Monthly Archives: January 2014

Here are examples of materials we tested this month:

Mechanical:

• Nanoindentation of wire cross sections

• Nanoindentation of Y2O3 thin films

• Nanoscratch of thin polymer films

• Nanoscratch of catheters

• Microindentation of oil-well cement

3D Non-Contact Profilometry:

• Roughness of catheters

• Finish of processed leather

• Topography of thin film particle contaminants

• Coplanarity of ball grid arrays

• Step height of microchannels

• Stribeck Curve evaluation of various lubrication

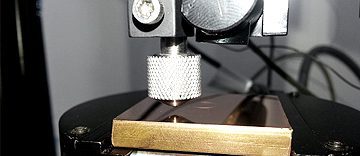

Initial Plastic Deformation To Wear Analysis

The wear process of a metal sample (Cu 110) and a polymer sample (teflon) is simulated in controlled and monitored manner using the Nanovea Mechanical Tester. In this study, we would like to showcase that the controlling and measuring the load and depth is ideal for wear analysis.

The Critical Effect Of Initial Plastic Deformation To Wear Analysis

Extreme Low Speed Friction Evaluation On Rubber

The coefficient of friction, COF, of rubber against different materials is measured in a controlled and monitored manner using the Nanovea Tribometer. In this study, we would like to showcase the capacity of the Tribometer for measuring the coefficient of friction of different materials at extreme low speeds.

Rubber Friction Evaluation At Extreme Low Speeds Using Tribometer

Surface Finish Measurement of Processed Leather

In this application, the Nanovea ST400 Profilometer is used to measure and compare the surface finish of 2 different but closely processed leather samples. Several surface parameters will be automatically calculated from the surface profile. Here we will focus on surface roughness, dimple depth, dimple pitch and dimple diameter for comparative evaluation.

Processed Leather Surface Finish Using 3D Profilometry