Importance of Wear Evaluation on DLC in Humidity

Diamond-like carbon (DLC) coatings possess enhanced tribological properties, namely excellent wear resistance and a very low coefficient of friction (COF). DLC coatings impart diamond characteristics when deposited on different materials. Favorable tribo-mechanical properties make DLC coatings preferable in various industrial applications, such as aerospace parts, razor blades, metal cutting tools, bearings, motorcycle engines, and medical implants.

DLC coatings exhibit very low COF (below 0.1) against steel balls under high vacuum and dry conditions��12. However, DLC coatings are sensitive to environmental condition changes, particularly relative humidity (RH)3�. Environments with high humidity and oxygen concentration may lead to significant increase in COF�4. Reliable wear evaluation in controlled humidity simulates realistic environmental conditions of DLC coatings for tribological applications. Users select the best DLC coatings for target applications with proper comparison

of DLC wear behaviors exposed to different humidity.

Measurement Objective

This study showcases the Nanovea Tribometer equipped with a humidity controller is the ideal tool for investigating wear behavior of DLC coatings at various relative humidity.

Test Procedure

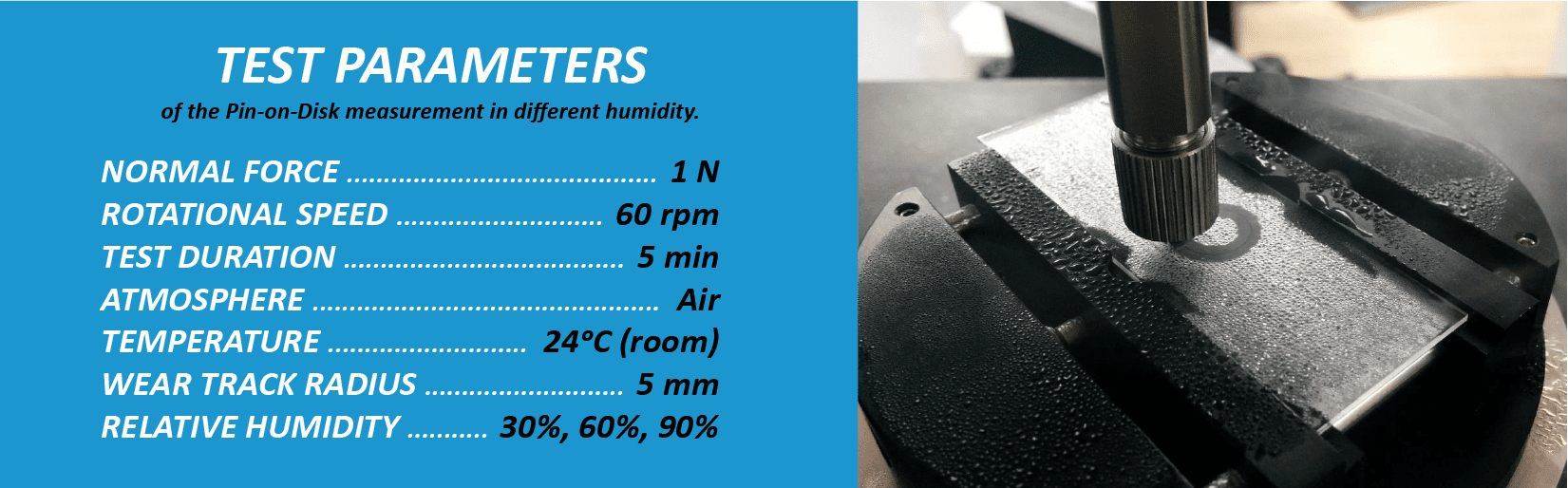

