synthetic bio fluid.

Here are examples of materials we tested this month:

Mechanical:

• Polymer Gel Hardness Nanoindentation DMA

• Nanoindentation yield strength of films

• Nanoindentation mapping of thermal coating

• Nanowear of biomedical coatings

• Microindentation fracture of composites

• Micro Scratch deformation of hard polymers

3D Non-Contact Profilometry:

• Roughness of pills

• Texture of films

• Profile consistence of micro mesh

• Step height of printed circuits

• Topography of spray coatings

• Dimension of machined polymer components

Tribology:

• Friction testing of plastic tubes

• Friction testing of plastic bushings

• Friction testing of aluminum silicon alloy

• Wear rate of engine components

• Wear rate of composites

Mechanical Characterization of Organic & Non Organic Shell

In this application, the Nanovea Mechanical Tester, in Nanoindentation mode, is used to study the mechanical characterization of an organic and a non-organic egg shell. The most critical aspect with Nanoidentation testing is securing the sample, here we took pieces of each sample and epoxy mounted leaving the edges exposed for testing.

Here are examples of materials we tested this month:

Mechanical:

• Nanoindentation of xylan coating

• Nanoindentation composite

• Nanoindentation mapping of wood

• Nanofriction of catheter

• Nano Scratch of silicon

• Micro Scratch of silicon nitride coating

3D Non-Contact Profilometry:

• Topography of corroded steel

• Dimension of optical lens samples

• Roughness of polymer molds

• Roughness of polymer casing

• Depth of pitted aluminum

• Step height micro features

• Friction Testing of various lubricants

• Xylan coatings wear resistance

• Wear rate (high speed) of hard plastic