Monthly Archives: October 2016

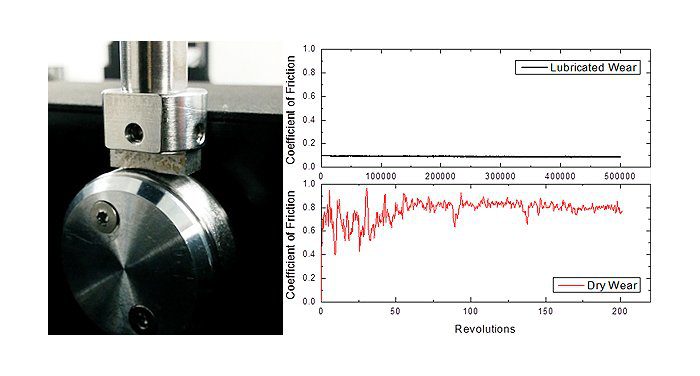

Block on Ring Tribometer Option

Block on Ring test is a widely used technique that evaluates the sliding wear behaviors of materials in different simulated conditions, allows reliable ranking of material couples for specific tribological applications. Sliding wear often involves complex wear mechanisms taking place at the contact surface, such as adhesion wear, two-body abrasion, three-body abrasion and fatigue wear. The wear behavior of materials is significantly influenced by the work environment, such as normal loading, speed, corrosion and lubrication. A versatile tribometer that can simulate the different realistic work conditions will be ideal for wear evaluation.

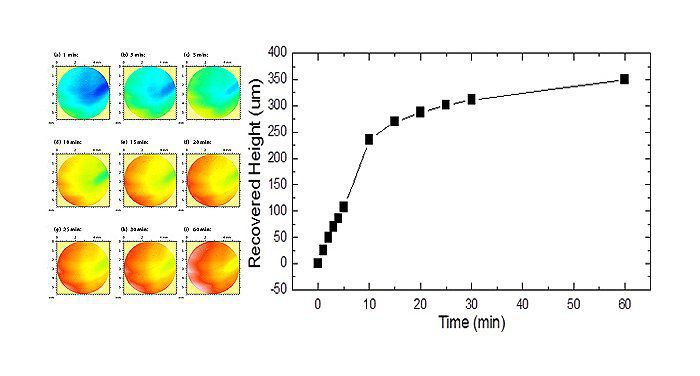

Compression Set Measurement With 3D Profilometry

Compression set measurement of rubbers progressively recover their shape after the compressive stress is removed. Accurate in situ monitoring of the shape evolution during the compression set period can provide important insight into the mechanism of material recovery. Moreover, real-time monitoring of surface morphologies is very useful in various materials applications, such as paint drying and 3D printing. The Nanovea 3D Non-Contact Profilometers measure the surface morphology of materials without touching the sample, avoiding introducing additional scratches or shape alteration which may be caused by contact technologies such as sliding stylus.

https://nanovea.com/App-Notes/compression-set-measurement.pdf