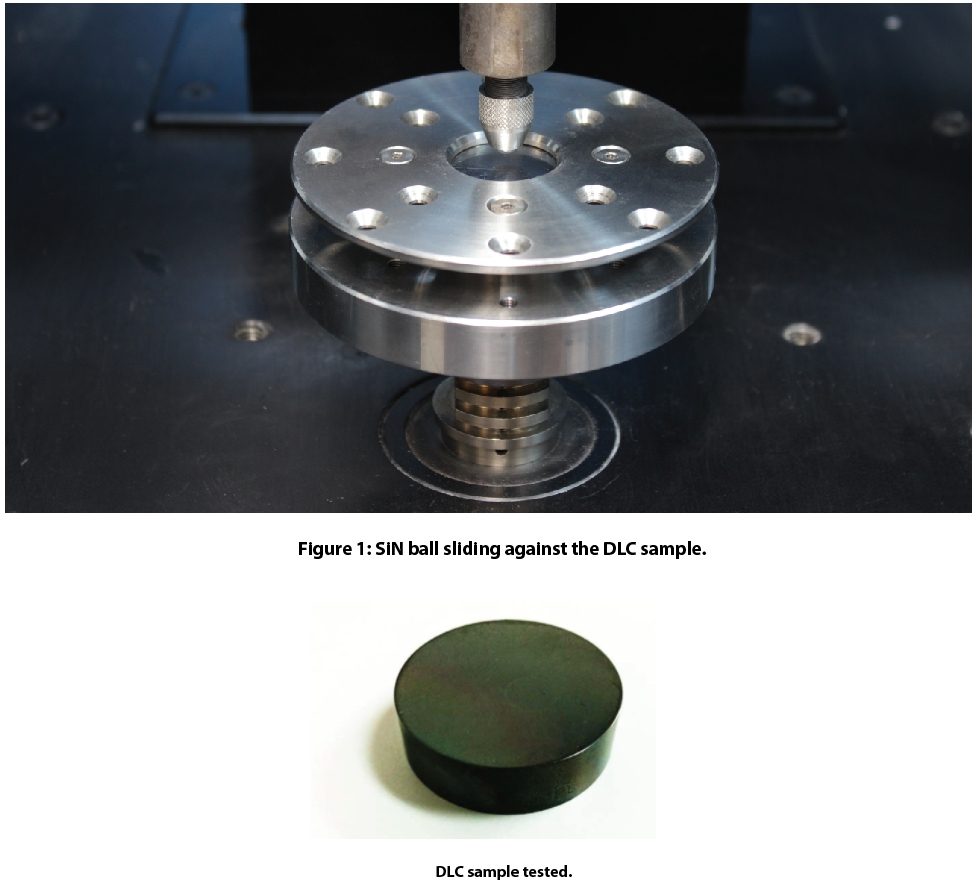

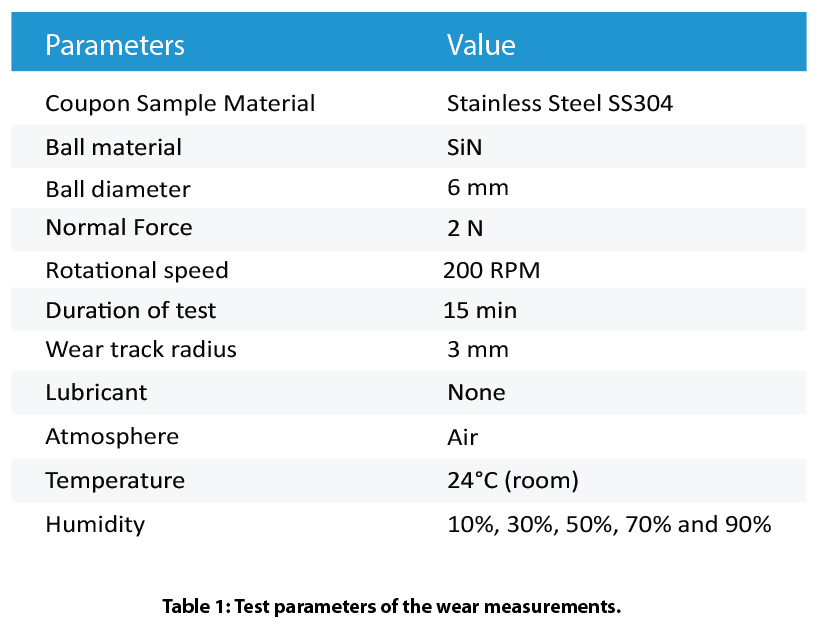

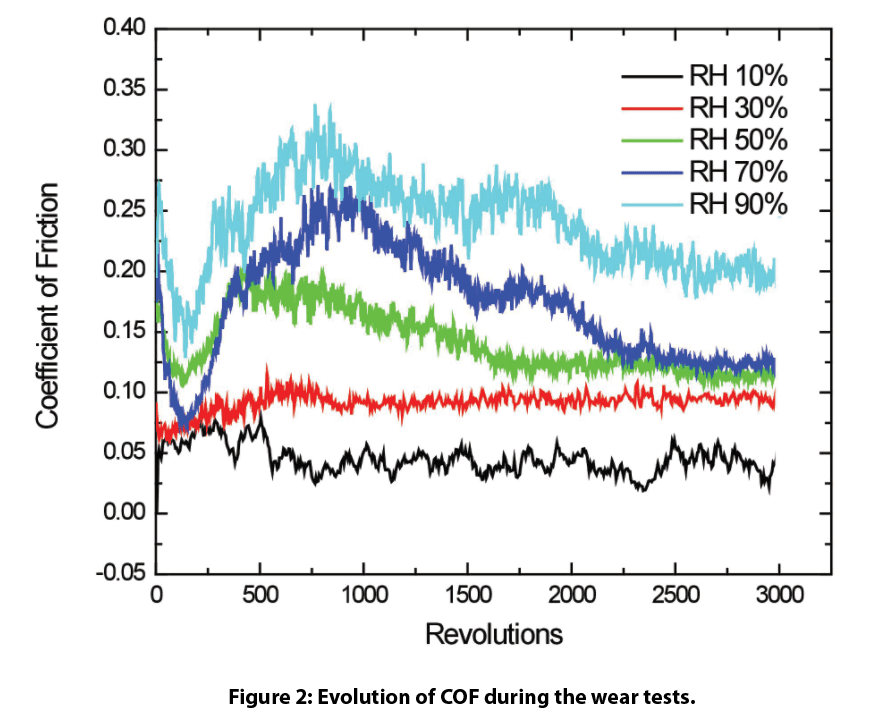

Friction and wear resistance of DLC coatings were evaluated by the Nanovea Tribometer. Test parameters are summarized in Table 1. A humidity controller attached to the tribo-chamber precisely controlled the relative humidity (RH) with an accuracy of ±1%. Wear tracks on DLC coatings and wear scars on SiN balls were examined using an optical microscope after tests.

Note: Any solid ball material can be applied to simulate the performance of different material coupling under environmental conditions such as in lubricant or high temperature.

