Monthly Archives: March 2012

Tablet Coating Failure With Micro Scratch Testing

In this application, the Nanovea Mechanical Tester, in its micro scratch mode, is used to measure the load required to cause the failure to a generic and brand tablet coating. We must simulate the process of scratching in a controlled and monitored manner to observe sample behavior effects. A 20μm diamond tipped stylus is used at a progressive load ranging from 4 N to 8 N to scratch the tablet coating. The point where the coating fails by cracking is taken as the point of failure. Hardness and elastic modulus will also be evaluated in nanoindentation mode.

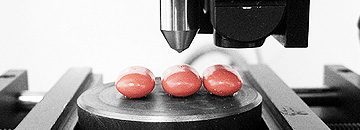

Roughness Measurement of Pill Using 3D Profilometry

In this application, the ST400 Profilometer is used to measure and compare surface roughness measurement values of different types of tablets. Excedrin, Advil, and generic forms of Excedrin and Advil, distributed by SUPERVALU Inc., are the tablets measured in this application. Comparisons can be made between generic and name brand tablet surface roughness, between coated and uncoated tablet surface roughness, and also among the same type of tablet to check the variations in surface roughness, mainly through the standard deviation.

Here are examples of materials we tested this month:

Mechanical:

• Nanoindentation of bone samples

• Nanoindentation yield strength of mems

• Nanoindentation creep of polymers

• Nano Scratch of optical coating

• Nano Scratch of microwire

• Micro Scratch of tooling parts

• Microindentation compression of micropillers

3D Non-Contact Profilometry:

• Dimensions of optic lens

• Roughness of textured aluminum

• Roughness of composites

• Thin film surface flatness

• Coplanarity of mems grid

• Volume loss of wear tracks

• Step heights of coating oxidation

Tribology:

• Friction testing of composites

• Friction testing of polymers

• Wear resistance of hard coatings

• Wear resistance of turbine sample

• Wear resistance of steel samples