Monthly Archives: February 2017

Corrosion Effect On Hardness Using Nanoindentation

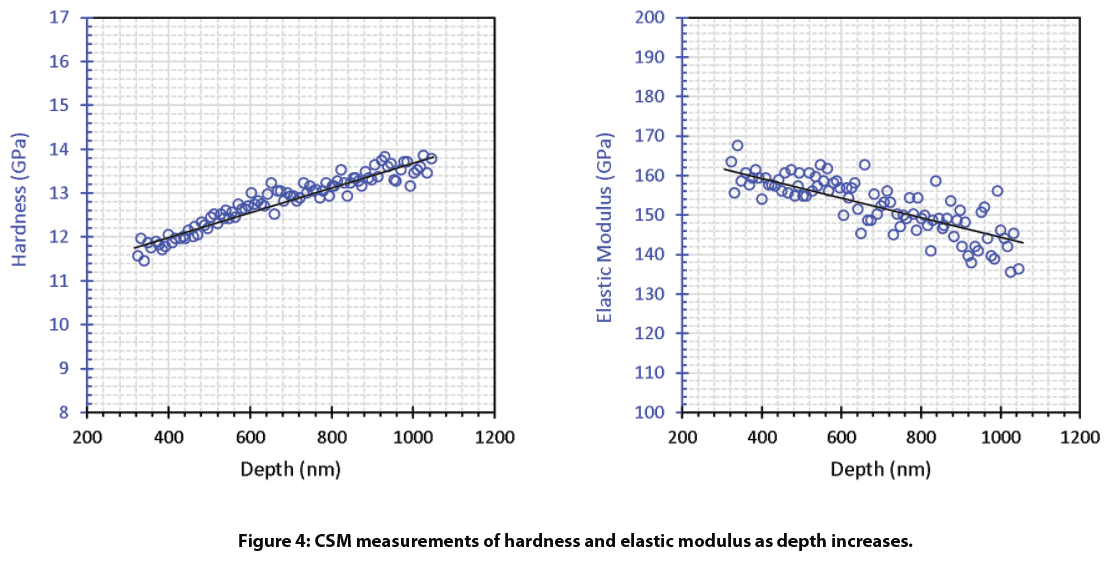

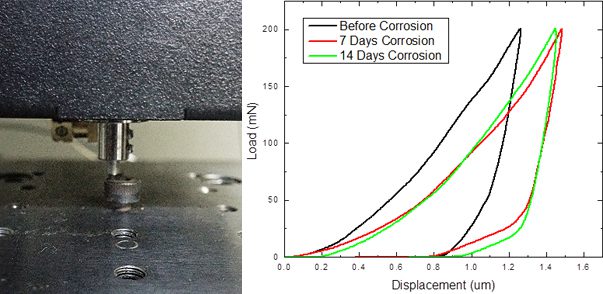

The mechanical properties of materials deteriorate during the corrosion process. For example, lepidocrocite (γ-FeOOH) and goethite (α-FeOOH) form in the atmospheric corrosion of carbon steel. Their loose and porous nature results in absorption of moisture and in turn further acceleration of the corrosion process. Akaganeite (β-FeOOH), another form of iron

oxyhydroxide, is generated on the steel surface in chloride containing environments. Nanoindentation can control the indentation depth in the range of nanometers and microns, making it possible to quantitatively measure the hardness and Young’s modulus of the corrosion products formed on the metal surface. It provides physicochemical insight in corrosion mechanisms involved so as to select the best candidate material for the target applications.

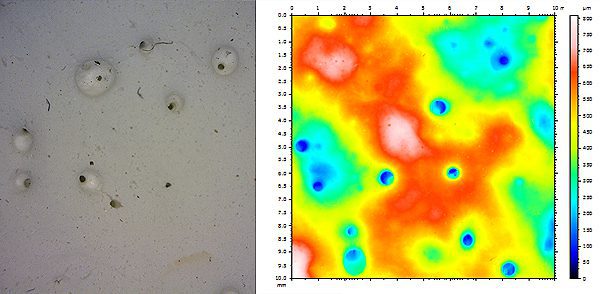

Drywall Texture & Pitting Using 3D Profilometry

Drywall texture and roughness is critical in the final products quality and appearance. A better understanding of the effect of surface texture and consistency on the moisture resistance of the coated drywall allows selecting the finest product and optimizing the painting technique to obtain the best result. Quantifiable, fast and reliable surface inspection of the coating surface is in need for quantitative evaluation of the surface quality. The Nanovea 3D Non-Contact Profilometers utilizes chromatic confocal technology with unique capability to precisely measure the sample surface. The line-sensor technique can finish scanning a large drywall surface in minutes.