Results and Discussion

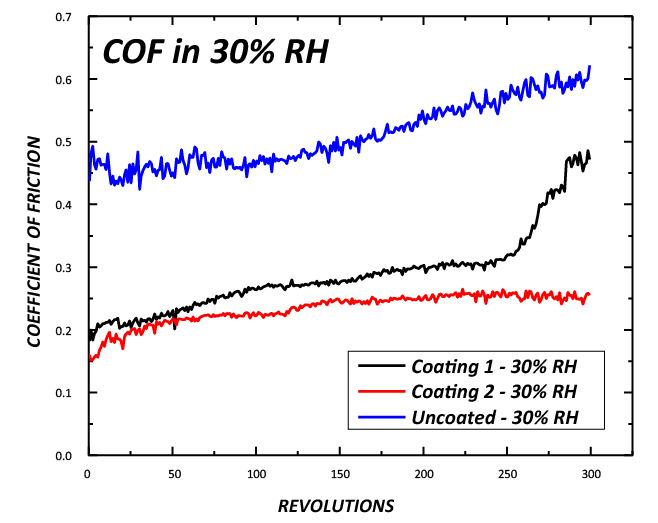

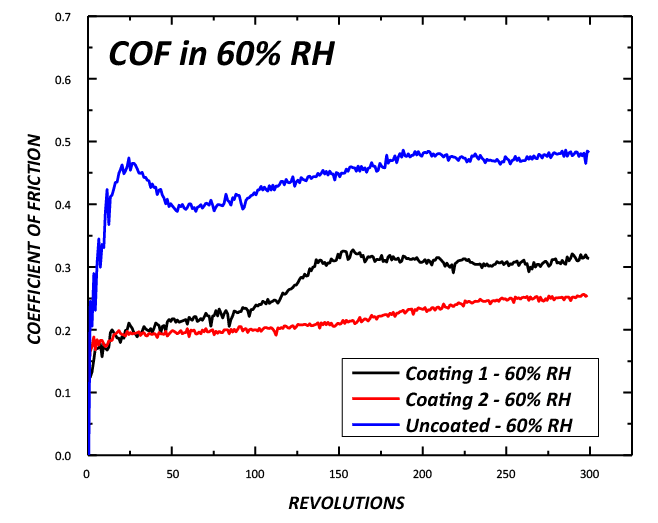

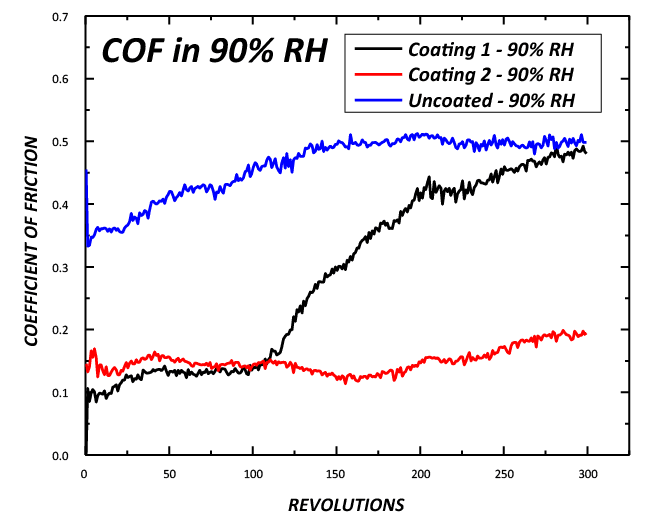

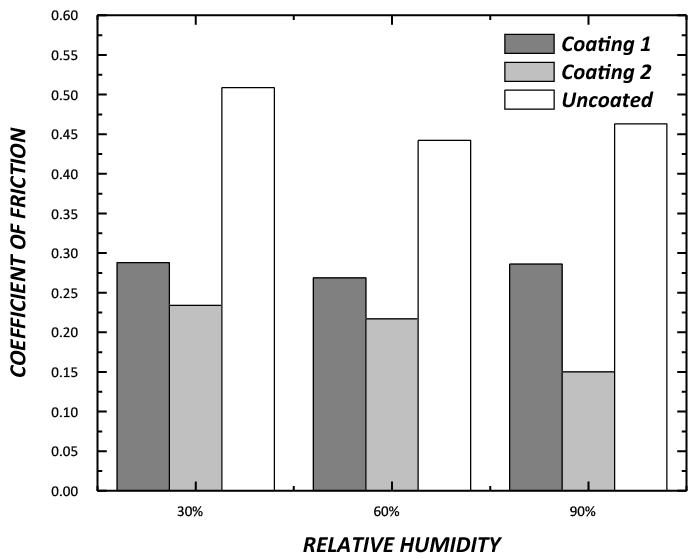

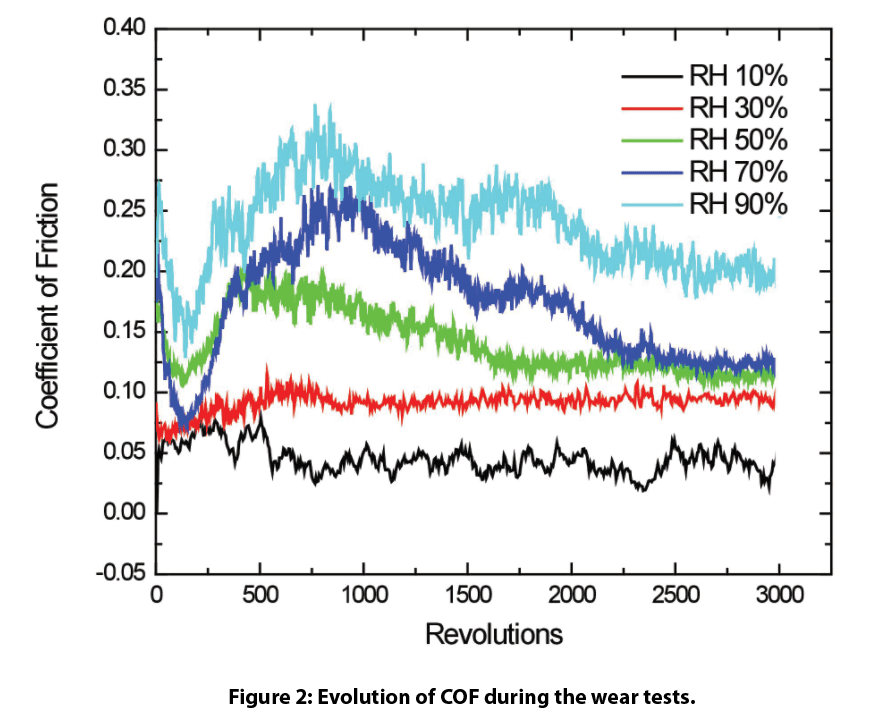

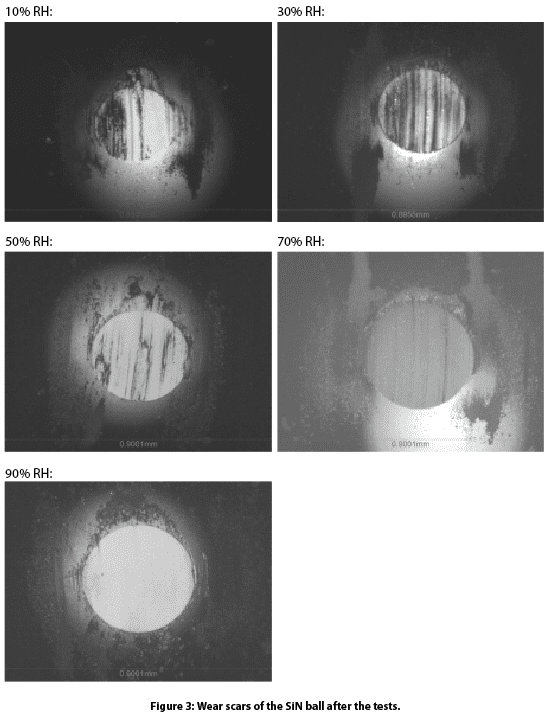

DLC coatings are great for tribological applications due to their low friction and superior wear resistance. The DLC coating friction exhibits humidity dependent behavior shown in Figure 2. The DLC coating shows a very low COF of ~0.05 throughout the wear test in relatively dry conditions (10% RH). The DLC coating exhibits a constant COF of ~0.1 during the test as RH increases to 30%. The initial run-in stage of COF is observed in the first 2000 revolutions when RH rises above 50%. The DLC coating shows a maximum COF of ~0.20, ~0.26 and ~0.33 in RH of 50, 70 and 90%, respectively. Following the run-in period, the DLC coating COF stays constant at ~0.11, 0.13 and 0.20 in RH of 50, 70 and 90%, respectively.

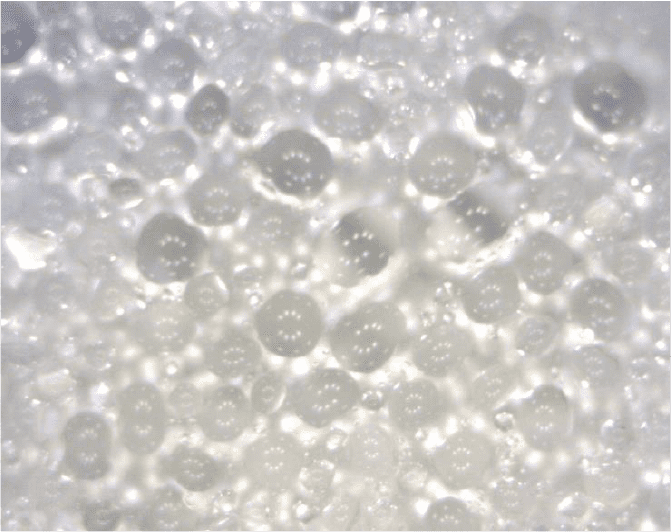

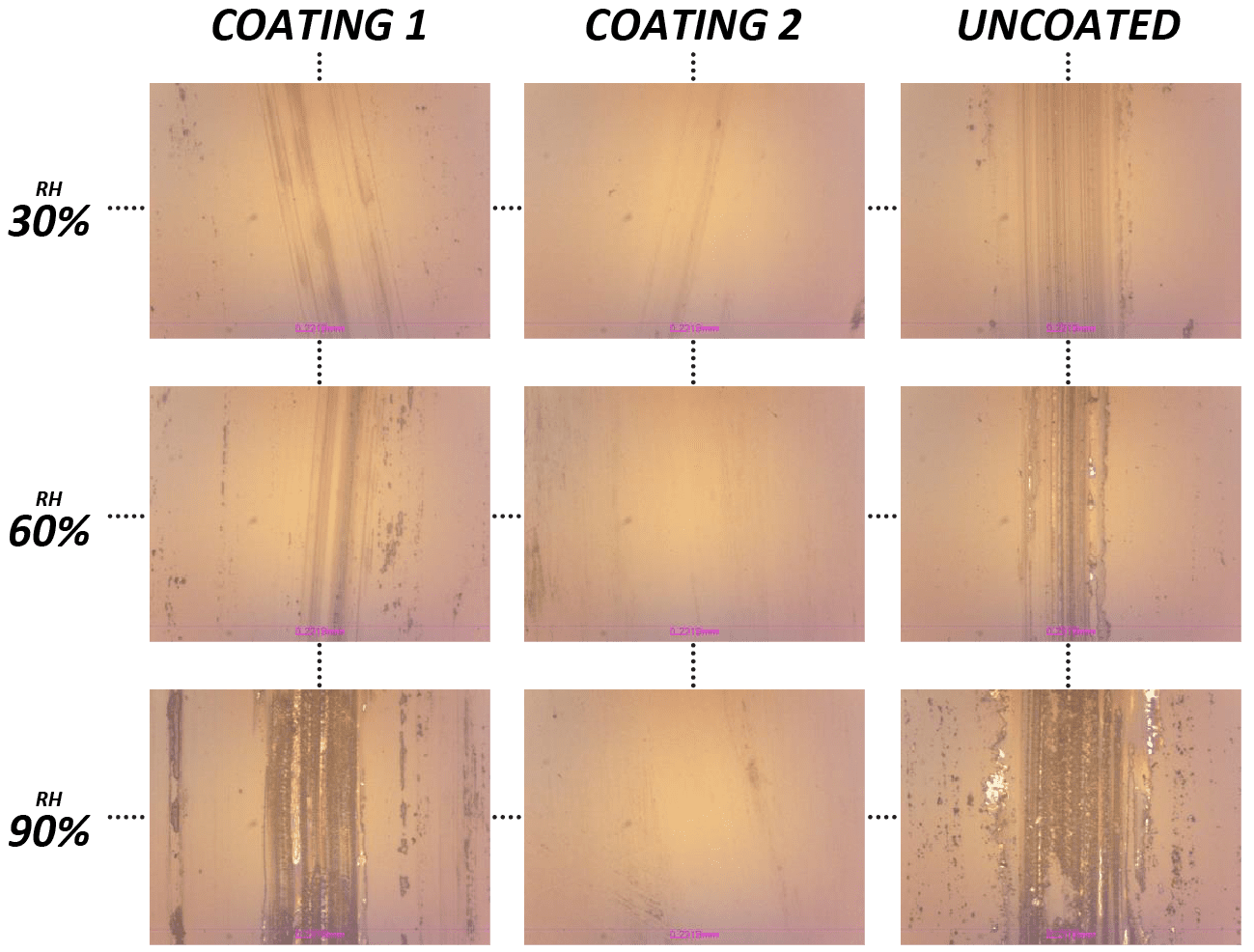

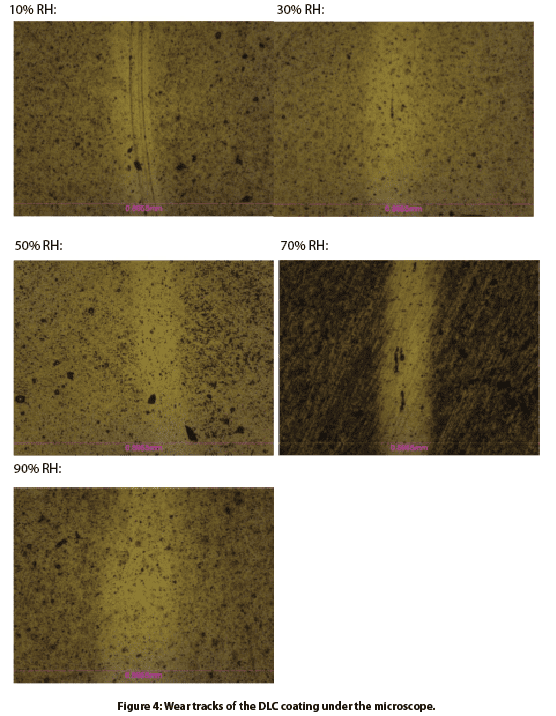

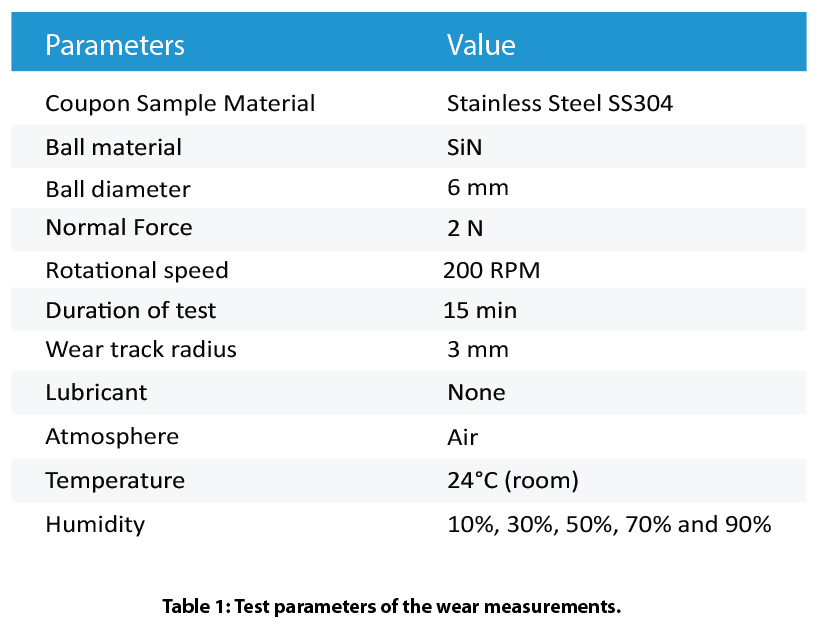

Figure 3 compares SiN ball wear scars and Figure 4 compares DLC coating wear tracks after the wear tests. The diameter of the wear scar was smaller when the DLC coating was exposed to an environment with low humidity. Transfer DLC layer accumulates on the SiN ball surface during the repetitive sliding process at the contact surface. At this stage, the DLC coating slides against its own transfer layer which acts as an efficient lubricant to facilitate the relative motion and restrain further mass loss caused by shear deformation. A transfer film is observed in the wear scar of the SiN ball in low RH environments (e.g. 10% and 30%), resulting in a decelerated wear process on the ball. This wear process reflects on the DLC coating’s wear track morphology as shown in Figure 4. The DLC coating exhibits a smaller wear track in dry environments, due to the formation of a stable DLC transfer film at the contact interface which significantly reduces friction and wear rate.

Conclusion

Humidity plays a vital role in the tribological performance of DLC coatings. The DLC coating possesses significantly enhanced wear resistance and superior low friction in dry conditions due to the formation of a stable graphitic layer transferred onto the sliding counterpart (a SiN ball in this study). The DLC coating slides against its own transfer layer, which acts as an efficient lubricant to facilitate the relative motion and restrain further mass loss caused by shear deformation. A film is not observed on the SiN ball with increasing relative humidity, leading to an increased wear rate on the SiN ball and the DLC coating.

The Nanovea Tribometer offers repeatable wear and friction testing using ISO and ASTM compliant rotative and linear modes, with optional humidity modules available in one pre- integrated system. It allows users to simulate the work environment at different humidity, providing users an ideal tool to quantitatively assess the tribological behaviors of materials under different work conditions.

Learn More about the Nanovea Tribometer and Lab Service

1 C. Donnet, Surf. Coat. Technol. 100–101 (1998) 180.

2 K. Miyoshi, B. Pohlchuck, K.W. Street, J.S. Zabinski, J.H. Sanders, A.A. Voevodin, R.L.C. Wu, Wear 225–229 (1999) 65.

3 R. Gilmore, R. Hauert, Surf. Coat. Technol. 133–134 (2000) 437.

4 R. Memming, H.J. Tolle, P.E. Wierenga, Thin Solid Coatings 143 (1986) 31